Residential Factory-Assembled Manual Mugnaini Imports, Inc. 3

TABLE OF CONTENTS

1. RECEIVING THE OVEN

Delivery Location......................................................................................................................................................4

Crate Contents...........................................................................................................................................................4

Forklift and Pallet Jack Requirements................................................................................................................4

2. UNLOADING, MOVING AND SETTING THE OVEN

Unloading the Oven: Forklift Required! ............................................................................................................5

Opening the Crate....................................................................................................................................................5

Tools Required ..........................................................................................................................................................5

Moving the Oven......................................................................................................................................................6

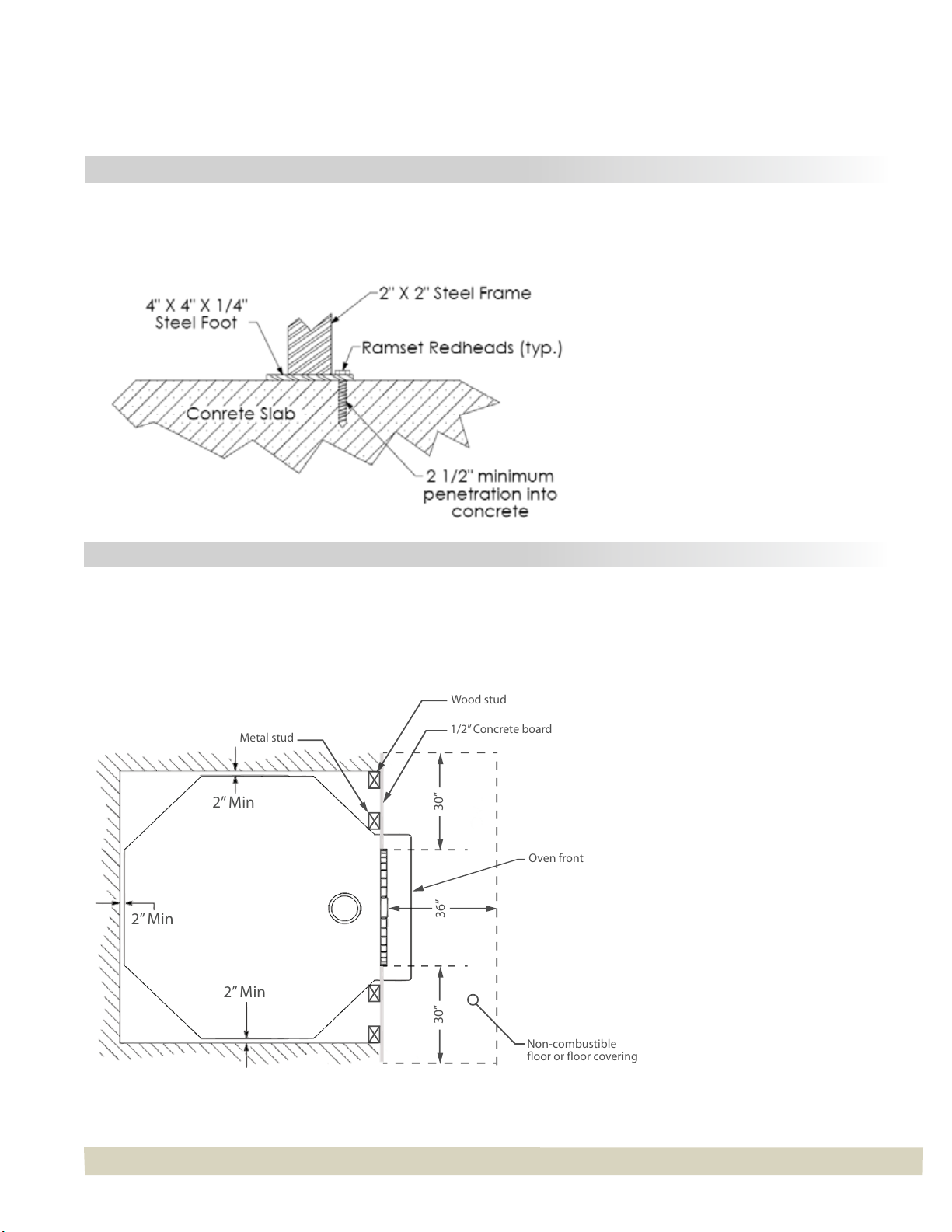

3. CLEARANCES AND FACADES

Setting the Oven.......................................................................................................................................................7

Clearances to Combustible Construction.........................................................................................................7

Installation Accessories ..........................................................................................................................................8

Finish Materials .........................................................................................................................................................8

Covering the Arch ....................................................................................................................................................8

4. VENTING THE OVEN

Overview.....................................................................................................................................................................9

Exhaust Vent Requirements ..................................................................................................................................9

5. DIRECT VENTING WITH FACTORY BUILT CHIMNEY

Direct Vent Requirements Using Factory Built Chimneys......................................................................... 10

Additional Requirements for Canada.............................................................................................................. 10

Oven Flue Outlet.................................................................................................................................................... 10

6. CURING A WOODFIRED OVEN............................................................................................................................ 11

Instructions.............................................................................................................................................................. 12

Selecting The Proper Wood For Your Oven ................................................................................................... 12

Fire Starting Tools.................................................................................................................................................. 12

Using The Door....................................................................................................................................................... 13

How to Measure Oven Temperature ............................................................................................................... 13

Starting a Fire.......................................................................................................................................................... 14

Curing The Oven.................................................................................................................................................... 14

Curing Schedule .................................................................................................................................................... 18

7. LIMITED WARRANTY ............................................................................................................................................... 19