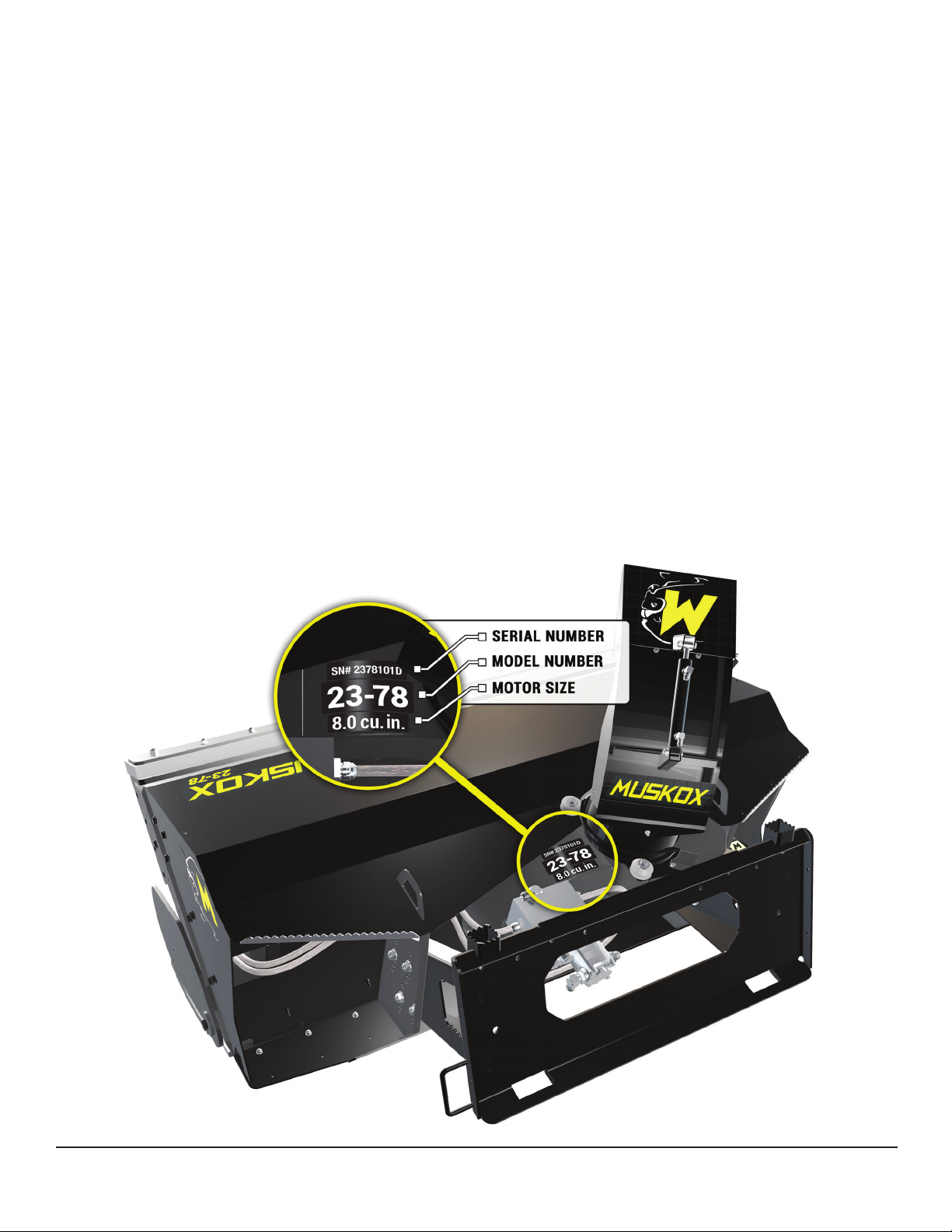

MUSKOX OPERATOR’S MANUAL5

MUSKOX MODELS 23-78 AND 23-78 DUALLY

CAUTION

Caution indicates a hazardous situation which,

if not avoided, could result in minor or moderate

injury.

NOTICE

Notice indicates information considered

important, but not hazard-related (e.g. messages

relating to property damage).

This symbol by itself or used with a warning

word throughout this manual is used to call

your attention to instructions involving your personal

safety or the safety of others. Failure to follow these

instructions can result in injury or death.

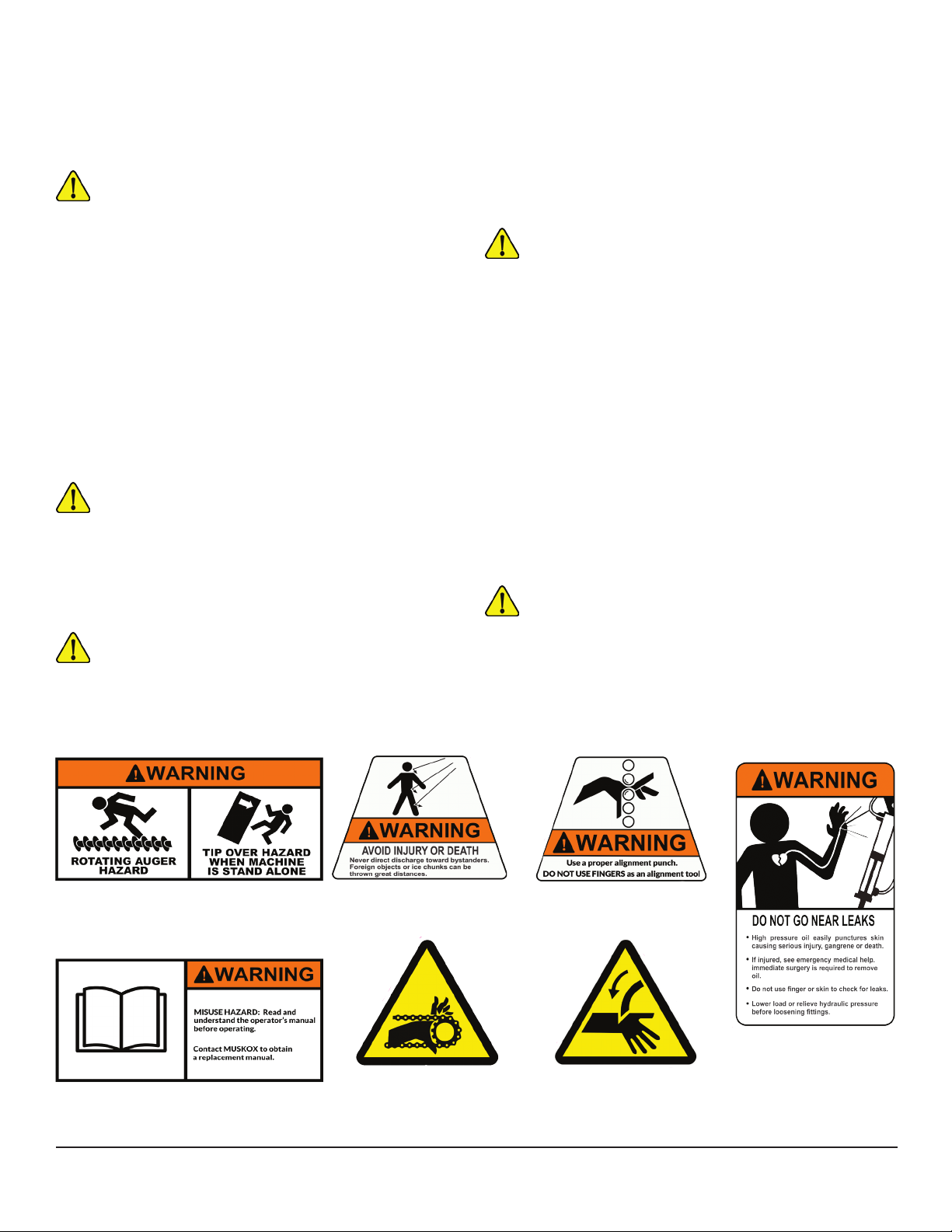

SAFETY DEFINITIONS

The purpose of safety symbols is to attract your

attention to possible dangers. The safety symbols,

and their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions

or warnings they give are not substitutes for proper

accident prevention measures.

DANGER

Danger indicates a hazardous situation which, if

not avoided, will result in death or serious injury.

WARNING

Warning indicates a hazardous situation which,

if not avoided, could result in death or serious

injury.

SAFETY STATEMENTS

General Safety Precautions

READ MANUAL

PRIOR TO INSTALL

Improper installation, operation, or

maintenance of this equipment could result in

serious injury or death. Operators and maintenance

personnel should read this manual as well as all

manuals related to this equipment and the prime mover

thoroughly before beginning installation, operation, or

maintenance. FOLLOW ALL SAFETY INSTRUCTIONS

IN THIS MANUAL AND THE PRIME MOVER’S

MANUAL.

READ AND UNDERSTAND

ALL SAFETY STATEMENTS

Read all safety decals and safety statements

in all manuals prior to operating or working on

this equipment. Know and obey all OSHA regulations,

local laws and other professional guidelines for your

operation. Know and follow good work practices when

assembling, maintaining, repairing, mounting, removing

or operating this equipment.

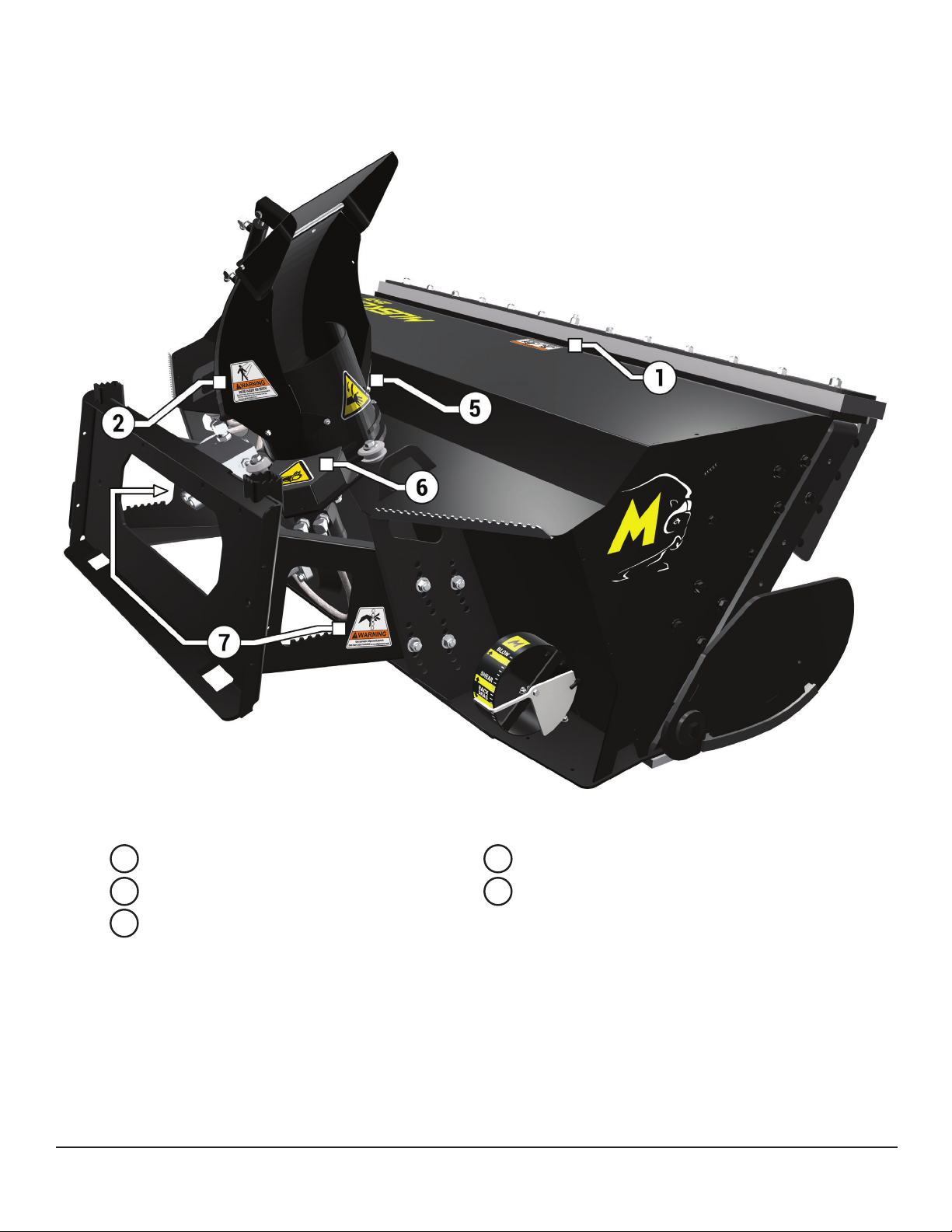

KNOW YOUR EQUIPMENT

Know your equipment’s capabilities, dimensions

and operations before operating. Visually

inspect your equipment before you start, and never

operate equipment that is not in proper working order

with all safety devices intact. Check all hardware to

assure it is tight. Make certain that all locking pins,

latches, and connection devices are properly installed

and secured. Remove and replace any damaged,

fatigued or excessively worn parts. Make certain all

safety decals are in place and are legible. Keep decals

clean, and replace them if they become worn and hard

to read. (Safety decal replacements are available free

of charge from the manufacturer).

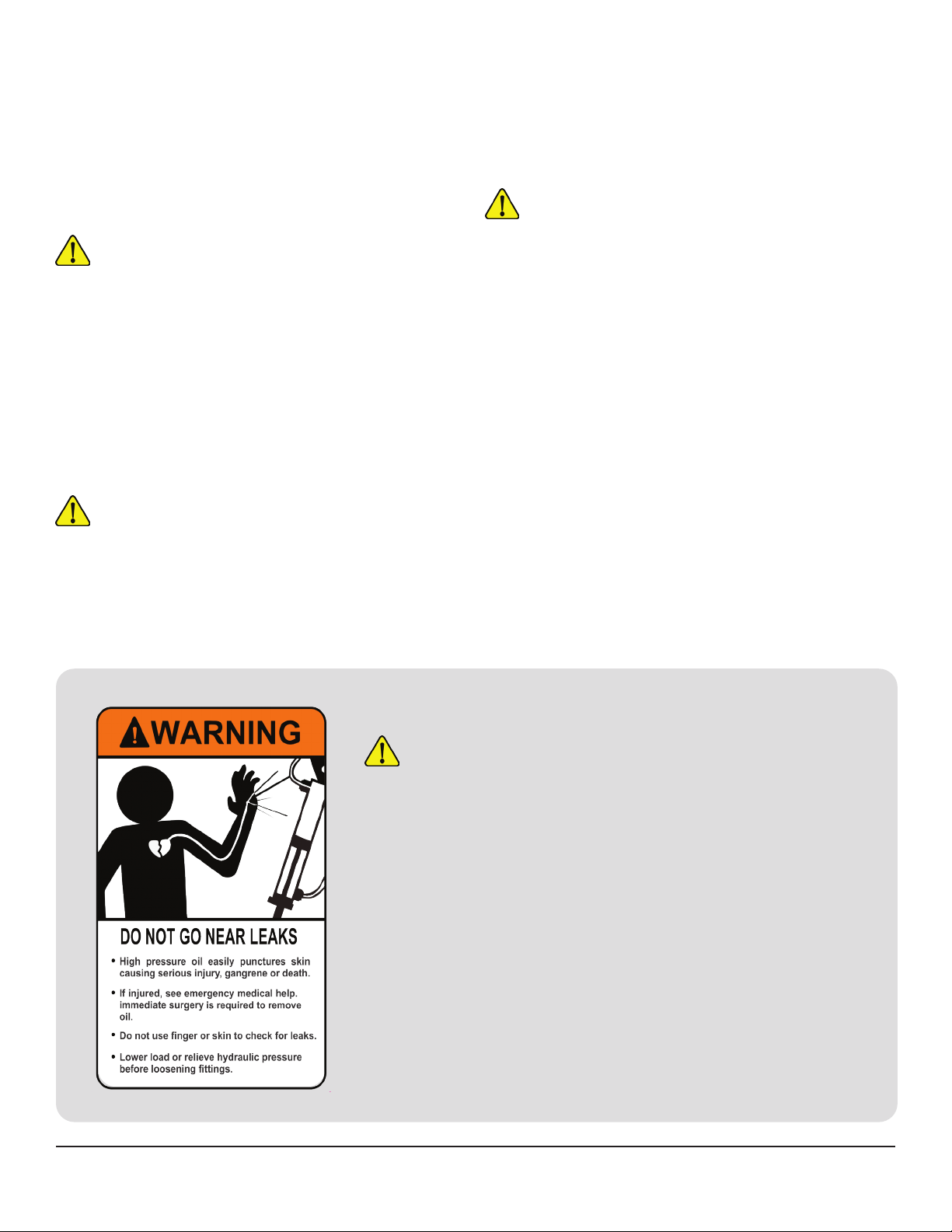

PROTECT AGAINST

FLYING DEBRIS

Always wear proper safety glasses, goggles

or a face shield when driving pins in or out or

when operation causes dust, ying debris, or any other

hazardous material.

LOWER OR SUPPORT

RAISED EQUIPMENT

Do not work under raised booms without

supporting them. Do not use support material

made of concrete blocks, logs, buckets, barrels or any

other material that could suddenly collapse or shift