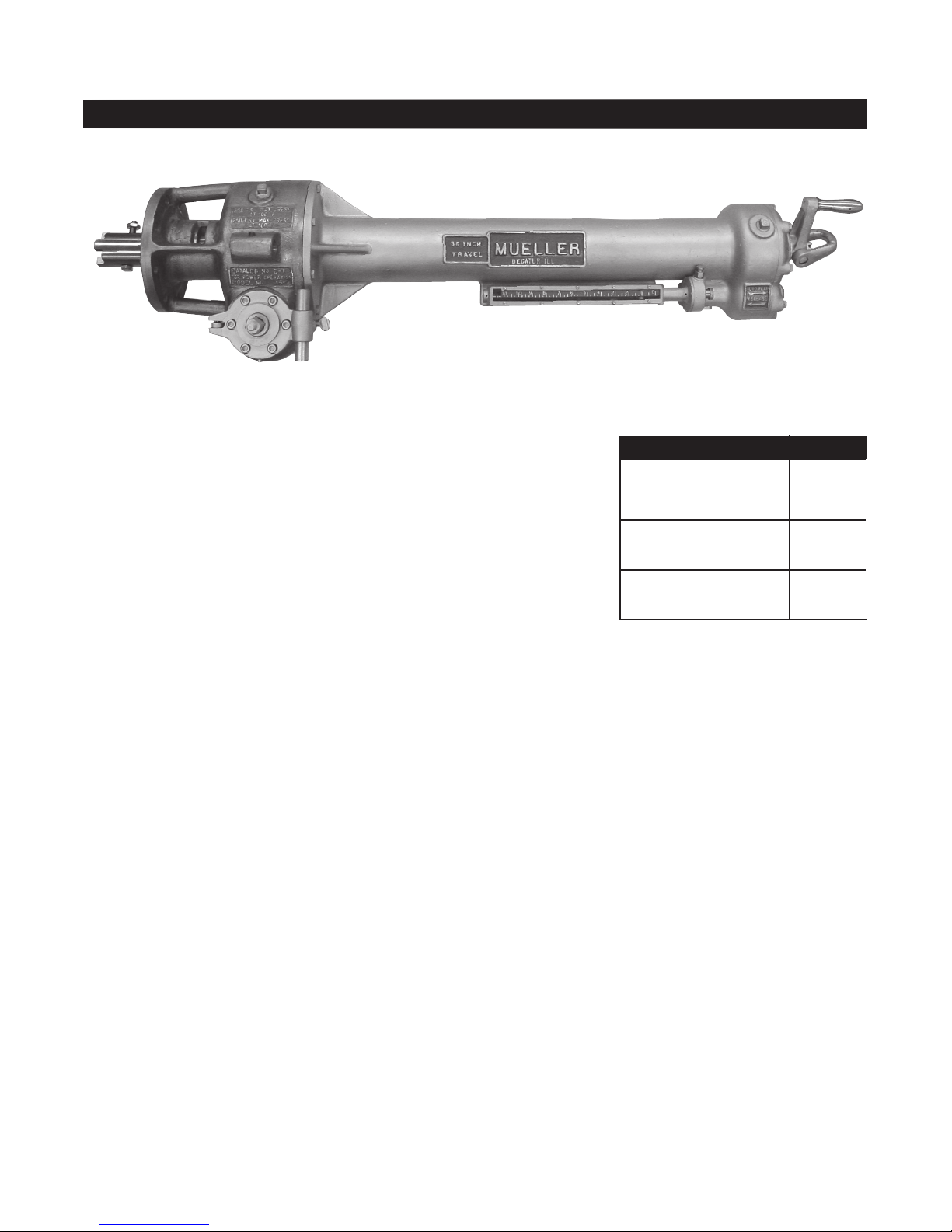

MUELLER® C1-36 Drilling Machines

Operating Instructions

4

b) 2½”– 3”/DN65 – DN80. Assemble

both the pilot drill and the shell

cutter to the cutter arbor Remove

retaining screw from the shank of

the arbor. Insert the shank of the

arbor into the socket in the boring

bar. Align the bolt hole in the end

of the boring bar with the tapped

hole in the shank of the arbor and

replace the retaining screw.

c) Sizes larger than 3”/DN80.

Assemble shell cutter and cutter

hub. Insert the end of the pilot

drill into the socket in the boring

bar. Slide cutter hub and shell

cutter over the end of the boring

bar. Align the holes in the cutter

hub, boring bar and pilot drill

and attach to boring bar with hub

retaining bolt.

Coat cutter and pilot drill thoroughly

with Mueller cutting grease. DO NOT

use cutting grease when cutting AC

or concrete pipe.

6. The term “valve”, as used in these

instructions, refers to whatever

type of valving means that is being

used between the machine and the

main. This might be a tapping valve,

standard gate valve or line stopper

tting. If valve is being used, open

completely and measure, or check,

the exact size of opening and size

of cutter to make sure the entire

opening is clear and unobstructed

and the cutter will pass freely.

7. Retract boring bar to its rearmost

position by rotating feed crank

clockwise.

8. Place the machine (with adapter

and drilling equipment assembled) in

drilling position. For horizontal use,

support the assemble by blocking up

under the machine and valve.

NOTE: Make certain machined

recess on adapter and lip on

adapter ange and machine

ange to be sure they are ush.

1. INSPECT CUTTER AND PILOT

DRILL TO MAKE SURE THAT THEY

ARE SHARP. IF CUTTER IS DULL

IT SHOULD BE SHARPENED AS

DESCRIBED IN MAINTENANCE

INSTRUCTIONS.

2. Bolt proper size adapter to front

of machine, being sure machine-to-

adapter gasket is in good condition

and in place. (All gaskets should be

replaced periodically.)

NOTE: Make certain machined

recess on adapter and lip on

adapter ange and machine

ange are ush.

3. Release automatic feed by

pulling out automatic feed knob or

disengaging with Auto Feed Lever.

(Directions are indicated on panel on

rear of torque tube.)

4. Advance boring bar by rotating

feed crank counter-clockwise until

hub retaining bolt in boring bar is

exposed beyond face of adapter.

(Directions are indicated on panel on

rear cover of torque tube.) Remove

hub retaining bolt.

5. Attach proper drilling equipment

to boring bar. Check detent type

pilot drills before each operation to

make sure the detents will move

completely to the submerged

position.

a) 1½”– 2”/DN40 – DN50. Remove

the retaining screws from the

shank of the drill. Insert the shank

into the socket in the boring

bar. Align the hole in the end of

the boring bar with the tapped

hole in the shank of the drill and

replace the retaining screws. See

instructions under CAUTION on

page 5.

a) Place machine and adapter

against valve, allowing cutter to

extend into the end of the valve.

Cutter must not interfere with

operation of the valve. (When

machine is used horizontally, the

driving spindle should be at a right

angle to the main.) Bolt adapter to

outlet ange of the valve, making

certain that the adapter gasket is

in place.

9.Test set up for pressure tightness.

10. Rotate feed crank counter-

clockwise to advance boring bar

until pilot drill contacts the main. One

turn of the feed crank moves the

boring bar 1/6“ (4mm) – 6 revolutions

equal 1” (25mm). For C1-36-99002

machine, 8 revolutions equal 1”

(25mm). Back up boring bar 1/4 turn

of feed crank clockwise to release

tension between pilot drill and main.

11. Engage automatic feed by

pushing in on automatic feed knob.

12. Rotate feed crank clockwise

until dive key engages. This can be

felt when feed crank ceases to freely

rotate.

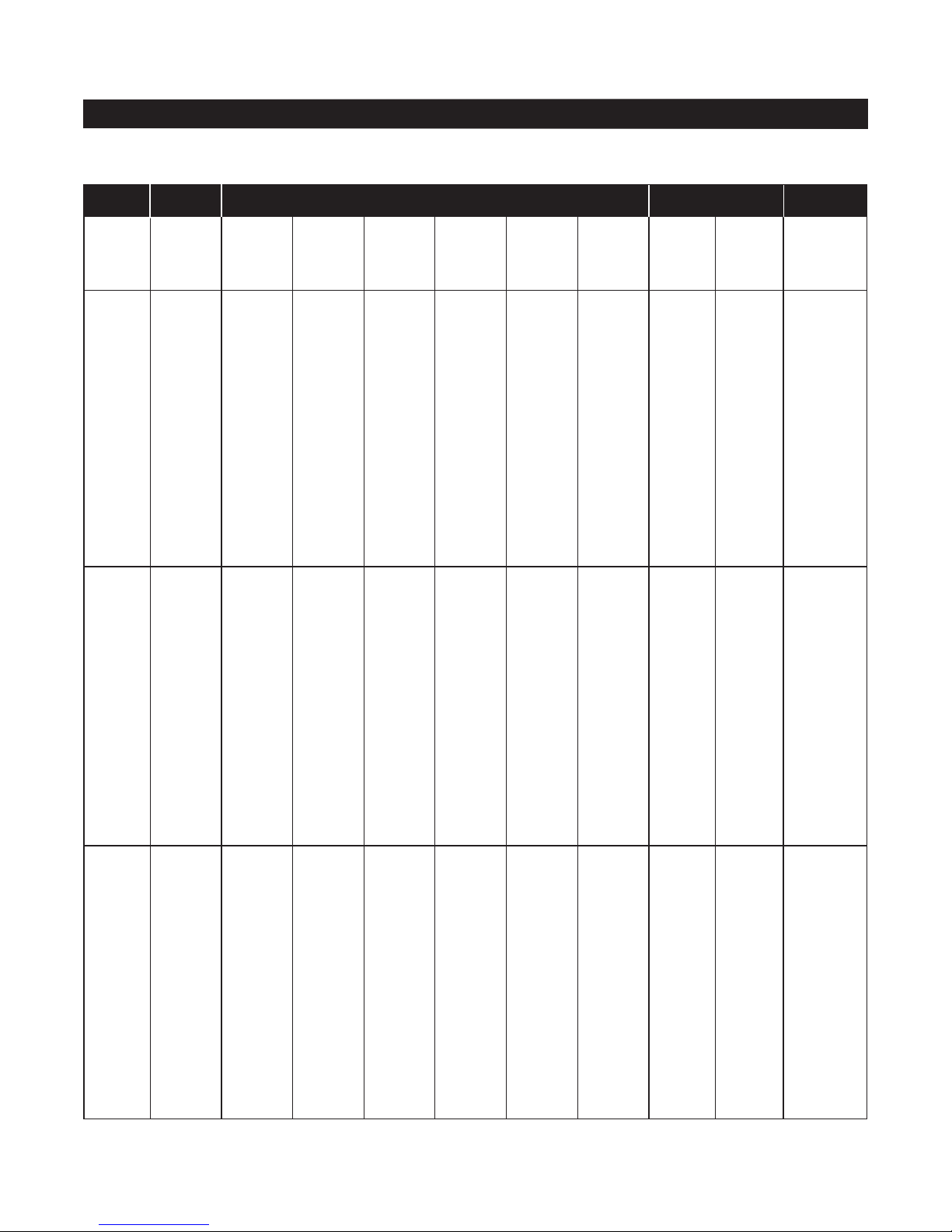

13. Set feed indicator to zero. Mark

the point on feed indicator that the

arrow will reach when cut will be

completed. See Pages 7, 8, 9 and

10 for travel chart.

a) When using the C1-36 Machine

and Mueller Air or Hydraulic

Motors

Refer to form 12237 for H-614 Air

motor, Form 12480 for Hydraulic

motor.

If cutting becomes difcult and

stalling occurs follow one of the

methods listed in instruction 20.