4FORM NO. L-20230-E-1107

INTRODUCTION

Read this manual carefully, making full use of its explanations and instructions. The “Know How” of safe, continuous,

trouble-free operation depends on the degree of your understanding of the system and your willingness to keep all

components in proper operating condition. Pay particular attention to all NOTES, CAUTIONS, and WARNINGS to

avoid the risk of personal injury or property damage. It is important to understand that these NOTES, CAUTIONS, and

WARNINGS are not exhaustive. Nexen cannot possibly know or evaluate all conceivable methods in which service may

be performed, or the possible hazardous consequences of each method. Accordingly, anyone who uses a procedure

that is not recommended by Nexen must first satisfy themselves that neither their safety or the safety of the product will

be jeopardized by the service method selected.

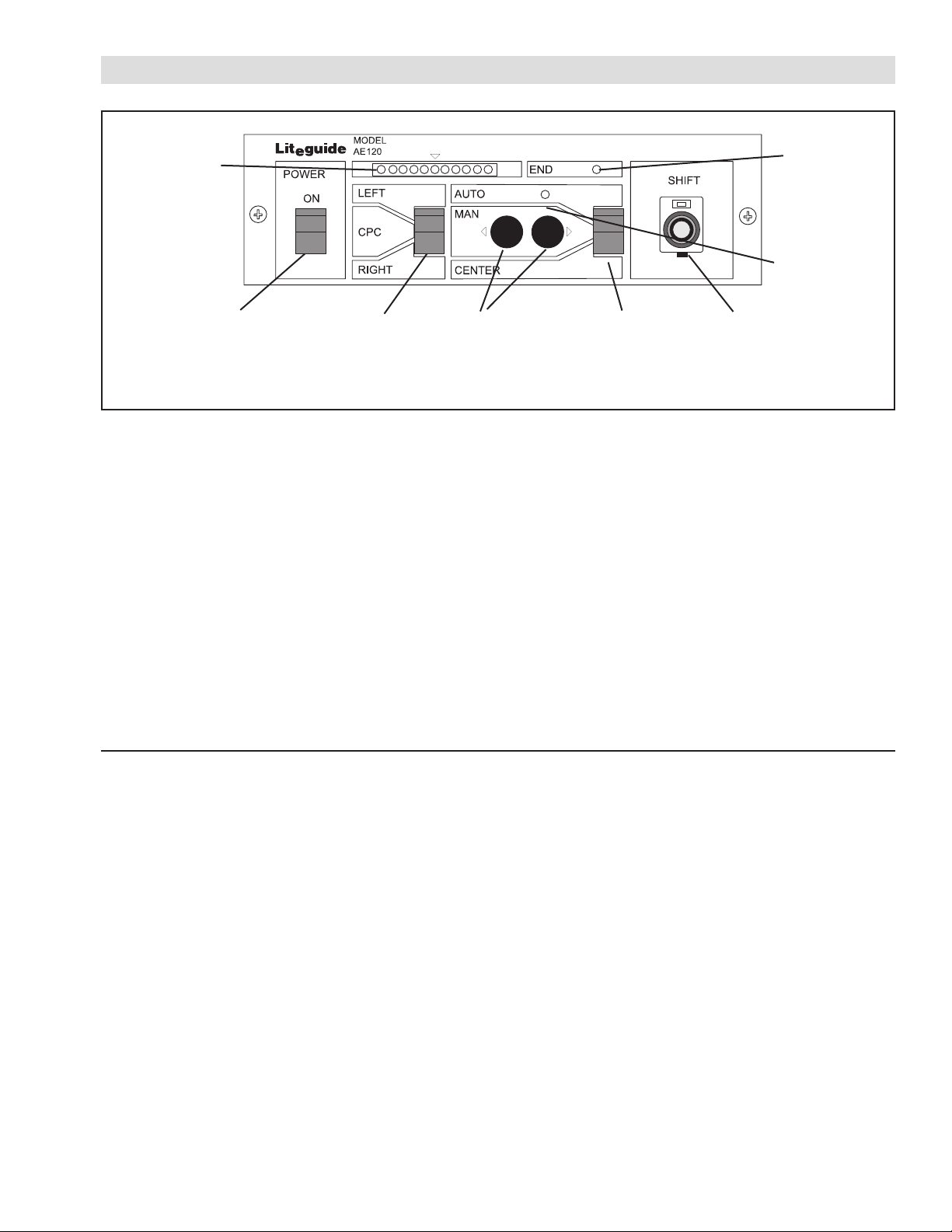

Print Drum

or Cylinder

Sensor

FIGURE 2

Center Position Control (CPC)

To maintain the centerline of the web

coincident with machine centerline: A=B

FIGURE 1

Edge Position Control (EPC)

To print 1" from web edge:

Align centerline of sensor 1"

outside of printed impression.

Nexen’s AE120 electronic amplifier and controller

receives web edge input signals from web guide sensors

and puts out a signal to correct the Web position within

the machine.

Edge position signals can be provided by an opaque

edge sensor (PH16 and PH46) or ultra sonic sensors

(UH21 and UH01) for transparent edges. Both types of

sensors can be mounted to control one side of the web

or Edge Position Control (EPC). Two sensors of either

type can be placed on either side of the webs to provide

Center Position Control (CPC).

With EPC, a single sensor is mounted on one side of the

web, with its measuring center aligned with the desired

position of the web edge. The primary purpose for EPC

is to maintain the edge of the web at the measuring

center of the sensor (See Figure 1).

With CPC, two sensors are mounted equally spaced

from the centerline of the machine. The primary purpose

of CPC is to maintain alignment of the web to the center

of the machine (See Figure 2).

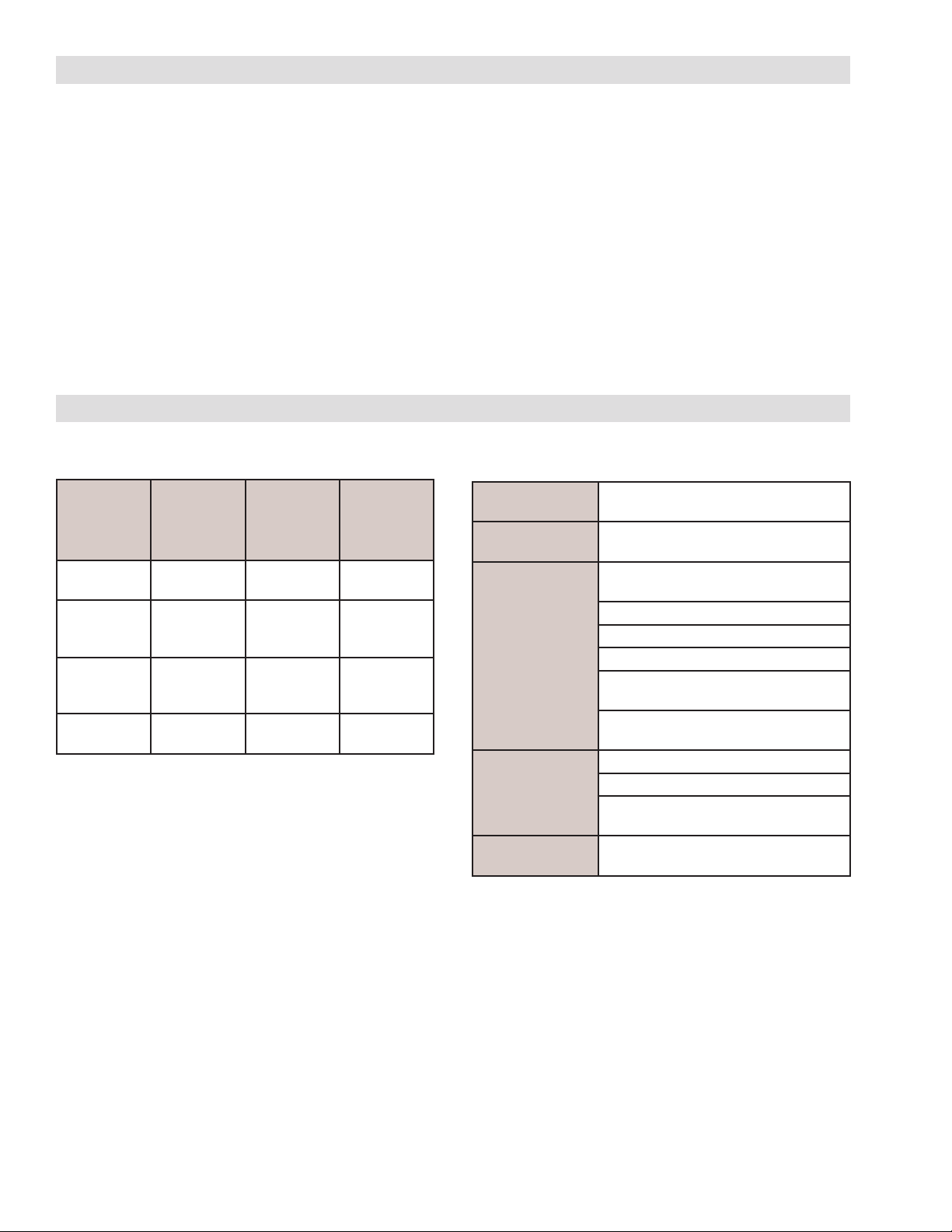

Nexen’s AE120 can also receive inputs from several

sources:

• An Automatic Centering Sensor can be attached to

guide roll assemblies or moveable roll stands.

Nexen’s AE120 uses a Proximity Sensor (Product

No. 912696) mounted to show the mechanical

device is at its center of travel or neutral position.

• A customer supplied 10K ohm Remote Fine

Adjustment Pot can be installed to allow remote fine

adjustment of the web position.

• A Remote Controller, model RP10 (Product No.

912695) can be connected to allow remote control

with a Fine Adjustment Pot, Mode Switch, and

Manual Control Switches.

• A customer supplied switch rated at 15VDC,

250 mA, can be used as a Lock Out Switch to

momentarily disable automatic correction.

The AE120 may be used with Travel Limit Switches.

These are not required for proper functioning of the

AE120 as it is equipped with an over current protection

circuit. In installations where the guide roll design or

moveable roll stand design requires limit switches, the

Travel Limit Switches can be used to interrupt output to

the actuator motor.

The AE120 output is a bipolar, 24VDC signal, rated

at 1.2 Amp. The output of a freestanding AE120 can

be applied to a linear or rotary actuator to control web

position with a web guide assembly or a moveable roll

stand.

Nexen’s AE120 also provides the excitation voltage for

the following sensors: PH16, PH46, UH21, or UH01.

An End of Travel Alarm is also available as both a front

panel warning light and a N. O. relay contact. The End

of Travel Alarm is given when the guide roll assembly or

moveable roll stand has moved to the end of its travel

limits and could not bring the web back into correct

alignment or when the optional Travel Limit Switches are

actuated.

Process