Nexxt Solutions NPC-T42U61B User manual

ProfessionalSeries

Semi-knocked down

floor cabinet

NPC-T27U68B

NPC-T32U68B

NPC-T37U68B

NPC-T42U68B

NPC-T42U61B

NPC-T47U61B

NPC-T27U66B

NPC-T32U66B

NPC-T37U66B

NPC-T42U66B

Caution: this product is heavy, at least two (2) qualified people should perform the

assembly procedure. Care must also be taken while moving or positioning the

equipment.

After the cabinet has been assembled, adjust the leveling feet for greater stability.

When lowered correctly, the four leveling feet should support the full weight of the rack.

Use extreme caution when unpacking or removing the product parts from the boxes to

avoid damaging or misplacing of parts.

Do not exceed the recommended load capacity and the maximum weight supported by

the enclosure, as specified by the manufacturer’s specifications. Failure to comply will

void the warranty of this product.

Avoid rolling the cabinet on floors with uneven or rough surfaces to prevent casters

from getting stuck in gaps or otherwise being unnecessarily damaged.

When rolling the cabinet on casters, push the cabinet from the front or rear only, to

prevent the structure from tipping on its side.

Caution: use the recommended tools to avoid damaging the parts.

CABINET TIPPING HAZARD: ensure that the cabinet is properly stabilized and

steady by extending the leveling feet after it is placed in its permanent location before

any equipment is installed.

1. Introduction

Thank you for purchasing the semi-knocked down [SKD) floor cabinet from Nexxt

Solutions. Each floor unit is housed in lockable heavy-gauge metal enclosure designed to

house any rack-mounted components, such as server and storage units, modular

network or voice switches, routers, telecommunication systems and IT equipment. Its

split rear door design easily accommodates to any telecommunications room layout, by

minimizing the space required for access behind the cabinet. Our floor cabinets provide

more space for networking equipment, including the easy integration of rack PDUs and

high-density cable managers. Built to EIA rack standards with square punched mounting

holes, the equipment can be quickly attached inside the enclosure for data center or

computer room applications. Enhanced cooling capabilities are made possible by the

integration of a fan tray assembly. Product available in 600mm wide configuration, with

27, 32, 37, 42 and 47 rack spaces.

Main features

• 1764lb (800kg) maximum load capacity

• Frame construction reinforced with steel, specially made to support heavy weight

• Superior management system, with top and bottom access to cables and PDUs

• Lockable access to front and rear doors, as well as side panels

• Standard square-punched mounting rails for faster component loading

• The front door can turn 245 degrees and the rear door can be opened up to 245

degrees

• High-density mesh back doors provide outstanding ventilation to avoid overheating

• Its vertical PDU/cable management rail adds versatility for power and cable

distribution inside the enclosure

• Each unit sits on four casters, for ease of deployment and mobility

• Adjustable leveling feet for added stability

• EIA-compliant mounting rail system can be easily adjusted for equipment varying

depths

• U-rack units are numbered front and back for easy equipment integration

• Powder coat finish prevents damage caused by rust and other external factors

For support and to find out more about our complete line of products and solutions,

we invite you to visit us at nexxtsolutions.com.

User manual

Carefully read and follow the safety

instructions included in this manual before

assembling and using the cabinet.

FAILURE TO FOLLOW THESE INSTRUCTIONS CAN LEAD TO

SERIOUS INJURY, DEATH, OR DAMAGE TO YOUR EQUIPMENT

IMPORTANT SAFETY INFORMATION

ELECTRICAL

SHOCK

HAZARD.

DANGER All parts of the unit must be properly grounded to the frame

of the enclosure and connected to the Common Bonding

Network (CBN) of your facility.

1 2

Split mesh rear door with lock

Frame

Horizontal beam

Vertical rails (with rack unit markings)

Bottom tray

Side panel

Side panel stopper

2.Preliminary steps

• Prior to installing this product, you must read all instructions thoroughly.

• Keep these instructions handy in an easily accessible location for future reference.

• A clean, flat, level, and protected floor area should be provided for cabinet assembly

to prevent damage to parts.

• The installers may need to have the following items and tools available to assemble

and install the cabinet. They are not included in the box.

3. Product overview and components

Upon opening the box, make sure to inspect and account that all the items

listed below are included.

1. Phillips screwdriver

2. Power drill with the following bits: Phillips-head tip

3. Pair of gloves

4. Long nose pliers

5. Cleaning towel

6. 3mx2m mat or padded surface

1 2 3 4 5

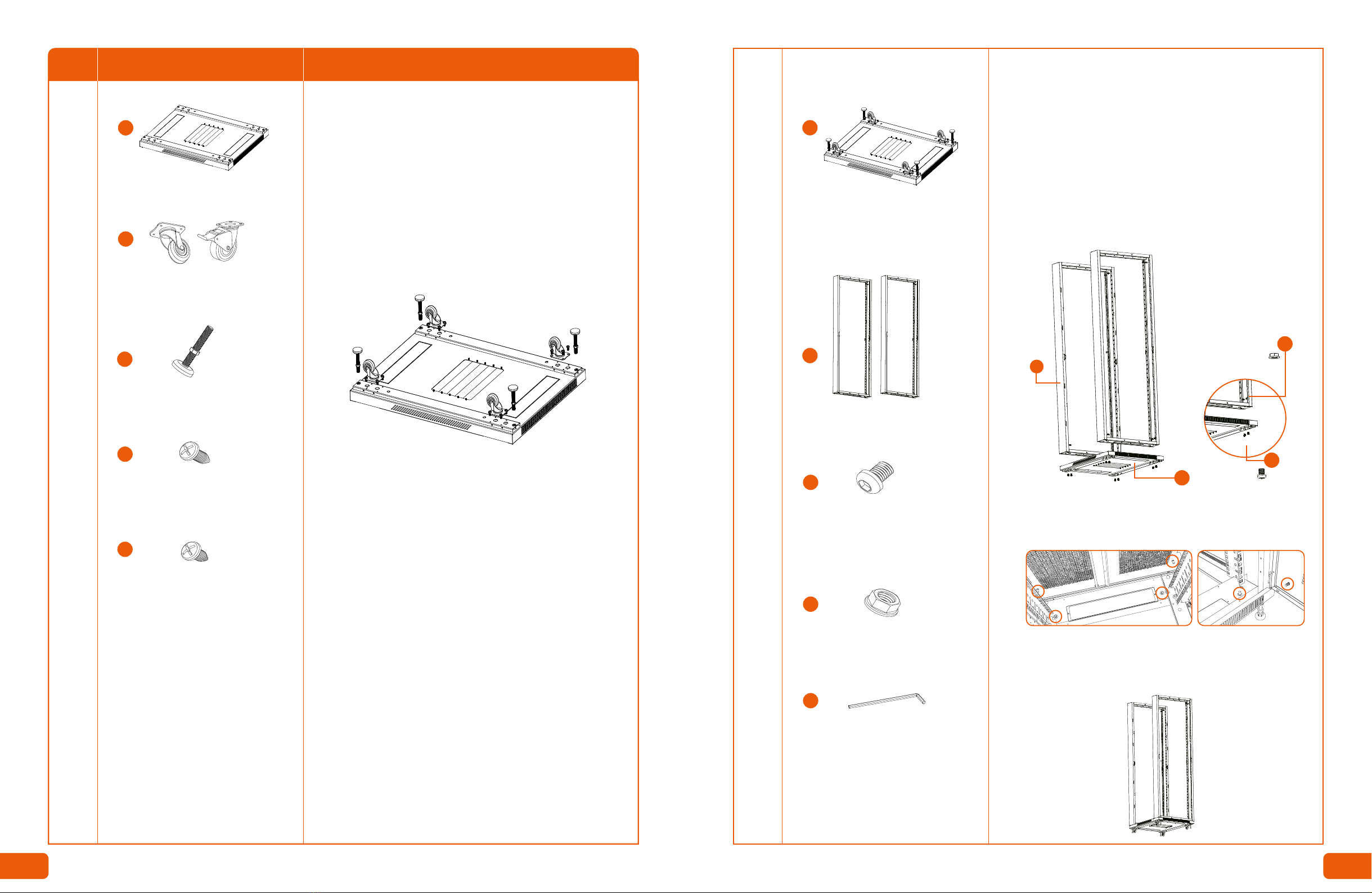

Part ID Item Quantity Image

Front glass door with lock

Top cover with fan tray assembly

1

1

1

2

4

1

2

4

1

2

3

4

5

6

7

8

9

Rack assembly components

3 4

4 6

≥32U≤32U

10

11

13

14

15

16

17

12

M12xL90 leveling foot

Caster wheel

Cable entry plate

Grounding cable with terminal rings

Bottom ventilation plate

Front door key

Rear door key

Side panel key

4

2 with brakes

2 without brakes

3

(1 for top and 2

for bottom panel)

3 sets

pre-installed

1 set (2 keys)

1 set (2 keys)

1 set (2 keys)

4. Assembly procedure (recommended)

Upon opening the box, inspect the contents to ensure that all the items listed above

are included:

• The illustration provides an exploded view of all the

enclosure components you are about to put together.

• Open the boxes and verify that all parts, hardware

and accessories are included in the package.

• Inspect the cabinet components and identify each

individual part to ensure proper assembly of the unit.

Rack assembly hardware ≤32U

≤27U >27 ≤37U >37 ≤47U

18

19

20

21

M6 cage nut

M6 plastic washer

M6x12mm phillps-head screw

M8x12mm hexagon socket head screw

M8 flange nut

M6x12mm self-taping screw

16

16

16

22

23

M4x8mm self-tapping screw

Door hinge bushing

L-shaped allen wrench

M6 cage nut

M6 plastic washer

M6x12mm phillips-head screw

User manual

15

3

1

Equipment mounting hardware

24

25

26

27

28

29

12

1

4

7

11 10

8

FRONT

VIEW

REAR

VIEW

4

3

5

6

5 6

≥32U

20

20

20

40

40

40

48

48

48

30

30

30

40

40

40

2

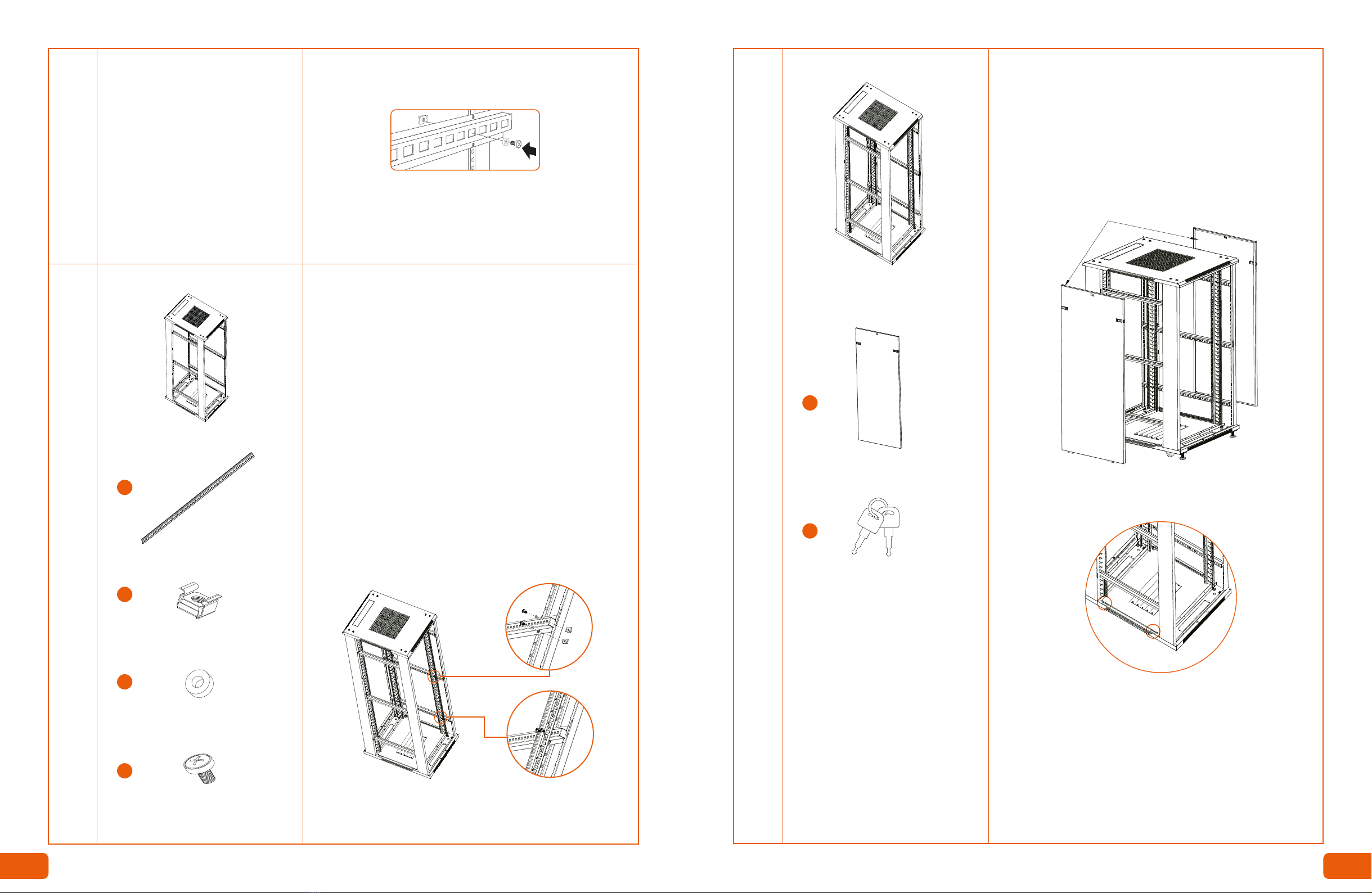

Frame installation to bottom tray

1. Align the frame (left side first) with the mounting holes on the

bottom tray. Using the M8 screws and M8 flange nuts, secure both

parts together.

Note: make sure not to fully tighten the screws until all have been

installed.

2. Repeat the same procedure for the right side.

Note: at this point, fully tighten all the screws to ensure proper

stability of the structure.

3. Make sure that the grounding post on the bottom frame aligns

with the grounding posts of the front and rear doors.

4. The bottom frame subassembly is now complete.

Bottom tray subassembly (1)

Frames (2)

M8x12mm hexagon socket

head screws (8)

M8 flange nuts (8)

7

4

21

22

1

Phase Required parts Steps

Bottom tray (1)

M6x12mm self-tapping screws (16 )

M4x8mm self-tapping screws (4)

Allen wrench

Caster wheels (4)

2 with brakes

2 without brakes

Leveling feet (4)

26

23

24

11

10

7

Installation of casters and feet

1. Identify the 2 caster wheels with brake mechanism and the 2

regular caster wheels which will be used in the back of the cabinet.

2. Align the two casters (with brakes) with the front mounting holes

of the bottom tray and secure them firmly using four (4) of the

supplied M6 self-tapping screws.

3. Repeat the same procedure for the remaining casters to be

placed in the rear section of the bottom tray.

4. Next, locate the mounting holes on each corner for the leveling

feet.

5. Screw the feet to the desired height, making sure all are

positioned at the same level.

Note: make sure not to fully extend the leveling feet to the floor until

it is placed in its permanent location. Otherwise you will not be able

to roll the cabinet using the casters.

6. Proceed to install the two cable entry plates on the tray openings

from the inside using four (4) M6 self-tapping screws.

21

22

4

7

FRONT

REAR

Front doorRear door

7 8

5. The top and bottom frame subassembly is now complete.

3

Bottom tray subassembly

M8 flanged nuts (8)

Side panel stoppers (4)

M4x8mm self-tapping screws (8)

Top cover with fan tray assembly (1)

M8x12mm hexagon socket

head screw (8)

22

24

9

21

2

Top cover assembly

1. Align the frame (left side first) with the mounting holes on the top

tray. Using the M8 screws and M8 flange nuts, secure both parts

together.

Note: position the top tray with the cable entry plates pointing

towards the rear section of cabinet.

Make sure not to fully-tighten the screws until all have been installed.

2. Repeat the same procedure for the right side of the structure.

3. Locate the mounting holes of the side panel stoppers, on the right

and left sides of the structure (front and rear), as per the illustration

below.The rubber stud should be facing outwards.

4. Attach the stoppers to the frames using the supplied M4

self-tapping screws (2 per stopper).

Note: at this time, make sure to fully tighten all the screws.

FRONT

FRONT

REAR

REAR

21

22

4

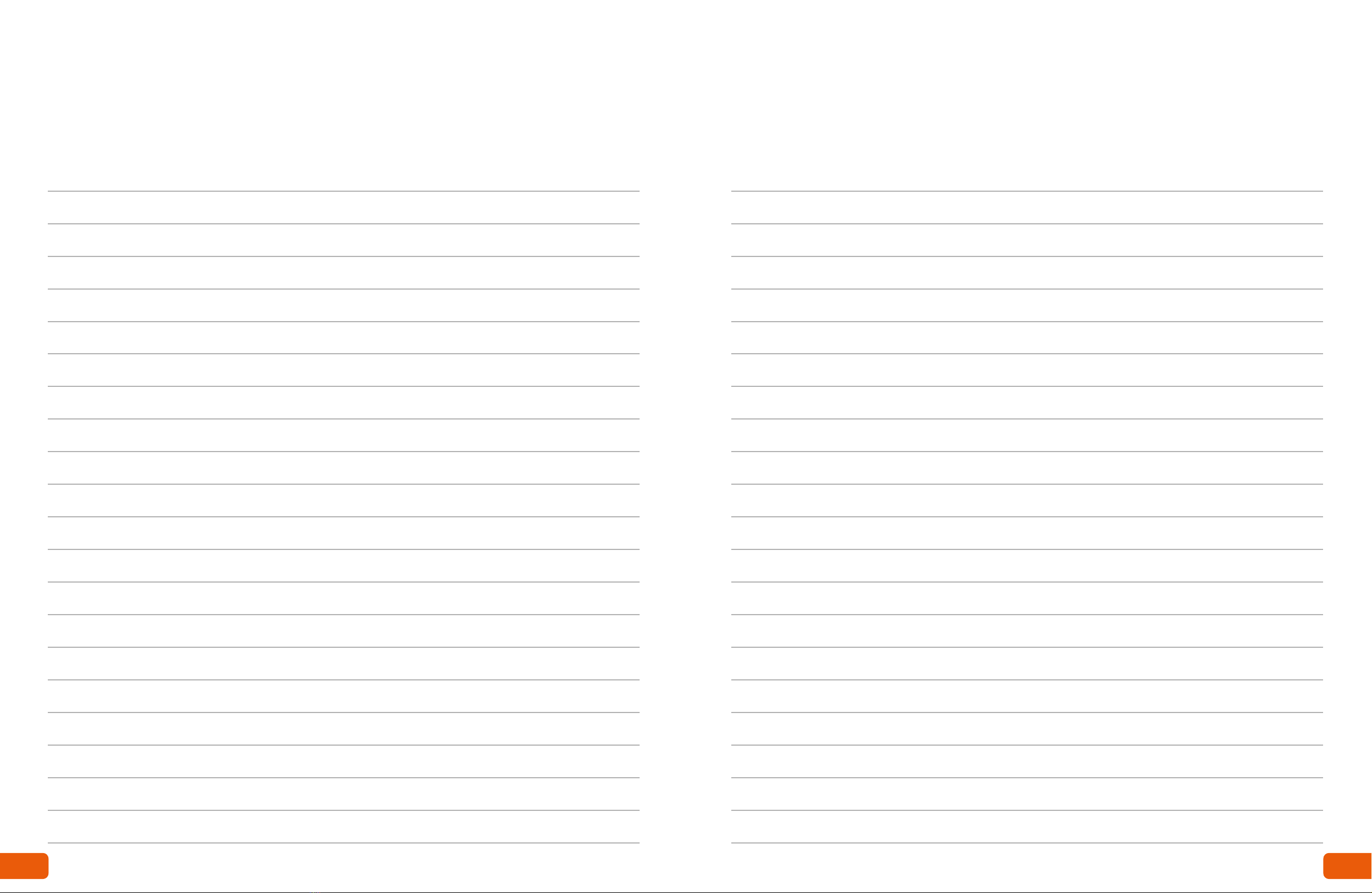

Installation of horizontal beams

1. Decide the height of the beam installation in the structure, as per

the mounting holes available in each section (top, middle and

bottom).

2. On the left frame, identify the mounting square holes, then insert

an M6 cage nut in each one, with the tabs facing outward.

Note: make sure that both ends (front and rear) of the beam are

placed at the same level.

Top and bottom frame subassembly

Top, middle and bottom beams (4 or 6)

M6x12mm phillps-head

screw (24)

5

20

M6 cage nuts (24)

M6 plastic washers (24)

18

19

9 10

Allen wrench

26

6

20

18

19

5

Vertical rails (4)

Installation of vertical rails

1. Using the structure with the beam subassembly, count up the

number of square holes on the beam from the front and rear ends

as needed, and insert two M6 cage nuts in each opening, with the

tabs facing inward.

2. Repeat this procedure until the first twelve (12) cage nuts are

installed on the left side.

3. Next, identify the 2 vertical perforated mounting rails.

4. Position the perforated mounting rails upright, so as to have the

number of rack units stamped from high (top) to low (bottom) on

each column.

Note: make sure that both ends (top and bottom) of the rail are

placed at the same level. In addition, the row of numbers on each

vertical rail must be facing each other, on the front and rear

sections of the unit.

5. Proceed to insert the M6 phillips-head screws and plastic

washers from the inside through the vertical mounting rails and into

the cage nut installed in each horizontal beam.

6. Repeat steps 1 through 5 for the right side.

Note: fully tighten the screws only after each pair of screws has

been inserted.

M6 cage nuts (24)

M6 plastic washers (24)

M6x12mm phillips screws (24)

3. Secure the assembly by inserting the M6 phillips-head screws and

washers from the inside through the horizontal beam holes and into

the cage nuts installed in the frames.

4. Repeat the same procedure for the installation on the right side.

5. After verifying that all beams are properly aligned, fully tighten all

the screws fixing the horizontal beams to the frames.

6. Now the horizontal beam subassembly is ready for the next phase.

Horizontal beam subassembly

6

3. Slide the plastic retaining latches on both sides of the panel to

their unlock position.

4. Push side panels against the support frames and release the

plastic retaining latches so as to re-engage them to their locked

position.

Note: each side panel features a pre-install key lock for securing both

sides of the enclosure. Insert the side panel key and turn it clockwise

to verify that the locking mechanism is working properly.

Installation of side panels

1. Next, identify the 2 lateral panels. Both are identical for this

model.

2. Align the tabs located on the bottom of each side panel with the

openings of the bottom tray.

Vertical rail subassembly

Side panels (2)

Side panel key set (1)

8

17

11 12

Rear door assembly

1. Identify the split rear door, bushings and pivot pins.

2. Insert the first bushing into the pivot pin at the bottom of the door

and hold it in place.

3. While supporting the door, align the bottom pivot pin with the

hinge hole on the frame, until it latches into position.

4. Next, pull down the pivot pin on the upper side of the door, align it

with the top hinge hole on the frame, and finally release it to secure

it into the enclosure.

5. Repeat the same steps to mount the other side of the door.

6. Verify that the doors are properly levelled and that both sides

open and close without friction or resistance.

7. Confirm that the door locks properly by closing the left door first,

followed by the right side door.

8. Lock the doors in position by inserting the key and turn it

clockwise to verify that the locking mechanism is working properly.

Split mesh rear door with lock (1)

Hinge bushings (2)

FRONT

REAR

7

3

25

16

Rear door key set (1)

Front door assembly

1. Identify the front door, bushing and pivot pins.

2. Insert the bushing into the pivot pin at the bottom of the door and

hold it in place.

3. While supporting the door, align the bottom pivot pin with the

hinge hole on the frame, until it latches into position.

4. Pull down the pivot pin on the upper side, align it with the top

hinge hole on the frame, and release to secure it into the enclosure.

5. Verify that the door is properly levelled and that it opens and

closes without friction or resistance.

6. Confirm that the door locks properly by pushing the handle inward,

insert the key in the lock and turn it clockwise.

7. Push the button to verify that the locking mechanism is engaged.

8. To open the door, turn the key counterclockwise and push the

button to release the handle from its locking position.

Hinge bushing (1)

Front door (1)

1

8

25

FRONT

REAR

Front panel key set (1)

15

Pivot pin Pivot pin

13 14

Equipment installation

The enclosure is now assembled and ready for equipment

installation.

1. Do not install any equipment until you have stabilized the

structure.

2. Always load the heavier items at the bottom first, followed by the

lighter equipment at the top of the enclosure, for safety reasons.

3. Identify the second and third square holes from the front (left and

right) and rear (left and right) ends and insert an M6 cage nut in

each opening, with the tabs facing inward.

4. Repeat this procedure until all M6 cage nuts are installed in the

square holes of the front and back rails.

5. Proceed to insert the M6x12mm phillips-head screws and plastic

washers from the inside through the vertical mounting rails and into

the nuts you installed in the previous step.

10

M6 cage nuts (20, 30 or 40)

M6 plastic washers (20, 30 or 40)

M6x12mm phillips-head

screws (20, 30 or 40)

29

27

28

LIGHT

HEAVY

LAST

FIRST

6. Finish by tightening the screws to secure the equipment inside

the enclosure.

Note: the square holes on the vertical rails are numbered to easily

identify each mounting point.

9

Grounding cables with terminal

rings (3 sets with copper split

and flat washers)

M4 self-tapping screw (1)

24

13

Grounding connection

1. Connect the first grounding cable to the door using the provided

hardware.

2. Likewise, connect the other end of the grounding cable to the

grounding post of the bottom tray using the hardware provided.

3.Next, connect the second grounding cable to the grounding post of

the rear door on the left side.

4. Then connect the other end of the grounding cable to the

grounding post of the bottom tray.

5. Repeat the same step for the door of the right side.

Note: fully-tighten the screws only after all the screws have been

inserted.

15 16

19 20

NotesNotes

This manual suits for next models

9

Table of contents