NETZSCH NEMO Manual

NEMO®Pump

Model Number

Sales Order/Job Number

Machine Number

Date of Issue

NM BY

In addition to the operating instruct-

ions and to the mandatoryrules and

regulations for accident prevention

Operating and

Maintenance Instructions

The Instruction Manual

on how to operate the machine

safely, properly and efficiently.

nnel with the national requirements

Important Note

These operating instructions

are designed to familiarize

the user with the machine

and its designated use.

help to avoid danger to reduce

to increase the reliability and life

Observing these instructions

∙Contains important information

∙Must always be available

NETZSCH Pumps North America, LLC

119 Pickering Way ∙Exton, PA 19341

610.363.8010 ∙ Fax 610.363.0971

Email: [email protected]

www.netzsch.com

repair costs and downtimes and

of the machine.

and environmental protection in the

country and place of use of the mac-

hine, the generally recognized tech-

Transport; shall be completed by

the end user and authorized perso-

in force for the prevention of acci-

dents and the environmental protec-

tion.

work, evacuation of production

waste, care and disposal of fuels

and consumables.

Maintenance (servicing, inspe-

any person in charge of carrying

nical rules for safe and proper

working must be observed.

wherever the machine is in use.

∙Must be read and applied by

ction, and/or repair)

out work with and on the mach-

ine. Such as:

Operation including setting up,

troubleshooting in the course of

NETZSCH Pumps North America, LLC

NETZSCH Pumps North America, LLC Website: www.netzsch.com Tel: +1 610-363-8010

119 Pickering Way Fax: +1 610-363-0971

WARNING!!!!

When Variable Frequency Drives (VFD’s)

are being used to vary the speed of the

NETZSCH Progressing Cavity Pumps, then they

MUST be CONSTANT TORQUE VFD’s.

How the pump works

NETZSCH Progressing Cavity Pumps operate at a constant torque requirement

for a specific operating pressure. The speed of the pump does NOT affect the torque

requirement. For example: a pump running at 60psi output pressure at a speed of 200

revolutions per minute requires the same toque input as if it were running at 60psi

output pressure at a speed of 600 revolutions per minute. The only exception to this rule

is during pump startup; at the moment the pump starts the motor must provide more

torque than the pump requires when it is running. This is due to the force of static

friction that the motor must overcome in order to begin rotation. Although this is only a

momentary force, enough torque has to be available to break the static load.

How the VFD works

Variable Frequency Drives work by taking the supplied power and modulating the

supplied power frequency in linear proportion to the supplied voltage. This proportional

modulation allows the motors speed to be altered without the motor drawing too many amps

and burning out. A VFD can be built to perform this modulation in one of two ways. The VFD

can be set to modulate the frequency above the normal supplied 60HZ frequency allowing the

output to provide a constant amount of power but the torque will drop off as speed is increased

(THIS IS A CONSTANT HP VFD) or it can modulate the frequency below the normal supplied

60HZ frequency allowing the output to provide constant Torque but the power will decrease as

the speed is reduced (THIS IS A CONSTANT TORQUE VFD). This relationship is shown in the

detail below. The manufacturers of VFD’s typically offer two service factors. Normal Duty; which

NETZSCH Pumps North America, LLC

NETZSCH Pumps North America, LLC Website: www.netzsch.com Tel: +1 610-363-8010

119 Pickering Way Fax: +1 610-363-0971

has an overload capacity of the VFD's full load ampere rating times 110% - 120% for one

minute and Heavy Duty; which has an overload capacity of the VFD's full load ampere rating

times 150% for one minute. Typically, constant Hp VFD’s are sold with a Normal duty rating

since the applications don’t call for high starting torque which causes amp draw to spike.

Constant torque VFD’s are usually sold with heavy duty ratings so that they can supply elevated

startup amp draws for high starting torque applications.

Application:

Because while running a progressing cavity pump the torque value required by the pump

is fixed; any reduction in supplied torque as a result of operational speed could cause the pump

to fail. Also, depending on the running speed required, a constant HP VFD may not be capable

of supplying the torque needed for pump startup. This is the reason a Constant Torque VFD

MUST be used to operate a progressing cavity pump.

Brad LaValley / Dan Bachrach

NETZSCH Pumps North America, LLC

Exton, November 2011

N

E

M

O

P

U

M

P

E

N

N

E

M

O

P

U

M

P

E

N

TABLE OF CONTENTS PAGE

0.0

Date Name Signed Revision: 2

issued 26.09.95 Mangel Substitute for issue

approved 27.09.95 Eitler of 18.03.94

released 28.09.95 Hantschk text no. 30100

copy to: 95

Page

1 Safety Precautions 1.0

2 Description 2.0

3 Packing, Transportation, Storage 3.0

4 Installation Instructions 4.0

5 Start-up 5.0

6 Temporary Shutdown 6.0

7 Maintenance 7.0

8 Trouble-Shooting and Remedying 8.0

9 Dismantling and Assembly of the Pump Housing 9.0

10 Dismantling and Assembly of the Rotating Parts 10.0

11 Removal and Fitting of the Connecting Shaft 11.0

12 Dismantling and Assembly of the Shaft Sealing 12.0

13 Dismantling and Assembly of Special Units 13.0

14 Recommended Stock of Wear Parts 14.0

15 List of Spares and Sectional Drawing 15.0

16 List of After-Sales Service Centres 16.0

GB

Remark: Because of data transfer the text sheet printouts of our operating

instructions do not contain a personal signature.

Continued Page 1.0R

N

E

M

O

P

U

M

P

E

N

1 SAFETY PRECAUTIONS

Date Name Signed Revision: 6

issued 16.06.03 Mangel Substitute for issue

approved 17.06.03 Denk of 31.10.96

released 17.06.03 Denk text no. 30100

copy to: 95

PAGE

1.0

1 Safety Instructions

Thismanualcontainsbasicinstructionswhich

must be observed when installing, operating

and servicing the machine / equipment. It is

essential therefore for the user / installer or

responsible technician to read the manual

thoroughly prior to installation and opera-

tion.

Acopyofthemanualmustalwaysbeathand

wherethemachine/equipmentisbeingused.

In addition to the general safety instructions

listed in this main section on safety, it is

necessary to observe the special safety rules

included in other sections of the manual, eg.

for private use.

1.1 Safety Signs

The signs below are printed in the manual as

general hazard / danger symbols to mark

those safety instructions whose non-obser-

vance can result in danger to personnel or to

the machine / equipment. These signs are:

Hazard sign DIN 4844 - W9

Danger to general public

Hazard sign DIN 4844 - W8

Risk of electric shock

Risk of injury from machinery

Danger from suspended loads

Damage to machinery

Risk of injury to your eyes: goggles required.

GB

Continued Page 1.1

1 SAFETY PRECAUTIONS

PAGE

1.0R

Revision: 6 Date Name Signed

Substitute for issue issued 16.06.03 Mangel

of 07.10.96 approved 17.06.03 Denk

text no. 30100 released 17.06.03 Denk

copy to: 95

Warningplateslocateddirectlyonthepump/

equipment showing for example the correct

direction of rotation or the fluid connections

usedmust always be observed and kept com-

pletely legible.

1.2 Personnel Qualifications and

Training

Operating, maintenance, inspection and

installationstaffmustpossessthecorrectqua-

lifications for their work. Areas of responsi-

bility, scope of authority and staff supervi-

sion must be exactly defined by the user. If

personnel do not have the necessary know-

ledge they must receive due training and

instruction. If necessary, the user of the ma-

chine / equipment can arrange for such trai-

ning and instruction to be provided by the

manufacturer / supplier. The user must also

make sure that the content of the manual is

fully understood by the staff concerned.

Responsibilites

All work on and operation of the pump/

equipment should be carried out by trained/

competent and qualified operators, trades-

men and / or engineers as appropriate.

Any person responsible for or in charge of

–working with lifting gear and ropes when

moving a pump / equipment will have to be

duly instructed prior to doing the transpor-

tation job;

–mounting a drive to a pump / equipment

must be qualified / trained as an industrial

mechanic / technician;

–setting up installations into a plant mustbe

qualified / trained as an industrial mechanic/

technician and must be familiar with the

design and functioning of the plant in which

the pump / equipment is being installed;

–doing work on starting up, operation and

maintenance must gain knowledge of the

pump / equipment principle prior to perfor-

ming such works and must study the safety

instructions and the manual thoroughly;

–doing repair works,andpriortodoingsuch

works, must be trained and skilled in the job.

He must have due knowledge of the pump/

equipmentsspecificdetailssetupintherepair

instructions. Unskilled personnel must be

trained and repair works checked.

1.3 Dangers arising from Non-

Observance of the Safety

Instructions

Non-observanceofthesafetyinstructionscan

resultindangertopersonnelaswellastothe

environment and the machine. Non-obser-

vance of the safety instructions can result in

the loss of claims for compensation.

Non-observanceofthesafetyinstructionscan

have, for example, the following consequen-

ces:

▲Failure of essential functions of the

machine / equipment

▲Failure of mandatory maintenance

and servicing methods

GB

Continued Page 1.1R

N

E

M

O

P

U

M

P

E

N

1 SAFETY PRECAUTIONS PAGE

1.1

Date Name Signed Revision: 6

issued 16.06.03 Mangel Substitute for issue

approved 17.06.03 Denk of 07.10.96

released 17.06.03 Denk text no. 30100

copy to: 95

▲Danger to personnel from electricity,

machinery and chemicals

▲Danger to the environment from

leakage of hazardous substances.

1.4 Safety Conscious Working

In addition to the safety instructions listed in

the manual, it is essential to observe the

national accident prevention directives

currently in force and any of the users own

internal regulations concerning work and

safety.

1.5 Safety Instructions

for the User / Operator

▲If there is a risk of danger from any hot

or cold machine component, the user

must fit protective guards to prevent

such components from being touched

(according to Standard EN 563).

▲Protective guards fitted to prevent

contact with moving parts (eg.

couplings) must be in position when

the machine / equipment is in use.

▲Leakages (eg. from a shaft seal) of

hazardous materials (eg. explosive,

toxic, hot material) must be

discharged in such a way that

neither personnel nor the

environment are placed at risk.

Legal directives must be observed.

▲All possible danger from electricity must

be eliminated (for details see eg. the

regulations of your local power supply

company).

1.6 Safety Instructions for

Maintenance, Inspection

and Installation

The user must ensure that all maintenance,

inspectionandinstallationworkiscarriedout

by authorized and qualified personnel who

understand the operating instructions and

are adequately trained.

Work on a pump / equipment must only be

carried out with the machine stopped and

electricalpowersupplyturnedoff.Thepump/

equipment must not be under any pressure

and must have cooled off. All procedures

detailed in these operating instructions on

the stoppage of the machine must always be

adhered to.

Pumps / equipment which convey harmful

media must be decontaminated.

Immediately after the maintenance work is

finishedallsafetydevicesandguardsmustbe

re-installed and the safety trips must be

tested.

Before putting the machine back into opera-

tion the points detailed in section "Start-up"

should be observed.

GB

Continued Page 1.2

1 SAFETY PRECAUTIONS

PAGE

1.1R

Revision: 8 Date Name Signed

Substitute for issue issued 16.06.03 Mangel

of 07.10.96 approved 17.06.03 Denk

text no. 30100 released 17.06.03 Denk

copy to: 95

GB

1.7 Unauthorized Modifications and

Manufacture of Spares

Modificationsorchangestomachines/equip-

ment are only permissible with the manu-

facturer's agreement. Original spare parts

and accessories authorized by the manufac-

turer ensure safety.

Theuseofothercomponentsrevokesanylia-

bility for consequences which may result.

1.8 Improper Application

Deliveredmachinery/equipmentisonlygua-

ranteed safe for the use specified.

This machine / equipment was designed in

accordancewiththeprescribedconditionsof

use.

The limits of use are laid down in the con-

ditions of use and should in no way be ex-

ceeded.

1.9 Specific Points for the Use of a

NEMO®Pump

A NEMO®pump must be used for the

purpose only for which it was sold.

If you change or wish to change the process

medium, you must check with either the

supplier or manufacturer that the pump is

suitable for the new medium. This is espe-

ciallyimportantwithaggressive,poisonousor

otherwise hazardous substances.

Pump criteria include:

1. Compatibility with the medium

2. Suitability for seal design / material,

especially the shaft seal

3. Resistance to pressure and temperature

of the medium.

Please note that NEMO®pumps are pro-

gressing cavity pumps and as such can gene-

rate very high pressure.

A blockage or the chance closure of a valve

in the discharge line can cause a pressure rise

manifold as high as can be tolerated by the

installation. This can result in the bursting of

pipes, which must be avoided especially in

the case of dangerous media.

Corresponding safety equipment must

therefore be installed, for example an

emergency stop button, a pressure relief

valve with return pipe or a bursting disc.

During maintenance and repair work on the

pump please note the following:

1. Ensure that the pump drive can not

be turned on without authorization.

2. When opening the pump follow

the instructions for handling the

medium (eg. protective clothing,

no smoking etc).

3. Before putting the pump back into

operation ensure that all guards and

other safety devices (eg. drive–belt

protection, coupling protection) are

properly re–installed.

1 SAFETY PRECAUTIONS

Always bear in mind your safety during

operation, maintenance and installation

of equipment. Please adhere to the EC-

Directive for machinery including the

national regulations and follow the US

OSHA regulation #1910.219 & 1910.147

titled Mechanical Power transmission

apparatus as well as the European

Standard EN 292 with the accidents

prevention rules laid down by the trade

unions and other appropriate technical

institutions.

Continued Page 1.2R

N

E

M

O

P

U

M

P

E

N

1 SAFETY PRECAUTIONS

Date Name Signed Revision: 4

issued 16.06.03 Mangel Substitute for issue

approved 17.06.03 Denk of 07.10.96

released 17.06.03 Denk text no. 30100

copy to: 95

PAGE

1.2

GB

Always bear in mind your safety during

operation, maintenance and installation

of equipment. Please adhere to the

EC-Directive for Machinery including

the national regulations and follow the

European Standard EN 292 with the

accident prevention rules laid down by

the trade unions and other appropriate

technical institutions.

Continued Page 1.3

1 SAFETY PRECAUTIONS

PAGE

1.2R

Revision: 2 Date Name Signed

Substitute for issue issued 16.06.03 Mangel

of 27.03.97 approved 17.06.03 Denk

text no. 30100 released 17.06.03 Denk

copy to: 95

GB

1.10 Notes on Inspection and Repair

The legal regulations for safety at work,

such as regulations for the workplace, regu-

lations governing dangerous materials, acci-

dent prevention, environmental protection

eg. regulations on disposal and water

balance obligate all commercial business to

protect their employees and / or people and

the environment from adverse effects

caused by contact with dangerous

materials.

Important:

Inspection / repair of machinery and its parts

only takes place when a safety conformity

certificate has been completed by an

authorizedandqualifiedspecialist.Pleaseuse

a copy and leave the original in the operati-

on and maintenance manual.

Where special safety precautions are neces-

sary in spite of careful emptying and clea-

ning of the machinery, the necessary infor-

mation must be given.

Machineryoperatingwithradio-activemedia

will only be repaired or inspected by one of

our specialist engineers under the safety of

the owner.

The safety conformity certificate is part of

the inspection / repair service. We reserve

the right to refuse acceptance of this order /

service for other reasons.

Continued Page 1.3R

N

E

M

O

P

U

M

P

E

N

1 SAFETY PRECAUTIONS PAGE

1.3

Date Name Signed Revision: 2

issued 23.10.03 Mangel Substitute for issue

approved 24.10.03 Denk of 13.08.03

released 24.10.03 Denk text no. 30100

copy to: 95

1.11 Instructions concerning explosion protection

The instructions below are to be considered and kept to when using

pumps in potentially explosive areas in order to guarantee durable

explosion protection of the pumps and avoid any danger of ignition.

In accordance with the regulations 94 / 9 / EC, the pumps are admitted

for use in the area II 2G IIB T 4 or II 2G IIB T 3

(pls. see manufacturer’s declaration or declaration of conformity).

It is to be taken into account that in case of aggregates the components

(e.g. gears, couplings) mounted on the pumps must comply with the

regulations 94 /9 / EC as well. The relevant documentation concerning

these components is to be considered.

The application area of aggregates is determined by the application area

of the mounted component with the lowest approval and thus may

deviate from the allowed application area of the pump.

The maximum conveying product temperatures apply when mechanical

seals of Messrs. Burgmann with carbide – carbide and carbide – carbon

as sliding material combinations are used.

In the case of other manufacturers or other sliding material combinations

it is necessary to consult the manufacturer.

1. Assembly and repair in potentially explosive areas

When performing assembly and repair work, it is to be seen to it that

no dangers of ignition arise especially during heating up the pump parts.

This means e.g. heating up by explosion-proof heating devices or exclusively

in non-explosive areas. The temperature of the heated part and the ignition

temperature of the materials by which the danger of explosion may be

caused are to be considered.

2. Dry-running protection

Under no circumstances is the pump to run dry.

The pump is to be equipped with an appropriate dry-running protection

device.

GB

Temperature category Max. temperature of the conveying product

T 4 100 °C

T 3 165 °C

T 2 265 °C

T 1 415 °C

Continued Page 1.4

1 SAFETY PRECAUTIONS

PAGE

1.3R

Revision: 1 Date Name Signed

Substitute for issue issued 13.08.03 Mangel

of 17.06.03 approved 13.08.03 Denk

text no. 30100 released 13.08.03 Denk

copy to: 95

GB

The device for dry-running protection should be self-regulating.

This means that this device can give alarm signals and/or switch off the

pump also in case of failures in its own control system.

Dry-running protection concerning stationary immersion pumps

(with mounting plate)

Operation is only permitted with redundant or self-regulating automatic

devices to guarantee dry-running protection as well as to control the pump

capacity.

Dry-running protection concerning movable immersion pumps

(drum pumps)

The filling with liquid during the operation is to be ensured by specific

requirements of behavior:

– Drum pumps may only be introduced in and removed from

the container in switched-off condition

– Drum pumps, after being introduced in the container to be discharged,

may only be started after they have immerged in the fluid.

– Drum pumps are to be switched off before they run dry or are

to be switched off at once when specific noises ("slurping” or speed

rise) suggest that dry running may or will immediately occur.

3. Overpressure protection

The pump must not be loaded over the maximum allowable pressure.

The pump is to be equipped with an appropriate overpressure protection

device. The pump must not convey against a closed slide valve.

The overpressure protection device should be self-regulating.

4. Drives

The drives must be adjusted to the performance of each pump.

In the case of a blocking of the pump, the drives must be turned off

automatically by means of a motor protection unit.

5. Alignment of the drive

(concerning the pump types SY / SH / SA / SO / SF / SP)

It is absolutely necessary that the drive be aligned within the maximum

allowable tolerances. Incorrect alignment causes damage to the seals

and the shaft bearings.

6. Potential equalization concerning immersion pumps

The immersion pumps are to be integrated in the potential equalization

of the installation. Hand-operated movable immersion pumps are to be

grounded before being introduced in the container.

Continued Page 1.4R

N

E

M

O

P

U

M

P

E

N

1 SAFETY PRECAUTIONS PAGE

1.4

Date Name Signed Revision: 1

issued 12.08.03 Mangel Substitute for issue

approved 13.08.03 Denk of 17.06.03

released 13.08.03 Denk text no. 30100

copy to: 95

The connection to ground is to be maintained until the pump has been

completely pulled out of the container.

There must not be any potential difference between the pump and

a conductive container. This means that container and pump are to be

connected at a common grounding point and thus be conductively

connected with each other.

(see information brochure "Statische Elektrizität, Zündgefahren und

Schutzmaßnahmen" (Static electricity, dangers of ignition and preventive

measures); Publisher: "Internationale Sektion für die Verhütung von

Arbeitsunfällen und Berufskrankheiten in der chemischen Industrie der IVSS"

(International section for the prevention of employment accidents and

occupational diseases in the chemical industry of the ISSA (International Social

Security Association)) , Heidelberg 1995).

The hand-operated movable immersion pumps are to be provided with an

indication referring to the grounding measure (pay attention to grounding).

7. Potential equalization concerning all other pump types (no immersion pumps)

All conductive parts of the pump are to be integrated in the potential

equalization of the pumping set unless the conductive connection to

the ground potential is guaranteed by the drive or connecting shafts

or otherwise.

8. Stator

The stator is to be regularly checked for wear. When the allowable

wear limit is reached, the stator is to be replaced. Before exchanging

the conveying product, the pump operator has to consult the

manufacturer concerning the durability of the stator unless the stator

has already been confirmed for the intended application.

Inspection and maintenance interval of the stator:

– in the case of an operating time of > 16 h/day, at least twice a year

– in the case of an operating time of < 16 h/day, at least once a year.

9. Joints / joint lubrication

The sealing and the lubrication of the joints are to be regularly checked.

If necessary, the seals and the lubricants are to be replaced.

Inspection and maintenance interval of the joints:

– in the case of an operating time of > 16 h/day, at least twice a year

– in the case of an operating time of < 16 h/day, at least once a year.

10. Inspection after initial startup

The aspects relevant for ensuring the explosion protection (such as

lubrication and wear check) are to be checked six months after the

initial startup of the pump at the latest.

GB

Continued Page 1.5

1 SAFETY PRECAUTIONS

PAGE

1.4R

Revision: 1 Date Name Signed

Substitute for issue issued 23.10.03 Mangel

of 17.06.03 approved 24.10.03 Denk

text no. 30100 released 24.10.03 Denk

copy to: 95

GB

11. Shaft bearings

(concerning the pump types SY / SH / SA / SO / SF / SP)

Replacement of the bearings after 14,500 operating hours (according

to prEN 13463-5: replacement after 90 % of the designated service life).

12. Materials

Although being allowed as material for the pumps, aluminum should

be avoided in potentially explosive areas.

The pumps may only be used if, under the particular operating conditions,

the materials are resistant to mechanical and/or chemical influences or

corrosion such that the explosion protection will be maintained.

13. Noise development

(concerning the pump types SO / BO / SF / BF / SP / BP)

As soon as unusual noises (such as knocking or rubbing) are realized,

the pump is to be switched off. The cause of the failure is to be

eliminated before the pump is reoperated.

Regular check of the paddle equipment.

14. Direction of flow of immersion pumps

The direction of flow of immersion pumps always has to be from the end

connection piece to the pressure nozzle at the top. The reverse direction

of flow is not allowed.

15. Mechanical seal of immersion pumps

Before the initial startup and after a prolonged shutdown, the mechanical

seal is to be lubricated from outside before the pump is started. In this

connection, the compatibility of the lubricant with the sealing material

is to be considered.

16. Impurities in immersion pumps

Especially in the case of hand-operated movable immersion pumps it is

to be seen to it that no impurities can get into the pump. The pumps

are to be deposited only on clean and solid ground or else to be suspended.

In case of unusual noises or power losses, the immersion pumps are to be

switched off immediately.

17. Gland

If a gland packing is applied it has to be observed that the permitted

temperature corresponding to the temperature category is not exceeded.

Recommendation: fasten the screws of the stuffing box gland only

with low torque (approx. 5 Nm).

N

E

M

O

P

U

M

P

E

N

1 SAFETY PRECAUTIONS PAGE

1.5

Date Name Signed Revision: 4

issued 16.06.03 Mangel Substitute for issue

approved 17.06.03 Denk of 07.10.96

released 17.06.03 Denk text no. 30100

copy to: 95

Safety Conformity Certificate

The machinery and its accessories together with this safety conformity certificate relating

to repair / inspection services given to the undersigned by ourselves

Machine Type .......................................

Number .......................................

Delivery Date ....................................... Delivery Note No. .......................................

was carefully emptied and cleaned both inside and ■■ yes

out in preparation for shipment ■■ no

Special safety precautions with regard to health or ■■ necessary

media endangered by water are to be implemented ■■ unnecessary

The machinery is set up to transport materials dangerous

to health or water and came in contact with ■■ yes

media containing harmful substances ■■ no

The following safety precautions are necessary with regard to irrigation media,

overflow liquid and waste management:

.................................................................................................................................................

.................................................................................................................................................

We confirm that the above mentioned details are correct and complete and that

despatch will follow in accordance with the legal requirements:

Company Telephone .............................................

........................................................................... Fax .............................................

........................................................................... Telex .............................................

Address

...........................................................................

...........................................................................

Name ............................................................. Position .............................................

....................................... .............................................

Date Company Stamp / Signature

GB

N

E

M

O

P

U

M

P

E

N

Continued Page 2.0R

N

E

M

O

P

U

M

P

E

N

2 DESCRIPTION AND GENERAL DATA PAGE

2.0

Date Name Signed Revision: 2

issued 03.08.98 Mangel Substitute for issue

approved 04.08.98 Hantschk of 18.03.94

released 05.08.98 Hantschk text no. 30100

copy to: 95

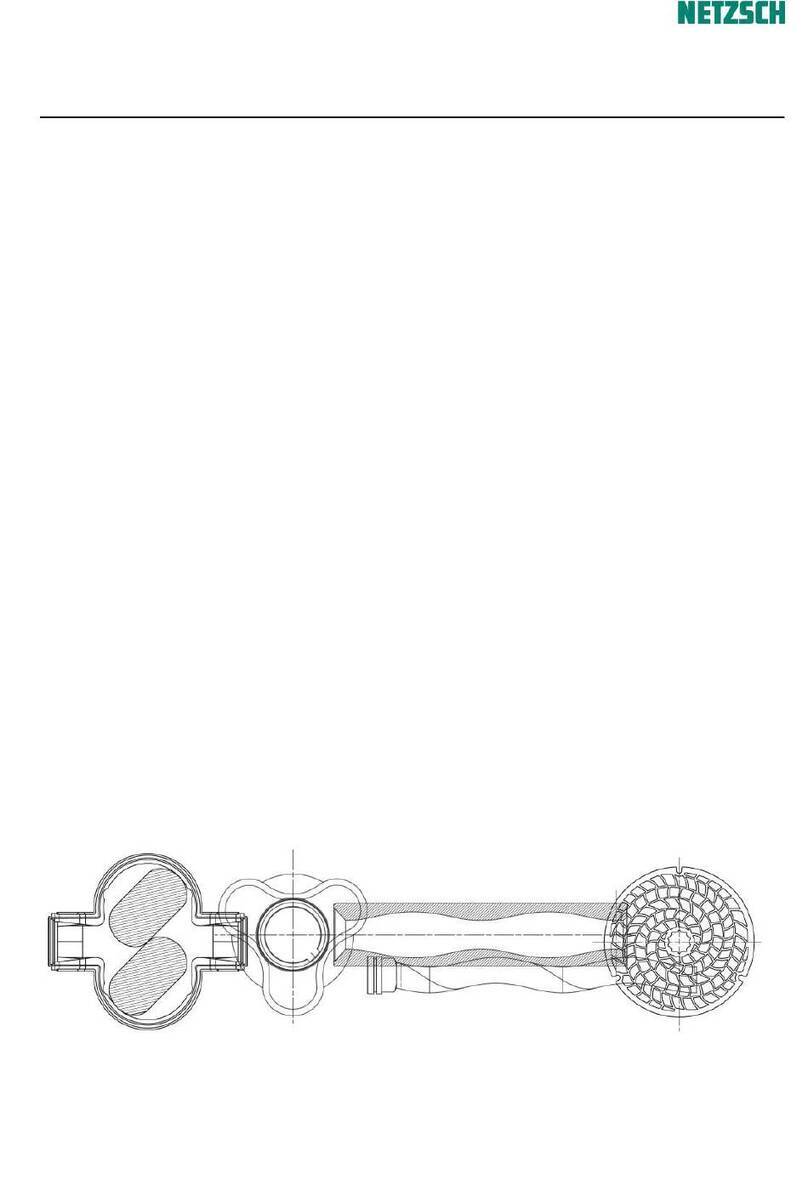

2 Description

The NEMO®pump is a progressing cavity

pump.

The main components which determine the

systemdiscoveredbyProfessorRenéMoineau

arearotatingpart,calledtherotorandasta-

tic part, called the stator.

The rotor is a helical screw with an extreme-

ly large pitch, large thread depth and small

centre diameter with round cross-section for

1/2-geometry and elliptical cross-section for

2/3-geometry. The stator has a two start or

resp. 3 start thread and is double or resp. 1.5

the pitch length of the rotor. This provides

spaceforthemediumbetweentherotorand

stator. When the rotor turns round inside the

stator the medium moves continuously from

the inlet to the outlet.

The universal NEMO®pump system unifies

many positive characteristics of other pump

types:

■Like centrifugal pumps NEMO®pumps

have no suction or pressure valves, but do

have a stable flow rate in proportion to the

number of revolutions.

■Like piston pumps NEMO®pumps have a

suction capability of up to 8.5 m vacuum

metric.

■Like membrane and peristaltic pumps the

NEMO®pump can transport every type of

inhomogenous,gaseousandabrasivemedia,

as well as those that are not of a liquid con-

sistencyorcontainsolidsand/orfibrousmate-

rial.

■Like gear pumps and screw pumps the

NEMO®pumpiscapableofcopingwithhigh

medium viscosities.

■Like piston, membrane, gear or screw

pumpstheNEMO®pumpcanperformdosing

operations.

Length and cross-sections through the rotor

and stator with 1/2-geometry during a

rotation.

0°/360°

90°

180°

270°

Rotor-

Stellun

g

STATOR

ROTOR

GB

Rotor

position

2 DESCRIPTION AND GENERAL DATA

PAGE

2.0R

Revision: 4 Date Name Signed

Substitute for issue issued 04.11.98 Mangel

of 05.08.98 approved 05.11.98 Denk

text no. 30100 released 06.11.98 Hantschk

copy to: 95

2.2 General Data

Noise emissions:

The maximum permitted noise emission level at a work place is 70 dB (A).

The noise level was measured in accordance with DIN Standard 45635-24-01-KL2

to assure that the pump does not exceed 70 dB (A).

Noises generated by the drive and pipes are not included in the above

emission value.

A prerequisite for the noise emission level of ≤70 dB (A) is that the pump

is operated in a cavity free regime and is bolted to a concrete base.

GB

Length and cross-sections through the stator with rotor

with reduced stator wall thickness

1/2-geometry

2/3-geometry

Date Name Signed Revision: 4

issued 23.06.98 Mangel Substitute for issue

approved 24.06.98 Denk of 07.12.94

released 25.06.98 Denk text no. 30100

copy to: 95

N

E

M

O

P

U

M

P

E

N

Continued Page 3.0R

N

E

M

O

P

U

M

P

E

N

3 PACKAGING, TRANSPORTATION, STORAGE PAGE

3.0

3 Packaging, Transportation, Storage

3.1 Packaging and Transportation

NEMO®pumps are shipped in railroad containers or crates

unless the customer specifies otherwise.

The packings are labelled and symbols give the handling instructions

in accordance with DIN 55402.

On receipt check for any transport damages.

Transport damages should be reported to the transporter immediately.

The pumps should be transported as closely as possible to the location

of installation and only there should they be uncrated.

Uncrated horizontal pumps should be lifted by using a shackle which

can be attached to the baseplate. The bolt holes of the frame or

the lifting lugs attached to the baseplate could be used as shown on

the installation drawing.

Vertical pumps should be lifted by using the bolt down holes,

lifting lugs or shackles attached to the baseplate. This is shown on

the installation drawing. For most applications, the drive is mounted

on top of the pump.

Be careful when lifting top heavy pumps. The centre of gravity may be

above the points where the lifting gear is attached to. If the case, secure

additionally against tipping over!

Vertical pumps should not be deposited unless they are secured vertically.

Hazards of tipping! Deposit only in horizontal position!

It is essential to avoid that the total pump unit be suspended with

eye bolts of the motor or gear box. These eye bolts should be used

for lifting the motor and/or the gear box only.

The Accident Prevention Rules, Section 18.4 relating to lifting accessories

for the lifting of loads (VBG 9a) must be strictly adhered to.

Because of the variety of possible pump designs and applications, only

general instructions can be given here. These should be good enough

for experienced assemblymen or transportation experts.

When in doubt, please ask for detailed information on the pump unit

concerned.

GB

3 PACKAGING, TRANSPORTATION, STORAGE

Continued Page 3.1

PAGE

3.0R

Revision: 4 Date Name Signed

Substitute for issue issued 23.06.98 Mangel

of 07.12.94 approved 24.06.98 Denk

text no. 30100 released 25.06.98 Denk

copy to: 95

When moving the pump or unit on wheels strictly attend to the following:

■Pad lock the motor drive and secure against unintended starting up.

■Move the pump unit carefully and slowly, especially where the ground is

uneven. Hazards of tipping!

■Ensure a stable position of the pump or unit at the operating/storage place

and secure it by actuating all clamping devices on all the wheels or rollers

against voluntary moving away.

■Where fitted loosely, carefully watch the pipe bends when pumping.

Power of repulsion!

■Where necessary, secure the pump unit additionally with support blocks.

3.2 Storage

The pumps are preserved for transport unless specified otherwise.

In cases of longer storage the pumps should be handled as follows

until installation:

■Stator:

If the pump is not to be used immediately, then the elastomer along

the contact line between rotor and stator may become permanently

distorted (compression-set). This will increase the break away torque.

Therefore, the stator should be removed and kept separately in a clean,

cool and dry environment.

Standard DIN 7716 summarizes detailed information on the storage

of rubber products, some of which is gathered here, and the following

notice applies to a storage for a period of up to six months.

General

Most of the rubber products may change their physical properties

under unfavourable conditions or if treated improperly, which will

result in a shorter lifetime.

Or they may become useless through excessive hardening, aging,

regenerating or permanent deformation, also because of blistering,

cracking or other damages appearing on the surfaces.

The changes may occur under the influence of oxygen, ozone, heat,

light, humidity, solvents or because of storing the products under

tension.

If stored and treated properly, the rubber products will keep their

properties, even over a long period of time (some years), almost

unchanged.

This does, however, not apply to uncured rubber compounds.

GB

Table of contents

Other NETZSCH Water Pump manuals

Popular Water Pump manuals by other brands

Clarke

Clarke GSE1 Operation & maintenance instructions

FILL-RITE

FILL-RITE FR100 Series Installation and operation manual

FLOJET

FLOJET quad II diaphragm 4125 series user guide

CVS

CVS 50-14-DMV instruction manual

Glentronics

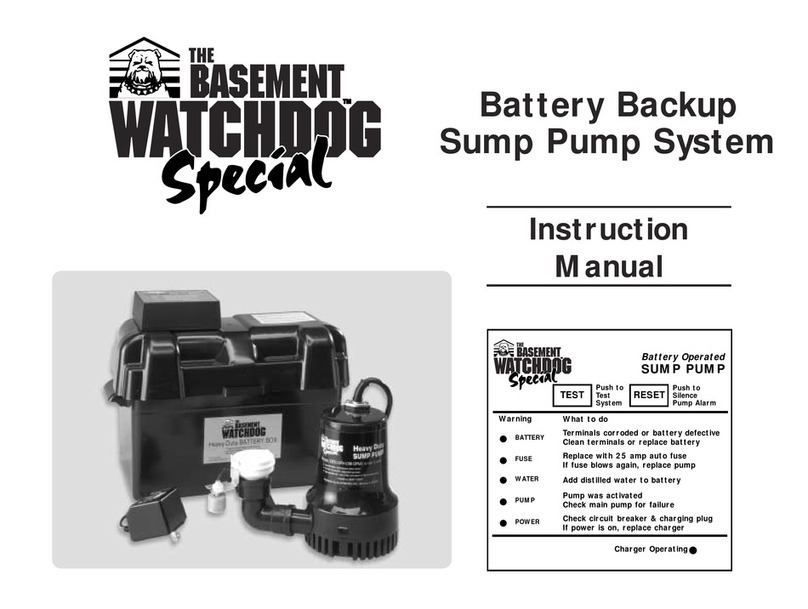

Glentronics The Basement Watchdog Special instruction manual

Wilo

Wilo TWI 5 Installation and operating instructions

Flotec

Flotec Vort 130/5 Auto Use and maintenance manual

Grundfos

Grundfos MAGNA3 25-100 (N) instructions

VERDER

VERDER VERDERFLEX Dura 55 Series operating manual

Euromatic

Euromatic SPC 250 operating instructions

Franklin Electric

Franklin Electric Inline 1100 Installation and operation manual

Liberty Pumps

Liberty Pumps LEH Series installation manual