Commercial 140 Wood AOS Manual Mugnaini Imports, Inc. 3

TABLE OF CONTENTS

1. INTRODUCTION

Package Contents and Dimensions....................................................................................................................4

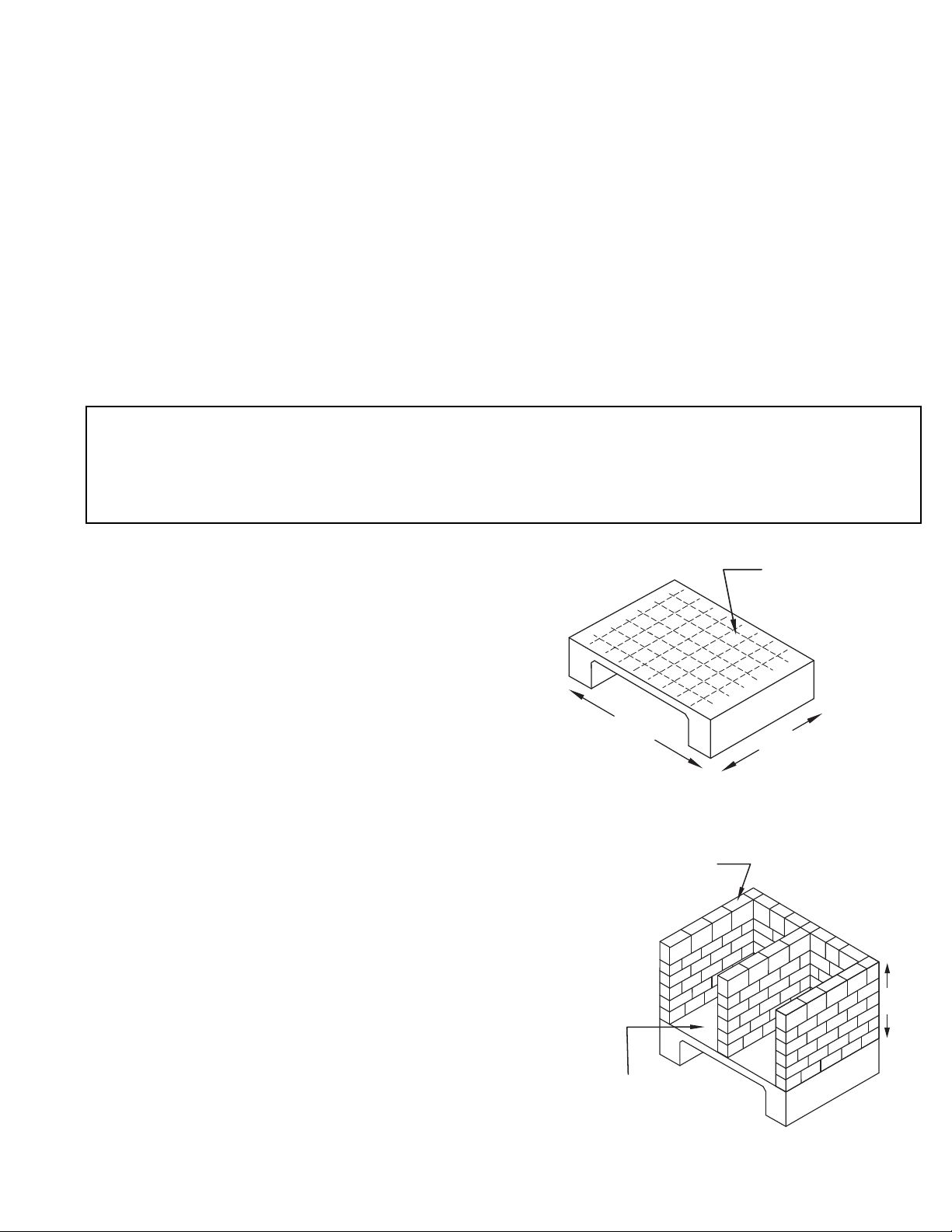

2. CONSTRUCTING THE OVEN BASE

Materials List and Step-by-Step Instructions...................................................................................................5

3. OVEN ASSEMBLY

Materials List ..............................................................................................................................................................7

Step 1 – Floor Layout...............................................................................................................................................7

Step 2 – Mortaring The Floor................................................................................................................................7

Step 3 – Crown Assembly ......................................................................................................................................8

Step 4 – Mortaring Crown Base ...........................................................................................................................9

Step 5 – Mortaring Crown Joints.........................................................................................................................9

Step 6 – Installing Flue Manifold ...................................................................................................................... 10

Step 7 – Insulation ................................................................................................................................................ 10

Step 8 – Oven Venting ......................................................................................................................................... 11

4. ENCLOSING THE OVEN

Flat Roof Enclosure Diagrams............................................................................................................................ 12

5. OVEN VENTING INSTRUCTIONS

Overview .................................................................................................................................................................. 14

Conditions of Acceptability................................................................................................................................ 14

Recommended Chimney Pipe........................................................................................................................... 15

Elbow Oset Chart................................................................................................................................................ 16

Precautions.............................................................................................................................................................. 17

6. CURING A WOOD-FIRED OVEN ............................................................................................................. 18

Instructions.............................................................................................................................................................. 19

Selecting The Proper Wood For Your Oven ................................................................................................... 19

Fire Starting Tools.................................................................................................................................................. 19

Using The Door....................................................................................................................................................... 20

How to Measure Oven Temperature ............................................................................................................... 20

Starting a Fire.......................................................................................................................................................... 21

Curing The Oven.................................................................................................................................................... 21

Curing Schedule .................................................................................................................................................... 25

6. LIMITED WARRANTY ............................................................................................................................................... 26