3

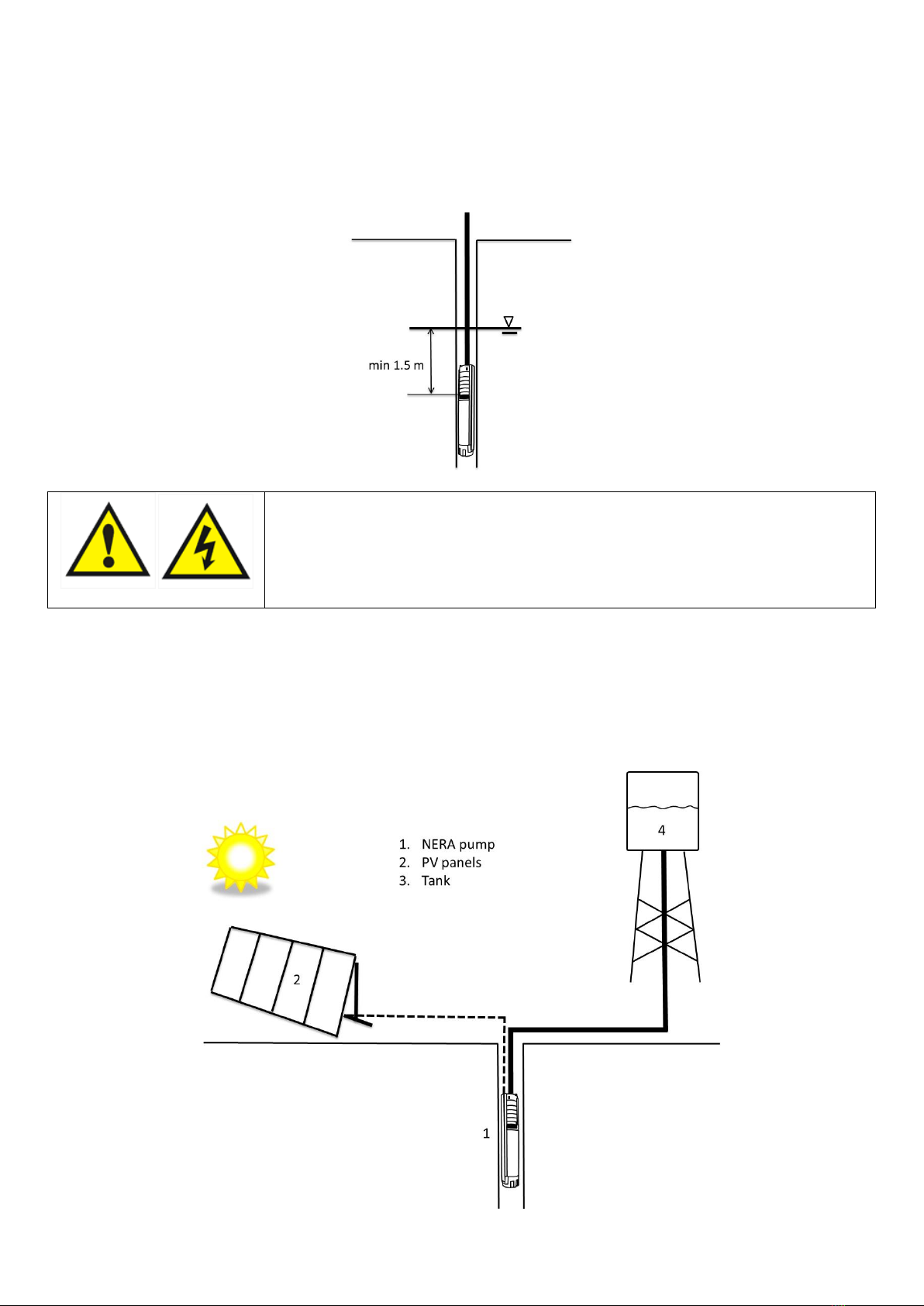

1. Introduction to the NERA solar submersible pumps range

NERA are a 4” submersible solar pumps for clean water composed by:

three phase permanent magnet motor with wet rotor and canned type resin filled stator.

Stator on-board inverter.

Multi stage pump entirely made of AISI 304 stainless steel (centrifugal models)

Helical rotor pump (helical rotor model)

NERA pumps are fed by DC voltage with wide margins of operating voltage (70-190 VDC).

In the application with photovoltaic panels, the MPPT algorithm maximizes, for various conditions of irradiation and

temperature, the electric power obtained from the panels thus the amount of water extracted.

Pump speed is adjusted in relation to solar irradiation. When solar irradiation increases, pump will run faster thus

pumping more water. When solar irradiation decreases (clouds moving or different hours of the day) pump will

reduce its frequency and so delivery but it continues pumping till solar irradiation reaches the minimum value

necessary for working.

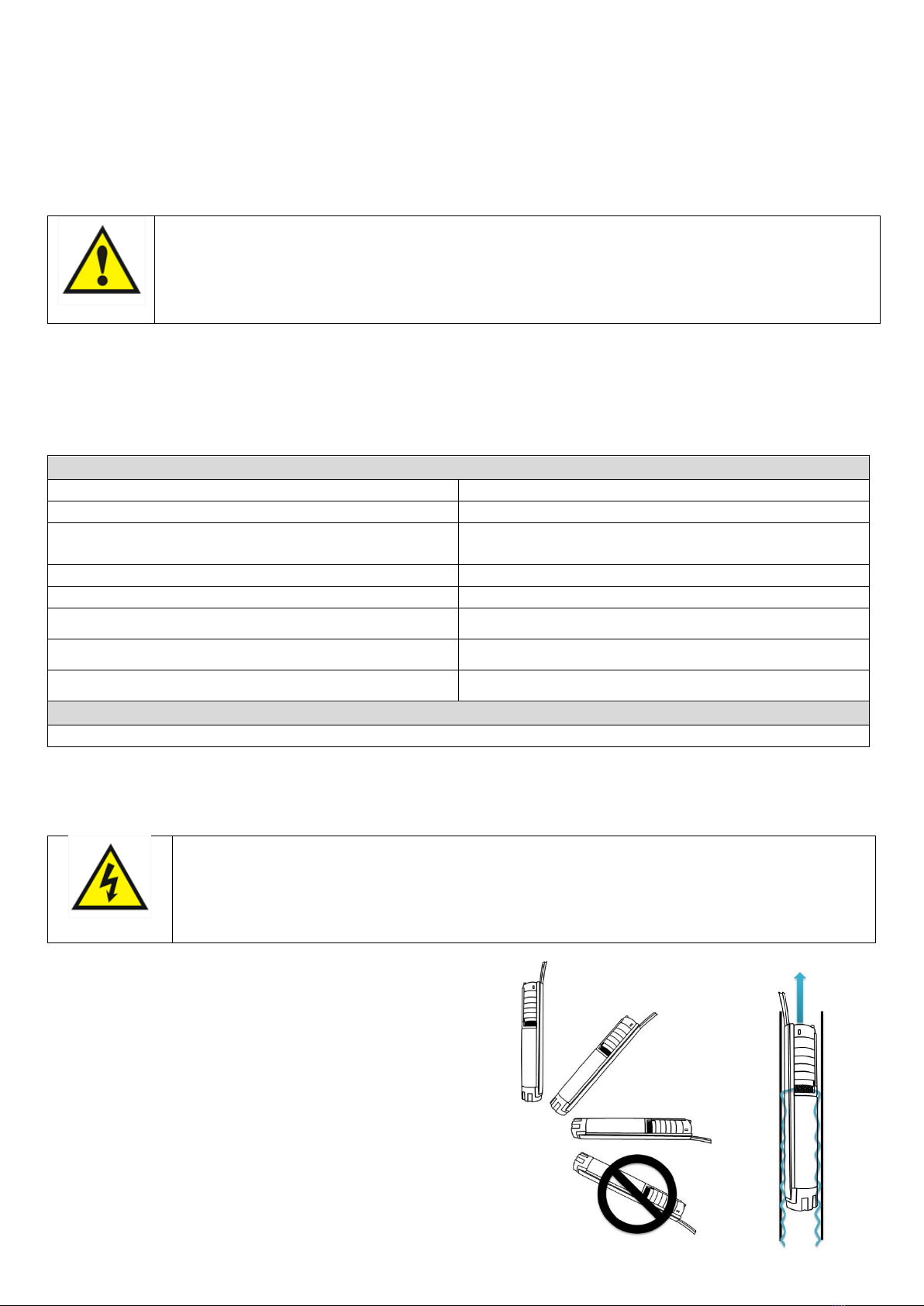

2. Safety Instructions

The manufacturer strongly suggests to reading carefully this operation manual before using and installing its

products

Any operation (installation, maintenance and repair) must be carried out by trained, skilled and qualified personnel.

Failure to observe and follow the instruction of this manual may result fatal in dangerous electric shock.

The unit must be connected to the power supply by a switch granting the

complete visual disconnection (separation) from the line before any operation.

Disconnect the unit from the power supply before any operation.

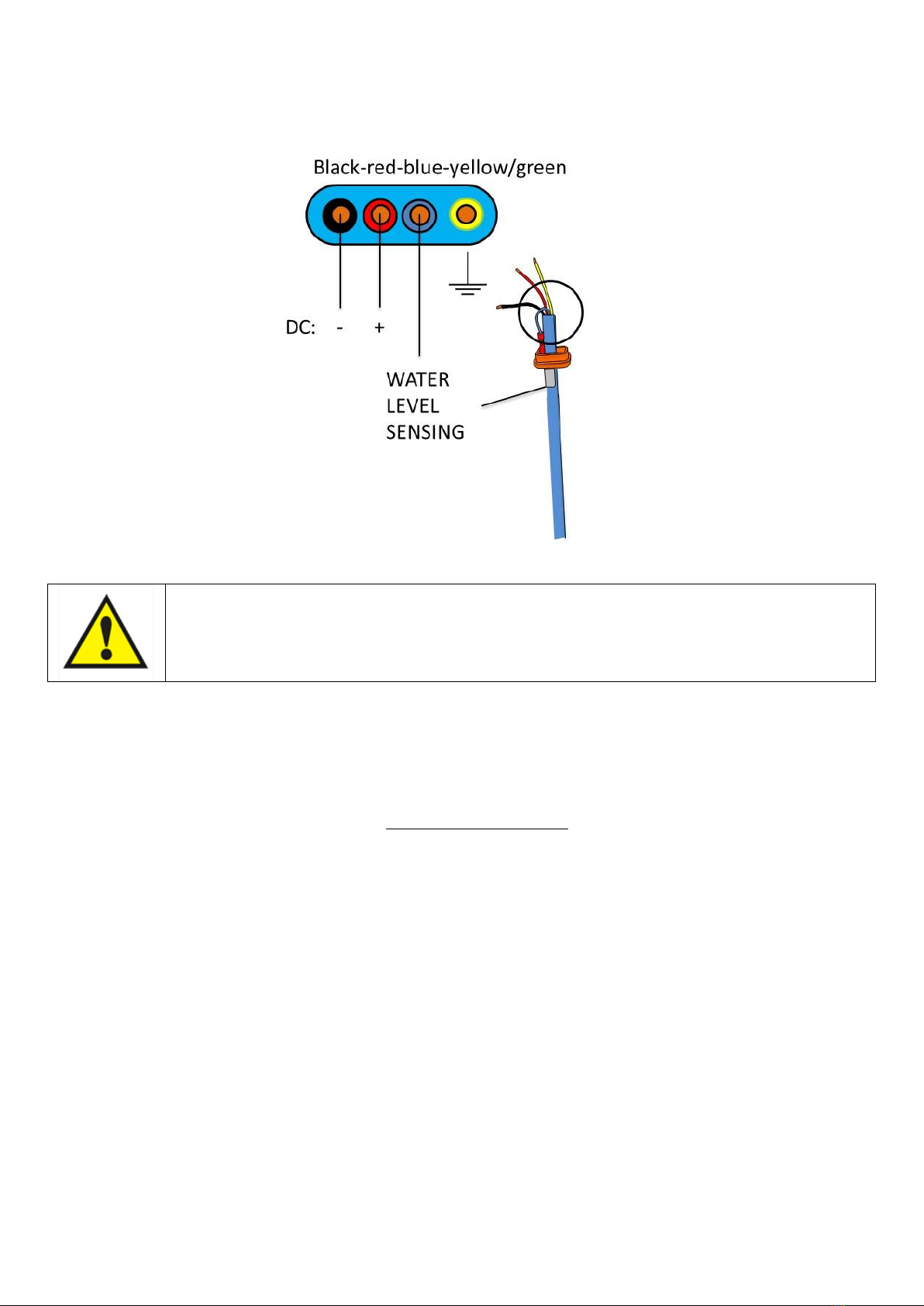

NERA and pump system must be grounded properly before any operation.

Do not start the pump for any reason if not completely immersed in water.

Avoid any shock or serious impact during transportation.

Damages due to transportation, incorrect installation, or improper use of the device will null and void the warranty.

The manufacturer cannot be held responsible for any damage to people and/or property due to improper use of

its products.

3. Stocking conditions

Store the product on its packaging in a dry and well ventilated environment within a temperature range from -20 ° C

to 50 ° C.

If the pump remains in stock for more than a year is recommended to disassemble the rotating parts and test their

functionality. It 'also need to power the electric pump (without running the motor) to allow charging of electrolytic

capacitors of the inverter module.

If the pump has already been put into operation and is then placed in storage, the minimum storage temperature is

4 ° C. Alternatively you need to add anti-freeze fluid.