Nederma Airflow Alarm Kit User manual

User Manual

Airflow monitoring and measuring

Airflow Alarm Kit

www.nederman.com

A L A R M O N

P O W E R

FA I L U R E

Originaluser manual

EN USER MANUAL

Translation of originaluser manual

DA BRUGERVEJLEDN NG

DE BED ENUNGSANLE TUNG

ES MANUAL DE USUAR O

PL NSTRUKCJA OBSŁUG

SV ANVÄNDARMANUAL

2022-11-25 2130059 (06)

EN

DA

DE

ES

PL

SV

Airflow Alarm Kit

Trace back information:

Workspace Main version a73

Checked in 2022-11-25

Skribenta version 5.5.022

Airflow Alarm Kit

Declaration of Conformity ........................................................ 4

Figures .......................................................................................... 6

English ........................................................................................... 10

Dansk ............................................................................................. 20

Deutch ........................................................................................... 30

Español .......................................................................................... 40

Polski ............................................................................................. 50

Svenska ......................................................................................... 60

3

Airflow Alarm Kit

Declaration of Conformity

EN Englis

Declaration of Conformity

We, AB Ph. Nederman & Co., declare under our sole responsibility that

the Nederman product:

Airflow Alarm Kit (Part No. **, and stated versions of **) to which this

declaration relates, is in conformity with all the relevant provisions of

the following directives and standards:

Directives

2014/35/EU, 2014/30/EU, 2011/65/EU.

Standards

EN 60730-1:2012, EN 61000-6-3:2007, EN 61000-6-1:2007, EN SO

20607:2019

The name and signature at the end of this document is the person re-

sponsible for both the declaration of conformity and the technical file.

DA Dansk

Overensstemmelseserklæring

AB Ph. Nederman & Co., erklærer som eneansvarlige, at følgende pro-

dukt fra Nederman:

Airflow Alarm Kit (Artikel nr. **, og erklærede versioner af **), som den-

ne erklæring vedrører, er i overensstemmelse med alle de relevante

bestemmelser i de følgende direktiver og standarder:

Direktiver

2014/35/EU, 2014/30/EU, 2011/65/EU.

Standarder

EN 60730-1:2012, EN 61000-6-3:2007, EN 61000-6-1:2007, EN SO

20607:2019

Navnet og underskriften sidst i dette dokument tilhører den person,

der er ansvarlig for såvel overensstemmelseserklæringen som den tek-

niske dokumentation.

DE Deutc

Konformitätserklärung

Wir, AB Ph. Nederman & Co., erklären in alleiniger Verantwortung, dass

das Nederman Produkt:

Airflow Alarm Kit (Art.-Nr. **, und bauartgleiche Versionen **), auf wel-

ches sich diese Erklärung bezieht, mit allen einschlägigen Bestimmun-

gen der folgenden Richtlinien und Normen übereinstimmt:

Ric tlinien

2014/35/EU, 2014/30/EU, 2011/65/EU.

Standards

EN 60730-1:2012, EN 61000-6-3:2007, EN 61000-6-1:2007, EN SO

20607:2019

Der Name und die Unterschrift am Ende dieses Dokuments sind die für

die Konformitätserklärung und die technischen Unterlagen verant-

wortlichen Personen.

ES Español

Declaración de Conformidad

Nosotros, AB Ph. Nederman & Co., declaramos bajo nuestra exclusiva

responsabilidad que el producto de Nederman,

Airflow Alarm Kit (Ref. n.º ** y las versiones indicadas de **), al que ha-

ce referencia esta declaración, cumple con todas las provisiones rele-

vantes de las Directivas y normas que se indican a continuación:

Directivas

2014/35/EU, 2014/30/EU, 2011/65/EU.

Normas

EN 60730-1:2012, EN 61000-6-3:2007, EN 61000-6-1:2007, EN SO

20607:2019

El nombre y firma que figuran al final de este documento corresponden

a la persona responsable, tanto de la declaración como de la ficha técni-

ca.

PL Polski

Deklaracja Zgodności

My, AB Ph. Nederman & Co. niniejszym oświadczamy na naszą własną

odpowiedzialność, że Nederman produkt:

Airflow Alarm Kit [nr części ** oraz wskazane wersje **], który jest

przedmiotem niniejszej deklaracji, spełnia wszystkie odpowiednie wy-

magania wymienionych niżej dyrektyw i norm:

Dyrektywy

2014/35/EU, 2014/30/EU, 2011/65/EU.

Normy

EN 60730-1:2012, EN 61000-6-3:2007, EN 61000-6-1:2007, EN SO

20607:2019

Na końcu niniejszego dokumentu znajdują się imię i nazwisko oraz pod-

pis osoby odpowiedzialnej za deklarację zgodności oraz dokumentację

techniczną.

SV Svenska

Överensstämmelsedeklaration

Vi, AB Ph. Nederman & Co., förklarar under vårt fulla ansvar att Neder-

man-produkten:

Airflow Alarm Kit (artikelnummer **, och angivna versioner av **) som

denna deklaration avser, är i överensstämmelse med alla relevanta be-

stämmelser i följande direktiv och standarder:

Direktiv

2014/35/EU, 2014/30/EU, 2011/65/EU.

Standarder

EN 60730-1:2012, EN 61000-6-3:2007, EN 61000-6-1:2007, EN SO

20607:2019

Namnet och signaturen i slutet av detta dokument är den person som

ansvarar för både försäkran om överensstämmelse och den tekniska fi-

len.

**

40780434, 40780435, 40780436, 40780437, 40780438, 40780439, 40780440, 40780441

AB Ph. Nederman & Co.

P.O. Box 602

SE-251 06 Helsingborg

Sweden

Anna Cederlund

Product Center Manager

Technical Product Management

2022-11-25

4

Airflow Alarm Kit

UK Declaration of Conformity

We, AB Ph. Nederman & Co., declare under our sole responsibility that the Nederman product:

Airflow Alarm Kit (Part No. **, and stated versions of **) to which this declaration relates, is in conformity with all the relevant pro-

visions of the following regulations and standards:

Relevant legislation

Electrical Equipment (Safety) Regulations 2016, Electromagnetic Compatibility Regulations 2016, The Restriction of the Use of

Certain Hazardous Substances in Electrical and Electronic Equipment Regulations 2012

Standards

EN 60730-1:2012, EN 61000-6-3:2007, EN 61000-6-1:2007, EN SO 20607:2019

The name and signature at the end of this document is the person responsible for the declaration of conformity.

The UK importer is authorised and responsible to compile the technical file.

**

40780434, 40780435, 40780436, 40780437, 40780438, 40780439, 40780440, 40780441

AB Ph. Nederman & Co.

P.O. Box 602

SE-251 06 Helsingborg

Sweden

Anna Cederlund

Product Center Manager

Technical Product Management

2022-11-25

UK mporter:

Nederman Ltd

91 Seedlee Road,

Walton Summit Centre,

Bamber Bridge,

Preston,

Lancashire,

PR5 8AE

5

Airflow Alarm Kit

Figures

www.nederman.com

A L A R M O N

P O W E R

FA I L U R E

1

2

3

4

5

6

1

6

Airflow Alarm Kit

PSU2L

PSU2N

PSU1L

PSU1N

Alarm NO

Alarm C

Alarm NC

1 5 6 7

Output

12 VDC

Fan Constant

80-230VAC Power

Input

80-230 VAC

2 3 4

P-SW

P-SW

GND Out Alarm

+12V Out Alarm

8

3 2

OPS Alarm Flash

Open = Alarm

9 10 11

Output

12 VDC

Input

80-230 VAC

Relay in alarm

state

GND_DC

+12V

Black

Red

+

−

85- 230 VAC

fan on 85- 230 VAC

Power

Central

surveillance

COM

2 NO

1 NC

P

3

21 3 4 5

2

7

Airflow Alarm Kit

Pressure switch

Airflow alarm and pressure switch mounted

Airow alarm

1

2

3

8

Airflow Alarm Kit

P

V

PS

V

-10%PS

90%-95%

4

9

Airflow Alarm Kit

EN Englis

User Manual

Table of contents

Figures ............................................................................................................................................................................. 6

1 Preface ............................................................................................................................................................................ 11

2 Safety .............................................................................................................................................................................. 11

2.1 Classification of important information ......................................................................................................... 11

3 Description ..................................................................................................................................................................... 11

3.1 ntended use ....................................................................................................................................................... 11

3.2 Function ............................................................................................................................................................... 11

3.3 Main parts ............................................................................................................................................................ 11

3.3.1 Airflow Alarm - Control box ................................................................................................................ 11

3.4 Technical data ..................................................................................................................................................... 12

4 nstallation ...................................................................................................................................................................... 13

4.1 Control box .......................................................................................................................................................... 13

4.2 Electrical connections ....................................................................................................................................... 13

4.3 Monitoring point ................................................................................................................................................. 13

4.4 Startup ................................................................................................................................................................. 13

4.4.1 Adjustment ........................................................................................................................................... 13

5 Use ................................................................................................................................................................................... 14

5.1 Control box LEDs and indications .................................................................................................................... 15

6 Maintenance .................................................................................................................................................................. 16

7 Troubleshooting ............................................................................................................................................................ 17

8 Spare Parts ..................................................................................................................................................................... 18

8.1 Ordering spare parts .......................................................................................................................................... 18

9 Recycling ......................................................................................................................................................................... 18

10 Control protocol for Airflow Alarm ............................................................................................................................. 19

10

Airflow Alarm Kit

1Preface

Thank you for using a Nederman product!

The Nederman Group is a world-leading supplier and

developer of products and solutions for the environ-

mental technology sector. Our innovative products

will filter, clean and recycle in the most demanding of

environments. Nederman's products and solutions will

help you improve your productivity, reduce costs and

also reduce the impact on the environment from in-

dustrial processes.

Read all product documentation and the product iden-

tification plate carefully before installation, use, and

service of this product. Replace documentation imme-

diately if lost. Nederman reserves the right, without

previous notice, to modify and improve its products

including documentation.

This product is designed to meet the requirements

of relevant EC directives. To maintain this status, all

installation, maintenance, and repair is to be done

by qualified personnel using only Nederman original

spare parts and accessories. Contact the nearest au-

thorized distributor or Nederman for advice on tech-

nical service and obtaining spare parts. f there are

any damaged or missing parts when the product is de-

livered, notify the carrier and the local Nederman rep-

resentative immediately.

2Safety

2.1Classification of important informa-

tion

This document contains important information that

is presented either as a warning, caution or note, ac-

cording to the following examples:

WARNING!Risk of personal injury

Warnings indicate a potential hazard to the

health and safety of personnel, and how that

hazard may be avoided.

CAUTION!Risk of equipment damage

Cautions indicate a potential hazard to the

product but not to personnel, and how that

hazard may be avoided.

NOTE!

Notes contain other information that is import-

ant for personnel.

3Description

3.1Intended use

The Airflow Alarm monitors pressure conditions in a

suitable duct.

3.2Function

The Airflow Alarm is connected to a fan starter so that

Airflow Alarm starts to monitor automatically and sim-

ultaneously with the fan. The alarm is activated when

the static pressure in the duct is outside preset limits.

The Airflow Alarm can either monitor one particular

exhaust point at a workplace or a group of workplaces

connected to a single air duct leading to the fan.

3.3Main parts

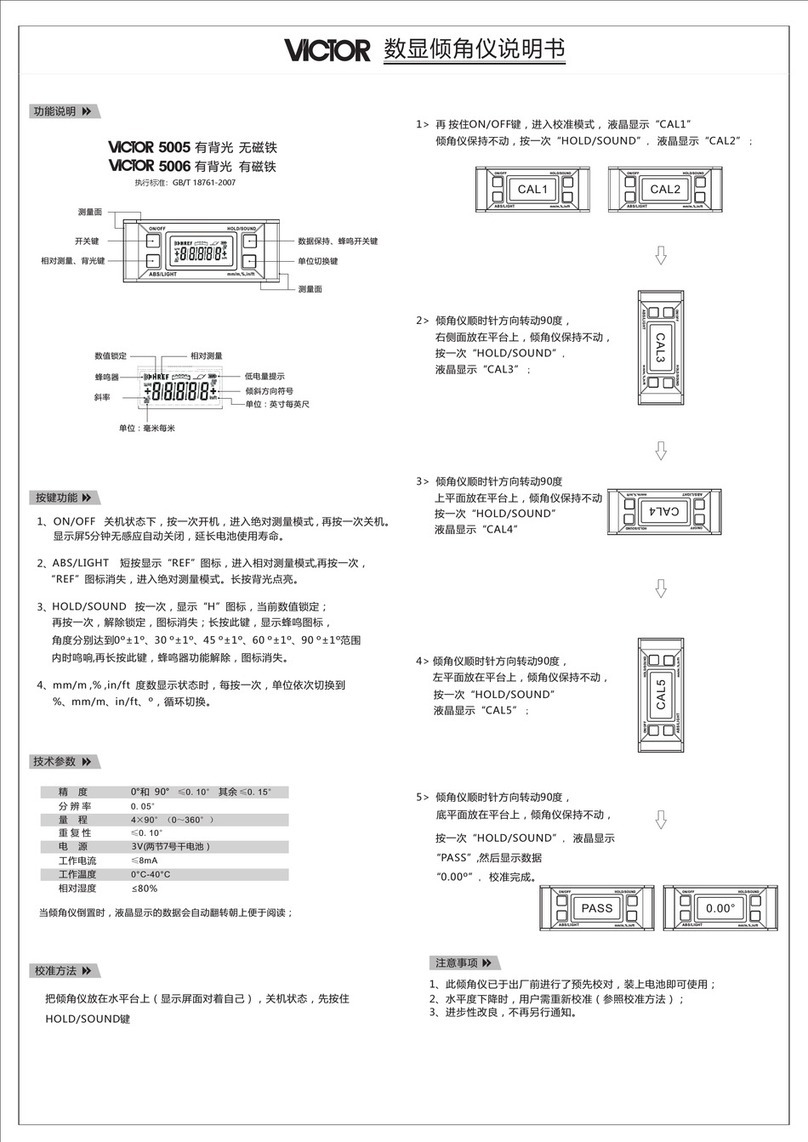

See Figure1. The Airflow Alarm Kit consists of:

1 Airflow Alarm - Control box.

2 Pressure switch. Available as a standard model,

and an ATEX-approved model for zone 2/22.

3 Protection filter.

4 Rubber fitting

5 Flashlight (optional)

6 Cable gland (optional)

3.3.1 Airflow Alarm - Control box

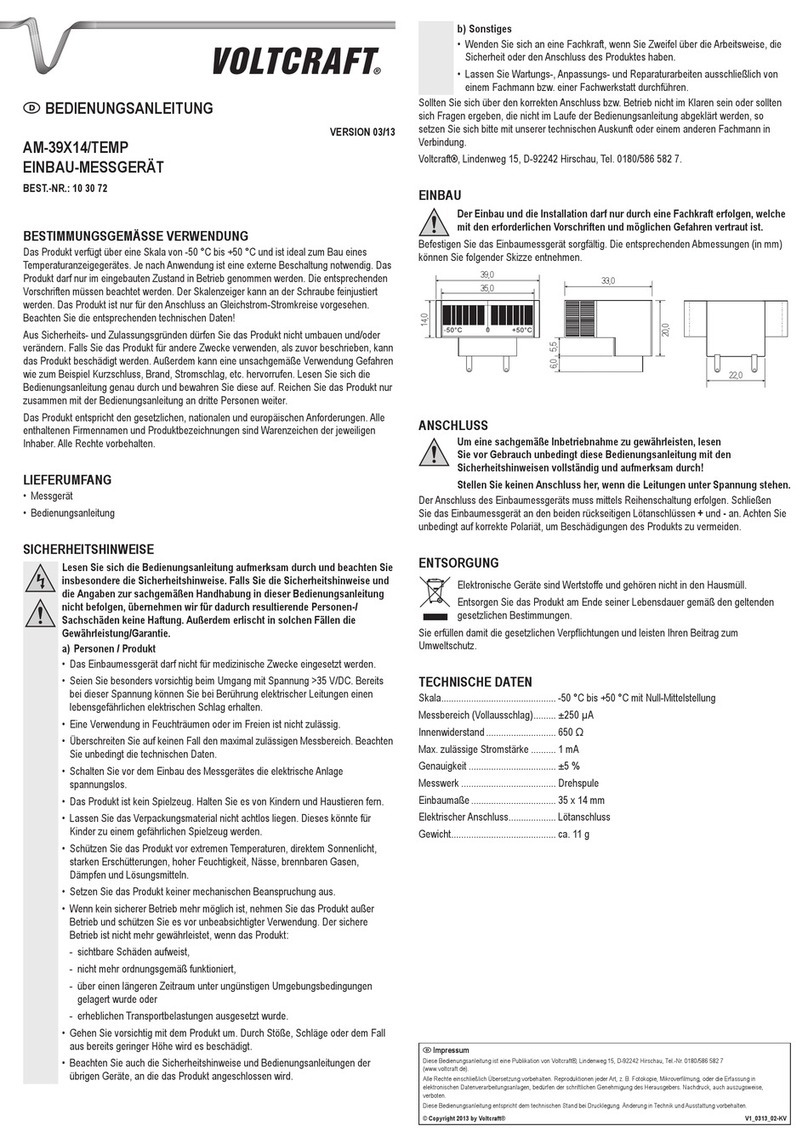

See Figure2. The Airflow Alarm contains a terminal

block that includes connections to:

1 85-230 VAC power supply (Phase 1). Signal in from

fan to activate monitoring.

2 85-230 VAC power supply (Phase 2). Power into

Airflow Alarm.

3 External connection to central surveillance (Op-

tional)

4 Pressure switch

5 External Airflow Alarm devices, such as a flash-

light

NOTE!

Drill an extra hole and install a cable gland if the

Control box is to be directly connected to both

a flashlight and central surveillance. See Fig-

ure1 (6).

EN

11

Airflow Alarm Kit

EN 3.4Tec nical data

Part Description

Supply PSU1 85 - 230V AC, 50-60Hz, max. 13A Fuse

Supply PSU2 85 - 230V AC, 50-60Hz, max. 13A Fuse

Pressure switch External contact must be below 100 Ohm

12 V DC out alarm 12 V DC maximum 200 mA

Alarm relay Maximum 8A AC1 250 VAC

9V battery 6LR61, non-rechargeable

Dimensions 120 mm x 170 mm x 60 mm

Fuse 5 x 20 T500mA

Operating temperature 0 - 50 °C

P Class Control box P54

P Class Pressure Switch Standard P54

P Class Pressure Switch ATEX P65, ATEX model approved for zone 2/22.

12

Airflow Alarm Kit

4Installation

nstallation, repair and maintenance work is to be car-

ried out by qualified personnel using only original Ne-

derman spare parts. Contact your nearest authorized

distributor or Nederman for advice on technical ser-

vice.

4.1Control box

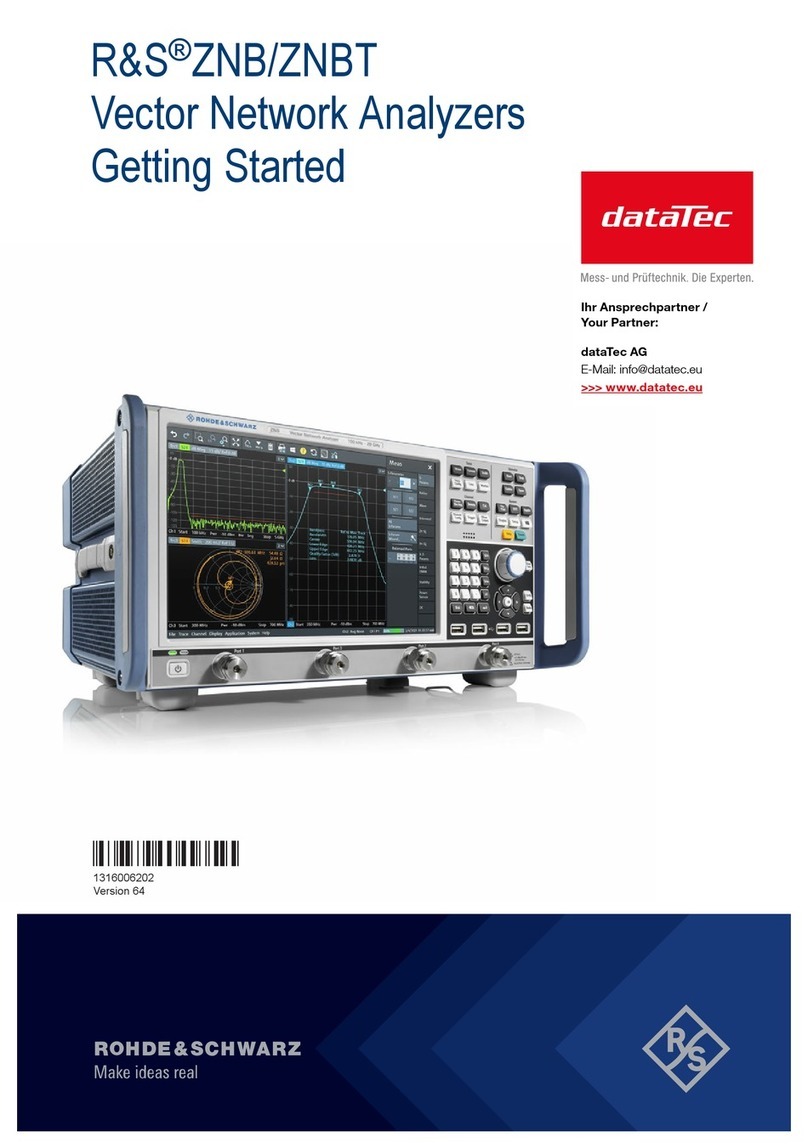

Figure3 shows the Airflow Alarm and pressure switch

mounted.

1 Pressure switch

2 Airflow alarm

NOTE!

• Before starting installation, an unused volts-

free contact from the fan starter should be

wired through to the Fan ON position.

• The Airflow Alarm control box must be in-

stalled outside the ATEX classified zone.

• The optional flashlight should be situated at

a location visible from the workplace(s) mon-

itored.

• The electrical enclosure should be mounted

near the workplace so that the alarm LEDs

can be clearly seen and noted from the oper-

ator’s working place.

• f the operator does not have a permanent

place or where several working places are su-

pervised by one alarm, a flashlights should

be installed so that the alarm may be clearly

seen from the operator’s working places.

4.2Electrical connections

WARNING!Risk of personal injury

Work with electric equipment is to be carried

out by a qualified electrician.

Figure2 shows the wiring diagram and cabling for ter-

minals for the Airflow Alarm.

Electrical connections between components should

comply with current national regulations.

4.3Monitoring point

WARNING!Risk of personal injury

• f there is flammable dust present, turn off

the fan.

• Eliminate ignition sources such as heat or

sparks.

• Wear a dust mask.

NOTE!

• A non-ATEX-approved differential pressure

switch must be installed outside of an ATEX

classified zone.

• Any screws or other fixings used into the air

duct must not cause any collection of dust/

chips. f the differential pressure switch

housing is conductive, there needs to be con-

tact between the pressure switch housing

and the metal duct or ground.

The monitoring point is selected as follows:

W en monit-

oring Location

One single

workplace Between dust extraction point,

such as a suction hood, and a

connection to the duct system.

A group of

workplaces Close to the connection point

farthest away from the fan. See

Figure3.

The pressure switch can be mounted on the air duct.

NOTE!

When drilling in air ducts, safety regulations

must be kept in mind.

The hose is connected to the hose connection on the

pressure switch marked with a minus (-) sign. Nothing

is connected to the hose connection marked plus (+)

atmospheric pressure.

4.4Startup

When the fan starts, the alarm is activated, and the

ALARM LED remains lit until the required pressure is

reached. The ON LED is also lit.

4.4.1Adjustment

1 A suitable part of the duct is selected, and a hole

for the protection filter is drilled close to the last

connection point. See Chapter4 nstallation.

2 The maximum airflow according to the order ac-

knowledgement, technical specifications etc.

must be determined and the corresponding air ve-

locity calculated.

3 The air velocity is measured with the planned

number of extraction points open. f the airflow is

larger than (V0), reduce the airflow. For example,

this can be done by inserting a plate in front of the

fan outlet flange to reduce the airflow until the

airflow (V0) planned is reached.

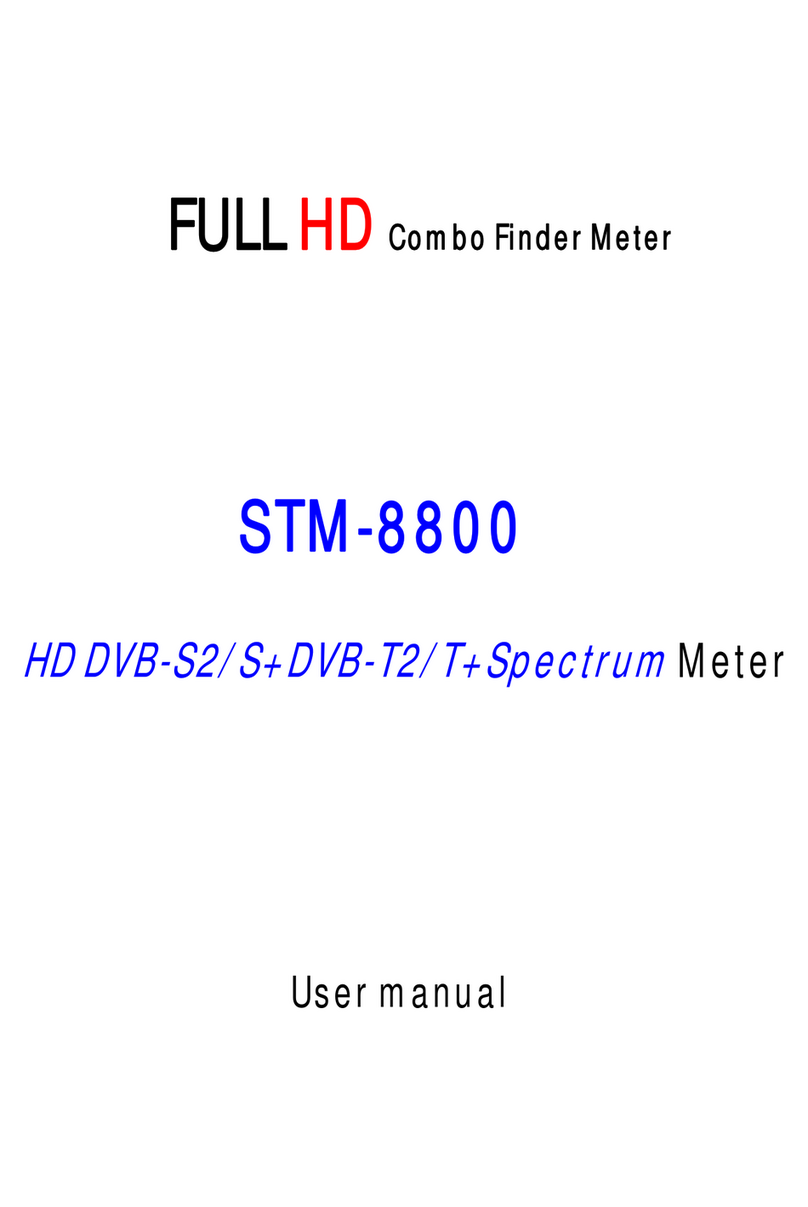

4 At this airflow, the static vacuum at the monit-

oring point (PS0) is measured, and the pressure

monitor is set 10% lower. See Figure4, where the

alarm limit setting is represented with the dotted

line.

EN

13

Airflow Alarm Kit

EN NOTE!

f the pressure switch measuring range

does not cover the setting value required,

the pressure switch is replaced by one with

a relevant measuring range.

5 The main airflow is reduced slowly by inserting the

plate in the fan outlet flange until the alarm is re-

leased.

6 The air velocity is measured and the airflow is cal-

culated. f it is between 90 and 95% of the airflow

specified, the adjustment has been completed.

7 f the airflow is less than 90% of the airflow spe-

cified, set the pressure switch 5% higher, and re-

peat item 5.

8 f the airflow is higher than 95% of the airflow

specified, set pressure switch 5% lower, and re-

peat item 5. t might be necessary to remove the

plate in front of the fan outlet flange.

9 When the adjustment has been completed,

note the following in the control protocol, see

Chapter10Control protocol for Airflow Alarm:

Make a copy of the control protocol for the Nederman

service technician.

5Use

WARNING!Risk of personal injury

f there is work with hazardous substances that

are assigned mandatory exposure limits and

there is a problem with the Airflow Alarm, stop

work immediately and fix the problem.

NOTE!

n the event of an alarm, the red ALARM LED

on the Airflow Alarm control box will be lit, and

any external connected alarm devices will be

activated. Stop work at once, find the cause

of the alarm, and fix the problem. See also

Chapter7Troubleshooting.

The Airflow Alarm limit has been set according to the

arrangement and operating parameters of the partic-

ular extraction system. Normally, the Airflow Alarm

limit will be at 90% airflow per workplace, 100% be-

ing the airflow specified. When monitoring a group of

workplaces, the airflow per workplace is an average

value. The Airflow Alarm limit setting is found in the

control protocol for the exhaust alarm.

The Airflow Alarm begins monitoring as soon as the

fan starter is activated, and monitors pressure condi-

tions in a suitable duct. The alarm is activated when

the static air pressure in the duct is outside the preset

limits.

When the cause of the alarm has been fixed, and the

static pressure in the duct returns to within the nor-

mal range, the alarm will turn off automatically, and

the Airflow Alarm will resume monitoring.

NOTE!

During normal operation, the green ON LED

should be lit, which indicates that the 230 V

source works. f the green ON LED is not lit dur-

ing normal operation, one of the 230 V sources

is defective and the red POWER FA LURE LED

will also be flashing. The 230 V source must be

fixed and reconnected at once. f changing a

fuse cannot solve the problem, contact an au-

thorized Nederman technician for assistance.

14

Airflow Alarm Kit

5.1Control box LEDs and indications

Indicator Lig t Description

ALARM Red Too low airflow in the system.

POWER FA LURE Red Problem with electrical supply to unit.

ON Green Unit active/standby. System is working.

Alarm LEDs Alarm Status PSU1

Fan PSU2

Constant P-SW Alarm

Out Relay Internal

battery

used

Fan OFF OFF ON Open/

Closed OFF

NO

5

6

7

NO

Operating mode:

Normal

Flow=OK

ON ON ON

(Closed) OFF

NO

5

6

7

NO

Low flow ON ON OFF

(Open) ON

NC

5

6

7

NO

Power failure ON OFF ON

(Closed) ON

NC

5

6

7

NO

Low flow

Power failure OFF ON OFF

(Open) ON

NC

5

6

7

NO

Power OFF OFF OFF OFF OFF

NC

5

6

7

YES

EN

15

Airflow Alarm Kit

EN 6Maintenance

nstallation, repair and maintenance work is to be carried out by qualified personnel using only original Neder-

man spare parts. Contact your nearest authorized distributor or Nederman for advice on technical service.

WARNING!Risk of personal injury

Before restarting, close and reconnect guards, doors/hatches, etc.

When any defective components are found, they should be replaced, and the unit re-adjusted by a Nederman

service technician. f the Airflow Alarm control box is defective, it must be replaced.

Maintenance Mont ly/Operating ours interval

Check that the green ON LED on the controller is lit during nor-

mal operation. Daily

Check correct start-up sequence. Airflow Alarm must be re-

leased immediately and stay active until the fan has reached

normal speed and vacuum has been built up in the system.

Daily

Check the hose and the protection filter between the pressure

switch and air duct for clogging. Blow air to clean if necessary. Every 3 months or 1,000 hours

Check the Airflow Alarm limit setting*.Every 12 months (annually)

*To be performed by qualified personnel.

16

Airflow Alarm Kit

7Troubles ooting

All troubleshooting and similar activities should only be performed by skilled personnel with knowledge of the

plant function and construction, and in accordance with safety regulations, maintenance instructions, etc.

Fault Possible cause Solution

Alarm occurring briefly at

startup Fan starts slowly. Alarm is activated for a maximum of 60 seconds dur-

ing startup. The alarm at startup may be considered

as a daily function check.

Alarm occurring periodic-

ally • Extraction system

overloaded by too

many exhaust points

being opened at the

same time.

• Extraction system

overloaded by a bad

connection on one or

more exhaust points.

• Protection filter regen-

eration occurs too in-

frequently.

• Airflow Alarm Kit limit

set too high.

• Shut unused exhaust points.

• Limit the number of exhaust points to the capacity

of the plant.

• Establish automatic dampers and connect control

with max. limit.

• Extend extraction system capacity.

• Re-establish correct connections such as smaller

hose diameter, longer hoses, hoses without holes,

etc.

• For plants with filter regeneration during opera-

tion: Reduce time interval between regeneration /

decrease cleaning start level.

• For plants with regeneration in breaks: Stop the

plant more frequently or establish regeneration

during operation.

• Call Nederman service technician.

Alarm activated perman-

ently or for extended

periods.

• Extraction system ca-

pacity less than before.

• Extraction system

overloaded by hav-

ing too many exhaust

points connected.

• Extraction system

overloaded by de-

fective connection on

one or more exhaust

points.

• The hose assembly

between air duct

and pressure switch

clogged.

• Airflow Alarm defect-

ive.

• Clean or replace clogged protection filter in the ex-

traction system.

• Clean clogged air ducts/fan.

• Replace flexible connections at the fan.

• Replace defective V-belt drives/fan motor.

• Fix or replace defective fan.

• Shut unused exhaust points.

• Limit number of exhaust points to plant capacity.

• Establish automatic dampers and connect control

with max. limit.

• Extend extraction system capacity.

• Re-establish correct connections, such as smaller

hose diameter, longer hoses, hoses without holes

etc.

• Check the hose and the protection filter between

the pressure switch and the air duct for clogging.

Blow air to clean if necessary.

• Call Nederman service technician.

EN

17

Airflow Alarm Kit

EN Fault Possible cause Solution

Alarm is not activated in

connection with startup

or when it is supposed to

be activated.

• No power supply.

• The hose/protection

filter is clogged.

• Hose assembly for

the pressure switch

clogged.

• Pressure switch de-

fective.

• Change the defective fuse.

• Have an electrician check the wiring system.

• Disconnect the pressure switch, and clean the

hose and protection filter. Recconect the pressure

switch.

• Check the hose and the protection filter between

the pressure switch and the air duct for clogging.

Blow air to clean if necessary.

• Call Nederman service technician.

• See also Section5.1Control box LEDs and indica-

tions.

The POWER FA LURE LED

is not lit. • A connection to the

voltage supply has

been cut off.

• Battery backup is de-

fective.

• See Section5.1Control box LEDs and indications.

• Change the fuse.

• Have an electrician check the voltage supply.

• Replace the battery.

8Spare Parts

CAUTION!Risk of equipment damage

Use only N$e$d$e$r$m$a$n$ original spare parts and ac-

cessories.

Contact your nearest authorized distributor or

N$e$d$e$r$m$a$n$ for advice on technical service or

if you require help with spare parts. See also

w$w$w$.$n$e$d$e$r$m$a$n$.$c$o$m$.

8.1Ordering spare parts

When ordering spare parts always state the following:

• The part number and control number (see the

product identification plate).

• Detail number and name of the spare part (see

w$w$w$.$n$e$d$e$r$m$a$n$.$c$o$m$/$e$n$/$s$e$r$v$i$c$e$/$s$p$a$r$e$-$p$a$r$t$-

$s$e$a$r$c$h$).

• Quantity of the parts required.

9Recycling

The product has been designed for component mater-

ials to be recycled. Different material types must be

handled according to relevant local regulations. Con-

tact the distributor or$N$e$d$e$r$m$a$n$ if uncertainties arise

when scrapping the product at the end of its service

life.

f the Airflow Alarm Kit needs to be removed, the

sensor hole in the duct should be sealed. f hazardous

dust is likely to be present, suitable precautions must

be taken such as the use of goggles, dust mask and

gloves.

18

Airflow Alarm Kit

10 Control protocol for Airflow Alarm

Copy the control protocol, fill it in and save it as a service record.

NOTE!

f a value is outside its accepted level, or a result is incorrect or missing, fix the problem before initial star-

tup and normal operation.

Monitoring

point Work-

places

covered by

t e monit-

oring

Adjust-

ment date Adjusted

by Airflow

planned V0

Static va-

cuum at V0

Alarm limit

setting

Company

Date Sign

EN

19

Airflow Alarm Kit

DA

Dansk

Brugervejledning

Ind oldsfortegnelse

Figurer ............................................................................................................................................................................. 6

1 Forord .............................................................................................................................................................................. 21

2 Sikkerhed ........................................................................................................................................................................ 21

2.1 Klassificering af vigtige oplysninger .............................................................................................................. 21

3 Beskrivelse ..................................................................................................................................................................... 21

3.1 Tiltænkt anvendelse ......................................................................................................................................... 21

3.2 Funktion ............................................................................................................................................................... 21

3.3 Hoveddele ........................................................................................................................................................... 21

3.3.1 Airflow Alarm-kontrolboks ................................................................................................................ 21

3.4 Tekniske data ...................................................................................................................................................... 22

4 nstallation ...................................................................................................................................................................... 23

4.1 Kontrolboks ......................................................................................................................................................... 23

4.2 Elektriske tilslutninger ...................................................................................................................................... 23

4.3 Overvågningspunkt ........................................................................................................................................... 23

4.4 gangsætning ...................................................................................................................................................... 23

4.4.1 Justering ................................................................................................................................................ 23

5 Anvendelse ..................................................................................................................................................................... 24

5.1 Styreboksens LED'er og kontrollamper .......................................................................................................... 25

6 Vedligeholdelse ............................................................................................................................................................. 26

7 Fejlfinding ....................................................................................................................................................................... 27

8 Reservdele ...................................................................................................................................................................... 28

8.1 Bestilling af reservedele ................................................................................................................................... 28

9 Genbrug ........................................................................................................................................................................... 28

10 Kontrolprotokol for Airflow Alarm .............................................................................................................................. 29

20

This manual suits for next models

8

Table of contents

Languages: