Nexsys 12NXS26 User manual

Purchaser

Battery Part Number

Battery Type

Battery Serial Number

Date Supplied

Despatch Voltage

Vehicle Model

Customer Spec Number

Customer Fleet / Truck Number

Instruction Manual

Block & Traction batteries

NexSys®series batteries : Valve regulated lead acid (VRLA) , Thin Plate Pure Lead (TPPL) technology

1. Nominal capacity C5 : See Battery plate / decal

2. Nominal voltage : See Battery plate / decal

3. Discharge current : C5/5h

4. Rated temperature : 30°C

The NexSys®battery series are valve-regulated lead-acid with Thin Plate Pure Lead technology, available in both

traction and block types. Unlike conventional batteries with liquid electrolyte NexSys batteries have immobilised

electrolyte. Instead of a vent plug, a valve is used to regulate the internal gas pressure, preventing the ingress of

oxygen from the air and allowing the escape of excess charging gases should an overcharged condition occur.

When operating valve-regulated lead-acid batteries the same safety requirements as for vented batteries apply to

protect against hazards from electric current, from explosion of electrolytic gas and with some limitations - from the

corrosive electrolyte.

Battery valves should never be removed. These batteries do not require topping up with distilled or de-mineralised

water. EnerSys® approved fasteners and exible connectors must be used for all connections.

Ignoring the operating instructions, repair with non-original parts and disconnection of the Wi-IQ®or LVA controller ,

where tted, will render the warranty void. All failures, malfunctions or defaults of the battery, the charger or any other

accessories, must be notied to our Service department immediately.

Rating Data

Pay attention to the operating instructions

and keep them close to the battery.

Work on batteries should be carried out by

skilled personnel only

Use protective glasses, clothes and

footwear when working on batteries.

Pay attention to local accident prevention

rules or DIN EN50272-3 / IEC 62485_3

DIN EN50110-1 & AS/NZ1 337

No smoking!

Do not expose batteries to naked ame,

glowing embers or sparks, as it may cause

the battery to explode

Avoid sparks from cables or electrical

apparatus and electrostatic discharges.

Acid splashes into the eyes or on the skin

must be washed immediately with plenty of

clean water. After ushing, consult a doctor

immediately

Clothing contaminated by acid should be

washed in water

Do not remove the vent caps

Electrolyte is highly corrosive

In normal operation of this battery, contact

with acid is not possible. If the cell containers

are damaged, the immobilised electrolyte

(absorbed in the separator) is corrosive like

liquid electrolyte

Risk of explosion and re

Always use insulated tools. Metal parts of

battery are always live. Do not place tools

or other metal objects such as jewelry on

top of the battery!

Dangerous electrical voltage!

Avoid short circuits

NexSys batteries are capable of high short

circuit currents

Batteries are heavy!

Ensure a secure installation and use only

suitable lifting equipment

Lifting hooks must not damage battery,

connectors or cables

Do not place batteries in direct sunlight

without protection

Discharged batteries can freeze - always

store in a frost free zone

Pay attention to the environmental hazards

that can be caused by the wrong disposal

of batteries

Dispose of batteries correctly according to

the relevant local rules

Safety Precautions

NexSys®batteries are supplied in a fully charged

condition. The battery should be inspected to ensure it is

in perfect physical condition prior to placing into service.

The battery cables must have good contact to terminals,

check that the polarity is correct otherwise battery, vehicle

or charger could be damaged.

Never directly connect an electrical appliance (for

example a warning beacon) to a part of the battery. This

could lead to an imbalance of the cells during recharge

with loss of capacity, risk of insufcient charge time and

damage to cells, effecting battery life and VOIDING THE

WARRANTY.

Charge the battery (see point 4.0) before use and in the

case of NexSys blocks, only blocks with the same state

of charge should be connected together.

The specied torque loading for the bolts of the cables

and connectors for both NexSys blocks and traction

batteries are detailed below.

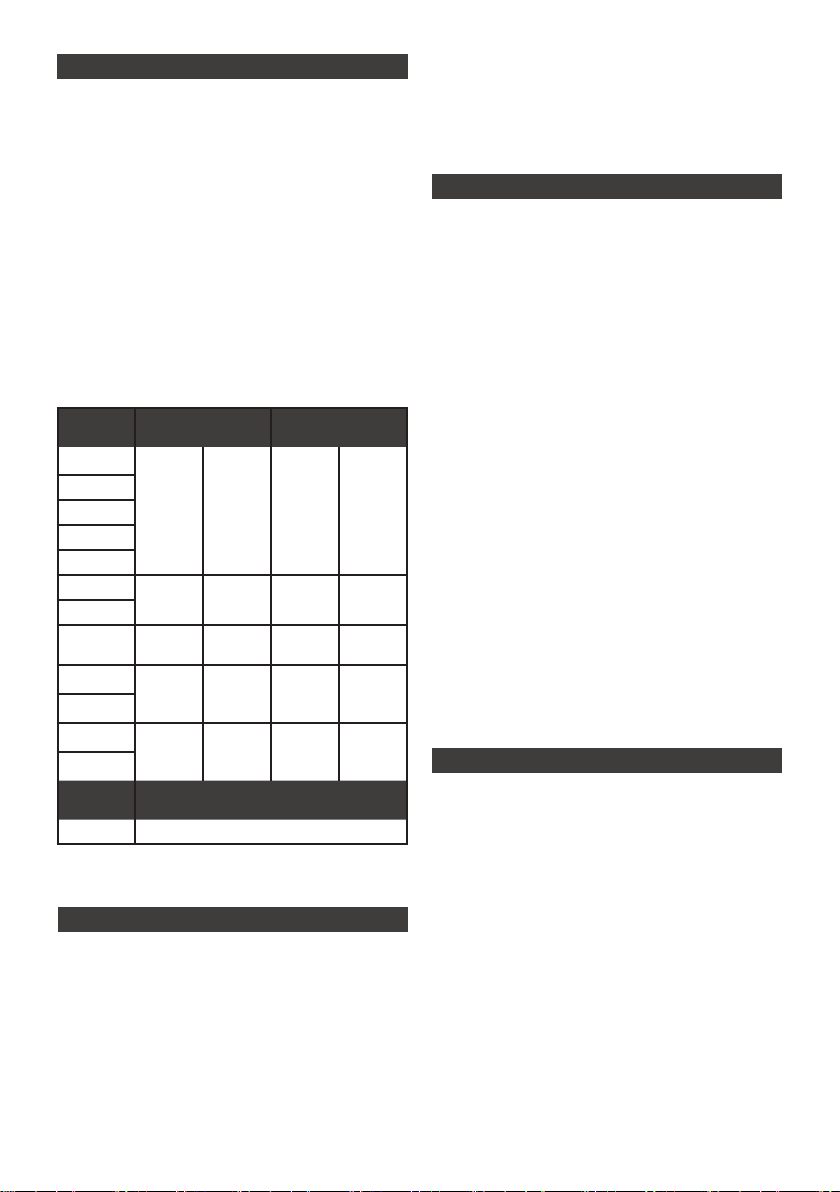

Block

Battery

Terminal Torque

Standard Terminal

Terminal Torque

Terminal Adaptor

12NXS26

M6

Female 6.8 Nm SAE 6.8 Nm

12NXS36

12NXS38

12NXS90

12NXS120

12NXS61 M8

Female 9.0 Nm NA NA

12NXS85

12NXS86 3/8 - 16”

Female 6.8 Nm SAE 6.8 Nm

12NXS137 M6

Female 9.0 Nm

M6 Male

Front

Terminal

9.0 Nm

12NXS157

12NXS158 M8

Female 9.0 Nm

M6 Male

Front

Terminal

9.0 Nm

12NXS177

Traction

Battery Terminal Torque (all connector and cable)

All Cells 25Nm +/- 2

Use special coding systems (colour plug etc) for NexSys

batteries on the charging plug and socket devices to

prevent accidental connection to a wrong type of charger.

DIN EN50272-3 / IEC 62485_3 and AS2402.2.2-2005

AS2359.2-1985 Part 2.7 apply to the operation of sealed

VRLA traction batteries and battery electric industrial

trucks in general.

The optimum life of the battery depends on the operating

conditions (temperature and depth of discharge).

The ambient temperature range of use is 5°C to 45°C for

traction batteries and 0°C to 40°C for the blocks. Any use

outside of this range must be approved by the EnerSys®

technical department.

Optimal battery life is obtained with a battery temperature

of 15-35°C.

Higher temperatures shorten the life of the battery

(according to IEC1431), lower temperatures reduce the

available capacity which falls considerably under 0°C.

The battery obtains its full capacity after about 3 charging

and discharging cycles.

The cycle life of the NexSys block and traction battery will

be maximized if the batteries are shallow discharged and

recharged as often as practicable. Depths of Discharge

(DOD) to 40% of rated C5 capacity are the optimum level,

followed by a recharge.

NexSys batteries are ideally suited to opportunity charging

and can operate in a Partial State of Charge (PSOC)

condition without any adverse effect on performance or

service life. The cycle life of the battery is dependent on

the Depth of Discharge (DOD). The higher the DOD, the

shorter the cycle life. Always limit the discharge to

a maximum of 80% DOD. Discharges over 80% are

categorized as deep discharges and are not allowed

as they will considerably reduce the life expectancy

of the battery or cause permanant damage.

The presence of a discharge limiter on the vehicle is

imperative. The following voltage cut-off settings must

be used.

(When discharged with currents in the range of I1 to I5)

60% DOD set at 1.96 Volts per cell.

80% DOD set at 1.92 Volts per cell.

For batteries tted with an LVA, the customer must

observe the visual and audible warning signals that the

battery has reached the required discharge levels and

must be recharged immediately.

Safety when discharging -

The valves on top of the battery must not be removed,

sealed or covered. Electrical connections (e.g. plugs)

must only be connected or disconnected in the open

circuit condition. Discharged batteries MUST be

recharged immediately and MUST not be left in a

discharged condition. Discharged batteries can freeze.

NexSys batteries MUST be charged using an approved

NexSys charger. Failure to do so will affect the

performance and life of the battery and void any warranty.

The specic charging prole developed for NexSys

blocks (NXBLOC) will allow rapid recharge in 3 to

6 hours from 60% DOD at charge rates 0.2 to 0.7 C5

with opportunity charging as often as needed without

damaging the batteries - see technical manual.

The NexSys traction battery series are available for both

Standard duty and Heavy duty applications.

In Standard duty applications the charger has NXSTND

prole at a charge rate of 0.20 C5, and should recharge

the battery in less than 6 hours from 60% depth with

opportunity charging allowed (up to 20% extra energy

reintegrated in 1 hour).

In Heavy Duty applications the charger has NXFAST

prole at charge rates 0.25 to 0.40 which allows fast

recharge in 3.5 to 4 hours at 60% DOD with opportunity

charging allowed up to 80% extra energy reintegrated

(40% in 1h).

1. Commissioning Battery

2. Operation

3. Discharging

4. Charging

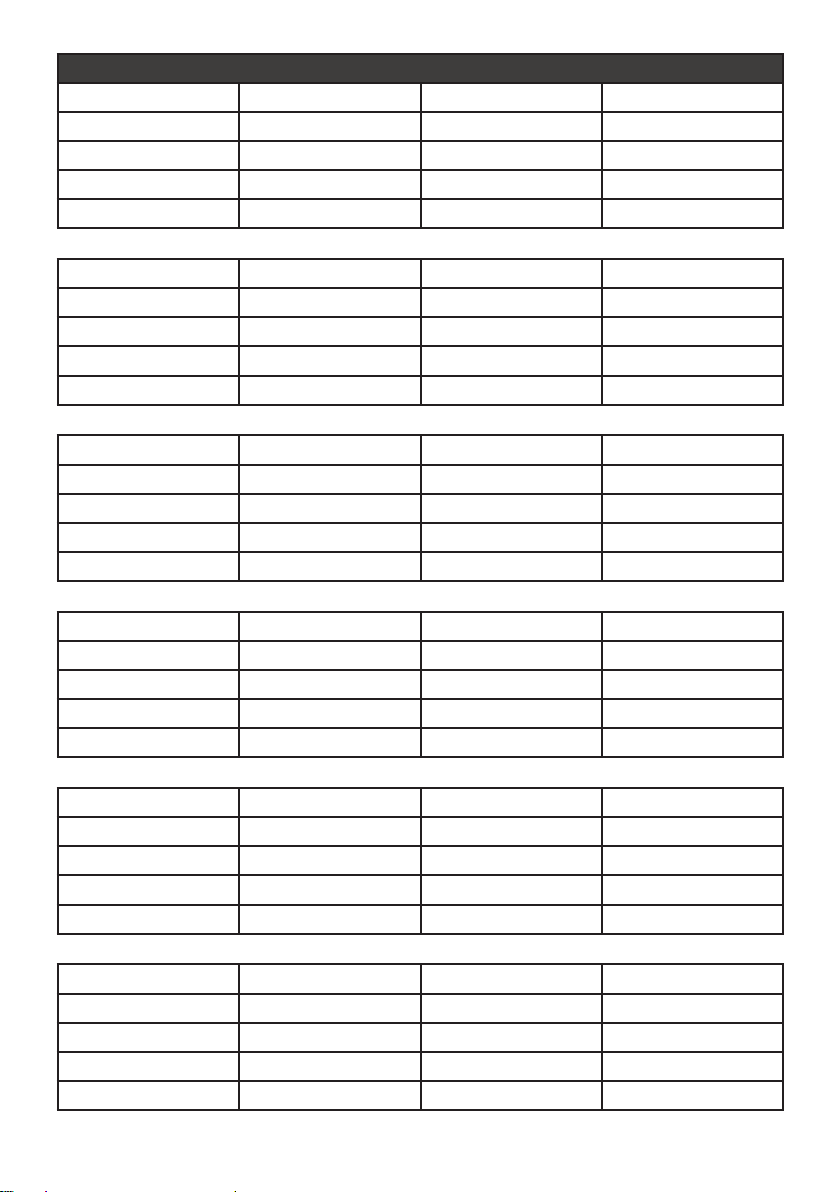

Charge

rate

C5

80%

DOD

> Full

charge

60%

DOD

> Full

charge

40%

SOC

> 80%

SOC

40%

SOC

> 98%

SOC

Traction Battery

0.4 4.2 3.4 1.2 2.0

0.32 5.0 4.0 1.5 3.4

0.2 7.4 5.8 2.4 4.0

Block Battery

0.7 2.8 2.37 0.7 0.9

0.5 3.6 2.9 1.0 1.5

0.2 7.4 5.8 2.4 4.0

Table above shows estimated charge times based on %

DOD. Times may vary.

It is important that the battery receives a complete

charge (returning battery to 100% of its rated

capacity) at least once per week.

NexSys®batteries have an extremely low gas emission,

however provision must be made for the venting of

charging gases should any error in charging occur.

For safety purposes when calculating gas emission

levels, use 1.5A / 100AhC5.

Doors, battery container lids and the covers of battery

compartment must be opened or removed.

With the charger switched off, connect the battery

to the charger, ensuring that the polarity is correct.

(Positive to Positive, Negative to Negative).

Now switch the charger ON.

Always switch the charger OFF before disconnecting

the battery.

NexSys chargers include specic automatic features

embedded in the prole to ensure that the battery

remains fully charged and balanced.

The electrolyte is immobilised, therefore the density of the

electrolyte cannot be measured. Never rell with water!

Never remove the safety valves from the blocks or cells.

The battery should always be kept clean and dry to

prevent current leakage. Damage to the coating of the

tray should be repaired after cleaning, to ensure a good

insulation and to prevent tray corrosion.

If any service is required or any damage has occurred to

any component of the system, please contact our Service

Department without delay.

Recharge the battery after every discharge.

Check the condition of the plugs, cables and that all

insulation covers are in place and in good condition.

Visually inspect for signs of dirt and mechanical damage

to all components of the battery, paying particular

attention to the battery charging plugs and cables.

Ensure that the battery receives a full charge each week.

At the end of the charge, carry out end of charge voltage

readings, measure and record the voltage of the complete

battery and the voltages of the individual blocks or cells.

If signicant changes from earlier measures or differences

between the blocks or cells are found, please contact our

Service Department.

If the discharge time of the battery is not sufcient,

• Check that the required work load and pattern is

compatible with the battery capacity.

• The capacity and settings of the charger are correct and

sufcient charge time is being applied.

• The vehicle discharge limiter settings are correct.

Remove dust from inside the charger.

Test all electrical connections of battery and charger

(sockets, cables, and contacts).

Check the torque loading of all the bolts and screws on

the batteries.

Check the insulation resistance of the truck and battery

in accordance with DIN EN 1175-1, DIN EN 1987 part 1.

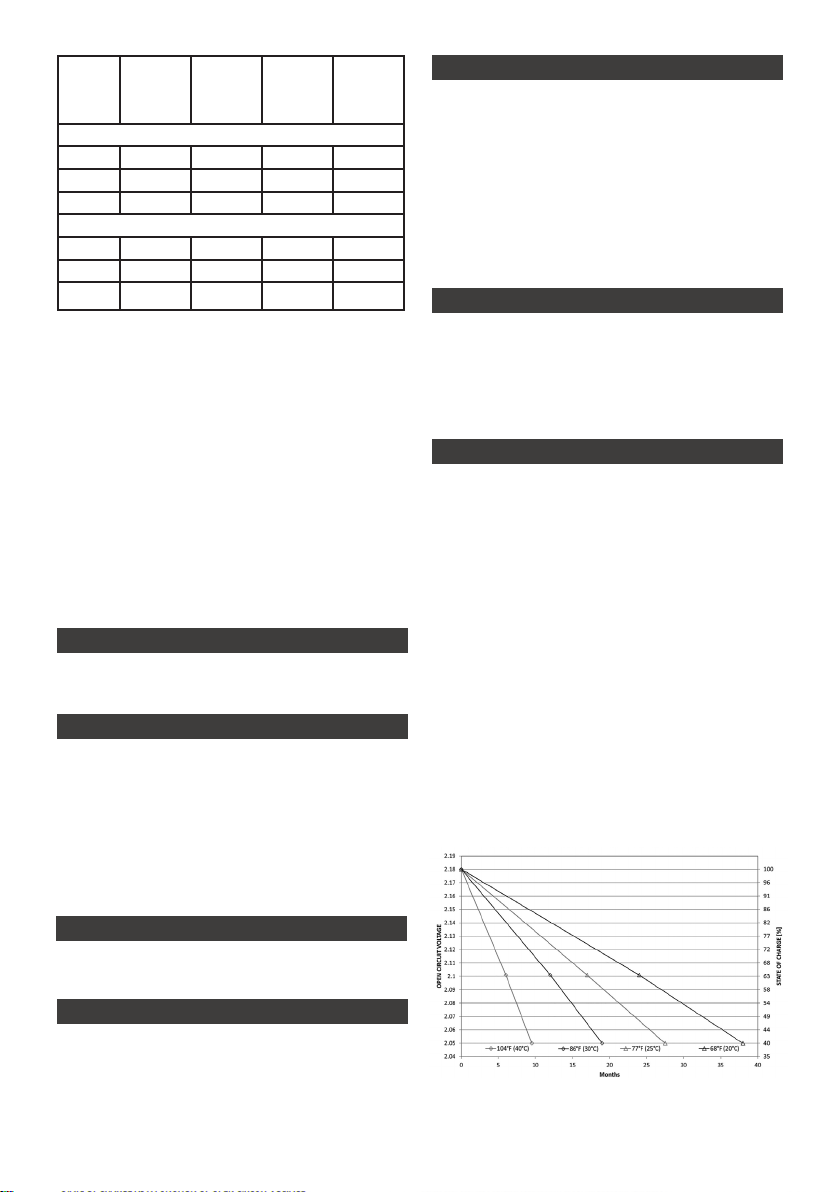

Batteries are dispatched from the manufacturer in a fully

charged condition. The state of charge will decrease with

storage when allowed to stand due to chemical reaction

or parasitic standing loads. The rate of self-discharge

is non-linear and decreases with decreasing state of

charge. It is also strongly inuenced by temperature.

High temperatures greatly reduce storage life.

It is recommended that the battery be stored in a fully

charged condition in a cool dry place, ideally below 20°C,

with no parasitic standing loads and unplugged from the

truck.

If the truck or battery is going to be decommissioned for a

period of 1 month or longer, disconnect battery from truck

and professionally disconnect all electronic devices (such

as the Wi-IQ®, LVA™).

Contact our Service Department for assistance.

It is advisable to conduct regular inspections of the Open

Circuit Voltage (o.c.v) and recharge if the o.c.v is less

than 2.10 Volts per cell.

The graph below shows the relationship between

temperature storage time and o.c.v. when not installed

in vehicle.

6. Maintenance

6.1 Daily Maintenance

6.2 Weekly Maintenance

6.3 Quarterly Maintenance

6.4 Annual Maintenance

7. Storage

5. Equalise Charging

If malfunctions are found on the battery or the charger, our Service Department should be called without delay. The

measurements taken in point 6.3 will facilitate fault nding and their elimination.

A service contract with us makes it easier to detect and correct faults in good time.

NexSys®batteries are lead acid and are therefore very recyclable. Scrap batteries must be packaged and transported

in accordance with local transportation regulations and disposed of in compliance with local and national laws by

a licensed recycler.

NexSys batteries could be tted with both the Wi-IQ® and LVA™battery monitoring devices.

The Wi-IQ device provides visual warnings to the operator on the current status of the battery. Refer to table below.

The Wi-IQ also measures current and Ah throughput. The information is stored in memory and can be transferred to a

computer via the Wi-IQ Reporting Suite software.

The Low Voltage Alarm (LVA) device alerts the user that the battery requires recharge. By analyzing the battery

voltage during operation and storage the LVA emits a visible and audible signal to alert the user of the impending and

immediate need to recharge the battery.

8. Malfunction

9. Disposal

10. On Board Electronic systems

LVA™(Low Voltage Alarm) - Default settings

Custom SOC warning setting available

Description Comment Stop

LED

Slow

ashing

green

Normal

Operation

LED

Fast

ashing

green

Normal

Operation

Battery on

charge

LED

Flashing

green

0.2s ON

5s OFF

Normal

Operation

Battery on

discharge

LED Flashing

Red

SOC

less than 40%

Needs to be

recharged

Recharge

battery

V >2.08

vpc

Buzzer

Beep

3 times

every

5 minutes

SOC

less than 40%

Needs to be

recharged

Recharge

battery

V >2.08

vpc

Buzzer

Beep

1 time

every

5 seconds

SOC

less than 20%

Needs to be

recharged

Recharge

battery

V >2.08

vpc

Wi-IQ®

Description Comment

Tri

Colour

LED

Flashing

green Hardware OK

Fast ashing

blue Wireless ID

Flashing

red

Temp

Warning

Over 55°C

Blue

LED

Fast

ashing Wireless ID

Slow

ashing

Voltage

Balance

warning

Tricolour LED

Blue LED

BuzzerLED

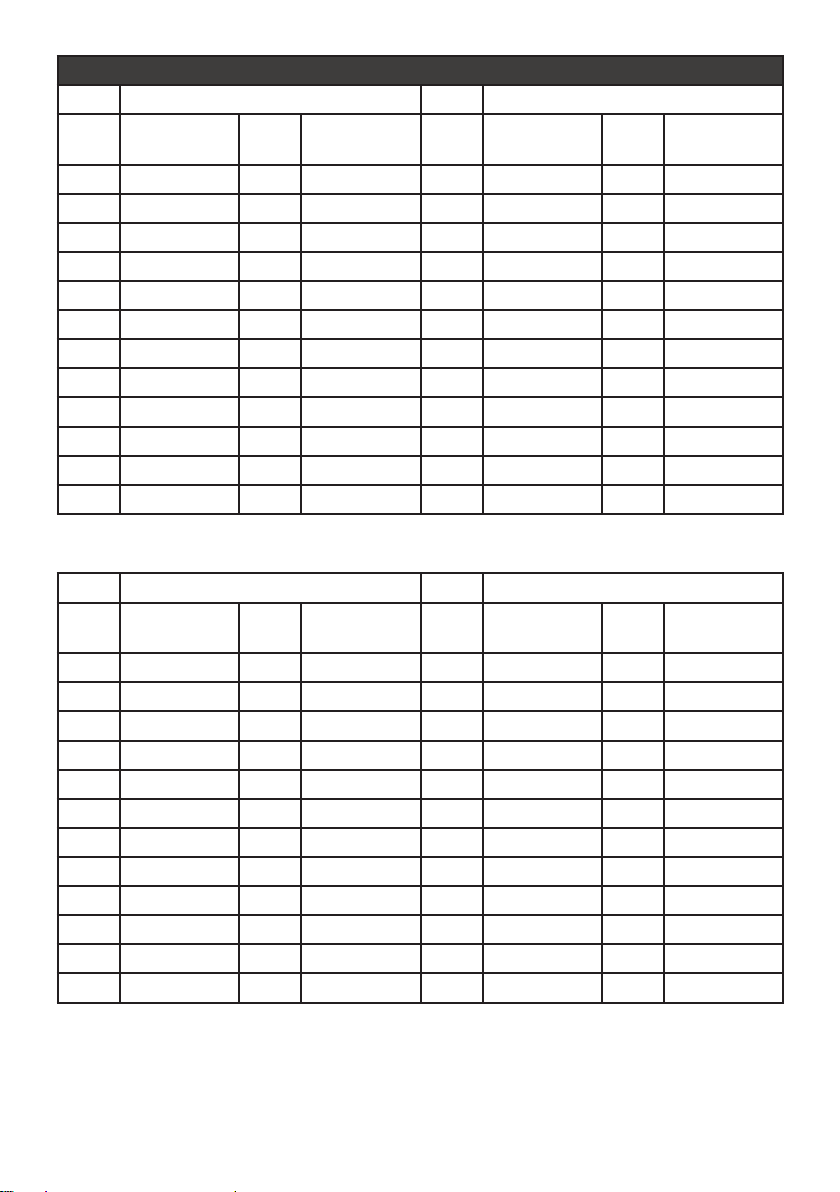

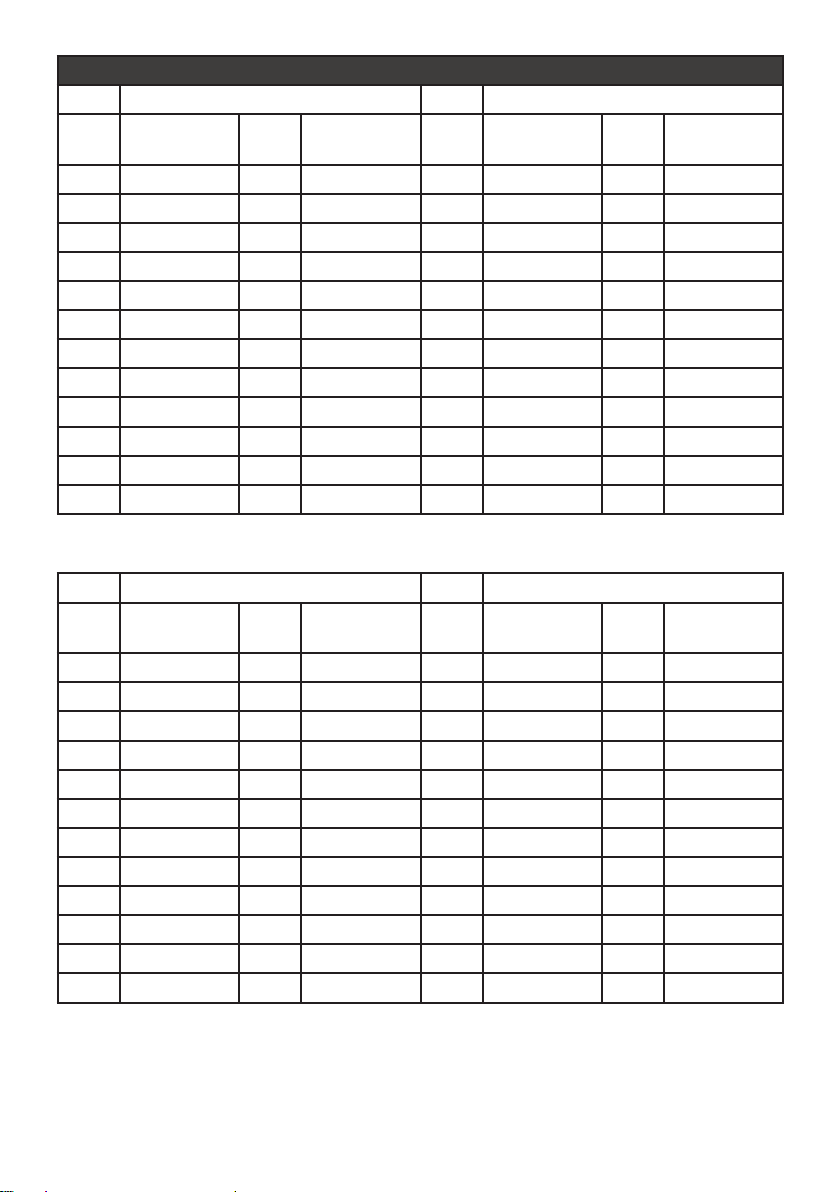

NexSys®Block

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

NexSys®Block

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

Date: Open Circuit Voltage Date: Open Circuit Voltage

Block 1 Block 1

Block 2 Block 2

Block 3 Block 3

Block 4 Block 4

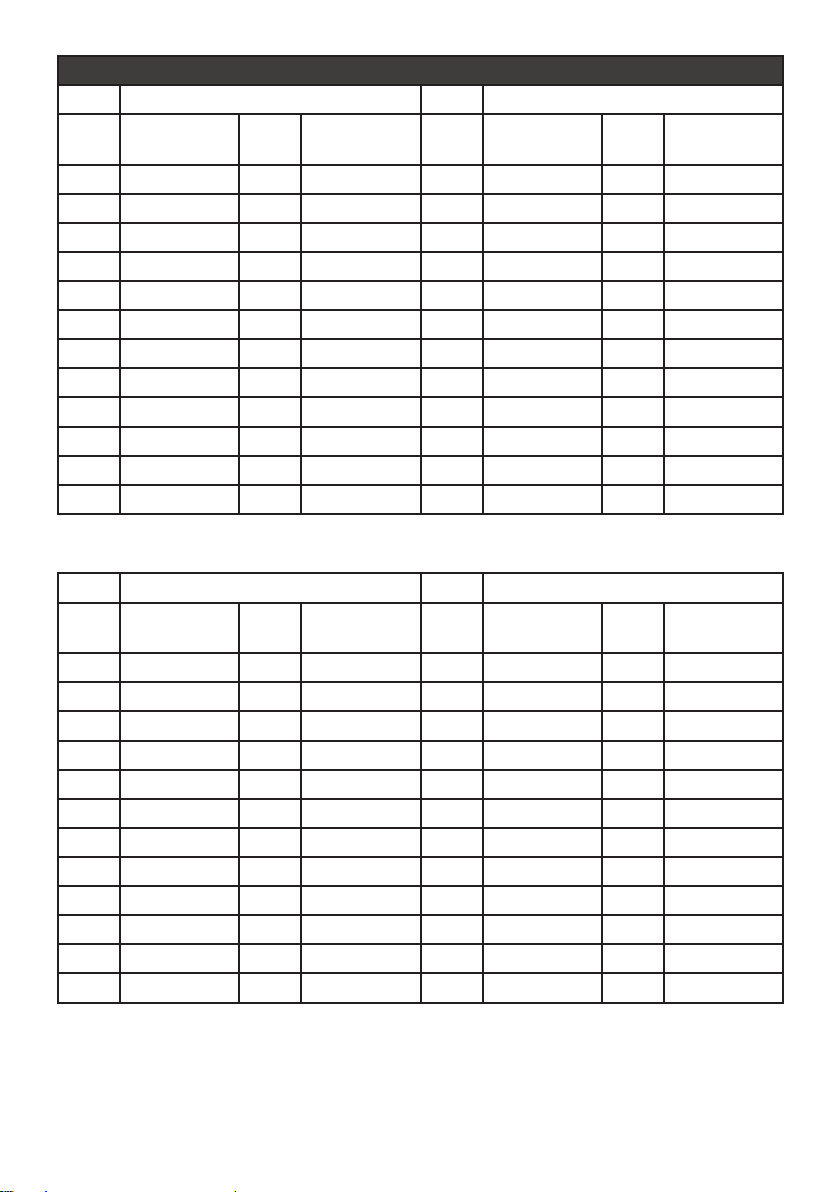

NexSys®Traction Battery

S/N: Date:

Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage

1 13 25 37

2 14 26 38

3 15 27 39

4 16 28 40

5 17 29

6 18 30

7 19 31

8 20 32

9 21 33

10 22 34

11 23 35

12 24 36

S/N: Date:

Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage

1 13 25 37

2 14 26 38

3 15 27 39

4 16 28 40

5 17 29

6 18 30

7 19 31

8 20 32

9 21 33

10 22 34

11 23 35

12 24 36

NexSys®Traction Battery

S/N: Date:

Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage

1 13 25 37

2 14 26 38

3 15 27 39

4 16 28 40

5 17 29

6 18 30

7 19 31

8 20 32

9 21 33

10 22 34

11 23 35

12 24 36

S/N: Date:

Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage

1 13 25 37

2 14 26 38

3 15 27 39

4 16 28 40

5 17 29

6 18 30

7 19 31

8 20 32

9 21 33

10 22 34

11 23 35

12 24 36

NexSys®Traction Battery

S/N: Date:

Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage

1 13 25 37

2 14 26 38

3 15 27 39

4 16 28 40

5 17 29

6 18 30

7 19 31

8 20 32

9 21 33

10 22 34

11 23 35

12 24 36

S/N: Date:

Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage

1 13 25 37

2 14 26 38

3 15 27 39

4 16 28 40

5 17 29

6 18 30

7 19 31

8 20 32

9 21 33

10 22 34

11 23 35

12 24 36

NexSys®Traction Battery

S/N: Date:

Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage

1 13 25 37

2 14 26 38

3 15 27 39

4 16 28 40

5 17 29

6 18 30

7 19 31

8 20 32

9 21 33

10 22 34

11 23 35

12 24 36

S/N: Date:

Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage Cell Open Circuit

Voltage

1 13 25 37

2 14 26 38

3 15 27 39

4 16 28 40

5 17 29

6 18 30

7 19 31

8 20 32

9 21 33

10 22 34

11 23 35

12 24 36

Back to the manufacturer!

Batteries with this sign must be recycled.

Batteries not returned for the recycling process must be disposed of as hazardous waste!

When using motive power batteries and chargers, the operator must comply with the current standards

laws, rules, and regulations in force in the country of use !

Publication: MPANXS10.2016

© 2016 EnerSys. All rights reserved.

All trademarks and logos are the property of EnerSys and its afliates unless otherwise noted.

Subject to revisions without prior notice. E&OE

Singapore

No. 85 Tuas Ave 1

Singapore, 639518

+65 6558 7333

Japan

5F Mitaka Mitsubishi Building

Shimorenjyaku 3-26-12

Mitaka, 181 0013

Tokyo

+81 0422 70 3831

Australia / New Zealand

46 Egerton Street

Silverwater, NSW, 2128

Australia

+61 2 9739 9999

Malaysia

No. 10 Jalan Anggerik Mokara 31/47

Kota Kemuning, Seksyen 31

40460 Shah Alam

Selangor Darul Ehsan, Malaysia

+60 3 5125 1111

India

Plot No. 1057M, 1st Floor

Road #45, Jubilee Hills

Hyderabad, 500033

+91 40 670 46701

China

Room 902, Sheng Gao Int. Building

No. 137 Xian Xia Road

Shanghai, PRC, 200131

+86 21 6273 6300

Asia Regional Headquarters

#11-03

Gateway East Building

152 Beach Road

Singapore, 189721

Other manuals for 12NXS26

1

This manual suits for next models

11

Table of contents

Other Nexsys Camera Accessories manuals