17

1. Remove Safety Relief Valve using extreme care

to avoid damaging it.

2. Partiallyllboilerandaddcausticsodaor

trisodium phosphate. Add an appropriate amount

of recommended boil out compound.

3. Replace Safety Relief Valve.

4. Fill the entire system with water.

5. Startringtheboiler.

6. Circulate the water through the entire system.

7. Vent the system, including the radiation.

8. Allow boiler water to reach operating

temperature, if possible.

9. Continue to Circulate the water for a few hours.

10. Stopringtheboiler.

11. Drain the system in a manner and to a location

that hot water can be discharged with safety.

12. Remove plugs from all available returns and

wash the water side of the boiler as thoroughly

as possible, using a high-pressure water stream.

13. Rellthesystemwithfreshwater.

C. Add appropriate boiler water treatment compounds

asrecommendedbyyourqualiedwatertreatment

company.

D. Make pH or Alkalinity Test.

After boiler and system have been cleaned and

relledaspreviouslydescribed,testthepHofthe

water in the system. This can easily be done by

drawing a small sample of boiler water and testing

with hydrion paper which is used in the same

manneraslitmuspaper,exceptitgivesspecic

readings. A color chart on the side of the small

hydrion dispenser gives the reading pH. Hydrion

paper is inexpensive and obtainable from any

chemical supply house or thru your local druggist.

The pH should be higher than 7 but lower than

11. Add appropriate water treatment chemicals,

ifnecessary,tobringthepHwithinthespecied

range. With this lower level of protection, care must

be exercised to eliminate all of the free oxygen in

the system.

E. Boiler is now ready to be put into service.

TNATROPMI

SITI,NOITAREPOLAMRONGNIRUD,FI

EROMRETAWDDAOTYRASSECEN

,HTNOMAECNONAHTYLTNEUQERF

ECIVRESDEIFILAUQATLUSNOC

METSYSRUOYKCEHCOTNAICINHCET

.SKAELROF

A leaky system will increase the volume of make-up

watersuppliedtotheboilerwhichcansignicantly

shorten the life of the boiler. Entrained in make-up

water are dissolved minerals and oxygen. When the

fresh, cool make-up water is heated in the boiler the

minerals fall out as sediment and the oxygen escapes

as a gas. Both can result in reduced boiler life. The

accumulation of sediment can eventually isolate

the water from contacting the steel. When this

happens the steel in that area gets extremely hot and

eventually cracks. The presence of free oxygen in

the boiler creates a corrosive atmosphere which, if

the concentration becomes high enough, can corrode

the steel through from the inside. Since neither of

these failure types are the result of a manufacturing

defect the warranty does not apply. Clearly it is

in everyone’s best interest to prevent this type of

failure. The maintenance of system integrity is the

best method to achieve this.

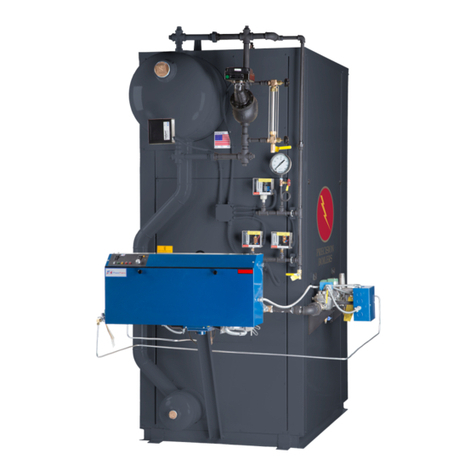

14. HINTS ON COMBUSTION

A. NOZZLES — Although the nozzle is a relatively

inexpensive device, its function is critical to the

successful operation of the oil burner. The selection

of the nozzle supplied with the microTEK3 boiler

is the result of extensive testing to obtain the best

ameshapeandefcientcombustion.Otherbrands

of the same spray angle and spray pattern may be

used but may not perform at the expected level of

CO2and smoke. Nozzles are delicate and should be

protected from dirt and abuse. Nozzles are mass-

produced and can vary from sample to sample. For

all of those reasons a spare nozzle is a desirable item

for a serviceman to have.

B. FLAME SHAPE — Looking into the combustion

chamberthroughtheameplughole,theame

should appear straight with no sparklers rolling up

towardthetopofthechamber.Iftheamedragsto

the right or left, sends sparklers upward or makes

wet spots on the rear door insulation piece, the

nozzle should be replaced. If the condition persists

look for fuel leaks, air leaks, water or dirt in the fuel

as described below.

C. FUEL LEAKS — Any fuel leak between the

pump and the nozzle will be detrimental to good

combustion results. Look for wet surfaces in the

air tube, under the transformer, and around the air

inlet. Any such leaks should be repaired as they may

cause erratic burning of the fuel and in the extreme

casemaybecomearehazard.

D. AIR LEAKS — Any such leaks should be repaired,

as they may cause erratic burning of the fuel and in

extremecasesmaybecomearehazard.

There are many possible causes of air leaks in oil

lines such as:

1. Fittingleaksduetomis-aredtubingor

damagedtting.

2. Fuel line leak due to crushed or bent

tubing.