nekos KH1 User manual

Code 4420077

KH1

INSTRUCTION MANUAL

UNIT FOR THE VENTILATION OF 1 230V~ MOTOR

NEKOS S.r.l. -

Via Capitoni, 7/5

+39 0424 411011

EN

KH1

– KH1R

INSTRUCTION MANUAL

UNIT FOR THE VENTILATION OF 1 230V~ MOTOR

Via Capitoni, 7/5

- 36064 Colceresa – VI

–

+39 0424 411011

– +39 0424 411013 - www.nekos.it -

info@nekos.it

Edition 2003

UNIT FOR THE VENTILATION OF 1 230V~ MOTOR

–

ITALY

Page 2

USER INSTRUCTIONS

CAUTION. Carefully observe all the following installation

instructions to ensure personal safety.

The device is not intended for use by persons (including

children) with reduced physical, sensory or mental capabilities,

or lacking experience and knowledge. Do not allow children to

play with the fixed controls and keep any remote-control units

out of their reach.

Have installation checks performed periodically by qualified

personnel from a service centre authorised by the

manufacturer. Do not use if repair or adjustment is required.

CAUTION. Disconnect the power supply during cleaning or

maintenance operations. Do not use solvents or jets of water to

wash the appliance; the appliance should not be submerged in

water.

In the event of fault or malfunction, switch off the device at the

main switch. All repairs and adjustments must only be

performed by qualified personnel from a service centre

authorised by the manufacturer.

Always request exclusive use of original spare parts. Failure to

respect this condition could compromise safety and invalidate

the benefits contained in the warranty for the appliance. In the

event of any problems or queries, consult your agent or contact

the manufacturer directly.

Carefully preserve these instructions after installation.

The product must be disposed of in compliance with

local environmental regulations and not as household

waste.

INSTALLER INSTRUCTIONS

nekos

products have been manufactured in accordance with safety standards and

conforms to the stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions, t

will not generate any danger for persons, animals or items.

Symbols used in the manual

DANGER

Contents

1.

SAFETY INDICATIONS

1.1. General notes

................................

1.2. Notes for installer

................................

2.

CONSTRUCTION AND REGULATORY REFERENCES

3. TECHNICAL DATA

................................

4.

ID PLATE AND MARKING DATA

5.

RECOMMENDATIONS AND INSTRUCTIONS FOR ASSEMBLY

6.

TECHNICAL OPERATING INFORMATION

6.1.

General instructions

6.2. Programming

................................

6.3. Settable functions

................................

6.4.

Saving a PIK radio remote control

6.5.

Saving a radio remote control without access to the board

7.

OVERALL DIMENSIONS

8.

CONNECTION DIAGRAM OF THE 230V KH1 and KH1R STATION

9.

ENVIRONMENTAL PROTECTION

10.

CERTIFICATE OF GUARANTEE

11. DECLARATION OF

CONFORMITY

Page 3

INSTALLER INSTRUCTIONS

products have been manufactured in accordance with safety standards and

conforms to the stipulations of current standards in force.

When correctly assembled, installed and used according to the present instructions, t

will not generate any danger for persons, animals or items.

Symbols used in the manual

This indication draw the attention about potential

dangers for safety and health of peoples and animals.

SAFETY INDICATIONS

................................

................................

................................

................................

................................

................................

CONSTRUCTION AND REGULATORY REFERENCES

...............................

................................

................................

ID PLATE AND MARKING DATA

................................

................................

RECOMMENDATIONS AND INSTRUCTIONS FOR ASSEMBLY

TECHNICAL OPERATING INFORMATION

................................

General instructions

................................

................................

................................

................................

................................

................................

Saving a PIK radio remote control

................................

Saving a radio remote control without access to the board

OVERALL DIMENSIONS

................................

................................

CONNECTION DIAGRAM OF THE 230V KH1 and KH1R STATION

ENVIRONMENTAL PROTECTION

................................

..............................

CERTIFICATE OF GUARANTEE

................................

................................

CONFORMITY

................................

.............................

INSTALLER INSTRUCTIONS

products have been manufactured in accordance with safety standards and

When correctly assembled, installed and used according to the present instructions, t

hey

This indication draw the attention about potential

dangers for safety and health of peoples and animals.

................................

................. 4

................................

......................... 4

................................

.................... 4

...............................

5

................................

........................ 5

................................

... 5

RECOMMENDATIONS AND INSTRUCTIONS FOR ASSEMBLY

................ 5

................................

................... 6

................................

................ 6

................................

......................... 7

................................

................... 9

................................

......................... 11

Saving a radio remote control without access to the board

................... 12

................................

............ 12

CONNECTION DIAGRAM OF THE 230V KH1 and KH1R STATION

........... 14

..............................

15

................................

. 15

.............................

16

1. SAFETY INDICATIONS

1.1. General notes

ATTENTION:

Before installing this appliance, ensure all safety indications

have been read carefully and understood in order to prevent contact with

electricity, injury or any other incident. The manual should be conserved

for further consultation at a later date.

The manufacturer accepts no responsibility for damage to people,

animals or things incurred by improper use or inobservance of the basic

safety rules described in this manual.

Use for any applications other than those indicated must be authorised

by

the manufacturer after technical review of the assembly.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge.

Do not allow children to play with

control units out of their reach.

Do not use solvents or jets of water to wash the appliance.

1.2.

Notes for installer

This device is intended only and exclusively for the use for which it was

designed, and the

improper use.

KH1 and KH1R

have been designed and constructed exclusively to execute maneuvers

for closing and/or opening windows, roll

the aid of sensors

for rain and wind.

Specific use is reserved for automatic ventilation and air

carried out through the connected motors

The appliance must be installed by competent and qualified technical

personnel following

make the unit dangerous for people and things.

A device which assures the complete omnipolar disconnection from the grid,

with minimum distance of 3 mm between contacts, should be installed

upstream of the automation control line.

The box containing the electric panel must be placed in a proper environment,

fixed with suitable screws and using its supports.

For the electrical connection to feeding grid use cables suitable for power

supply in buildings and other civil engineering works, e.g. H05VV

Before carrying out any cleaning or maintenance, make sure the equipment

has been disconnected from the electricity supply.

Attention:

in the event of breakage or malfunction,

the general switch and call for the services of a qualified technician.

Repairs should only be performed by qualified personnel at assistance centres

authorised by the manufacturer.

Always request original spare parts. Failu

compromise safety and invalidate the benefits contained in the warranty for the

appliance.

Page 4

Before installing this appliance, ensure all safety indications

have been read carefully and understood in order to prevent contact with

electricity, injury or any other incident. The manual should be conserved

for further consultation at a later date.

The manufacturer accepts no responsibility for damage to people,

animals or things incurred by improper use or inobservance of the basic

safety rules described in this manual.

Use for any applications other than those indicated must be authorised

the manufacturer after technical review of the assembly.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge.

Do not allow children to play with

the fixed controls and keep any remote

control units out of their reach.

Do not use solvents or jets of water to wash the appliance.

Notes for installer

This device is intended only and exclusively for the use for which it was

designed, and the

manufacturer cannot be held liable for damage due to

have been designed and constructed exclusively to execute maneuvers

for closing and/or opening windows, roll

-

up blinds, curtains and sunshades, assisted by

for rain and wind.

Specific use is reserved for automatic ventilation and air

-

conditioning of rooms, which is

carried out through the connected motors

.

The appliance must be installed by competent and qualified technical

personnel following

manufacturer’s indications. Improper installation and use

make the unit dangerous for people and things.

A device which assures the complete omnipolar disconnection from the grid,

with minimum distance of 3 mm between contacts, should be installed

upstream of the automation control line.

The box containing the electric panel must be placed in a proper environment,

fixed with suitable screws and using its supports.

For the electrical connection to feeding grid use cables suitable for power

supply in buildings and other civil engineering works, e.g. H05VV

Before carrying out any cleaning or maintenance, make sure the equipment

has been disconnected from the electricity supply.

in the event of breakage or malfunction,

switch the appliance off at

the general switch and call for the services of a qualified technician.

Repairs should only be performed by qualified personnel at assistance centres

authorised by the manufacturer.

Always request original spare parts. Failu

re to respect this condition could

compromise safety and invalidate the benefits contained in the warranty for the

Before installing this appliance, ensure all safety indications

have been read carefully and understood in order to prevent contact with

electricity, injury or any other incident. The manual should be conserved

The manufacturer accepts no responsibility for damage to people,

animals or things incurred by improper use or inobservance of the basic

Use for any applications other than those indicated must be authorised

the manufacturer after technical review of the assembly.

The device is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lacking experience and knowledge.

the fixed controls and keep any remote

-

Do not use solvents or jets of water to wash the appliance.

This device is intended only and exclusively for the use for which it was

manufacturer cannot be held liable for damage due to

have been designed and constructed exclusively to execute maneuvers

up blinds, curtains and sunshades, assisted by

conditioning of rooms, which is

The appliance must be installed by competent and qualified technical

manufacturer’s indications. Improper installation and use

A device which assures the complete omnipolar disconnection from the grid,

with minimum distance of 3 mm between contacts, should be installed

The box containing the electric panel must be placed in a proper environment,

For the electrical connection to feeding grid use cables suitable for power

supply in buildings and other civil engineering works, e.g. H05VV

-F type.

Before carrying out any cleaning or maintenance, make sure the equipment

switch the appliance off at

the general switch and call for the services of a qualified technician.

Repairs should only be performed by qualified personnel at assistance centres

re to respect this condition could

compromise safety and invalidate the benefits contained in the warranty for the

In the event of any problems or queries, consult your agent or contact the

manufacturer directly.

2.

CONSTRUCTION AND REGULATORY

This product was designed to be used with products suitably studied for the

specific application. If assembled incorrectly, use of the product with other

devices may result in damage or malfunctions.

The power supply system and electrical

standards for electrical systems.

The equipment has double electrical insulation and thus does not require

an earth wire. All devices connected to the station must be earthed by the

installer unless equipped with double insul

All the devices connected to the control units must be manufactured according

to current regulations.

3. TECHNICAL DATA

Model

Power supply voltage of the station

Maximum current absorbed from the

electrical grid

Output voltage

Maximum switchable output current

Service type

Setup for connection to external devices

Electrical insulation class

Operating temperature

Degree of protection of the electrical devices

The data provided in these illustrations is non

4.

ID PLATE AND MARKING DATA

KH1 and KH1R have

marking and are destined for use in the European Union without

further requirements.

ID plate data are indicated on a polyethylene adhesive label applied externally on the

outside of the container, printed in black on a grey background. Values conform

requirements in force.

5.

RECOMMENDATIONS AND INSTRUCTIONS FOR ASSEMBLY

T

HESE INSTRUCTIONS AR

E INTENDED FOR TECHN

T

HUS BASIC SAFETY AND

In order to guarantee perfect operation of the

instructions and warnings below.

Page 5

In the event of any problems or queries, consult your agent or contact the

manufacturer directly.

CONSTRUCTION AND REGULATORY

REFERENCES

This product was designed to be used with products suitably studied for the

specific application. If assembled incorrectly, use of the product with other

devices may result in damage or malfunctions.

The power supply system and electrical

connection must comply with EU

standards for electrical systems.

The equipment has double electrical insulation and thus does not require

an earth wire. All devices connected to the station must be earthed by the

installer unless equipped with double insul

ation.

All the devices connected to the control units must be manufactured according

to current regulations.

KH1

Power supply voltage of the station

230 V~ 50 Hz

Maximum current absorbed from the

2.5A

230 V~

Maximum switchable output current

Max 1x

Continuous

Setup for connection to external devices

Wind -

Rain

Temperature Sensor

command

-5°C

-

Degree of protection of the electrical devices

IP

The data provided in these illustrations is non

-

binding and subject to change, even without advance notice.

ID PLATE AND MARKING DATA

marking and are destined for use in the European Union without

ID plate data are indicated on a polyethylene adhesive label applied externally on the

outside of the container, printed in black on a grey background. Values conform

RECOMMENDATIONS AND INSTRUCTIONS FOR ASSEMBLY

E INTENDED FOR TECHN

ICAL AND SPECIALIZED

HUS BASIC SAFETY AND

WORKING TECHNIQUES A

RE NOT DISCUSSED

In order to guarantee perfect operation of the

system and facilitate installation, follow the

instructions and warnings below.

In the event of any problems or queries, consult your agent or contact the

This product was designed to be used with products suitably studied for the

specific application. If assembled incorrectly, use of the product with other

connection must comply with EU

The equipment has double electrical insulation and thus does not require

an earth wire. All devices connected to the station must be earthed by the

All the devices connected to the control units must be manufactured according

KH1R

230 V~ 50 Hz

2.5A

230 V~

50 Hz

Max 1x

2.5A

Continuous

Rain

- Brightness –

Temperature Sensor

– open/close

command

II

-

+65ºC

IP

65

binding and subject to change, even without advance notice.

marking and are destined for use in the European Union without

ID plate data are indicated on a polyethylene adhesive label applied externally on the

outside of the container, printed in black on a grey background. Values conform

to EC

RECOMMENDATIONS AND INSTRUCTIONS FOR ASSEMBLY

ICAL AND SPECIALIZED

PERSONNEL

.

RE NOT DISCUSSED

.

system and facilitate installation, follow the

Perform a thorough visual inspection of the device to ensure it wasn't damaged

during transport.

To avoid the hazard of injury or death caused by the electrical current,

disconnect the voltage from the power supply line before carrying out any wiring

or adjustment operation.

The electrical power supply system must be designed and implemented in

compliance with current standards.

Caution.

Check that the elect

specified on the “technical data” label attached to the station.

When assembling the KH1 and KH1R stations, in order to guarantee perfect operation of

the system and facilitate installation, follow the

The rain and wind detectors are placed outside in direct contact with the weather, on the

roof or in a similar position if possible.

Some advises:

a)

The rain sensor should be placed in a slightly inclined position in order to

water run-

off and in a position which is not protected from falling rain; positioning the

sensor underneath trees is not recommended as this will alter the natural

meteorological event.

b)

The wind sensor should be placed far from obstacles that d

wind flow; thus avoid placing the sensor near gutters, trees, walls, etc.

c)

Select the most suitable location for the control unit based on the shape and structure

of the building. The station does not require any maintenance, th

an out-of-the-

way position, protected against direct weather exposure.

d)

Position the box of the device in the selected position and use a pencil to mark the

drilling hole on the support (wall or other).

e)

Drill the hole using a drill b

fastening screw.

f)

Mount the equipment box and fix the screws definitively.

g)

Drill the box to allow passage of the connection cables in the desired position using a

Ø10 drill bit. Remove the electronic bo

permanently when drilling.

h)

Complete the path of the electrical connection cables. Make the electrical connections

according to the wiring diagram provided on the following pages.

i)

Perform the final test checking the int

commands (see paragraph 6.2)

6.

TECHNICAL OPERATING INFORMATION

6.1.

General instructions

The station can control one

switchable current specified in the “Technical Data” table.

motor, the installation of a manual button

“deadman's switch”, is recommended.

The KH1R

model provides for use of both the

433.92 MHz proprietary protocol, and manual control.

Page 6

Perform a thorough visual inspection of the device to ensure it wasn't damaged

To avoid the hazard of injury or death caused by the electrical current,

disconnect the voltage from the power supply line before carrying out any wiring

or adjustment operation.

The electrical power supply system must be designed and implemented in

compliance with current standards.

Check that the elect

ric power supply used corresponds to that

specified on the “technical data” label attached to the station.

When assembling the KH1 and KH1R stations, in order to guarantee perfect operation of

the system and facilitate installation, follow the

instructions and warnings below.

The rain and wind detectors are placed outside in direct contact with the weather, on the

roof or in a similar position if possible.

The rain sensor should be placed in a slightly inclined position in order to

off and in a position which is not protected from falling rain; positioning the

sensor underneath trees is not recommended as this will alter the natural

The wind sensor should be placed far from obstacles that d

eform or protect against the

wind flow; thus avoid placing the sensor near gutters, trees, walls, etc.

Select the most suitable location for the control unit based on the shape and structure

of the building. The station does not require any maintenance, th

way position, protected against direct weather exposure.

Position the box of the device in the selected position and use a pencil to mark the

drilling hole on the support (wall or other).

Drill the hole using a drill b

it with diameter corresponding to the selected plug or

Mount the equipment box and fix the screws definitively.

Drill the box to allow passage of the connection cables in the desired position using a

Ø10 drill bit. Remove the electronic bo

ard from the box to avoid damaging it

Complete the path of the electrical connection cables. Make the electrical connections

according to the wiring diagram provided on the following pages.

Perform the final test checking the int

ervention of the automatic devices.

commands (see paragraph 6.2)

.

TECHNICAL OPERATING INFORMATION

General instructions

The station can control one

actuator at 230V~ 50 Hz;

pay attention to the maximum

switchable current specified in the “Technical Data” table.

For control of the connected

motor, the installation of a manual button

voltage-free n.o.

type

“deadman's switch”, is recommended.

model provides for use of both the

PIK

model radio remote control, with

433.92 MHz proprietary protocol, and manual control.

Perform a thorough visual inspection of the device to ensure it wasn't damaged

To avoid the hazard of injury or death caused by the electrical current,

always

disconnect the voltage from the power supply line before carrying out any wiring

The electrical power supply system must be designed and implemented in

ric power supply used corresponds to that

specified on the “technical data” label attached to the station.

When assembling the KH1 and KH1R stations, in order to guarantee perfect operation of

instructions and warnings below.

The rain and wind detectors are placed outside in direct contact with the weather, on the

The rain sensor should be placed in a slightly inclined position in order to

facilitate

off and in a position which is not protected from falling rain; positioning the

sensor underneath trees is not recommended as this will alter the natural

eform or protect against the

wind flow; thus avoid placing the sensor near gutters, trees, walls, etc.

Select the most suitable location for the control unit based on the shape and structure

of the building. The station does not require any maintenance, th

us it can be placed in

way position, protected against direct weather exposure.

Position the box of the device in the selected position and use a pencil to mark the

it with diameter corresponding to the selected plug or

Drill the box to allow passage of the connection cables in the desired position using a

ard from the box to avoid damaging it

Complete the path of the electrical connection cables. Make the electrical connections

according to the wiring diagram provided on the following pages.

ervention of the automatic devices.

And of all

pay attention to the maximum

For control of the connected

type

, also known as a

model radio remote control, with

Page 7

6.2. Programming

6.2.1. Programming Display and Programming Menu

A display is installed on the electronic board with a programming menu for all the station

functions.

All the settings of the PXXX functional parameters must be made through the keys and

display of the station, changing the preset values F [factory-set].

The OK key is used to enter the programming menu and confirm the setting of each

individual parameter.

The + (plus) key is used to scroll up through the programming menu or increase the

value of the parameter within the menu.

The – (minus) key is used to scroll down through the programming menu or decrease

the value of the parameter within the menu.

The + (plus) and – (minus) keys pressed together are used to exit the programming

menu.

(display)

The initial menu is free of any writing when no input is active; otherwise

it shows the activated function with the following messages:

in1

in2

pk01 - channel 01 of the PIK radio remote control

u Km - wind speed

r - rain state

t °C - temperature

Pressing + (plus) and – (minus) together displays the total number of

channels of the PIK radio remote control saved in the memory.

-↑ ↓+

P001

Wind sensor activation threshold (5 ÷ 50) Km/h F[30]

-↑ ↓+

P002

Temperature sensor minimum threshold (5 ÷ 43) Km/h F[5]

-↑ ↓+

P003 Temperature sensor maximum threshold (7 ÷ 45) °C F[30]

-↑ ↓+

P004 Brightness sensor activation threshold (1 ÷ 50) Klux F[5]

-↑ ↓+

P005

Rain sensor exclusion time (0 ÷ 10) min F[0]

-↑ ↓+

P006 Sensor priority (1 ÷ 4) F[1]. Priority can be selected for only one sensor,

where 1=rain, 2=wind, 3=temperature, 4=sun

Page 8

-↑ ↓+

P007

Temperature sensor function (0 ÷3) F[0]. Set the action when:

0 – not active,

1 – open if t° > P003 and close if t° < P002,

2 – open if t° > P003,

3 – close if t° < P002.

-↑ ↓+

P008

Brightness sensor function (0 ÷ 2) F[0]. Set the action when:

0 – not active,

1 – open if lux > P004,

2 – close if lux > P004.

-↑ ↓+

P009

IN1

input function (1 ÷ 3) F[1]. Set the action when:

1 – open in self-hold and deadman mode (n.o.),

2 – step system (n.o.),

3 – block automatic movements (n.c.).

-↑ ↓+

P010

IN2 input function (1 ÷ 4) F[1]. Set the action when:

1 – close in self-hold and deadman mode (n.o.),

2 – photocell (n.c.),

3 – timer open (n.o.),

4 – timer close ( n.o.)

-↑ ↓+

P101 Motor work time (10 ÷ 120) s F[60]

-↑ ↓+

P102 Motor reset time (0 ÷ 240) s F[0]

-↑ ↓+

P103 Wind sensor function (0 ÷ 2) F[0]. Set the action when active as follows:

0 – none, 1 – open, 2 – close

-↑ ↓+

P104

Rain sensor function (1 ÷2) F[2]. Set the action when the input is active, as

follows:

0 – none, 1 – open, 2 – close.

-↑ ↓+

Add Adds PIK radio remote control channel in the memory

-↑ ↓+

dEL Deletes PIK radio remote control channel from the memory

-↑ ↓+

rESE Restores the Default values (press twice and the message “end” appears).

Page 9

6.2.2. Errors table

(display) The following messages appear on the display in case of error:

FULL – radio remote control memory full

Err - the radio remote control is not recognized in either delete or write

t--- - temperature out of range >60 °C < 0 °C

6.3. Settable functions

6.3.1. In1, In2 - Parameters P009 – P010

For reasons of simplicity, from now on the opening of the window is associated with

forward movement of the actuator and closing of the window is associated with its

backward movement.

Two voltage-free control inputs “in1” and “in2” are provided on the terminal block and can

be configured in the following modes described below.

When the inputs are activated, the respective message appears on the display: “in1” and

“in2”.

- Open/Close function in self-hold mode (n.o.). (P009=1, P010=1)

Upon closure of the contact - and immediate release - the station instructs the

forward/backward operation of the motor for the motor work time set in P101.

If you would like to stop the movement of the motor, just give another pulse to the

command of that particular operation direction. Vice versa, if you give a pulse in the

opposite direction of movement, the motor changes operation direction.

- Deadman Open/Close function (n.o.). (P009 =1, P010=1)

Upon closure of the contact - and retention for more than 2 seconds - the station

instructs the forward/backward operation of the motor until the contact itself is

released.

- Step function on IN1 (n.o.). (P009=2, P010 =3)

With the IN1 input only, the motor can be controlled according to the step sequence,

that is open-stop-close-stop-open... with each closure and release of the contact itself.

- Block automatic movements from IN1 sensors function (n.c.) (P009=3)

This function provides that the motor movement occurs only by means of the PIK radio

remote control present on the radio remote controlled version.

If activated (opening of the contact), it allows to block operation of the

rain/wind/light/temperature sensors until the contact is closed.

- Safety function - IN2 Photocell (n.c.). (P010=2, P009=2,)

This function is used to manage a closing safety, that is, if the contact is opened

during the closing phase, the motor stops and does not continue in the same direction

until the n.c. contact is restored (e.g. photocell). When setting this function, it is

mandatory to manage IN1 in step mode. Or manage the movements of the motor

through the PIK radio remote control present in the radio remote controlled version.

- IN2 Timer function (n.o.). (P010 = 3 or P010=4)

With this function when the input IN1 is selected the Step sequence becomes

operational automatically, regardless of the mode set with the parameter P009 of IN1.

Alternatively, the movements of the motor can be controlled with the PIK radio remote

control present in the radio remote controlled version.

Page 10

The IN2 Timer function provides for a voltage-free (also known as “potential-free”)

“n.o.” contact at the input. Upon activation of the timer the contact closes and the

station instructs the opening (P010=3) or closing (P010=4) of the motor.

6.3.2. Rain sensor - Parameters P005 – P104

Upon activation of the rain sensor, the respective message “r” appears on the display,

The RAIN input is set up to be connected to a device that detects rain and provides a

voltage-free n.o. contact. The opening/closing action of the window can be set using

the P104 menu.

Supply voltage 12V for rain sensor

Tension (V) Maximum Current (mA)

12V 100mA

Please contact Nekos technical office to use rain sensors other than NSR1

In case of rain with the window closed, the window can be reopened by

excluding intervention of the rain sensor for the time set in parameter P005.

Caution.

If you do not want to use this function, leave the parameter P005 = 0

6.3.3. Wind sensor - Parameter P103

Upon activation of the wind sensor, the respective message appears on the display: “u

XX”, where XX is the value of the detected wind speed expressed in Km/h.

The intervention threshold of the wind sensor is set by parameter P001 within the range 5

Km/h - 50 Km/h. The opening or closing of the window can be set by P103. Temporary

wind gusts do not activate the function.

6.3.4. Temperature sensor – Parameters P002 – P003 – P007

Upon activation of the sensor, the respective message appears on the display: “t XX”

where XX is the detected temperature in °C (degrees Celsius or Centigrade).

The input is set up for a temperature sensor of the type NTC 10 Kohm at 25 °C.

The station manages two temperature thresholds; a minimum threshold settable by the

P002 menu and a maximum threshold settable by P003. The two thresholds can be set

within the limits provided by the menu with an automatic shift set at 2 °C minimum.

It is advisable to keep the two thresholds with a margin greater than the minimum 2 °C .

The opening or closing of the window can be set by the parameter P007.

6.3.5. Brightness sensor – Parameters P004 – P008

Upon activation of the sensor, the respective message appears on the display: “S XX“

where XX is the detected brightness value in KLUX. The lux values of brightness are

indicated in the table below.

Page 11

Direct sunlight 50 Klux

Daylight with clear sky 10 ÷ 20 Klux

Daylight with cloudy sky 1 ÷ 5 Klux

Office interior 200 ÷ 800 lux

Sunset (beginning) 10 lux

The station manages the opening or closing of the window when the threshold set by

parameter P004 is exceeded and operates in the direction set by P008.

6.3.6. Sensor priority – Parameter P006

By means of parameter P006, higher priority can be assigned to one of the sensors in

case events occur simultaneously.

6.3.7. Motor reset time – Parameter P102

After intervention of the sensors (rain, wind, temperature, sun) and the reset time set by

parameter P102 has passed, the window returns to the previous scenario.

Caution. If you do not want to use this function, leave the parameter P102 = 0

With P102 = 0, when a sensor intervenes the window goes to the position instructed by

the sensor and remains there.

6.3.8. Other parameters – Parameters P101 – Add – dEL – rESE

- The parameter P101 is used to set the work time of the motor on the window.

- The parameter “Add” of the menu is used to save one or more channels of the PIK

radio remote control in the station.

- The parameter “dEL” of the menu is used to delete one or more channels of the PIK

radio remote control saved previously.

- The parameter “rESE” of the menu is used to restore the factory-set values

(Default).

6.4. Saving a PIK radio remote control

This paragraph concerns only the KH1R station equipped with PIK radio remote control.

THE CONTROL UNITS LEAVE THE FACTORY WITH THE REMOTE CONTROL ALREADY INSERTED IN

THE MEMORY; CARRY OUT THE MEMORIZATION PROCEDURE ONLY IF YOU WANT TO ASSOCIATE

OTHERS.

The remote electronic control or, more simply, radio remote control, is the standard-

supplied device for controlling the KH1R station.

For more details on the characteristics and operation of the PIK radio remote control,

consult the instructions manual provided with the radio remote control itself; not all the

functions of the radio remote control are listed in this manual.

The KH1R station can accept up to 6 PIK radio remote controls. The KH1R functions only

with the PIK radio remote control with NEKOS proprietary code (rolling code).

Page 12

Save procedure:

a. Equip yourself with the radio remote control, checking beforehand that it is working,

has charged batteries and is in good condition.

b. Select the “Add” item in the menu.

c. Select the desired channel on the PIK radio remote control (see the instructions

provided with the radio remote control).

d. Press the “OK” button of the control unit. The message “Push” will appear on the

display.

e. Press any one of the ▲ arrow, ▼ arrow or STOP buttons on the remote control for

about 1 second.

f. The “OK” message will appear on the display indicating that the save process was

successful.

g. End of procedure.

Repeat the procedure for any other radio remote controls or channels.

6.5. Saving a radio remote control without access to the board

Saving a new radio remote control remotely, i.e. without access to the electronic board of

the station, can occur only if the user already has a previously saved radio remote control.

Obtain the instructions manual of the PIK radio remote control for consultation.

The programming is achieved by carrying out the following procedure:

Equip yourself with the PIK radio remote control to be saved and set it on any channel

(see the instructions of the radio remote control).

Equip yourself with the already saved and operational radio remote control, press the

following buttons in sequence: F1, F2 and then STOP.

Within 5 seconds on the radio remote control to be saved, press one of the ▲ arrow,

STOP or ▼ arrow buttons twice.

Now the second radio remote control is operational.

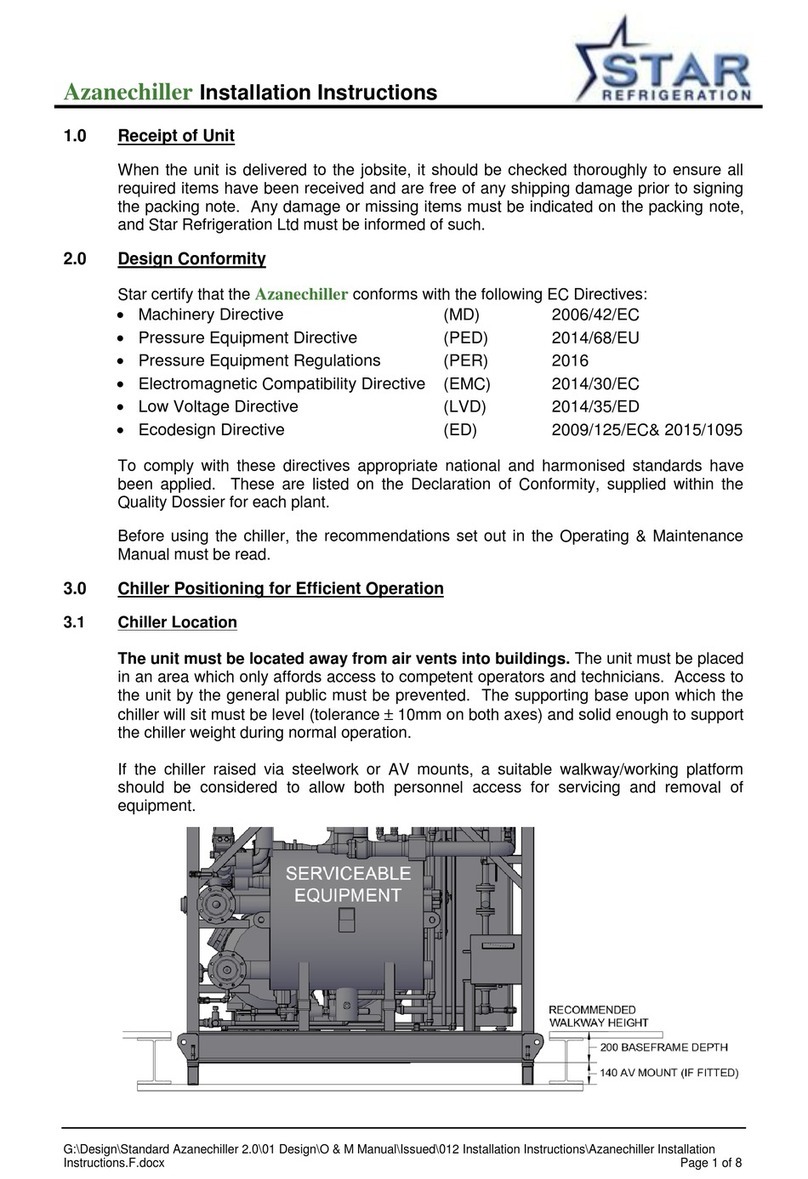

7. OVERALL DIMENSIONS

The container box is made of impact-resistant ABS engineering plastic, RAL7035 grey

colored, having a cover with gasket and IP65 degree of protection.

The feed-through holes for the cables, both those for the electric power supply and those

coming from the sensors, as well as those going to the motors to be controlled, are not

present on the box. The holes must be made by the installer as needed.

During the drilling of the holes, be very careful so as not to damage the

electronic board.

Page 13

Dimension

A B C D E

100 100 60 79,5 60,5

Page 14

8. CONNECTION DIAGRAM OF THE 230V KH1 and KH1R STATION

WHITE

YELLOW (Brown)

WIN D + LIGH T

GREEN

BLACK

BLUE

C

230V ~ 50H z

OK KEY

H EATED R AIN

M AN U AL COM M AN D

A

BROWN

BLACK

LIGHT (Grey)

M

L

N

M

0V

IN1

IN2

W

RAIN

+12V

NTC

NTC

- SUN

+SUN

+ KEY

- KEY

RAD IO R EM OTE C ON TR OL AN TEN NA

F1 M AX . . 8A 230V

RED

GREEN (Blue)

BLUE

TEMPERATURE SENSOR (NTC)

L N

M

0V

OP

CL

RA I N

+12V

NTC

NTC

-S UN

+SUN

W

OK + -

SEN SOR

SEN SOR

WIN D SENSOR

BROWN

BLUE

Page 15

9. ENVIRONMENTAL PROTECTION

All materials used in the manufacture of this appliance are recyclable.

We recommend that the device itself, and any accessories, packaging, etc. be sent to a

centre for ecological recycling as established from laws in force on recycling. The device

is mainly made from the following materials: aluminium, zinc, iron, plastic of various type,

cuprum. Dispose materials in conformity with local regulations about removal.

10. CERTIFICATE OF GUARANTEE

The manufacturer will guarantee good function of the appliance. The manufacturer shall

undertake to replace defective parts due to poor quality materials or manufacturing

defects in accordance with article 1490 of the Civil Code.

The guarantee covers products and individual parts for 2 years from the date of purchase.

The latter is valid as long as the purchaser possesses proof of purchase and completion

of all agreed conditions of payment.

Guarantee of good function of appliances agreed by the manufacturer implies that the

latter undertakes to repair or replace free of charge and in the shortest period possible

any parts that break while under warranty.

The purchaser is not entitled to any reimbursement for eventual direct or indirect damage

or other expenses incurred. Attempt to repair by personnel unauthorised by the

manufacture shall render the warranty null and invalid.

The warranty does not cover fragile parts or parts subject to natural wear and tear or

corrosion, overload, however temporary etc. The manufacturer will accept no

responsibility for eventual damage incurred by erroneous assembly, manoeuvre or

insertion, excessive stress or inexpert use.

Repairs performed under guarantee are always "ex factory of the manufacturer".

Respective transport expenses (out/back) are the responsibility of the purchaser

11.

DECLARATION OF CONFORMITY

The undersigned,

Company name: NEKOS S.r.l

Postal address:

Via Capitoni, 7/5

Telephone number:

+39 0424 411011

declare that

the document is issued under our sole responsibility and belongs to the following product:

Apparatus model / Product:

Ventilation unit for 1 230V motor

Trademark: NEKOS

Model/Type: KH1, KH1R

Batch: see data label

MODEL:

KH1R

The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

2014/53/EU Radio Equipment (RED)

2011/65/EU

Restriction of the use of certain hazardous substances Directive (RoHS

2015/863/EU Delegated Directive amending Annex II of Directive 2011/65/EU of the European Parliament and of the

Council regarding the list of substances with usage restrictions

The following harmonised standards and/or technical specifications

EMC: EN 61000-6-

3:2007 + A1:2011 + AC:2012

LVD EN 60335-

1:2012 + AC:2014 + A11:2014

RED ETSI EN 301 489-

3 V2.1.1, ETSI EN 301 489

ETSI EN 300 220-

2 V3.2.1

RoHS EN 50581:2012

MODEL: KH1

The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

2014/30/EU ElectroMagnetic Compatibility Directive (EMCD)

2014/35/EU Low Voltage Directive (LVD)

2011/65/EU Restriction

of the use of certain hazardous substances Directive (RoHS Directive)

2015/863/EU Delegated Directive amending Annex II of Directive 2011/65/EU of the European Parliament and of the

Council regarding the list of substances with usage restrictions

The

following harmonised standards and/or technical specifications have been applied:

EMC: EN 61000-6-

3:2007 + A1:2011 + AC:2012

LVD EN 60335-

1:2012 + AC:2014

RoHS EN 50581:2012

Place: Colceresa

Signature: Giuliano Galliazzo (

A.D.

I -

36064

Phone

(+39)

Page 16

DECLARATION OF CONFORMITY

Via Capitoni, 7/5

Postcode and city:

36064 Colceresa VI

+39 0424 411011

the document is issued under our sole responsibility and belongs to the following product:

Ventilation unit for 1 230V motor

Serial number: see data label

The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

Restriction of the use of certain hazardous substances Directive (RoHS

Directive)

2015/863/EU Delegated Directive amending Annex II of Directive 2011/65/EU of the European Parliament and of the

Council regarding the list of substances with usage restrictions

The following harmonised standards and/or technical specifications

have been applied:

3:2007 + A1:2011 + AC:2012

EN IEC 61000-6-2:2019

1:2012 + AC:2014 + A11:2014

3 V2.1.1, ETSI EN 301 489

-1 V2.2.3, ETSI EN 300 220-

1 V3.1.1,

2 V3.2.1

The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

2014/30/EU ElectroMagnetic Compatibility Directive (EMCD)

2014/35/EU Low Voltage Directive (LVD)

of the use of certain hazardous substances Directive (RoHS Directive)

2015/863/EU Delegated Directive amending Annex II of Directive 2011/65/EU of the European Parliament and of the

Council regarding the list of substances with usage restrictions

following harmonised standards and/or technical specifications have been applied:

3:2007 + A1:2011 + AC:2012

EN IEC 61000-6-

2:2019

1:2012 + AC:2014

+ A11:2014

Date: 04/03/2020

A.D.

– President)

NEKOS

S.r.l.

36064

- COLCERESA (VI) - Via Capitoni, 7/5

(+39)

0424 411011 Fax (+39) 0424 411013

info@nekos.it - http://www.nekos.it

36064 Colceresa VI

the document is issued under our sole responsibility and belongs to the following product:

The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

Directive)

2015/863/EU Delegated Directive amending Annex II of Directive 2011/65/EU of the European Parliament and of the

1 V3.1.1,

The object of the declaration described above is in conformity with the relevant Union harmonisation legislation:

of the use of certain hazardous substances Directive (RoHS Directive)

2015/863/EU Delegated Directive amending Annex II of Directive 2011/65/EU of the European Parliament and of the

2:2019

This manual suits for next models

1

Popular Fan manuals by other brands

Mezzo

Mezzo TF7507 instruction manual

Oceanic

Oceanic OCEAVT15CMRW user manual

Home Decorators Collection

Home Decorators Collection FAWNDALE 1005 819 911 Use and care guide

Westinghouse

Westinghouse ETL-ES-Alloy-WH21 owner's manual

Fanco

Fanco Horizon DC CFFCHZ23BLSMR installation manual

Bosch

Bosch DUH30252UC use and care manual

Vent-Axia

Vent-Axia Sentinel Kinetic B Installation & commissioning

Mr.Ken

Mr.Ken LA NEW ABS 56" user manual

Comfort Zone

Comfort Zone CZMC48B Series instructions

Somogyi Elektronic

Somogyi Elektronic home FK37 Series instruction manual

Star Refrigeration

Star Refrigeration Azanechiller installation instructions

Lasko

Lasko 4443 operating manual