EDF ENR PWT

D06‐P06‐01Indice1Date:3‐01‐13

EDFENRPWT

Sociétéparactionssimplifiéeàassociéunique–aucapitalde37505000€‐N°513281972RCSNANTERRE

Siègesocial:100EsplanadeduGénéraldeGaulle–CœurDéfense–TourB92932ParisLaDéfensecedex.

33,RueSaintHonoré‐Z.I.Champfleuri

38300BourgoinJallieu‐France

Tel:0474938020‐Fax:0474938040

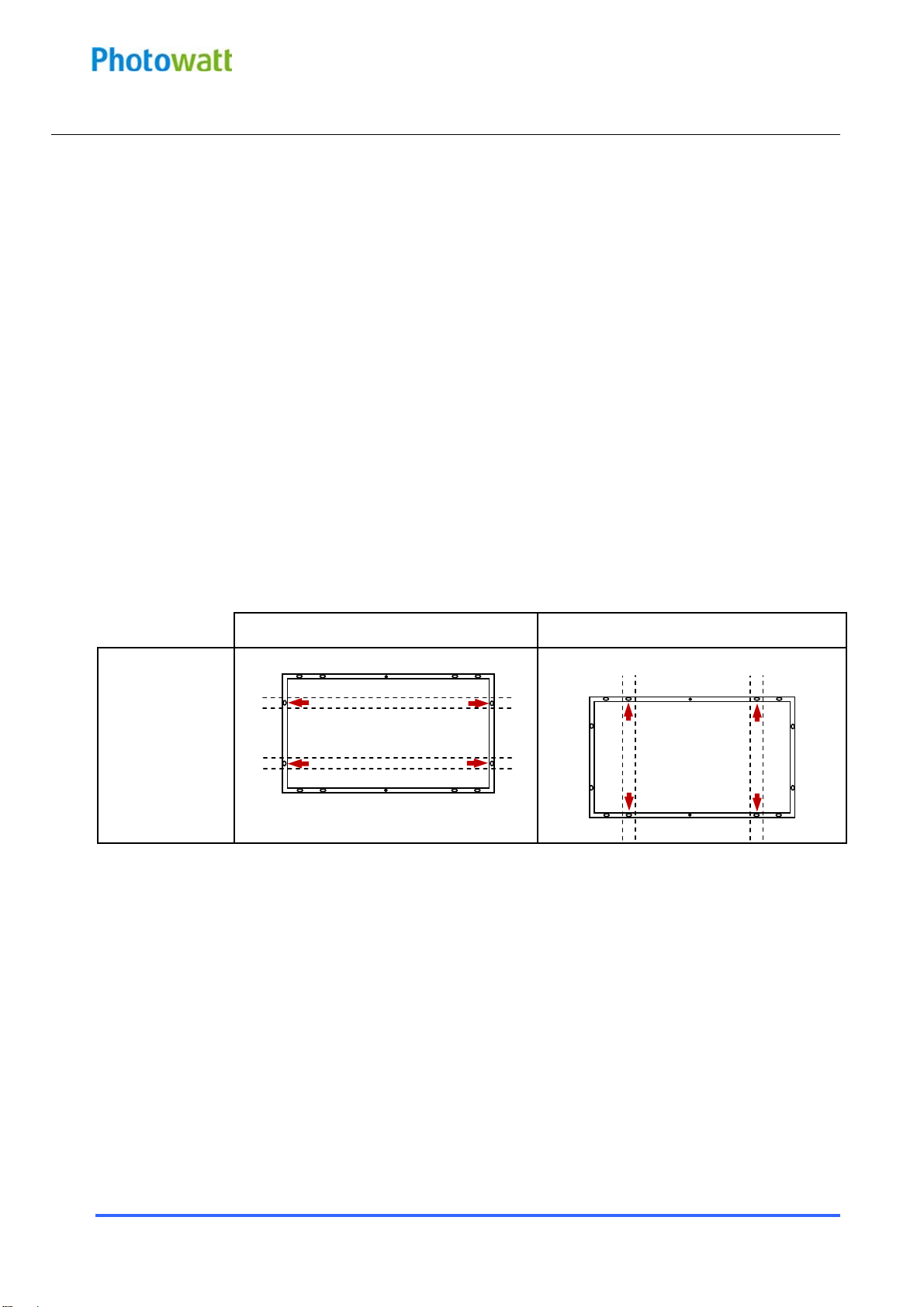

Clamp positions are of crucial importance for the reliability of the installation, the clamp centerlines must

only be positioned as indicated in table 2, depending on the configuration and load.

For the BIPV modules, please follow the specific Installation Manual.

5.2 MODULE WIRING

Correct wiring scheme

When designing the system, avoid forming loops (to minimize risk in the event of an indirect lighting

strike). Make sure that wiring is correct before starting up the system. If the measured open circuit voltage

(Voc) and short-circuit current (Isc) differ from the specifications, then there is a wiring fault.

Correct connection of plug connectors

Make sure that the connection is safe and tight. The plug connector should not receive outer stress. The

connector should only be used to connect the circuit. It should never be used to turn the circuit on and off.

Use of suitable materials

Use special solar cable and suitable plugs only (wiring should be placed in conduit that is sunlight-resistant

if exposed) in accordance with local fire, building and electrical codes. Ensure that they are in perfect

electrical and mechanical condition.

The permitted type of solar cable is single conductor, 2.5-10 mm2(8-14 AWG), 90°C wet rated, with proper

insulation to withstand the maximum possible system open-circuit voltage (such as TUV 2PfG1169

approved). The conductor material should be copper only. Select a suitable conductor gauge to minimize

voltage drop.

Cable protection

Secure the cables to the mounting system using UV-resistant cable ties. Protect exposed cables from damage

with appropriate precautions (e.g. locate them within plastic conduit).Avoid exposure to the direct sunlight.

6.0 MAINTENANCE

Regular maintenance is required to keep modules clear of snow, bird droppings, seeds, pollen, leaves,

branches, dirt spots and dust.

When there is a noticeable buildup of soiling deposits on the module surface, wash the PV array with water

and a gentle cleaning implement (a sponge) during the cool part of the day. Dirt must never be scraped or

rubbed away when dry, as this will cause micro-scratches.

Do not use high pressure cleaning systems on modules

If snow is present, a brush with soft bristles can be used to clean the surface of the module.

Periodically inspect the system to make sure all wiring and supports stay intact.

If you need electrical or mechanical inspection or maintenance, it is recommended to have a licensed,

authorized professional carry out the job to avoid hazards of electric shock or injury.

Do not change the PV components (diode, junction box, plug connectors). Doing so will void the warranty.

9