2

Index

1. Introduction of the 4HS submersible pumps range..................................................................................................3

2. Safety Instructions ....................................................................................................................................................4

3. Stocking conditions ...................................................................................................................................................4

4. Packing content......................................................................................................................................................... 5

5. General technical features....................................................................................................................................5

6. Pump installation ......................................................................................................................................................6

6.1 Installing pump in the well................................................................................................................................ 6

6.2 Pump cable........................................................................................................................................................ 7

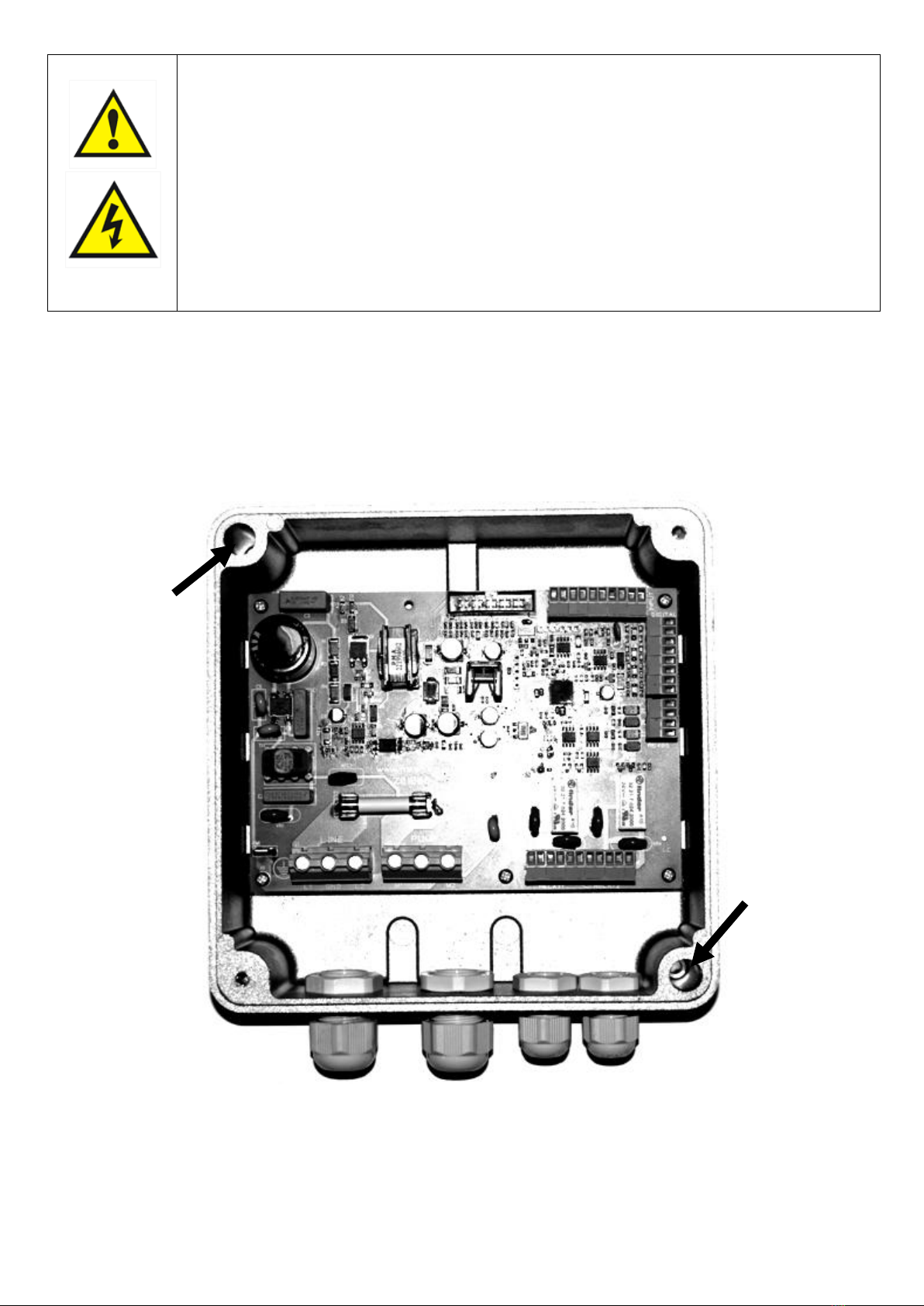

7 CM installation ..........................................................................................................................................................8

7.1 Electric wiring....................................................................................................................................................9

8. 4HS pumps installation for constant pressure mode..............................................................................................10

8.1 Pressure tank ..................................................................................................................................................11

8.2 Pressure sensor...............................................................................................................................................11

8.3 Minimum stop frequency at 0 delivery (f min Q=0) during constant pressure control..................................12

9. 4HS pumps performance range ..............................................................................................................................13

10. 4HS use and programming..................................................................................................................................16

10.1 Display.............................................................................................................................................................16

10.2 Initial setting ...................................................................................................................................................16

10.3 Initial view.......................................................................................................................................................18

10.4 Menu display...................................................................................................................................................19

10.5 Installer parameters........................................................................................................................................19

10.6 Advanced parameters.....................................................................................................................................24

11. Protections and alarms ...................................................................................................................................27

12. Trouble-shooting chart .......................................................................................................................................30

13. Technical Assistance ...........................................................................................................................................31