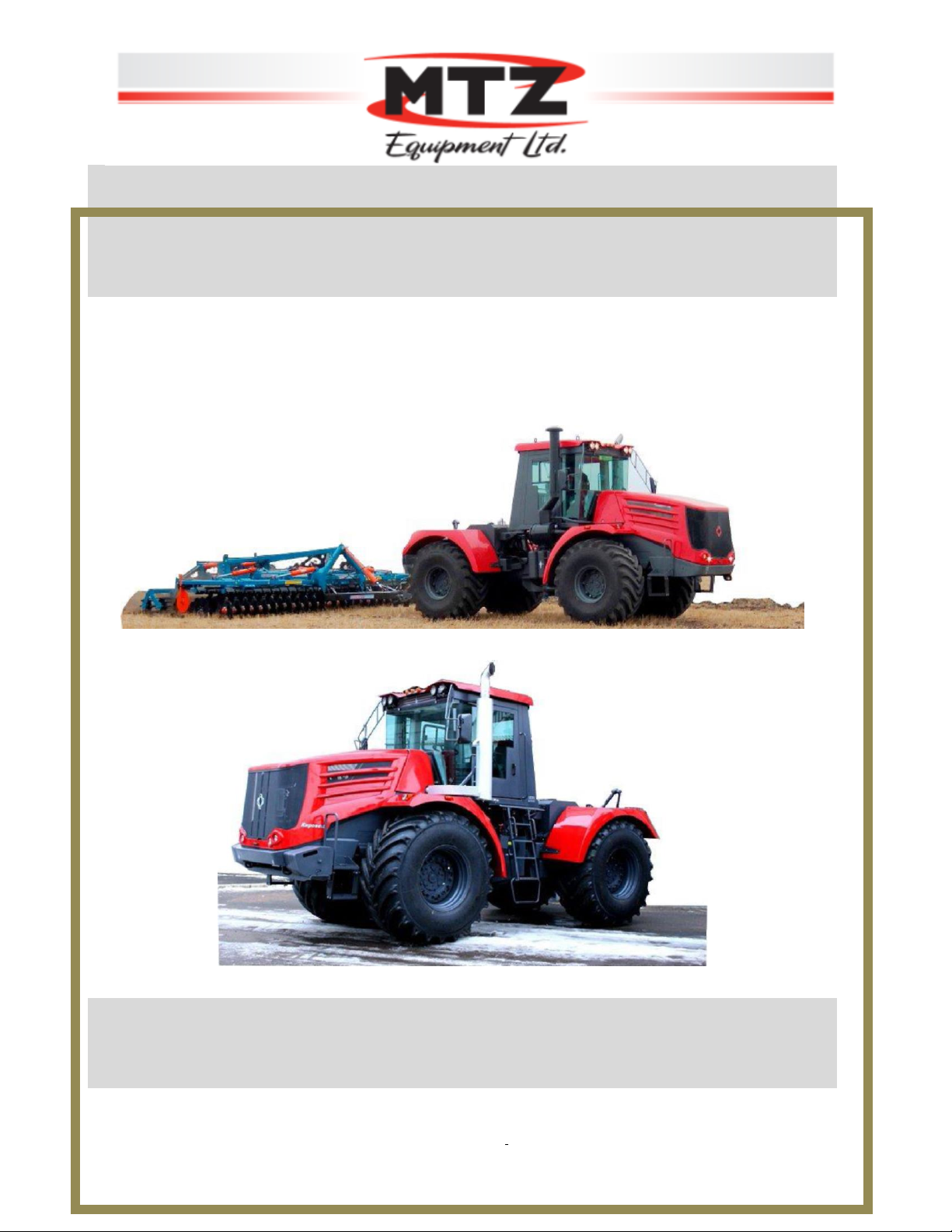

MTZ-KIROVETS K-744R1, K-744R2, K-744R3, K-744R4 tractors

4

CONTENTS

1 INTRODUCTION......................................................................................................................11

2 GENERAL DESCRIPTION AND TECHNICAL FEATURES...................................................11

2.1 PURPOSE AND SCOPE .........................................................................................................11

2.2 BRIEF DATA ON CONSTRUCTION AND LAYOUT........................................................................15

2.3 MAIN TECHNICAL DATA........................................................................................................29

3 SAFETY REQUIREMENTS.....................................................................................................32

3.1 GENERAL ...........................................................................................................................32

3.2 SAFETY MEASURES DURING DEPRESERVATION,INSTALLATION,TEST OPERATION AND

RUNNING-IN..............................................................................................................................33

3.3 SAFETY MEASURES DURING TRACTOR OPERATION................................................................33

3.4 SAFETY MEASURES DURING MAINTENANCE,TROUBLESHOOTING AND PLACEMENT FOR

STORAGE .................................................................................................................................38

3.5 FIRE SAFETY REQUIREMENTS ..............................................................................................39

4 CONTROLS .............................................................................................................................42

4.1 INSTRUMENT PANEL OF K-744R1 TRACTOR OF STANDARD DESIGN VERSION..........................42

4.2 INSTRUMENT PANEL FOR K-744R2, K-744R3, K-744R4 TRACTORS OF STANDARD

DESIGN VERSION.......................................................................................................................46

4.3 INSTRUMENT PANEL FOR K-744R1 TRACTOR OF THE PREMIUM DESIGN VERSION ...................49

4.4 INSTRUMENT PANEL FOR K-744R2, K-744R3, K-744R4 TRACTORS OF THE PREMIUM

DESIGN VERSION.......................................................................................................................53

4.5 TRACTOR SYSTEM CONTROL................................................................................................58

4.6 SWITCH BLOCK ON THE STEERING COLUMN ..........................................................................61

4.7 SWITCHES ON THE OVERHEAD PANEL IN THE CABIN...............................................................62

4.8 FUSE BLOCKS.....................................................................................................................62

4.9 DRIVER’S SEAT AND ADDITIONAL SEAT..................................................................................63

4.10 LIGHTING AND ALARMS......................................................................................................64

4.11 ENGINE PREPARATION AND START-UP................................................................................65

4.12 ENGINE START-UP AT NEGATIVE TEMPERATURES................................................................66

4.12.1 Safety measures when using the heater ...........................................................67

4.12.2 Heater operation...................................................................................................67

4.13 ENGINE START-UP FROM EXTERNAL POWER SUPPLY...........................................................70

4.14 HVAC SYSTEM OPERATION...............................................................................................71

4.15 TAKING OFF......................................................................................................................72

4.16 GEAR CHANGE..................................................................................................................73

4.17 STOP ...............................................................................................................................73

5 FINAL ASSEMBLY, ADJUSTING AND RUNNING-IN ...........................................................75

5.1 GENERAL ...........................................................................................................................75

5.1.1 Adjustment of lower links .....................................................................................77

5.1.2 Installation of light signaling equipment.............................................................78

5.1.3 Adjustment of head lights.....................................................................................79

5.1.4 Check of window washers ....................................................................................81

5.2 TRACTOR RUNNING-IN.........................................................................................................81

6 OPERATION AND ADJUSTMENT REGULATIONS .............................................................. 83

6.1 PROCEDURE FOR TRACTOR PREPARATION FOR OPERATION...................................................83

6.2 OPERATING RULES AND CONTROL OVER TRACTOR DURING OPERATION..................................85