To remove smudges and fingerprints:

Wipe surfaces with a quality Stainless Steel Cleaner/Polish.

Apply using a soft non-abrasive cloth, wipe surfaces with

stainless steel cleaner/polish.

Soap reservoirs and dispensers should be maintained

periodically to clear residue. This should be done in hot

water to clean the internal components. The valve should be

pumped multiple times to thoroughly clean any residue

inside. The reservoir and tubing should also be flushed and

cleaned with hot water. In cases of extreme clogs, the

dispenser should be disassembled and the parts thoroughly

cleaned.

Stainless steel should be kept clean at all times. If

maintained, stainless steel surfaces will retain their new,

clean, polished appearance indefinitely. To remove water

spots or rust spots, stainless steel cleaner/polish on a cloth

is recommended.

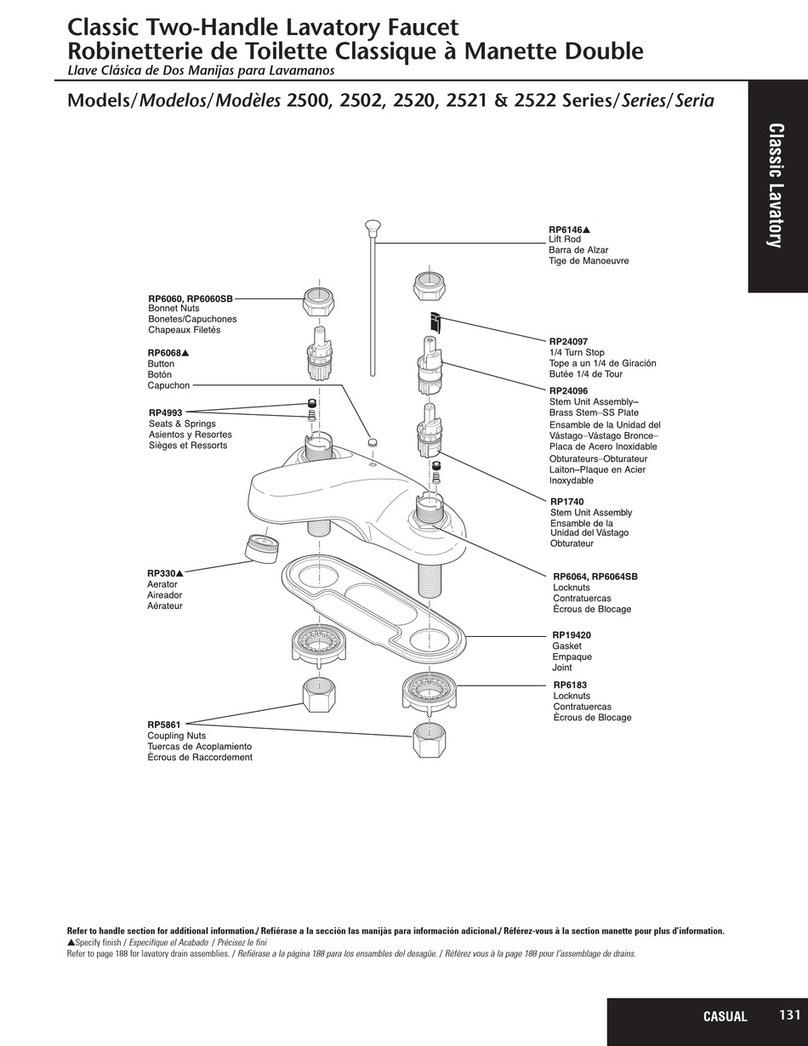

SOAP SYSTEMS

Acorn soap reservoirs and dispensers provide a dependable

operation over long term when proper maintenance is

performed and the correct soap is being used. The most

common problem with soap systems is that the wrong

viscosity (thickness) of soap is being used or high acidic pH

levels are in the ingredients. Soap thickness can be best

explained as no thicker or thinner than normal household

liquid dish soap. The pH level of the soap should be 6.5 to

8.5; more acidic soaps will corrode the metal parts and

degrade rubber or plastic components.

FOR HIGH POLISH STAINLESS STEEL

Note: High polish stainless steel surfaces should never

come into contact with any abrasive cleaning brush, cloth or

cleaning agent.

RECOMMENDED CLEANING SOLUTIONS

- Hand dishwashing liquid/soft water solution

- Mild soap/soft water solution

- 3M Stainless Steel Cleaner/Polish

- White vinegar/soft water solution

(for brightening, removing oil and

hard water deposits)

- CLR Brand Cleanser or baking soda/soft

water solution (for brightening, removing

hard water deposits)

- Club soda and sponge

WARNING: Some soap contains corrosive additives that

can cause rust on stainless steel surfaces. Acorn

recommends user/ maintenance personnel review MSDS

reports of soap and possible corrosive additives noted.

NORMAL CLEANING

Clean weekly or more often, as needed

(especially high polishing surfaces)

FOR TOUGH PROBLEMS

- CRES Cleaner specifically for rust stains (available from

Acorn)

- Tarn-X for general stains

- #7 chrome polish

- Silver polish

To remove stubborn spots or to treat a scratch

(Standard Satin Finish Only):

Use of synthetic, abrasive, general-purpose pads such as

Scotch Brite is recommended. Apply the stainless steel

cleaner/polish to the synthetic, abrasive pads and

CAREFULLY rub out spot with cleaner/ polish. Be sure to

rub in the direction of the grain! Do not allow steel wool to

come in contact with the stainless steel. Steel particles can

embed into the stainless steel surface and create rust!

REPAIRING SURFACE DAMAGE

Surface damage, such as minor chips, scratches, burn

marks and graffiti can be repaired with a fine grit abrasive

cleanser, such as a Scotch-Brite pad or fine grit sandpaper.

For more serious physical damage caused by vandals, an

Acorn Solid Surface Repair Kit is available. Contact the

factory for details. Refer to drawing #9927-160-002.

CARE, CLEANING, AND REPAIR

OF CORTERRA SOLID SURFACE

CARE AND CLEANING OF STAINLESS

STEEL SURFACE

IF SPOTS ARE STUBBORN OR IF YOU WISH TO TREAT A

SCRATCH: synthetic, abrasive, general-purpose pads such

as Scotch Brite are recommended. Apply the stainless steel

cleaner/polish to the synthetic, abrasive pad and

CAREFULLY rub out spot with cleaner/polish. Be sure to

rub in the direction of the grain! Do not allow steel wool to

come in contact with stainless steel. Steel particles can

embed into the stainless steel surface and create rust.

RECOMMENDED CLEANING MATERIALS

- Sponge – natural or artificial

- Nylon or other soft-bristle material brush

- Soft cloth (as used on automobile finishes)

CORTERRA SOLID SURFACE

Acorn's densified solid surface material is composed of

recycled solid-surface polymer resin, aluminum trihydrate

and fillers. It is resistant to stains, impact and burns and

complies with ANSI Z124.3. It is attractive, durable and easy

to maintain.

ROUTINE CLEANING

Corterra should be kept clean at all times. If maintained,

Corterra surfaces will retain their new, clean appearance

indefinitely. Wash with a non-abrasive all purpose cleaner

and water, then rinse. Wipe dry. (Never use cleaners with

strong chemicals such as toilet bowl cleaners, rust

removers, ceramic cook top cleaners, laquer thinners or

oven cleaners). To remove persistent stains use a Scotch

Brite pad and an abrasive cleaner or a solution of household

bleach and water (1 part water to 1 part bleach).

To remove rust stains:

Wipe surfaces with CRES (available from Acorn) or

equivalent cleaner. Use recommended solutions. Apply

using a soft non-abrasive sponge. Rinse surfaces

immediately after application. Always follow cleaner product

directions provided. Afterwards, using a soft, non-abrasive

cloth, wipe surfaces with stainless steel cleaner/polish.

Page 17 of 18

NEO-METRO FIELD SERVICE

TOLL FREE 800-743-8259 • LOCAL 626-855-4866 • FAX 626-855-4863

INSTALLATION, OPERATIONS

& MAINTENANCE MANUAL

Please visit for most current specifications.www.neo-metro.com

Date: 06/10/19

Part #: 6216-019-000