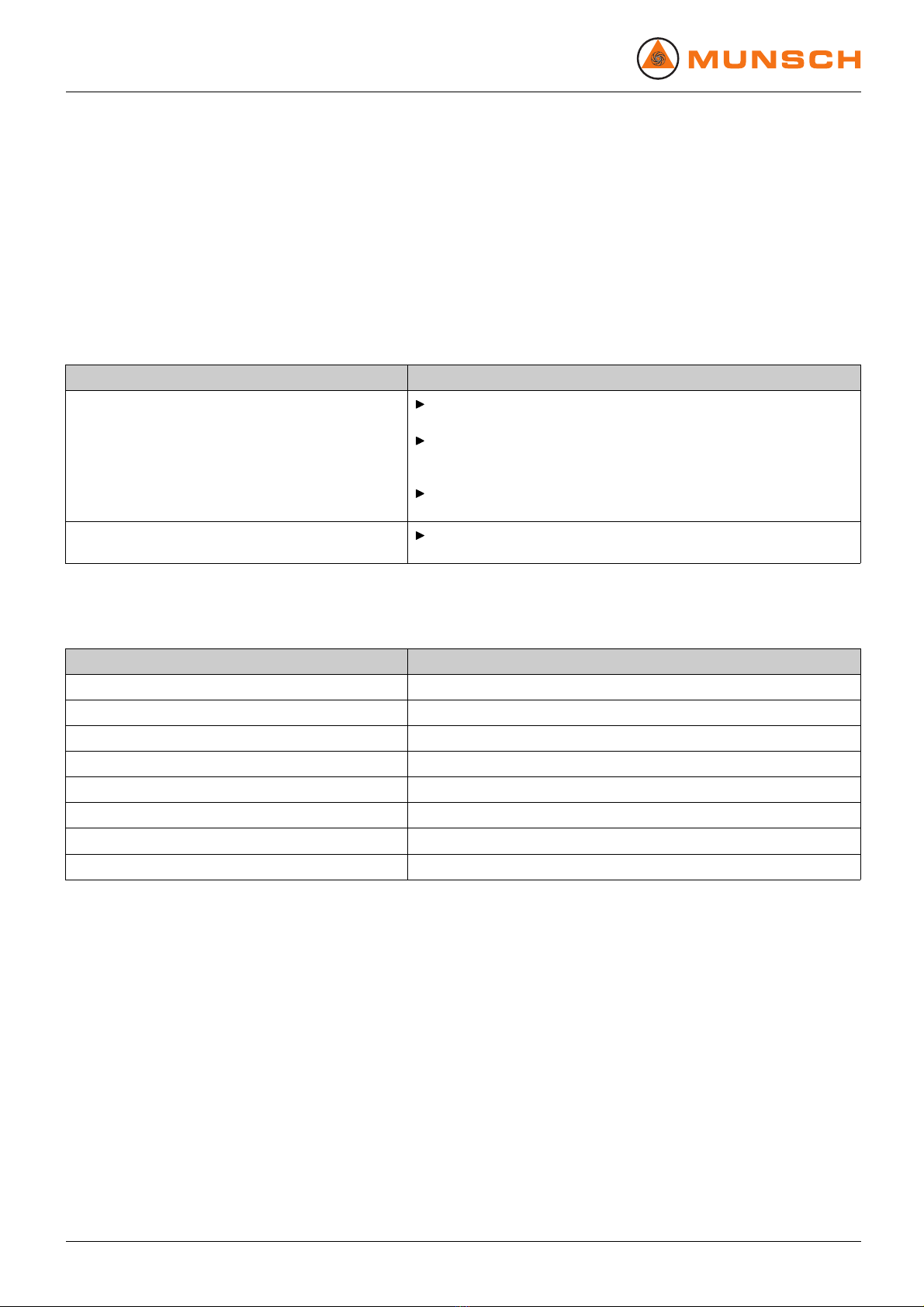

Table of contents

Table of contents

1 About this document ............................... 6

1.1 Target groups ................................. 6

1.2 Other applicable documents . . . . . . . .. . . . . . . . 6

1.3 Warning labels and symbols ................ 7

1.4 Technical terms ............................... 7

2 Security .............................................. 8

2.1 Intended use .................................. 8

2.2 General safety instructions .................. 8

2.2.1 Product safety ................................ 8

2.2.2 Duties of the operating company . . . . . . . . . .. 9

2.2.3 Duties of the operating personnel . . . . . . . .. . . 9

2.3 Special hazards .............................. 9

2.3.1 Explosion hazard area ....................... 9

2.3.2 Hazardous pumped media . . . . . . .. . . . . . . .. . . 9

3 Layout and function ................................ 10

3.1 Labels ......................................... 10

3.1.1 Type plate ..................................... 10

3.1.2 ATEX plate .................................... 10

3.1.3 Pump type code . . . . . . . . . . .. . . . . . . .. . . . . . . .. . . 10

3.2 Layout ......................................... 11

3.3 Shaft seals .................................... 11

3.3.1 Mechanical seals ............................. 11

3.4 Auxiliary operating systems ................. 12

3.4.1 Sealing systems .............................. 12

4 Transport, storage and disposal .................. 13

4.1 Transport ...................................... 13

4.1.1 Unpacking and inspection on delivery .. .. . . 13

4.1.2 Lifting .......................................... 13

4.2 Preservation .................................. 14

4.3 Storage ....................................... 14

4.4 Disposal ....................................... 14

5 Setup and connection .............................. 15

5.1 Preparing the setup .......................... 15

5.1.1 Checking the ambient conditions . . . . . . . .. . . 15

5.1.2 Preparing the setup site ..................... 15

5.1.3 Preparing the foundation and setup

surface ........................................ 15

5.1.4 Installing the heat insulation . . . . .. . . . . . .. . . . . 15

5.2 Setup with foundation ........................ 16

5.2.1 Setting the pump aggregate on the

foundation .................................... 16

5.2.2 Fastening the pump aggregate . . . . . . .. . . . . . 16

5.3 Setup without foundation .................... 17

5.4 Mounting the motor .......................... 17

5.5 Planning the piping ........................... 17

5.5.1 Avoid contamination of the piping . . . . . . . . . . . 17

5.5.2 Specifying supports and flange

connections . . . .. . . . . . .. . . . . . . .. . . . . . . .. . . . . . . . 17

5.5.3 Specifying nominal widths ................... 18

5.5.4 Specifying pipe lengths ...................... 18

5.5.5 Optimizing cross-section and direction

changes ....................................... 18

5.5.6 Arranging for safety and control devices

(recommended) .............................. 18

5.6 Connecting the pipes ........................ 18

5.6.1 Installing auxiliary pipes ..................... 18

5.6.2 Installing the suction pipe . . . . . . . . .. . . . . . . .. . . 18

5.6.3 Installing the pressure pipe . . . . . . . . . . . .. . . . . . 18

5.6.4 Inspection for stress-free pipe

connections . . . .. . . . . . .. . . . . . . .. . . . . . . .. . . . . . . . 19

5.6.5 Inspecting the support foot for

distortion ...................................... 19

5.7 Electrical connection ......................... 19

5.7.1 Connecting the motor ........................ 19

5.7.2 Checking the direction of rotation . . . . . . . .. . . 19

5.8 Fine alignment of the coupling . . . . . .. . . . . . . . 20

5.9 Aligning the motor ............................ 20

5.9.1 Aligning the motor using sets of shims .. . . . 20

6Operation ............................................ 21

6.1 Preparations for the initial start-up . . . . . . . . .. 21

6.1.1 Identifying the pump type .................... 21

6.1.2 Lubricating the bearings ..................... 21

6.1.3 Preparing auxiliary operating systems (if

available) ..................................... 21

6.1.4 Filling and bleeding .......................... 21

6.2 Start up ....................................... 22

6.2.1 Switching on .................................. 22

6.2.2 Switching off .................................. 22

6.3 Shut-down .................................... 23

6.4 Start-up following a shutdown period . . .. . .. 23

6.5 Running the stand-by pump ................. 23

7 Maintenance ......................................... 24

7.1 Inspections . . . . . . .. . . . . . . .. . . . . . . .. . . . . . .. . . . . 24

7.2 Maintenance .................................. 24

7.2.1 Roller bearings with grease lubrication .. . . . 24

7.2.2 Roller bearings with oil lubrication . . . . . . . . . . 25

7.2.3 Stationary seal rings ......................... 25

7.3 Disassembling . . . . .. . . . . . . .. . . . . . . .. . . . . . . .. . . 25

7.3.1 Returning the pump to the manufac-

turer ........................................... 26

7.3.2 Preparations for disassembling . . . . . . . . . . . . . 26

7.3.3 Loosening connectors (if available) . . .. . . . . . 27

7.3.4 Extracting the volute casing . . . . . . . .. . . . . . . .. 27

7.3.5 Disassembling the impeller . . . . . . . . . .. . . . . . . . 27

7.3.6 Disassembling a casing cover with

MUNSCH-REA-C mechanical seal . . . . . . . .. 28

7.3.7 Disassembling the atmosphere-side

stationary seal ring ........................... 28

7.3.8 Disassembling the bearing bracket . . . . . . . .. 29

7.3.9 Disassembling the pump shaft . . . . . . . .. . . . . . 29

7.4 Assembling ................................... 30

2 NPC series BA-2005.07 EN – 02