NEXTTEQ NXS Series User manual

Nextteq Portable

NXS Series

INSTRUCTION

MANUAL

Docking Station

2Designed, built and supported by industry professionals for industry professionals

Table of Contents

Warning ………………………………………………………………………………………… 3

1. Overview ……………………………………………………………………………………… 4

1.1 Description ………………………………………………………………………… 4

1.2 Instructions and Parts …………………………………………………………… 4

1.3 Key Features ……………………………………………………………………… 5

1.4 Specifications ……………………………………………………………………… 5

2. Set Up and Operation ………………………………………………………………………… 6

2.1 Power Turn On/Off ………………………………………………………………… 6

2.2 Bay LEDs and Meanings …………………………………………………………… 6

2.3 Charging Batteries ………………………………………………………………… 6

2.4 Exhaust Port & Fresh Air Inlet …………………………………………………… 6

2.5 Installation of Gas Cylinder………………………………………………………… 7

3. Testing ………………………………………………………………………………………… 7

3.1 Calibration ………………………………………………………………………… 7

3.2 Bump Test ………………………………………………………………………… 8

4. Troubleshooting ……………………………………………………………………………… 8

5. Docking Station Manager Software …………………………………………………………… 9

5.1 Software Installation ……………………………………………………………… 9

6. Connecting to the NXS Docking Station ……………………………………………………… 11

6.1 Connecting with Nextteq IR Link…………………………………………………… 12

6.2 Connecting with USB ……………………………………………………………… 12

7. Using Software ……………………………………………………………………………… 13

7.1 Overview of Software ……………………………………………………………… 13

7.1.1 Docking Station Tab ……………………………………………………… 14

7.1.2 NXS Tab ………………………………………………………………… 15

7.1.3 Logs Tab ………………………………………………………………… 16

8. Limited Warranty ……………………………………………………………………………… 17

8.1 Limited Warranty ………………………………………………………………… 17

8.2 Warranty Disclaimer ……………………………………………………………… 18

3

Tel: 813-249-5888 Toll free: 877-312-2333 Fax: 813-249-0188 Toll free: 877-312-2444 www.nextteq.com [email protected]

WARNING

Any unauthorized attempt to repair or modify the product, or any other cause of damage beyond the

range of the intended use including damage by fire, lightning, or other hazard, voids liability of the

manufacturer.

Do not use the device if it appears to be damaged.

Use the device in a clean environment, with no hazardous gases present.

Do not use expired gas cylinders.

Only use certified gas cylinders.

Ensure that the gas types and the concentrations match with the manual instructions and devices.

Severe vibration or shock to the device may cause a sudden reading change and cause the device

to malfunction.

Do not leave or use the device in a location where it will be exposed to moisture.

Do not use a gas detector which has failed or cannot pass a bump or calibration test.

Read the Operation Manual Before Use

Before operation, read the manual carefully and follow all the instructions.

IR link communication works only when it is placed in Bay 1 on the docking station device.

The device only operates when the power LED is lit green.

Before upgrading firmware, connect the plug to avoid any data loss or malfunction by unexpected

power failure. The firmware file names are listed below:

- Docking Station F/W File Name : DK_FW.bin

- NXS F/W Names : NXS_H2S_L5_H10_C25_V127.bin

NXS_O2_L195_H235_C180_V127_DD.bin

NXS_CO_L35_H200_C100_V127.bin

4Designed, built and supported by industry professionals for industry professionals

1. Overview

1.1 Description

A bump test and the calibration test are the key features to ensure the gas detectors are working properly

and the end users are safe. The NXS docking station provides bump testing, event management and

calibration from a simple-to-use multi-unit station and gives fleet or safety managers the ability to update

configurations on large fleets.

It also maintains all the important event logs that demonstrate users are working within company

requirements.

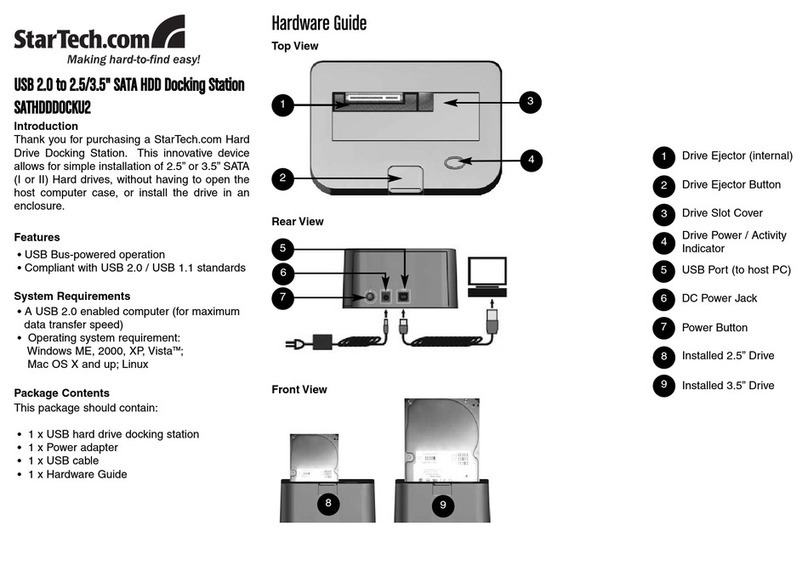

1.2 Instructions and Parts

aBay LED

bBay 1

cHandle

dThumbscrews

ePower LED

fBump Test button

gCalibration button

hBay 2, 3, 4

iPressure gauge

jCylinder 58L/116L

kCylinder Straps

lGas regulator

mCylinder compartment

nExhaust port

oFresh air Inlet

pLAN port

qCharging port

rUSB port

b

h

a

d

c

efg

i

j

k

l

r

m

p

on

q

5

Tel: 813-249-5888 Toll free: 877-312-2333 Fax: 813-249-0188 Toll free: 877-312-2444 www.nextteq.com [email protected]

1.3 Key Features

Zero and Span Calibration, Bump Test Function.

Rechargeable internal battery lasts up to 1000 bump tests on a single charge.

Indicate the current status of operation by the Power LED and Unit LED color.

Configure settings and automatic update firmware of up to four NXS devices.

Gas Ventilation system to purge any remaining gas.

Computer not required for normal operation.

Saves the log events after calibration and bump tests.

Enable users to adjust the setting points of docking station and NXS via IR Link or USB.

1.4 Specifications

Model NXS Series Dock

Size 52.5 x 43.7 x 21.3cm (20.66” x 17.20” x 8.40”)

Weight (Without gas cylinder) 11.0kg

Operating Temperature 41 to + 104˚F ( 5 to + 40˚C)

Warranty Full 2 years

Battery Type Rechargeable Lithium lon

Battery Life Up to 1000 Bump Tests

LEDs 6 Blue LEDs for each bay, 3 color LEDs for power,

Switch Back Light LED (Orange, Green)

Memory USB 8GB Standard

Log Capacity Approximately Up to 5 million tests

(8GB, removable USB memory)

Tests Performed Bump Test and Calibration

Information Stored Bump/Cal Logs, Individual Monitor Event Logs, Firmware

and Unit Configurations

Gases Available O2, CO, H2S

Unit Compatibility Works with NXS Series (O2, CO, H2S)

Calibration Gas Compatible with 58L & 116L cylinders with C10 fitting

Interface Ethernet RJ-45(TCP/IP), 10Mb/s

Charging Adapter DC12.0V, 3A/h

6Designed, built and supported by industry professionals for industry professionals

2. Set up and Operation

2.1 Power turn on/off

The NXS Docking Station operates using only 2 (two) buttons for calibration and Bump Test.

To turn on the power:

Press and hold either Calibration or Bump Test button for 2 seconds.

The Power LED turns on to orange and blinks during warm up and after a while will turn green

when it is ready for use. When the unit has a low battery, the LED will turn red.

To turn off the power:

Press and hold both Calibration and Bump Test buttons simultaneously for 2 seconds.

NOTE: If unit is inactive for 300 seconds, it will automatically turn off (Power Saver mode).

The unit only works when the power LED turns green.

2.2 Bay LEDs and meanings

Each Bay has six blue LEDs (see Figure 2) which indicates the process status. Each of them will turn on by

order from left to right while testing. After testing is finished, make sure all six blue LEDs are turned on. If

the test failed, the 3rd blue LED will be the only LED lit.

2.3 Charging battery

The unit`s Power LED turns to red when the battery is very low as shown above. However, it comes with

a DC adapter with 5 plugs which can be used to charge the unit using a 110V power supply. A full charge

will take approximately 3 hours and will last for approximately 1000 bump tests.

NOTE: Refer to Figure 1 for charging location.

Bump Test

Calibration

Power On & Off

Test Results

Insert the monitor(s) into the bay(s) facing down.

Press the Bump Test button for 2 seconds to initiate bump test.

Can perform up to 1,000 bump tests on a single charge.

Insert the monitor(s) into the bay(s) facing down.

Press the Calibration button for 2 seconds to initiate calibration

test.

All (six) blue Bay LEDs illumination indicates if the NXS has

passed the test.

If only the third blue Bay LED is illuminated, then the NXS has

failed the test.

Be sure the Docking Station is charged or plugged in before use.

(Note: A red power LED light indicates a low battery. To fully

charge the Docking Station, it should be plugged in for 3 hours.)

To turn on, press and hold the Calibration or Bump Test button

for 2 seconds.

The automatic power saver mode will turn off the unit after 5

minutes of inactivity.

To turn off, press and hold the Calibration and Bump Test button

for 2 seconds.

Docking Station for Nextteq Portable

NXS Series Single Gas Detectors

Calibration

button

Bump Test

button Power

button

Bay & Power LED

Troubleshooting

Bay Light does not turn on/test not performed

- Clean Monitor IR window

- IR interference (bright lights/sunlight)

- Monitor in gas alarm state

All tests fail

- Gas cylinder empty

- Gas Expired

- Wrong gas concentration(s)

Test results are not stored

- USB not attached or USB is full

If you’re unable to resolve technical issues, please contact the

product’s authorized reseller or the Nextteq service center.

Important Notes

USB drive must be installed to store the test results.

Be sure the latest NXS Firmware is installed in the Nextteq Docking Manager

Software. The NXS portable monitor firmware will then be updated during the

next calibration or bump test.

For bump testing, ensure the cylinder gas concentration is above the

“Low Alarm” setting of the NXS Single Gas Detector.

For calibration, ensure the NXS “Cal Concentration” setting is the same as

the cylinder gas concentration.

Any monitor that fails the bump test or calibration must be re-calibrated or

bump tested again. If the attempts fail continuously, please do not use the

detector and contact your authorized Nextteq International Distributor or

Nextteq International.

When changing NXS settings using the USB from the Docking Station or

when using IR Link in the Docking Station, remember to click the “write”

button to save customized settings.

Set up Calibration Gas Cylinder

Gas bottle

USB

Gas bottle

USB

Gas bottle

USB

Remove thumbscrews and lift the handle.

Install the cylinder onto the gas regulator.

Fasten the cylinder straps and close the cylinder compartment.

Check the pressure gauge on the front panel.

Re-install thumbscrews.

LED’s

Stand by

Injecting fresh air

Test

Purging remaining gas

Save a log data

Test passed

Test failed

Bay LED

Power LED

Green: Power on

Red: Low Battery

Orange: USB not attached or full storage

Quick Start Guide

For more information or to purchase

calibration gas mixtures call

Nextteq International:

Tel: 813-249-5888

Toll free: 877-312-2333

www.nextteq.com

Full range of calibration

gas mixtures available. NX90211

7

Tel: 813-249-5888 Toll free: 877-312-2333 Fax: 813-249-0188 Toll free: 877-312-2444 www.nextteq.com [email protected]

2.4 Exhaust Port & Fresh Air Inlet

There are two small ports on the left side of the charging port (see Figure 1). The Fresh air inlet port will

draw clean air in during an active test. The incoming air automatically counts as fresh air (O2, 20.9%vol).

The Exhaust port is the inverse of the Fresh air inlet port. During an active test, the used test gas will exit

the unit through the exhaust port. Optionally, tubing can be attached to the exhaust port using the included

twist connector to direct the used test gas to a suitable location.

2.5 Installation of Gas Cylinder

A gas cylinder which fits into the Docking Station must have the C10 fitting on it. Both 58L and

116L cylinders are suitable. Before installing the cylinder for testing the NXS, ensure that Calibration

concentration of gases are suitable for the NXS being tested.

To install a cylinder:

Remove thumbscrews and lift the handle up.

Install the cylinder to the gas regulator.

Fasten the cylinder straps and close the cylinder compartment.

Check the pressure gauge on the front panel.

After installing a gas cylinder, ensure USB is attached.

Re-install thumbscrews.

3. Testing

A Bump Test and a Calibration Test are the key features to ensure gas detectors are working properly

and the end users are safe. The NXS Docking Station provides bump testing, event management and

calibration from a simple to use multi unit station.

3.1 Calibration

Calibration is the comparison of measurement values delivered by a device under test with a calibration

standard of known concentration. It is very important to calibrate a device periodically for better

performance of the device and to assure sensor accuracy.

To perform a calibration:

Insert the monitor(s) into the bay facing down.

Slightly press down on the monitor until it locks into place.

Press the calibration button for 2 seconds to execute the Calibration test.

During the 90 second test period, bay LEDs begin to light as the test progresses.

When the test is finished, all (six) blue LEDs illuminate indicating the NXS has passed

the test (see Figure 3).

If only the third blue LED illuminates, the NXS has failed the test (see Figure 3).

Bump Test

Calibration

Power On & Off

Test Results

Insert the monitor(s) into the bay(s) facing down.

Press the Bump Test button for 2 seconds to initiate bump test.

Can perform up to 1,000 bump tests on a single charge.

Insert the monitor(s) into the bay(s) facing down.

Press the Calibration button for 2 seconds to initiate calibration

test.

All (six) blue Bay LEDs illumination indicates if the NXS has

passed the test.

If only the third blue Bay LED is illuminated, then the NXS has

failed the test.

Be sure the Docking Station is charged or plugged in before use.

(Note: A red power LED light indicates a low battery. To fully

charge the Docking Station, it should be plugged in for 3 hours.)

To turn on, press and hold the Calibration or Bump Test button

for 2 seconds.

The automatic power saver mode will turn off the unit after 5

minutes of inactivity.

To turn off, press and hold the Calibration and Bump Test button

for 2 seconds.

Docking Station for Nextteq Portable

NXS Series Single Gas Detectors

Calibration

button

Bump Test

button Power

button

Bay & Power LED

Troubleshooting

Bay Light does not turn on/test not performed

- Clean Monitor IR window

- IR interference (bright lights/sunlight)

- Monitor in gas alarm state

All tests fail

- Gas cylinder empty

- Gas Expired

- Wrong gas concentration(s)

Test results are not stored

- USB not attached or USB is full

If you’re unable to resolve technical issues, please contact the

product’s authorized reseller or the Nextteq service center.

Important Notes

USB drive must be installed to store the test results.

Be sure the latest NXS Firmware is installed in the Nextteq Docking Manager

Software. The NXS portable monitor firmware will then be updated during the

next calibration or bump test.

For bump testing, ensure the cylinder gas concentration is above the

“Low Alarm” setting of the NXS Single Gas Detector.

For calibration, ensure the NXS “Cal Concentration” setting is the same as

the cylinder gas concentration.

Any monitor that fails the bump test or calibration must be re-calibrated or

bump tested again. If the attempts fail continuously, please do not use the

detector and contact your authorized Nextteq International Distributor or

Nextteq International.

When changing NXS settings using the USB from the Docking Station or

when using IR Link in the Docking Station, remember to click the “write”

button to save customized settings.

Set up Calibration Gas Cylinder

Gas bottle

USB

Gas bottle

USB

Gas bottle

USB

Remove thumbscrews and lift the handle.

Install the cylinder onto the gas regulator.

Fasten the cylinder straps and close the cylinder compartment.

Check the pressure gauge on the front panel.

Re-install thumbscrews.

LED’s

Stand by

Injecting fresh air

Test

Purging remaining gas

Save a log data

Test passed

Test failed

Bay LED

Power LED

Green: Power on

Red: Low Battery

Orange: USB not attached or full storage

Quick Start Guide

For more information or to purchase

calibration gas mixtures call

Nextteq International:

Tel: 813-249-5888

Toll free: 877-312-2333

www.nextteq.com

Full range of calibration

gas mixtures available. NX90211

8Designed, built and supported by industry professionals for industry professionals

Figure 3

Note: Do not use the monitors that failed the calibration test.

3.2 Bump Test

Bump test is the process which checks and verifies the performance of the monitors and

ensures that sensors are correctly responding to the target gas.

To perform a Bump Test:

Insert the monitor(s) into the bay facing down.

Slightly press down on the monitor until it locks into place.

Press the Bump Test button for 2 seconds to execute the Bump test.

During the 20-30 second test period, bay LEDs begin to light as the test progress.

When test is finished, all (six) blue LEDs illuminate indicating the NXS has passed

the test (see Figure 3).

If only the third blue LED illuminates, the NXS has failed the test (see Figure 3).

4. Trouble Shooting

4.1 Bay Light does not turn on /test not performed

Clean Monitor IR window.

IR interference (bright lights/sunlight).

Monitor in gas alarm state.

4.2 All tests fail

Gas cylinder empty - check pressure gauge to be sure it indicates at least 100psi/10bar.

Gas Expired - check gas expiration date located on the cylinder.

Wrong gas concentration(s) - gas cylinder and NXS concentrations not same.

Wrong gas type - check the gas type.

NXS has passed the

test (six LEDs visible)

NXS has failed the test

(only 3rd LED visible)

9

Tel: 813-249-5888 Toll free: 877-312-2333 Fax: 813-249-0188 Toll free: 877-312-2444 www.nextteq.com [email protected]

4.3 Test results are not stored

USB not attached or storage is full.

4.4 Uploaded Settings are not saved

“Write” button has not clicked.

Connection was lost.

5. NXS Docking Station Manager Software

The purpose of NXS Docking Station Manager Software is to customize and configure the Station`s

settings and NXS devices` internal configurations. The software can adjust and make changes to the

Docking Station and the NXS units using Nextteq IR Link or the USB Disk.

5.1 Software Installation

After downloading the file, navigate to the saved file.

Double click the installation software to initiate the installation.

Click “Read More” or “Run Away” if you receive a warning message.

Click “Next” to install in default folder when the “Select Installation Folder” window appears.

To install to a different folder, click “Browse” or enter the link.

10 Designed, built and supported by industry professionals for industry professionals

Click “Install”.

11

Tel: 813-249-5888 Toll free: 877-312-2333 Fax: 813-249-0188 Toll free: 877-312-2444 www.nextteq.com [email protected]

Click “Yes” if you get the warning message below.

The Docking Station Setup Wizard is complete.

Click the “Finish” button to exit the Setup Wizard.

6. Connecting to the NXS Docking Station

When the Docking Manager software opens, the fields are grayed out. Before it can be

used, the IR Link must be connected to the Docking Station.

Note: The IR Link connection works only when it is placed into Bay 1.

USB drive must be installed to store the test results

Do not open the software if IR Link is not plugged to PC.

12 Designed, built and supported by industry professionals for industry professionals

6.1 Connecting with Nextteq IR Link

The Nextteq IR Link is a device which conveniently configures and communicates with NXS Docking

Station using the IR communication in Bay 1.

To connect the IR Link, follow the steps below:

Plug the IR link into a USB port on PC.

Power on (green LED) the Docking Station.

Place the IR Link facing up into the Bay 1(see Figure 4).

Double click and open the installed software.

Click “OPEN” button at the top right corner of the software interface.

The IR Link starts to flash rapidly.

After a few seconds, the “Read complete” message will be displayed, and the current settings of the

Docking Station will be show on the interface.

Note: If “Send timeOut ” message displays, the IR Link has failed to

communicate with the Docking Station. In this case, make sure IR Link screen

is aimed at the IR screen of Bay 1 and check to be sure the Power is on.

Figure 4

6.2 Connecting with USB

To connect the USB, follow the steps below:

Open the Cylinder compartment.

Find the USB port (see Figure 1) and remove the USB Disk.

Plug the USB into a PC.

Double click and open the installed software.

Select the “USB Disk” in the upper middle left corner.

Select the location of USB Disk and click “OK” button.

13

Tel: 813-249-5888 Toll free: 877-312-2333 Fax: 813-249-0188 Toll free: 877-312-2444 www.nextteq.com [email protected]

7. Using Software

7.1 Overview of Software

Figure 5

Figure 6

When IR Link is connected to the Docking Station, the window shown in Figure 5 will be displayed.

If it is connected using the USB Disk, the “Logs” tab will not be shown.

Serial Number

Detector User ID

Calibration Interval:

0-365 days

Bump Interval:

0-365 days

Self Test Interval:

0-20 hours

Low/High

Alarm Setting

Display Mode:

- Remain Life

- Measuring Mode

To connect to IR-Link To connect with USB

Location

Cylinder No.

Firmware Version

Save power Mode

(1~3600 sec)

Gas Expiration

date on cylinder

Reading or Writing

configuration on

Docking Station

Docking Station

firmware upgrade

Max Bump Time

(20-120 sec)

Enable/Disable

Cal./Bump Test

Bump result decision:

- Beep

- Concentration

- Beep + Concentration

Cal. Gas

Concentration

Firmware Upgrade

Reading or Writing

configuration on

Docking Station

14 Designed, built and supported by industry professionals for industry professionals

7.1.1 Docking Station Tab

Serial Number — Serial number of Docking Station (cannot be changed).

Version — The current firmware version.

Auto Power Off — The time when unit automatically goes to Save Power Mode. Min/max time can be

set 1 ~ 3,600 seconds.

Maximum Bump Time — The maximum and minimum time spent for Bump Test process. If unit

cannot respond correctly before time expires, the process will stop and result will be failure. Can be

adjusted to a min/max of 20 ~ 120 seconds.

Location — The location where test was done. It is beneficial when downloading the data logs. Can

add 12 alphanumeric characters.

Gas Expiration Date — Shows the date of expiration of gas in installed cylinder. Must be updated

after installing a new one.

Gas Bottle Lot # — Displays lot number of installed cylinder. Must be updated after installing a new

cylinder.

Info Read/Write — By pressing the “Read” it displays current setting of the Docking Station and will

discard any unsaved changes in the Tab.

Calibrate — If this box is not selected, calibration process will not proceed by pressing the Calibration

button. However, it will still update firmware and the configuration of NXS.

Bump Test — If this box is not selected, Bump test process will not proceed by pressing the Bump

Test button. However, it will still update firmware and configuration of NXS.

Bump Result Decision — The drop-down list can be selected for “Beep”, “Concentration”, or

“Beep + Concentration”. The “Beep” option will run the bump test until the alarm condition is met

and the audible alarm is detected. The “Concentration” option will run the bump test until the test gas

concentration is verified. If the units are in Stealth Mode, the Concentration option will be required

for a successful bump test. The “Beep + Concentration” option will run the bump test until the audible

alarm is detected and the test gas concentration is verified.

Browse & Write — To upgrade the latest firmware of Docking Station, click “Browse”, navigate to the

firmware location and click “Open”. Click “Write” to begin upgrading process.

Note: Without clicking the “Write” button, configured and customized

settings will not be saved.

15

Tel: 813-249-5888 Toll free: 877-312-2333 Fax: 813-249-0188 Toll free: 877-312-2444 www.nextteq.com [email protected]

7.1.2 NXS Tab

User ID — The User ID can be used to add a message.

Calibration Interval (Days) — The calibration reminder shows the calibration interval

(can adjust from 0 (n/a) ~ 365).

Bump Interval (Days) — The Bump test reminder shows the bump test interval

(can adjust from 0 (n/a) ~ 365).

Self Test Interval (Days) — The Self Test reminder shows the self-test interval

(can adjust from 0 (n/a) ~ 365).

Low Alarm & High Alarm — The 1st and 2nd alarm set points for each gas.

Display mode — Displays remaining lifetime of unit or gas concentration .

Gas Concentration — This allows a user to enter/amend correct concentration of the installed gas

cylinder on Docking Station.

NXS Option Info Read/Write — Pressing the “Read” button will display current setting of the NXS

and will discard any unsaved changes. By clicking the “Write” button, all configured and customized

settings will be saved on NXS monitor.

Browse & Write — To upgrade the latest firmware of NXS, click “Browse”, navigate to the firmware

location and click “Open”. Click “Write” button to begin upgrading process.

16 Designed, built and supported by industry professionals for industry professionals

7.1.3 Logs Tab

All logs will be stored on the USB Disk (logs are not available if USB is not plugged in) and can be

downloaded via Nextteq-IR-Link using the Docking Manager software. The log files will be created for each

device by their Serial numbers and will be in “.csv” format.

Note: the USB drive must be installed to store the test results (logs). By connecting directly to the USB

Disk, the “Logs” Tab is not available on the software interface. But logs are still available to download

from the “Events” file in the USB Disk. Click “Refresh” button to view and download the latest logs. After

clicking the “Refresh” button, all logs will be available to view (see Figure 7).

Figure 7

To download the logs:

Plug the IR Link into a USB port on PC and place into Bay 1.

Double click and open the installed software.

Click the “OPEN” button at the top right corner of the software interface.

Click the “Logs” Tab and Click the “Refresh” button.

Select needed log by indicating NXS`s serial number.

Click the “Local Save” button and a Browse window will open.

Select a location to save the file.

Click the “OK” button to begin the downloading process.

When downloading is finished, “Log data save success” message will come up.

17

Tel: 813-249-5888 Toll free: 877-312-2333 Fax: 813-249-0188 Toll free: 877-312-2444 www.nextteq.com [email protected]

8 Warranty

8.1. Limited Warranty

Nextteq warrants this product to be free from defects in material and workmanship under normal use and

service for a period of two years from the manufacturing date for this NXS product. This warranty is valid

only if the personal monitor is activated by the ‘activate by’ date on the external packaging. This warranty

extends only to the sale of new and unused products to the original buyer.

Warranty Procedure

To facilitate efficient processing of any claim, contact your local Nextteq agent/distributor, a Nextteq

regional office or our global customer support team (English speaking) at 813-249-5888 or

traceability purposes.

Be sure to include:

• Your company name, contact name, phone number and email address.

• Description and quantity of goods being returned, including any accessories.

• Instrument serial number(s).

• Reason for return.

Products will not be accepted for warranty without a Nextteq RMA #. It is essential that the address label

is securely attached to the outer packaging of the returned goods. The guarantee will be rendered invalid if

the instrument is found to have been altered, incorrectly stored, modified, dismantled, tampered with, has

not used Nextteq spares for replacement parts (including sensors) or has been serviced or repaired by any

party not authorized and certified by Nextteq to do so. The warranty does not cover misuse or abuse of the

unit including use outside of specified limits.

18 Designed, built and supported by industry professionals for industry professionals

8.2. Warranty Disclaimer

Nextteq accepts no liability for consequential or indirect loss or damage howsoever arising (including

any loss or damage arising out of the use of the instrument) and all liability in respect of any third

party is expressly excluded. This warranty does not cover the accuracy of the calibration of the unit or

the cosmetic finish of the product. The unit must be maintained in accordance with the instructions in

this manual. The warranty on replacement consumable items supplied under warranty to replace faulty

items will be limited to the unexpired warranty of the original supplied item. Nextteq reserves the right

to determine a reduced warranty period, or decline a warranty period for any sensor supplied for use

in an environment or for an application known to carry risk of degradation or damage to the sensor.

Our liability in respect of defective equipment shall be limited to the obligations set out in the guarantee

and any extended warranty, condition or statement, express or implied, statutory or otherwise as to the

merchantable quality of our equipment or its fitness for any particular purpose is excluded except as

prohibited by statute. This guarantee shall not affect a customer’s statutory rights.

Nextteq reserves the right to apply a handling and carriage charge whereby units returned as faulty are

found to require only normal calibration or servicing, which the customer then declines to proceed with.

For warranty and technical support inquiries please contact:

Nextteq International Customer Support

Tel: 813-249-5888

Toll Free: 877-312-2333

Fax: 813-249-0188

Toll Free: 877-312-2444

Email: [email protected]

19

Tel: 813-249-5888 Toll free: 877-312-2333 Fax: 813-249-0188 Toll free: 877-312-2444 www.nextteq.com [email protected]

©2020 Nextteq International LLC

All rights reserved.

This book is fully protected by copyright and no part of it may be

reproduced in any form, by photocopy, microfilm, or any other

means, without prior written permission of Nextteq International LLC.

P/N NX90228

Nextteq is a registered trademark of Nextteq International LLC. All

other brand names and trademarks mentioned in this document are

the properties of their respective holders.

Nextteq International LLC

Website http://www.nextteq.com

8406 Benjamin Rd., Suite J, Tampa, FL 33634

Tel: 813-249-5888

Toll Free: 877-312-2333

Fax: 813-249-0188

Toll Free Fax: 877-312-2444

Email: [email protected]

Printed in the United States of America

Table of contents