Table of contents

Table of contents

1 About this document ............................... 4

1.1 Target groups ................................. 4

1.2 Other applicable documents ................ 4

1.3 Warnings and symbols ....................... 5

1.4 Technical terms ............................... 5

2Security .............................................. 6

2.1 Intended use .................................. 6

2.2 General safety instructions .................. 6

2.2.1 Product safety ................................ 6

2.2.2 Operator's obligations ........................ 7

2.2.3 Duties of the operating staff ................. 7

2.3 Special hazards .............................. 7

2.3.1 Potentially explosive areas .................. 7

2.3.2 Hazardous pumped liquids .................. 7

2.3.3 Magnetic field ................................. 7

3 Layout and function ................................ 8

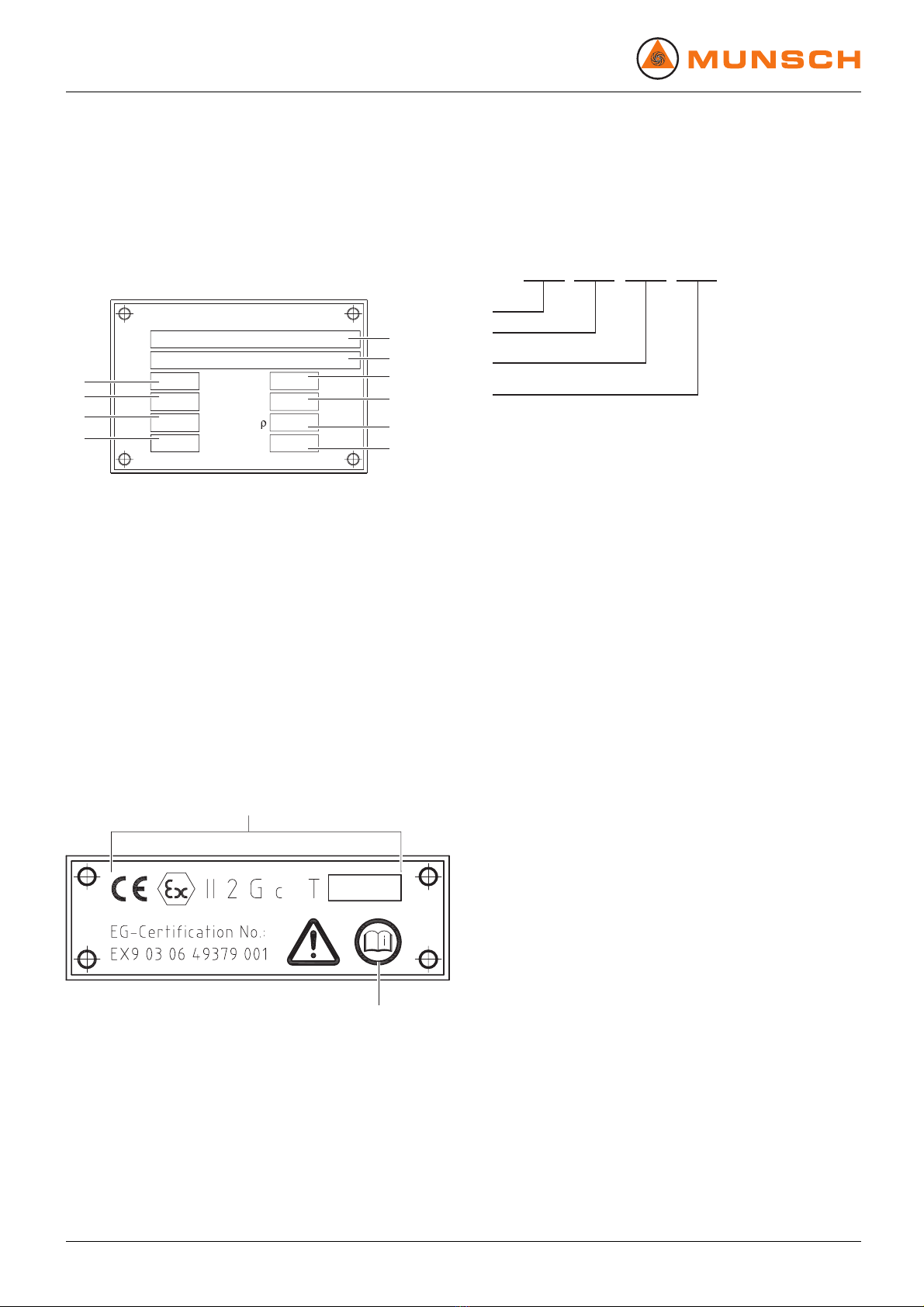

3.1 Labels ......................................... 8

3.1.1 Type plate ..................................... 8

3.1.2 ATEX plate .................................... 8

3.1.3 Pump type code .............................. 8

3.2 Layout ......................................... 9

4 Transport, storage and disposal .................. 10

4.1 Transport ...................................... 10

4.1.1 Unpacking and inspection on delivery . ..... 10

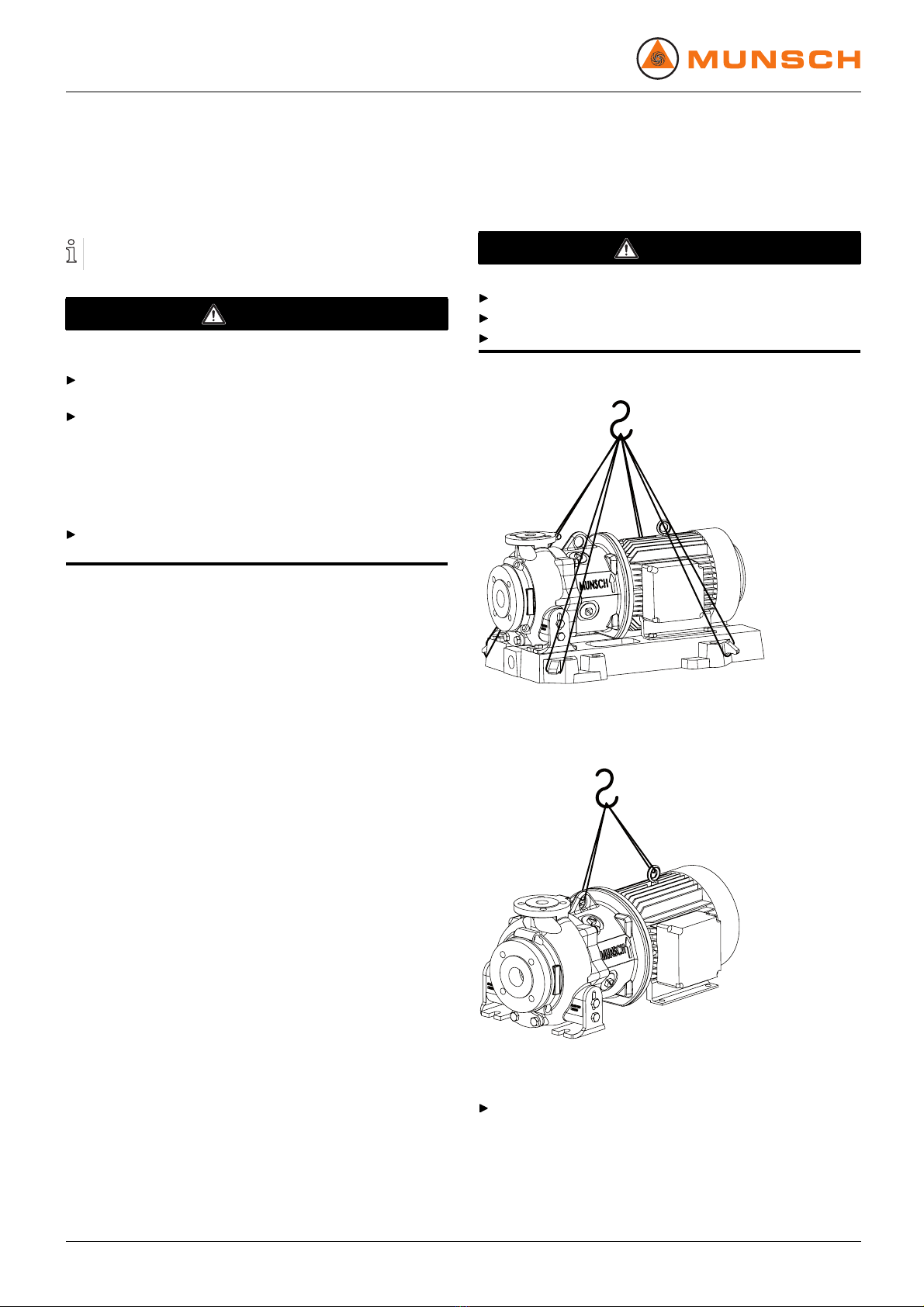

4.1.2 Lifting .......................................... 10

4.2 Preservation .................................. 11

4.3 Storage ....................................... 11

4.4 Disposal ....................................... 11

5 Setup and connection .............................. 12

5.1 Preparing the installation .................... 12

5.1.1 Checking the ambient conditions ... . .. . . .. . 12

5.1.2 Preparing the installation site ............... 12

5.1.3 Preparing the foundation and setup

surface ........................................ 12

5.1.4 Preparing the pump .......................... 12

5.1.5 Installing the heat insulation .. .. . . .. . . .. . ... . 12

5.2 Setup with foundation ........................ 13

5.2.1 Setting the pump group down on the

foundation .................................... 13

5.2.2 Fastening the pump group .................. 13

5.3 Setup without foundation .................... 14

5.4 Planning the pipes ........................... 14

5.4.1 Avoid impurities in the pipes ................. 14

5.4.2 Laying out supportsandflange

connections ................................... 14

5.4.3 Specifying nominal diameters ............... 14

5.4.4 Determining pipe lengths .................... 15

5.4.5 Optimising cross-section and direction

changes ....................................... 15

5.4.6 Providing safety and monitoring devices

(recommended) .............................. 15

5.5 Connecting the pipes ........................ 15

5.5.1 Installing auxiliary pipes ..................... 15

5.5.2 Installing the suction pipe .................... 16

5.5.3 Installing the pressure pipe .................. 16

5.5.4 Checking that the pipe connections are

stress-free .................................... 16

5.6 Connecting the electrical system . ... ... ... . 16

5.6.1 Connecting the motor ........................ 16

5.6.2 Checking the direction of rotation .. . . .. . ... . 16

6Operation ............................................ 17

6.1 Preparations for the initial start-up ... . .. . . .. 17

6.1.1 Identifying the pump version ................ 17

6.1.2 Checking downtimes ......................... 17

6.1.3 Preparing auxiliary operating systems . . . .. . 17

6.1.4 Filling and bleeding .......................... 17

6.1.5 Checking the direction of rotation .. . . .. . ... . 17

6.2 Putting the pump into service ............... 18

6.2.1 Switching on the pump ...................... 18

6.2.2 Switching off the pump ....................... 19

6.3 Shut-down .................................... 19

6.4 Restoring the pump to service .............. 20

6.5 Operating the stand-by pump ............... 20

7 Maintenance ......................................... 21

7.1 Inspections ................................... 21

7.2 Maintenance .................................. 22

7.3 Dismounting .................................. 23

7.3.1 Returning the pump to the manufac-

turer ........................................... 23

7.3.2 Preparing the dismounting .................. 24

7.3.3 Undoing connections (if available) ... . .. . . .. 24

7.3.4 Pulling off the volute casing ................. 24

7.3.5 Dismounting the impeller, plain bearing

bracket and pump rotor ...................... 24

7.3.6 Dismounting the drive rotor .................. 26

7.4 Installing ...................................... 26

7.4.1 Preparing the installation .................... 26

7.4.2 Installing the drive rotor ...................... 26

7.4.3 Installing the plain bearing bracket .. . ... . .. 27

7.4.4 Fitting the pump in the installation .......... 27

7.5 Ordering spare parts ......................... 27

8 Disturbance recovery .............................. 28

9 Appendix ............................................. 31

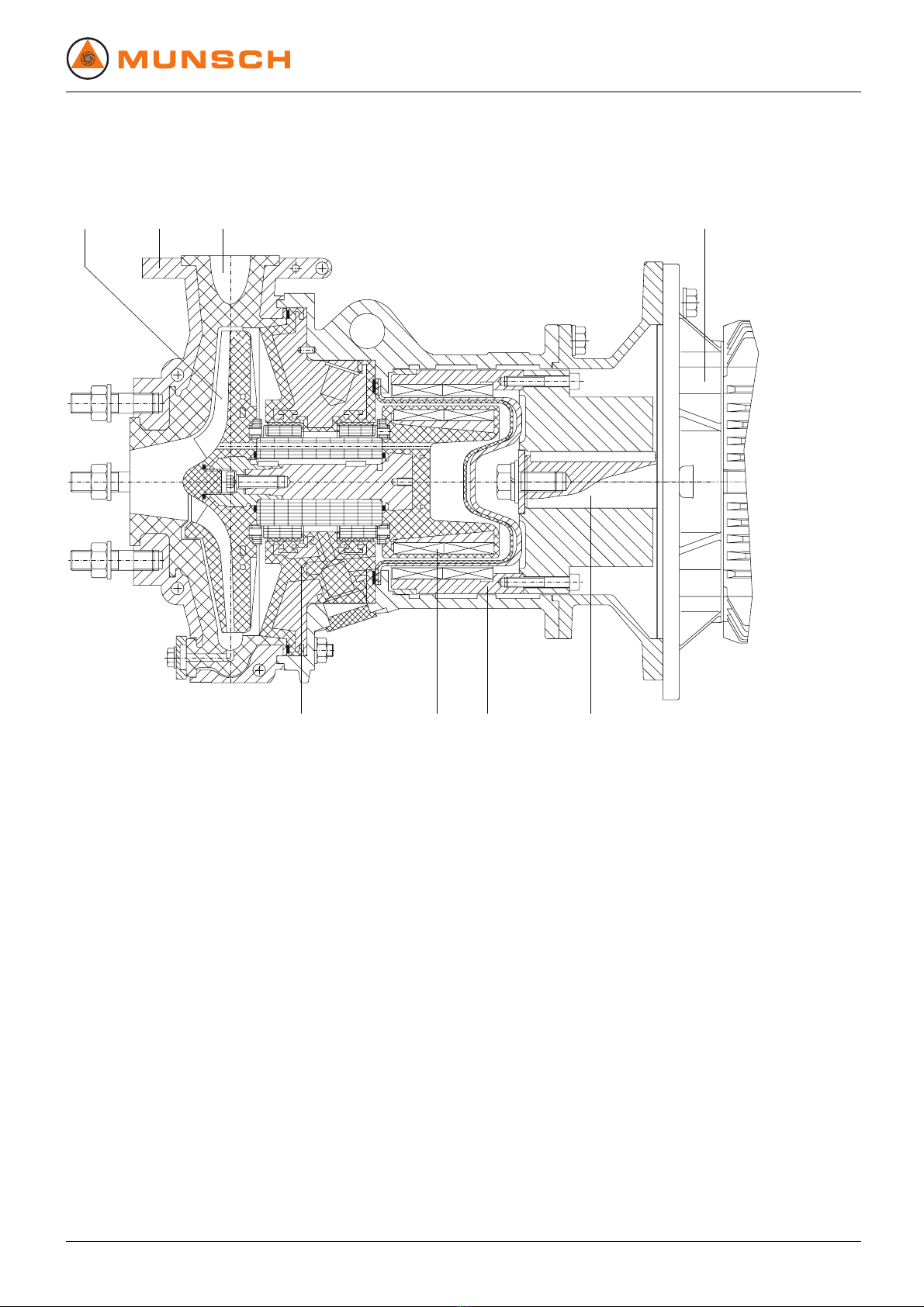

9.1 Sectional drawing ............................ 31

9.1.1 Part numbers and designations ... . .. . ... . .. 31

9.1.2 Overview sectional drawing ................. 32

9.1.3 Variants ....................................... 33

9.2 Technical specifications ...................... 33

9.2.1 Ambient conditions ........................... 33

9.2.2 Noise pressure level ......................... 33

9.2.3 Tightening torques ........................... 34

2 MPC-B series BA-2006.03 EN – 01