HydraGuard™ 10” UltraFilter - Flush, Instructions for Use

INTRODUCTION

Information on this sheet must be read before the use of this device to

ensure safe and effective operation.

Recommended Storage: Between 5 and 35°C (41 and 95°F).

INDICATIONS

Description: The HydraGuard 10” UltraFilter - Flush is a hollow fiber

ultrafilter that retains bacteria, viruses, and endotoxin from water.

Indications for Use: The HydraGuard 10” UltraFilter - Flush is intended

to be used to filter EPA quality drinking water. The filter retains bacteria,

viruses and endotoxin. By providing ultrapure water for patient washing

and drinking, the filter aids in infection control. The filter produces

water that is suitable for patient wound cleansing, cleaning of

equipment used in medical procedures and washing of surgeon’s hands.

The filter is not intended to provide water that can be used as a

substitute for USP sterile water.

Use Life: The device is intended for long term continuous use. Once it

completes its useful life, the filter should be replaced and discarded. Do

not attempt to sterilize or reuse it.

CONTRAINDICATIONS

Chemical: The HydraGuard 10” UltraFilter - Flush retains biological

contaminants. To obtain chemically pure water it is necessary to use the

filter in conjunction with other devices such as DI beds or RO systems.

WARNINGS & PRECAUTIONS

Pressure & Temperature: The HydraGuard 10” UltraFilter - Flush is

intended for a maximum incoming water pressure of 60 psi (4 bar) and

a maximum incoming temperature of 27°C (80°F).

Cyclic Use: The HydraGuard 10” UltraFilter - Flush is designed to achieve

a maximum of 6,000 on/off cycles.

Replacement: The filter should be replaced when the flow rate begins

to noticeably decrease. It is recommended to establish a maintenance

schedule of replacing the filter at least every 12 months dependent on

water quality.

Water Monitoring: After installation of the HydraGuard 10” UltraFilter

- Flush, periodic monitoring of the water is recommended. Water

quality is dictated by the intended use and should be established and

monitored by the facilities engineer. Nephros is available to assist with

establishing guidelines and acceptance criteria as needed.

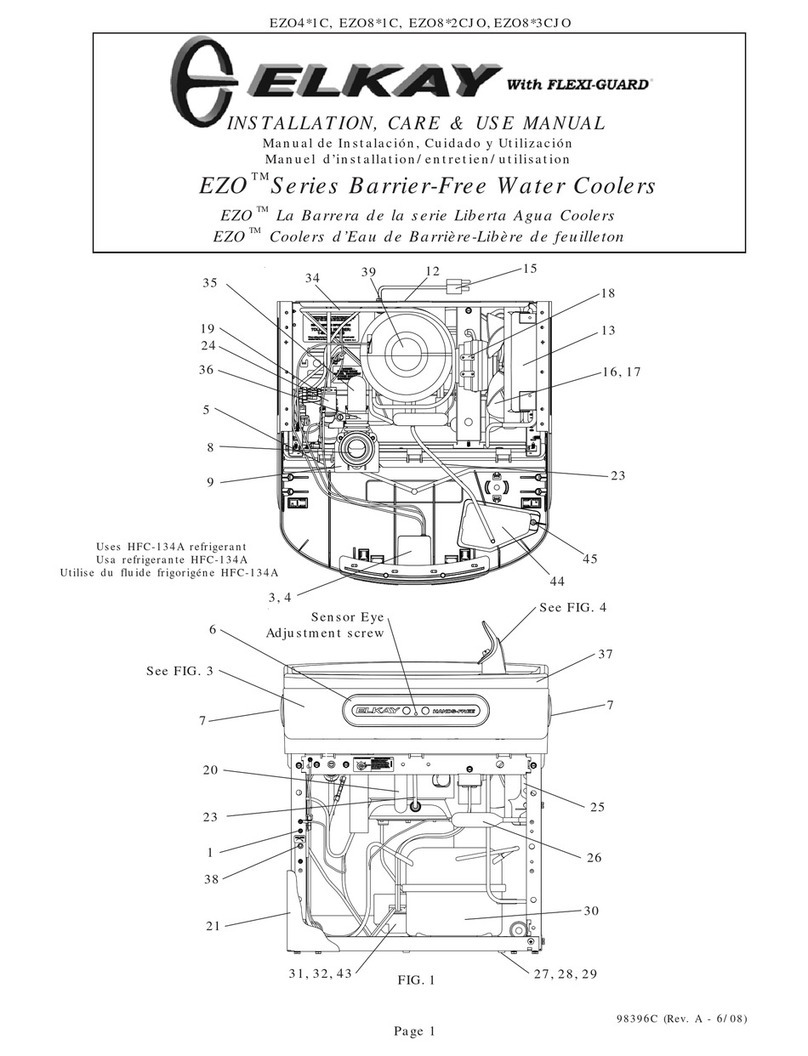

FILTER INSTALLATION & REMOVAL

New Install: If this is the first time any reusable cartridge type filter is

being installed in a location (i.e. there are no cartridge housings in

place), please refer to the second page of these instructions for

installation guidance before proceeding with the instructions below.

Note: Prior to handling a new filter, wash hands and wear disposable

gloves.

•Turn off the water source upstream of the filter and vent any excess

pressure from the housing via its bleed valve or flush port valve.

•Remove both the housing bowl/cover and the old filter.

Open a new filter blister pack and aseptically remove the filter.

•Insert one end of the filter into the head of the housing cap. It may

be necessary to use a twisting motion to ensure that the filter is firmly

in place and the O-rings seat properly. Re-attach the housing

bowl/cover, to the housing cap.

•Open the flush port valve and the upstream water source to prime

the new filter.

•Close the flush port valve after 20-30 seconds, and continue to

prime the filter for 5 minutes to purge it of trapped air (if the

housing has a bleed valve, open it at the same time to assist

purging).

•Close the outlet test valve (and bleed valves if present) and verify

there are no leaks.

OPERATION

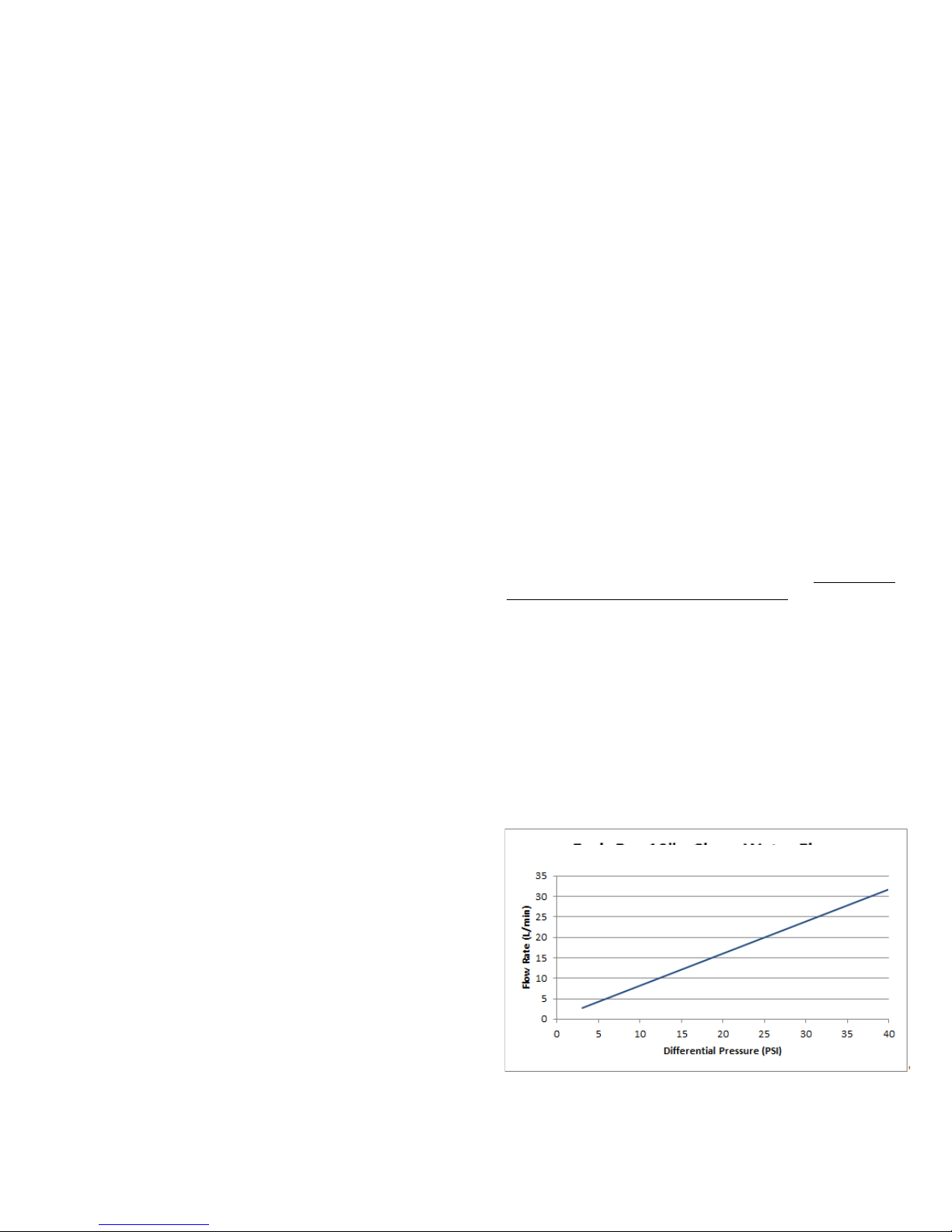

After a new HydraGuard 10” UltraFilter - Flush is installed, water should

be run through the filter for approximately 5 minutes to purge it of

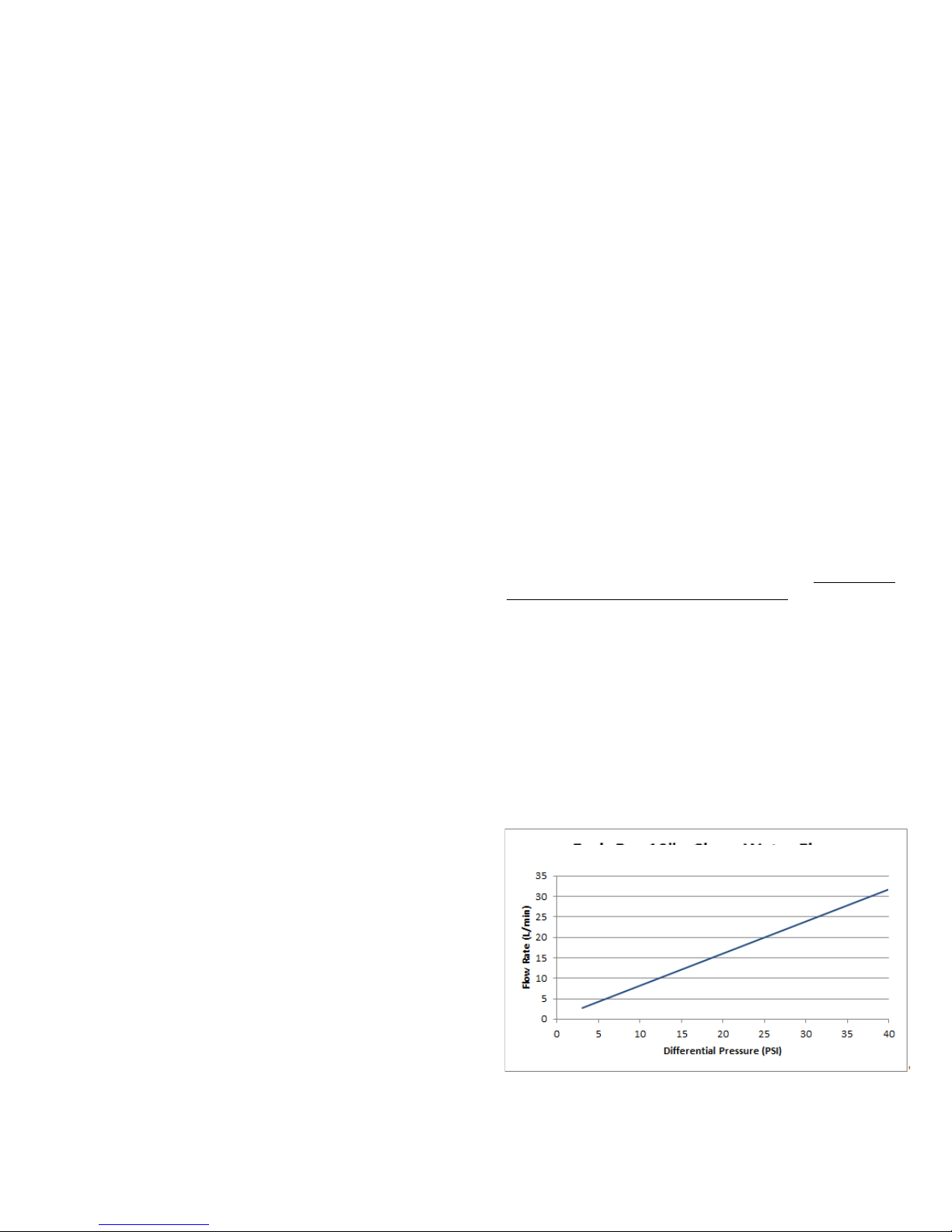

trapped air. The pressure drop across the HydraGuard 10” UltraFilter -

Flush generally reduces the flow rate by about 10-20% of the rate

without a filter. The HydraGuard 10” UltraFilter - Flush is designed with

a flush capability for periodic filter flushing. The filter should operate for

up to 12 months of normal use with minimal degradation in flow

(dependent on water quality and flush frequency). If the flow rate

degrades significantly, the filter should be replaced.

INTEGRITY TESTING

•The filter integrity can be verified with a pressure holding test after

the filter has been properly primed and there are no connection

leaks.

•Turn off the water source and open the inlet test valve to bleed off

any residual pressure.

•Connect an air source (compressed air or air pump) to the inlet test

port as shown in Housing and Filter Installation Example. Note that a

pressure gauge must be installed to monitor the inlet filter pressure

to carry out this test.

•Open both test valves, and pressurize the filter inlet; ensure the

outlet test port is venting. Raise the air pressure to 15 psi at the filter

inlet and allow water to exit from the outlet test port. Do not exceed

30 psi to prevent damage to the filter membrane.

•When water stops coming out from the outlet test port close the

outlet test valve and check for external leaks (via pressure gauge).

•Open the outlet test valve and re-pressurize as necessary to reach 15

psi at the filter inlet.

•With the outlet test valve open, close the inlet test valve and allow

the pressure to stabilize for 5 to 10 seconds.

•Monitor the pressure gauge and determine the pressure drop for a

period of 1 minute.

•If the pressure drops by more than 1 psi over a minute, check for leaks

and repeat the test to confirm. If the filter fails, it must be replaced.

•Close the outlet test valve and remove air source. Open water source

valve and re-prime filter to return to operation.

HydraGuard 10” UltraFilter – Flush, Clean Water Flow