WARNINGS AND ADVICE

Installation Position

Do not install the water softener

next to a boiler where it may be

subjected to excessive heat.

Freezing

The softener and pipework

including the drain must

be installed such that the

installation is not subjected to

freezing conditions.

Hoses

The hoses must be approved hoses

as supplied in the recommended

installation kit. Do not use washing

machine or garden hose as these

are not suitable.

Heat

Do not run the hoses close to

boilers, radiators, or hot water

pipes. Never run behind boilers

or radiators. Remember, heat

melts hoses.

Separate Hard Water

Drinking Tap?

Whilst many authorities

recommend a separate hard

water drinking tap it is essentially

the customers choice.

If you do fit a tap it does not

have to be at the kitchen

sink. Any suitable position is

acceptable.

Where the water hardness is

below 400ppm the softened

drinking water is suitable for

everybody.

Above 400ppm the softened

water is not recommended for

the mixing of baby feeds or the

immunocompromised but is ok

for everyone else.

For further information ask

your water softener dealer for

the booklet Softened Drinking

Water L458 or visit www.

ministryofcommonsense.org.

Copies of WRAS guidance

note No 9-07-01 Installation of

Ion Exchange Water Softeners

explain the plumbing regulations

regarding separate drinking

water taps. Copies are available

from your water softener dealer.

Condensation

In some damp kitchen

environments there is a problem

with condensation. To prevent

this lag the pipe-work connected

to the softener.

Electrical Earth Bonding

If you alter the rising main

pipework, ensure that you

maintain the integrity of the

earth bonding.

Dishwashers

When installing a water softener,

note should be taken of whether

the dishwasher should be connected

to the hard or soft supply. Consult

the dishwasher manufacturers’

instructions for advice

.

New Dwellings

When installing a softener into a

new dwelling the softener should

not be put into service before

the entire plumbing system has

been completed and flushed.

Hygiene

Remember that you are dealing

with drinking water. Exercise

normal domestic hygiene

precautions particularly when

breaking into the water supply

and connecting the bypass

system. Flush the system

thoroughly before use.

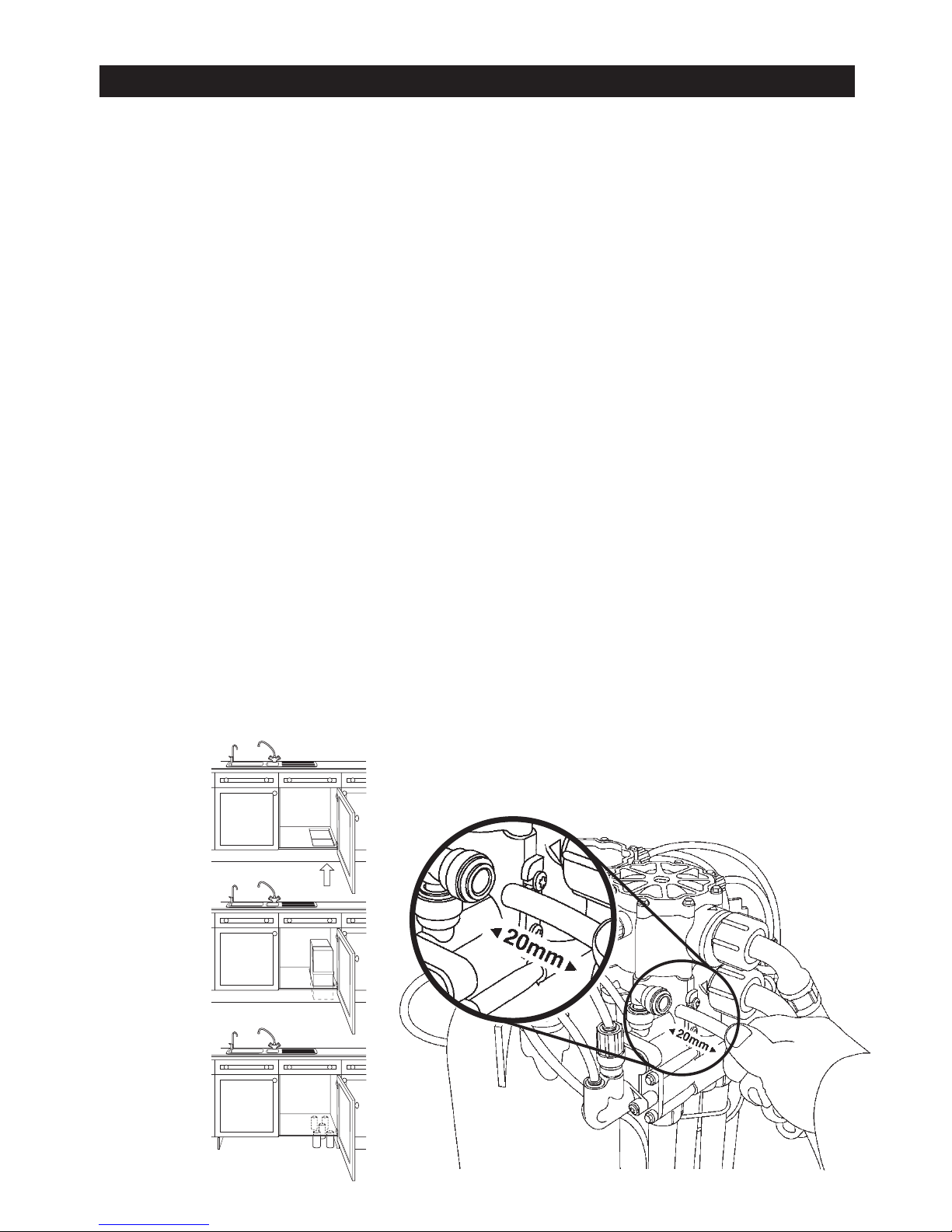

Kitchen Units

When installing a Block Salt

Softener inside a kitchen base unit,

you must either: Acut through the

floor of the unit so that the water

softener sits on the kitchen floor,

or Bfit supports underneath the

floor of the kitchen unit to sustain

the very heavy weight of the

water softener.

Option A

Cut hole to the size

of softener.

Option B

Cut 5 pieces of 11/

2

”

waste pipe to fit

between floor and

base of unit.

Option A

Drop softener

through hole on to

kitchen floor.

Drain connection

The drain tube is connected to the grey JG elbow. The tube must

be pushed into the elbow 20mm to ensure a leak free joint.

Check joint does not leak during regeneration.

Kitchen Units