Nedap PowerRouter PR30S Instruction Manual

1

PowerRouter application guideline

Technical information about a self-use installation

2

Contents

Introduction ..................................................................................................................... 3

Step 1. Assembly............................................................................................................. 4

Step 2. PowerRouter AC connection............................................................................... 5

External relay for the backup power supply .................................................................... 8

External relay for load management................................................................................ 9

Step 3: Connecting the sensor...................................................................................... 11

Step 4: Connecting the solar strings ............................................................................. 14

Step 5: Connecting the batteries................................................................................... 17

Step 6: Connecting the internet connection.................................................................. 23

Step 7: Initialising the PowerRouter............................................................................... 25

Three-phase self-use system ........................................................................................ 27

Glossary ........................................................................................................................ 28

3

Introduction

This document explains, step-by-step, how to install a PowerRouter with batteries (PowerRouter Solar Battery

– PRxxSB-BS) to create a self-use system. It also describes important aspects that must be considered during

installation.

The steps in this document are based on the standard procedure for connecting the system. Detailed

information about the installation can be found in the installation manual that comes with the PowerRouter. That

manual can be downloaded from www.PowerRouter.com. Nedap recommends you read this manual thoroughly

before beginning the installation.

If you have any questions during con guration and installation, please get in touch with your local PowerRouter

Business Partner.

The PowerRouter is intended for use in a single-family household with a maximum service entrance rating of

13.8 kVA. The PowerRouter is the core element of the self-use system, as shown in the following section.

Figure 1: Schematic depiction of a self-use system with PowerRouter

017763

017763

LOCAL OUT

4

Step 1. Assembly

Important considerations

> The ingress protection rating of the PowerRouter is IP20 (protected against objects >12.5 mm; not protected

against water)

> The PowerRouter must be installed in a well-ventilated room in which the temperature is maintained between

-10 and 40 °C.

> Maintain a gap of 30 cm above and below the PowerRouter to allow sufcient ventilation.

> Maintain a gap of 80 cm above and below the PowerRouter when two systems are mounted one above the

other.

First attach the supplied mounting bracket to the wall. A drill template is provided to help you determine where

the holes are to be drilled for the mounting bracket. Use mounting hardware suitable for the wall to which the

PowerRouter is being attached.

Attach the PowerRouter to the bracket, as shown below.

Figure 2: Attaching the PowerRouter to the mounting bracket

4 x

2 x

Drill template the PowerRouter

5

Step 2. PowerRouter AC connection

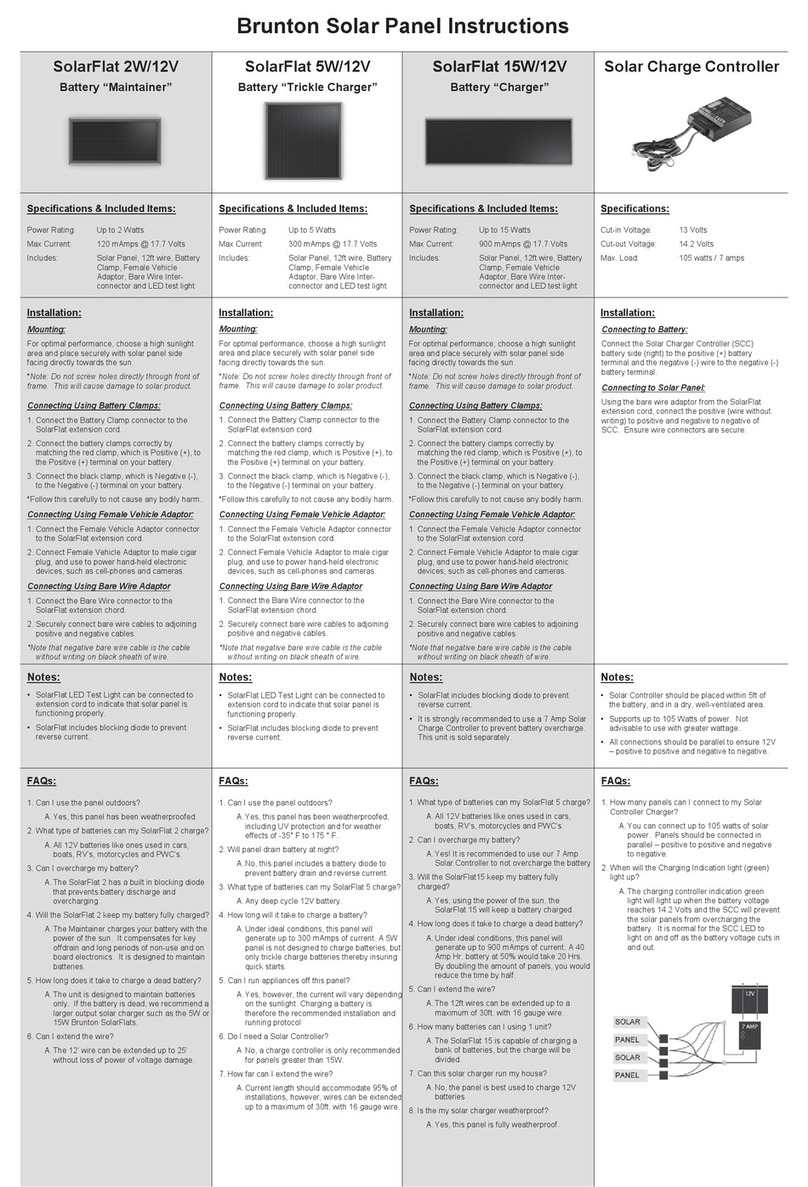

The PowerRouter is a 1-phase inverter that is connected to the utility grid via the ‘AC grid’ connection. Figure

3 is a simplied technical diagram of a self-use system based on the PowerRouter. Although not shown in this

drawing, circuit breakers and a master switch must be installed.

The PV counter, designed as an optional extra for the PowerRouter, registers the amount of energy derived from

the PowerRouter. The amount of energy fed into the grid and the amount used from the grid are measured using

the bi-directional (generation/consumption) meter. These three values enable you to calculate the percentage of

self-use.

Figure 3: Technical diagram of a self-use system

0 1 7 7 6 3

0 1 7 7 6 3

AC GRID CAN

300A

25A

16A

Sensor

6

Optional backup power supply

The PowerRouter provides users with a self-use system with backup power supply which intervenes in the

event of a power outage. The PowerRouter has two AC connections: an AC GRID and an active AC LOCAL

OUT. In the event of a grid failure, the PowerRouter will switch selected loads over to AC LOCAL OUT via an

external 230V relay*, providing them with power.

*Recommended external relay UK: chint – NCI – 9508 – 230 VAC or an equivalent type

Recommended external relay rest of Europe: PRA1RLY available from your local PowerRouter distributor

The mains power supplied to the PowerRouter is connected to the AC GRID terminal (see gure 4) and must be

between 180 and 264 VAC at a frequency of 45 to 55 Hz. Backup power is provided from the AC LOCAL OUT

connection, and the attached electrical load must be one or more 1-phase devices.

017763

017763

AC

GRID CAN

AC

LOCAL

OUT

300A

25A 25A

230 Vac

95A

16A

Figure 4: Connection diagram for a 1-phase self-use system with backup power supply

Sensor

7

Earthing and current system

The PowerRouter is compliant with the following

earthing systems: TN-S, TN-C, TNC-S or TT.

AC fuse

Nedap recommends that you add a 16 A circuit breaker

with B or (preferably) C characteristics to the AC GRID

line connection between the PowerRouter and the

electric utility meter. We also recommend installing the

same type of 16 A circuit breaker in the AC LOCAL OUT

line connection. It must be possible for the installation

engineer to switch off the circuit breakers to de-

energise the PowerRouter so work on the system can

be performed safely.

RCD rating PowerRouter type

16 A PR30S

PR30SB-BS

PR37S

PR37SB-BS

25 A PR50S

PR50SB-BS

Cable cross section

Nedap recommends you to connect the PowerRouter in the vicinity of the grid connection and use copper

cables with a minimum cross section of 4 mm2. This eliminates unnecessary losses in the internal system and

also prevents voltage disconnects caused by high grid impedance when supplying a high output current.

The diagram below shows that the PowerRouter must increase the AC voltage in order to feed the generated

electricity into the grid. This is because the impedance of the cable to the on-street transformer plays an

important role in this. However, the home installation is connected to the PowerRouter, so the voltage should

never be too high. The PowerRouter software will decrease the output current when this nears the maximum

permissible voltage (cut-off limit). This functionality is added to avoid any unnecessary cut-off in the event of an

ineffective AC grid.

Figure 6: In uence of grid impedance on AC voltage

Figure 5: AC connection terminals on the PowerRouter

NNL

L

AC GRID AC LOCAL OUT

NO NO

NC NC

250 V

230 V

Street transformer

Grid impedance20A

20V

1Ω

8

External relay for the backup power supply

Connecting an external relay

Through use of an external relay, some of the single

phase loads can be connected to the AC LOCAL OUT

connection on the PowerRouter, which provides backup

power during a power outage. This creates a backup

system with a switch-over time of ≥ 1 second providing

the connected loads with an backup with a stable 230

VAC/50 Hz output. The power provided during a power

outage comes simultaneously from the solar energy

that is being generated at that moment and from the

batteries. It is important to note, however, that only

a portion of the loads can be supplied with backup

power, because the reserve capacity of a self-use

system is limited by the available solar energy and the

size of the battery bank.

A benecial aspect of this switching conguration is

that loads draw power from the grid whenever the

PowerRouter is restarted or in standby.

The PowerRouter has two sets of congurable potential-free contacts. When a grid outage occurs, loads are

switched to backup power via an external relay. An advantage to this system is that there is no current owing

through the relay coil during normal use. In addition, the PowerRouter controls the exact moment of switch-

over, which enables it to bring the current provided at AC LOCAL OUT into synch with the mains current as

the grid power is restored. Another advantage is that delay times can be congured, using the PowerRouter

Software Installation Tool*. This makes it possible to prevent the backup power provision from responding to

brief power interruptions (brown-outs).

*For more information about the settings, please consult the PowerRouter application guideline - Software Installation Tool, which you can

download from our website.

Technical data - external relay

The external relay can be any standard, commercially available relay with the technical specications shown

below.

Europe except UK UK

> Coil voltage: 230 VAC > Coil voltage: 230 VAC

> Contact ratings: 40 A for both N/O and N/C contacts > Contact ratings: 95 A for both N/O and N/C contacts

> Contact conguration: 2 contacts, or 2 N/Os and 2 N/Cs > Contact conguration: 2 contacts, or 2 N/Os and 2 N/Cs

> Contact gap: ≥ 3.2 mm > Contact gap: ≥ 3.2 mm

As indicated in the picture above, only single-phase consumers can be connected to AC LOCAL OUT. When

producing backup power, the PowerRouter generates its own AC output which cannot be synchronised with the

other two phases.

Figure 7: Connecting an external relay for backup power

0 1 7 7 6 3

0 1 7 7 6 3

tuolacolCAdirgCA

L3

NLNCNO

NL

L2L1N

L3

R1 R2

3 4

L2

L1

L

N

N

R7 R8

5 6

A1 A2

9

External relay for load management

Connecting the external relay

To increase self-use it is possible to have the PowerRouter

automatically connect larger loads when excess solar

energy is available. Below is a circuit diagram which

shows how the external relay (p/n PRA1RLY) is controlled

by one set of potential-free contacts.

Activating load management

Load management is activated using the Software

Installation Tool. This is done by conguring the

parameters as shown below. These values are based

on the capacity being fed into the grid, which means

that this is power above and beyond what is being used

to charge the battery.

A: The capacity of the consumer to be connected when

extra solar energy is available that is not being used

to charge the battery.

B: The percentage of value A that must be available

before the load will be connected. In this example

the extra load will be connected once at least 100%

of 500 W is being fed back into the grid.

C: The percentage of value A at which the load will

be disconnected (can be set at 20-200%). In this

example, the extra load will be disconnected once

the excess power falls below 20% of 500 W.

D: Delay in seconds before the load is switched on,

once the activation conditions have been met (0-100

seconds).

E: Delay in seconds before the load is switched off,

once the deactivation conditions have been met (0-

100 seconds).

F: The maximum time the load will remain connected,

regardless of the available solar power.

G: The minimum time the load will remain connected,

regardless of the available solar power. Figure 9: Activate load management

Figure 8: Connecting an external relay for load management

0 1 7 7 6 3

0 1 7 7 6 3

AC grid

L3

NCNO

NL

L2L1N

L3

3 4

R1 R2

L2

L1

L

N

N

5 6

R7 R8

A1 A2

10

Connecting alarm to potential-free contact

Once the alarm settings have been congured, the

alarm must be assigned to a set of potential-free

contacts. The terminals for these contacts are labelled

K201 (relay 1) and K202 (relay 2) and are located to the

right of the AC LOCAL OUT connection.

The potential-free contact can be activated in two ways:

1. Normal: The contact closes when the alarm is

activated and opens when the alarm is deactivated.

2. Pulse: The contact opens and closes at the selected

frequency for the congured length of time when the

alarm is activated and does so again when the alarm

is deactivated.

Figure 10: Relay 1 of 2

11

Step 3: Connecting the sensor

The 1-phase sensor (p/n PRA1SENSE) or the 3-phase sensor (p/n PRA3SENSE) measures the ow of current

to and from the public electricity grid. This enables the PowerRouter to measure the demand from the loads

and detect the amount of power being supplied to the grid. When the battery is not fully charged, priority is

rst given to charging the battery. During the evening and night, when no solar power is being generated, the

power needed for the loads in the home is drawn from the battery. The grid and the loads are connected to the

PowerRouter’s AC GRID connection via a parallel switch.

1-phase sensor for consumption monitoring

Figure 11: Position of the 1-phase sensor in the self-use system

It is possible to connect a 1-phase sensor to the PowerRouter Solar Inverter (PRxxS) to measure single-phase

consumption. It is also possible to connect a 3-phase sensor to the PowerRouter Solar Inverter.

The 1-phase sensor must be connected to the external line (L) conductor at a point where it is possible to

measure the electricity owing towards the utility grid. The sensor will only work correctly if the arrow on the

sensor is pointing towards the utility grid.

Sensor

AC Grid

N L

0 1 7 7 6 3

0 1 7 7 6 3

N

L

N L

12

Figure 12: 1-phase sensor Figure 13: Connecting the 1-phase sensor

The cable on the sensor is terminated with an RJ45 plug, which must be inserted into the PowerRouter’s CAN

terminal. The sensor must be connected to the lower RJ45 socket, which is covered by a blind hole cover (see

Figure 13). Remove the blind hole cover and insert the RJ45 plug in the socket. The standard cable length is 1

metre, but it can be extended with a CAT-5e cable having a maximum length of 10 metres by means of a CAT-

5e cable coupling.

Figure 14: CAT-5e coupling Figure 15: CAT-5e cable

Important information about the 3-phase grid connection

When a 3-phase grid connection is available the sensor must be connected to the same external conductor to

which the PowerRouter is connected. During initialisation of the system, sensor operation is tested to ensure

that the system is connected correctly. If the current sensor is not connected correctly, code P105H will appear

on the display.

13

3-phase sensor

With a 3-phase sensor, load demand can be measured for all three phases at the same time. When used

with a generation/consumption meter that is capable of two-way communication, this makes it possible to

compensate for consumption on one phase by feeding power into the grid on the other two phases.

With this two-way communication, all power ows can be added together, so the meter indicates the total

positive or negative balance. In the example below, there is 2.5 kW of consumption and 2 kW of generation,

so the meter indicates 0.5 kW of consumption from the grid. The 2 kW of available generated power is fed into

the grid on phase 1 to compensate for the consumption drawn from phases 2 and 3. This method enables the

1-phase PowerRouter to work as a 3-phase system.

Figure 16 : How a meter with two-way communication works

The 3-phase sensor must be connected to the home wiring connected directly to the generation/consumption

meter, before any branches to consumers in the house. The PowerRouter uses the sensor to measures the

amount of energy being consumed at any moment on any phase.

The PowerRouter only works with this type of 3-phase sensor (p/n PRA3SENSE), and a 3-phase sensor can

only be connected to one PowerRouter.

Figure 17: Connecting a 3-phase sensor

Note: For a more detailed explanation of how to connect the 3-phase sensor, please refer to the manual

included with the 3-phase sensor.

Import

kWh

kWh

Export

0.0

0.5

1 kW1,5 kW2 kW

Import

kWh

kWh

Export

1.5

0

1 kW1,5 kW4 kW

41 Green/white wire 42 Green wire 43 Orange/white wire

11 N

fuse 315 mA

to the grid

to the installation

1 L1

4 L2

7 L3

9 L3

6 L2

3 L1

fuse 315 mA

to the grid

to the installaon

0 1 7 7 6 3

0 1 7 7 6 3

NL1L2

SENSOR

369

1

11 4 7

Fuse

315 mA

L3

L1L2L3

14

Step 4: Connecting the solar strings

Because the PowerRouter’s photovoltaic connections are electrically isolated from the AC section, the

PowerRouter can be used with all kinds of solar modules and a wide range of input voltages.

Modules that can be connected to the PowerRouter:

> Monocrystalline modules

> Polycrystalline modules

> Thin-layered or amorphous modules

The 3.7 and 5 kW versions of the PowerRouter have two isolated photovoltaic connections. The 3kW version

only has one photovoltaic connection. MC4 connectors are used for the photovoltaic connections on the

PowerRouter. Each photovoltaic connection has its own MPP tracker in order to maximise the output from the

modules.

Figure 18: Photovoltaic connections on the PowerRouter

Each input has a wide open-circuit voltage (VOC) range of 150-600 VDC and is designed for a maximum input

current of 15 A. Warning: The 600 VDC threshold must never be exceeded. If the 15 A is exceeded, the solar

input will limit the current.

In the morning, the PowerRouter switches on at around 150 VDC with a power of 40 W based on 2 solar inputs.

After switching on, the MPP tracker seeks to provide the best possible power output level; it does so at a

voltage level of 100- 480 VDC.

The optium MMP-voltage for each string input of the PowerRouter at 25°C ambient temperature is 330Vmmp.

The two solar inputs can be used non-symmetrically (e.g. input 1 at 2kWp, input 2 at 4 kWp), but the maximum

solar output fed to both inputs at any given moment is limited to 6 kW. If too much current is being supplied, the

MPP point will be adjusted to limit the solar power. In the event of gradual changes >6kW (cloud in front of the

sun), a power-overload message will appear on the display of the PowerRouter and via myPowerRouter.com.

15

Connecting the photovoltaic modules

To optimally congure the solar modules, take a look at our PV calculation tool (available online at

www.PowerRouter.com/calculator). You can choose the PowerRouter version and photovoltaic modules you are

using. The calculator tool then calculates the correct string conguration for this combination.

Solar cables

Photovoltaic modules often come with short cable connections (usually Ø 4 mm2) with MC4 connectors. If

the total length of the free running cable between the modules and the PowerRouter is less than 50 m, Nedap

recommends that you use a double-insulated solar cable with a diameter of 4 mm2. If the length exceeds 50 m,

we recommend you use 6 mm2cables.

Warning: The plus and minus cables must not be run in the same conduit.

Earthing photovoltaic modules

Earthing varies according to the type of photovoltaic module in use and is different for the xed frame and thin

lm types.

The contact protection on the metal frame and the frame surrounding the photovoltaic module has a

considerable bearing on safety. Nedap therefore recommends that you connect the metal frame to earth.

The PowerRouter has an earthing bonding terminal to which an earth cable can also be connected. Since the

photovoltaic section of the PowerRouter is also electrically isolated from the AC part, ESD spikes do not affect

operation of the PowerRouter.

Thin lm modules produced by various manufacturers are earthed in different ways; consult the manufacturer’s

specications. For this type of module, one of the connections must be earthed. Depending on the brand/

manufacturer, it may be the frame or the ‘+’ or ‘-’ terminal that is to be earthed. These photovoltaic modules

will degrade more quickly if they are not connected to earth. The PowerRouter has been designed with this in

mind: it has an earth connection between the photovoltaic connections. Figure 19 provides an overview of the

possible earthing congurations.

In the case of negative earthing, only 1 ‘-’ input needs to be earthed, because the 2 ‘-’ inputs are connected

together inside the PowerRouter. In the case of positive earthing, the special adapted shown in the gure below

must be connected to the two inputs.

Figure 19: Ground connection possibilities for photovoltaic modules

16

DC disconnection switch

Since the voltage across the photovoltaic connections can be very high, it is important that the PowerRouter

can be disconnected from the photovoltaic modules for assembly or maintenance or in an emergency. A DC

switch is located on the back side of the PowerRouter. On PowerRouters with two photovoltaic inputs, this

switch disconnects both at the same time.

Figure 20: DC disconnection switch on the PowerRouter

17

Step 5: Connecting the batteries

The PowerRouter has an integrated intelligent 24 Vdc battery manager capable of temperature-compensated

charging based on current and voltage regulation, which extends the life of the batteries and improves the

charging process of the batteries. This way it also ensures the safety.

Suitable types of battery

Different types of battery can be connected to the PowerRouter.

Sealed lead-acid batteries

Sealed lead-acid batteries offer good value for the money. These batteries are available in a 2 V version as

well as versions that produce a higher voltage (e.g. 12 V), which are made up of multiple 2 V cells. There are

two versions of this battery type: gel-cell batteries (with a gel-like electrolyte) and AGM (Absorbent Glass Mat)

batteries. Both battery types have a sealed construction and are 100% maintenance-free.

Lead-acid wet battery

Lead-acid (wet) batteries are also suitable. However, they require more maintenance than the sealed type: for

instance, they need to be regularly replenished with distilled water. Charging also generates gas. This means

that these batteries must be installed in a well-ventilated room.

Determining the required battery capacity

The purpose of a self-use system is to enable the household to maximise its own use of the solar power it

generates. In other words, the batteries must be able to store enough energy to meet the power requirements

in the home during the evening and night. The average energy consumption during non-daylight hours can be

used to work out the required battery capacity.

The battery capacity can be compared using the calculation tool at www.PowerRouter.com. This tool enables

you to enter the annual consumption and the consumption prole. The energy that will be available with

different battery sizes is shown. The calculation is based on the rule of thumb that 1 kWh is stored for every 100

Ah (24 V) and that a fully-charged battery can be discharged to 50% DOD.

Nedap recommends that you connect a battery of at least 150 Ah at 24 V. The capacity value is specied in the

battery datasheet as a C10 value (the 10 here stands for the time to discharge).

For determining the (optimum) battery capacity it is important to keep three things in mind:

1. Annual household consumption (kWh)

2. Household consumption prole (at home or away during the day)

3. Size of PowerRouter system (kW)

Optimum battery capacity recommendations

5.0 kW PowerRouter Solar Battery Battery bank with a capacity of at least 200 Ah but not more than 600 Ah

3.7 kW PowerRouter Solar Battery Battery bank with a capacity of at least 200 Ah but not more than 500 Ah

3.0 kW PowerRouter Solar Battery Battery bank with a capacity of at least 200 Ah but not more than 400 Ah

18

Batteries from Nedap

Nedap supplies batteries manufactured by Hoppecke. Each battery bank comes complete with external

housing with two fuses and a set of cables. We also supply Enersys batteries which also include a set of cables

and a fuse.

Figure 21: Enersys type SBS 190F Figure 22: Hoppecke type OPzV

Battery service life

A battery’s service life is usually expressed in terms of the number of charge/discharge cycles and the depth

of discharge (DOD) value. The number of charge/discharge cycles is high for self-consumption, since energy

is drawn from the battery every night. The number of achievable battery cycles drops the higher the depth

of discharge (see chart). For this reason, the PowerRouter is con gured to limit discharge to 50% by default.

Determination of a battery’s service life should be based on the manufacturer’s speci cations. A graph like the

one shown below ( gure 23) is usually provided to indicate the service life (measured in accordance with IEC

standards).

Looking at the number of cycles, we can assure one cycle per day. This does not include days when the system

is in winter mode. Deducting two months of operation in winter mode, this amounts to 300 cycles per year. A

cycle is understood to be charging from 50% to 100% and discharging to 50% again.

Figure 23: Number of cycles versus DOD value

The display and the graphs for the PowerRouter do not show the depth of discharge (DOD), but rather the

charging status. This is 100% when the battery is fully discharged and 0% when fully charged.

When used for backup power, the battery can discharge to a lower depth than for self-use. At that point more

energy is available from the battery. The DOD can be con gured using the Software Installation Tool.

When using a 3-phase sensor, Nedap recommends limiting the level to which the battery can discharge. This is

to avoid discharging the battery too quickly so that the C10 value no longer applies.

100

0

10000

11000

12000

9000

8000

7000

6000

5000

4000

3000

2000

1000

20 30 40 50 60 70 80 90 100

SBS 190F

OPzV

19

Temperature effects

Ambient temperatures have a large inuence on battery capacity. At low temperatures, the capacity drops

quickly. This is illustrated in gure 24 (capacity of a gel battery). The temperature of the room where the

batteries are installed must therefore be kept above 10 °C.

Maximising battery service life

Batteries must not be left in the discharged state for too long, because doing so reduces their service life. With

this in mind, various protection mechanisms have been built into the PowerRouter.

Maintenance charging

At regular intervals – once every 3 weeks – the battery

is forced to run through the 3-state charging cycle.

If maintenance charging coincides with a request for

self-generated power, charging will take priority. Once

the battery is fully charged and the SOC is 100%,

maintenance charging is complete and the battery

becomes available for self-use again.

Likewise, in the winter mode, this cycle of maintenance

continues. The battery module is activated and the

battery charged to 100%, after which the winter mode

is once again activated.

It is possible to start or stop the maintenance charging

manually in the PowerRouter’s display menu. However,

to achieve the maximum service life from the battery,

this is not recommended.

Winter mode

This mode is for using the batteries in the winter, when

there is less solar output and greater demand. This

annual cycle is shown in gure 25, as the blue line

which represents total household consumption.

Because solar output only now and again exceeds

consumption, full charging of the battery occurs less

frequently. Longer periods without full charging shorten

the service life of the battery. This is the reason for the

winter mode, as this protects the battery and ensures a

longer service life.

The moment the system is switched to winter mode, maintenance charging begins, to fully charge the battery.

Once at maximum charge, the PowerRouter’s battery module is switched off. There is no more self-use from

the battery. The period during which the battery is in the winter mode can be programmed with the installation

tool. The standard period is from 1 December to 1 February. At the end of this period, the system completely

recharges the battery again and it can be used for self-use. It is important to choose this period carefully, taking

into account whether or not the system is equipped with a 3-phase sensor. If it is, consumption will be higher

than for a 1-phase measurement.

Figure 24: Temperature versus battery capacity

Figure 25: Winter mode

800

700

600

500

400

300

200

100

0

jan feb mar apr may jun jul aug sep okt nov dec

Wintermodus Solar

20

When in winter mode, maintenance charging continues to be performed as usual. If the PowerRouter is

congured to perform maintenance charging once every three weeks, the battery will be fully recharged at

this interval. Even in winter mode, the battery is always available to provide backup power. When needed, the

battery is reactivated and then used to provide the backup power.

Battery charging methods

The PowerRouter can be congured to use either of the two available battery charging methods: xed oat

voltage or 3-state adaptive charging. The 3-state adaptive charging method is best suited for rapid battery

charging. This is the best conguration for a self-use system.

3-state adaptive charging

In the rst stage the battery is charged at a high current

until it reaches 70-80% of the battery’s charge capacity

(blue line). The battery voltage (green) rises to the bulk

voltage during this stage. In the second stage, the

voltage applied to the battery remains constant, while

the charging current gradually drops to a quarter of

the bulk current. This stage ends once the battery has

reached approximately 85-90% of its capacity. In stage

3 the charging voltage is reduced to the trickle-charge

voltage and the battery is gradually charged to 100%.

This nal stage lasts the longest.

Battery discharge limiter

To protect the battery against excessive discharge

current, it is possible to limit the discharge power

during self-use. This limit value can be congured in

the Software Installation Tool. The value that should

be set depends on how the batteries are connected

(number of parallel branches). When using batteries

for which the battery supplier species a maximum

discharge rate of 100 A, for example, the limit value for

four 12V batteries connected in two parallel strings of

two should be (2x100Ax24V=) 4800W, but for two 12V

batteries connected in a single string (in series) the

limit value should be just (100Ax24V=) 2400W. When

the system is providing backup power, however, it

temporarily disables the limiter.

Figure 26: 3-state adaptive charging

Figure 27: Battery discharge limiter

12V

12V

12V

12V

100A

100A

200A

Other manuals for PowerRouter PR30S

1

This manual suits for next models

5

Table of contents

Popular Solar Panel manuals by other brands

Eterbright

Eterbright CIGS-3000A1 Series Installation and safety manual

Dometic

Dometic NDS BS 115WP Short Operating Manual

PNI

PNI PSF6020 user manual

TSI Instruments

TSI Instruments 8145-SO Operation and maintenance manual

Wolf

Wolf CFK-1 Installation, operating and maintenance instructions

Segway

Segway SP-100 user manual

NexSens

NexSens SP Series quick start guide

Sonnenkraft

Sonnenkraft SK500 DBP manual

Sunways

Sunways SM 230M Installation and operating instructions

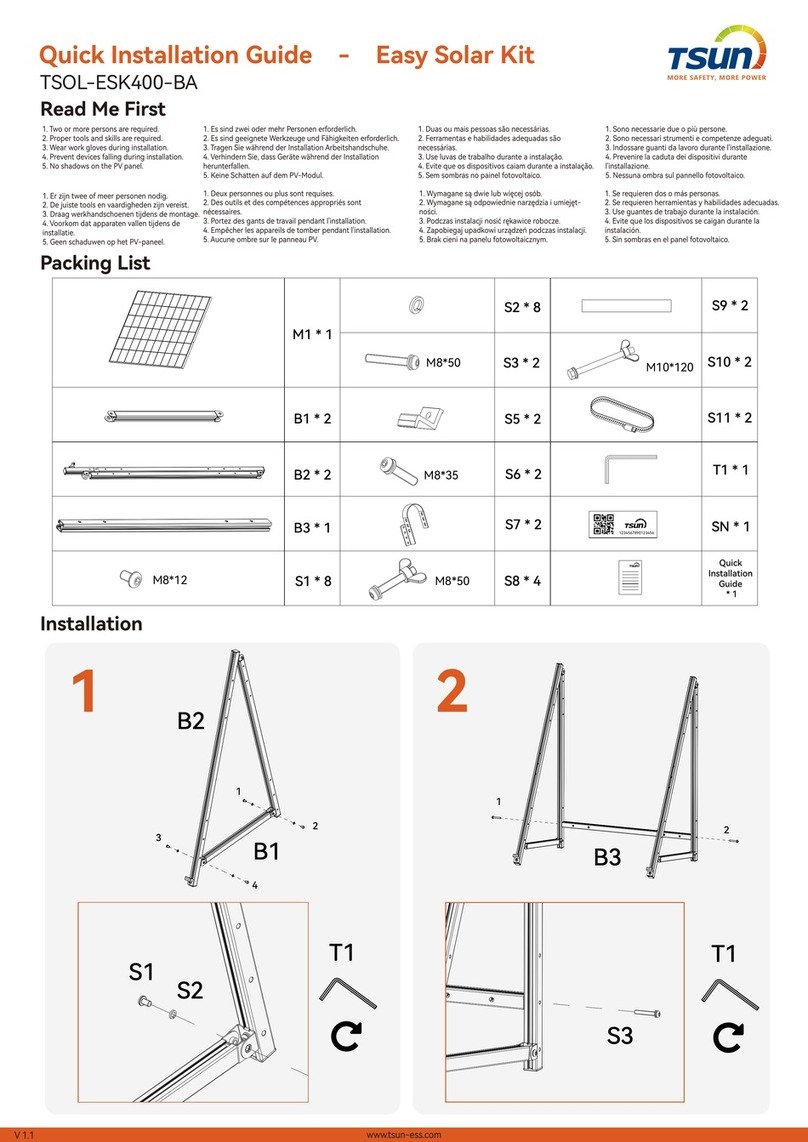

Tsun

Tsun TSOL-ESK400-BA Quick installation guide

Maxray

Maxray Folding Solar Panel instruction manual

Roofit.Solar

Roofit.Solar ClicSeam Safety and installation manual