Nicotra Gebhardt FAN Commander 200 User manual

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 1 on 24

Operating manual EN

FAN Commander 200

BA-ECE 03 – Release 2020-04-06

ECE 03-0200-5E- M

D 155444 D 155445

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 2 on 24

Warn

ing

Present operating manual is a part of the product.

Before installing and using you ha e to read all safety

instructions, warnings and cautions carefully. Make

sure that the warning labels are in readable

conditions, replace missing or damaged ones.

Contact data for further information

Nicotra Gebhardt GmbH

Gebhardtstraße 19-25 Phone: +49 (0)7942 / 101 - 0

74638 Waldenburg

Germany E-Mail: Info.ng.de@regalbeloit.com

Table of Content

1

General Information....................................................................................................... 3

2

O er iew ....................................................................................................................... 6

3

Features ........................................................................................................................ 6

3.1

Basic features of the de ise .................................................................................... 6

3.2

Inputs and Outputs ................................................................................................. 6

3.3

Fan Network – RS485 link ...................................................................................... 7

4

Installation ..................................................................................................................... 8

4.1

Ambient Operating Conditions ................................................................................ 8

4.2

Mechanical Installation ........................................................................................... 9

4.2.1

Wall-Mounted Style .......................................................................................... 9

4.2.2

Counter-Sunk Style .......................................................................................... 9

4.3

Electrical Installation ............................................................................................. 10

4.3.1

Connection O er iew ..................................................................................... 10

4.3.2

Description Connection .................................................................................. 11

4.3.3

Connection Details ......................................................................................... 11

4.3.4

Connection Example ...................................................................................... 14

4.3.5

Wiring of Nicotra Gebhardt FFU Controller .................................................... 15

5

Working with the FC 200 ............................................................................................. 16

5.1

Software ............................................................................................................... 16

5.2

Commissioning ..................................................................................................... 17

5.2.1

Quick Commissioning – fan dri en by speed setting ...................................... 17

5.2.2

Quick Commissioning – fan dri en by closed loop control ............................. 17

6

Technical Data ............................................................................................................ 18

6.1

Connection ........................................................................................................... 18

6.2

Housing ................................................................................................................ 18

6.3

Ambient Operating Conditions .............................................................................. 18

6.4

IN/- and OUTPUTs ............................................................................................... 19

6.5

Fan Network ......................................................................................................... 19

7

Additional Hints ........................................................................................................... 20

7.1

Manufacturing ....................................................................................................... 20

7.2

Packing and Shipping ........................................................................................... 20

7.3

Ser ice .................................................................................................................. 20

8

Notes ........................................................................................................................... 21

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 3 on 24

1 General nformation

Definition and Meanings

For all different safety instructions special symbols are used in this manual.

Follow all hints and warnings to a oid any injury or material damage. The user of the

de ice is fully responsible.

Warnings

„Warning“ indicates that death, se ere personal injury or extensi e

property damage can result if proper precautions are not taken.

Danger

„Danger“ indicates an immediate risk of electric shock which will

result in death, injury or serious damage if the applicable safe

ty

regulations are not followed

Caution

The symbol refers to a possible hazardous situation that could

cause material or en ironmental damage.

Recommendation and useful information and ad ices for an efficient

operation free of malfunctions and faults.

Qualified personal only

Only qualified person(s) must operate with the present de ice. This qualified personal

must be familiar to these types of products and associated with danger and risks,

authorized to install, mount, commission and use these types of product.

Designated use

Use this de ice only in the manner intended by the manufacturer, according to the manual

and only in combination with the described products only.

Safety nstructions

All Warnings, Cautions and Hints shown in this document are pro ided for your safety and

as a means of pre enting damage to the product. This section lists Warnings, Cautions

and Hints, which apply generally when handling the FC 200, classified as General,

Transport & Storage, Commissioning, Operation, Ser ice and Repair. Specific Warnings,

Cautions and Hints that apply to certain specific chapters are listed at the beginning of the

rele ant chapters. Please read the information carefully, since it is pro ided for your own

personal safety and it will also help prolong the ser ice life of your product.

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 4 on 24

Warn

ing

This equipment controls potentially dangerous rotating mechanical

parts. Noncompliance with Warnings

or a miss to follow the

instructions contained in this manual can result in loss of life, se ere

personal injury or serious damage to property.

Only suitable qualified personal

should work on this equipment,

and only

after becoming familiar with all safety notices, installation,

operation and maintenance procedures contained in this manual.

The successful and safe operation of this equipment is

dependent

upon its proper handling, installation, operation and maintenance.

Children and the general public must be pre ented from accessing

or approaching the equipment!

nformation

Keep these operating

instructions within easy reach of the

equipment and

make them a ailable to all users. Whene er

measuring or testing has to be

performed on li e equipment suitable

electronic tools should be used.

Before installing and commissioning, please read these saf

ety

instructions and

warnings carefully and all the warning labels

attached to the equipment.

Transport & Storage

Warning

Correct transportation and

storage, erection and mounting, as well

as careful operation and maintenance are essential for proper and

safe operation of the equipment.

Protect the de ice against physical shocks and ibration during

transport and

storage. Also be sure to protect it against water

(rainfall) and excessi e temperatures.

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 5 on 24

Commissioning and Operation

Warn

i

ng

Use for intended purpose only.

The manual of the controlled fan

regardless whether type of fan it

is, is unconstrained by

advices in this manual, especially in questions of safety.

Some

parameter and settings lead to automatic restart of controlled fan

after switch-on.

Service & Repair

Warn

i

ng

Repairs and Ser ice on the de ice may only be carried out or

ad ised by

Approbations

All de ices of the FC 200 series are manufactured according

D RECT VE 2011/65/EU on the restriction of the use of certain hazardous

substances in electrical and electronic equipment

under consideration of the following harmonized standard:

EN 50581:2012.

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 6 on 24

2 Overview

All de ices of brand FC 200 (ECE 03-0200-5E-MG) are a stand-alone monitoring and

control unit for up to 200 fans with RS485-based interface of different brands.

A clear and simple menu guide has been realised bilingual (English/German) and offers a

ery easy access to 2 separate, free configurable and indi idual operating closed loop

cycles (Volume, Pressure, Temperature …).

The de ices are chose able as IP65-wallmounted solution or IP20-counter sunk design

a ailable with identic functions as well as customized OEM-solution in front design and

software.

3 Features

3.1 Basic features of the devise

main supply 24V DC @ 100 mA

Usage/addressing Standalone de ice for monitoring and control of up to 200

fans

Addressing 0(1) … 99(100) according to applied field bus

Temperature 0°C … 40°C operation (32°F … 104°F)

-20°C … 70°C storage temperature (-4°F … 158°F)

Display Amber colored full graphic display

Access easy access push encoder (IGR)

Time base Real-time-clock

3.2 nputs and Outputs

3 Digital Inputs (DIs) day-/night

DI1

DI2

for day/night shift

for external enable of group1

for external enable of group2

trigger +24V DI

2 Digital Outputs (DOs) Error

contact1

Error

contact2

“error”

for acknowledged, but still existing faults

“new error”

for new, unacknowledged faults

programmable as low-acti e or high-acti e

maximum contact load:

60V/500mA (peak AC / DC)

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 7 on 24

2 Analogue Outputs (AOs) +10V

+24V

for sensor or potentiometer supply internal

connected on 2 contacts (group 1 / 2)

maximum load in total

20mA (peak AC / DC)

for sensor supply internal connected on 4

contacts

maximum load in total

100mA (peak AC / DC)

2 Analogue Inputs (AIs) AI1

AI2

external sensor- or set alue input of group1

external sensor- or set alue input of group2

3.3 Fan Network – RS485 link

Interface Line 1

Line 2

2 identical lines - fieldbus - programmable

Nicotra||Gebhardt – odbus, GBUS

Hardware Transcei er acc. RS485 specification

Half duplex

1/8 Load up to 256 nodes (subscriber limited to 100 per line)

maximum 400m line length

Data Baud rate: 9600, 19200, 38400, 57600

Parity: none, e en, odd

Stop bits: 1, 2

Features set alues speed

enable

maximum speed

minimum speed

fault

(depending on chosen fan brand)

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 8 on 24

4 nstallation

Warning

Installation of the FC 200 by qualified personal only. This

qualified personal must be familiar to these types of products

and associated with danger and risks, authorized to install,

mount, commission and use these types of product.

Some parameters can cause a start of connected and

powered fans, without any further confirmation required

(scheduler, day/night shift …).

The de ice is fed be safety extra-low oltage (SELV) and

matches to protection class .

4.1 Ambient Operating Conditions

De ices of the FC 200 series are designed and

manufactured for indoor installation.

Wall mounted ariation ha e with closed lid IP 65

(en ironmental protection class). De ices in counter-sunk

style rated as IP20, additional sealed, transparent lid

a ailable on request

Shock

Warn

i

ng

Do not drop the de ice or expose to sudden shock.

Do not use the de ice in an area where it is likely to

be exposed to constant ibration higher than

2,5 mm*s

-1

.

Temperature

Warn

i

ng

Do not use de ice outside temperature range of 0°C … 40°C

(32°F … 104°F)

Electromagnetic Radiation

Warn

i

ng

Do not use the de ice near sources of

electromagnetic radiation.

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 9 on 24

4.2 Mechanical nstallation

4.2.1 Wall-Mounted Style

dimensions

in mm

drill pattern

in mm

4.2.2 Counter-Sunk Style

required mounting section: 137x68 mm

160

166

106

72

144

122

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 10 on 24

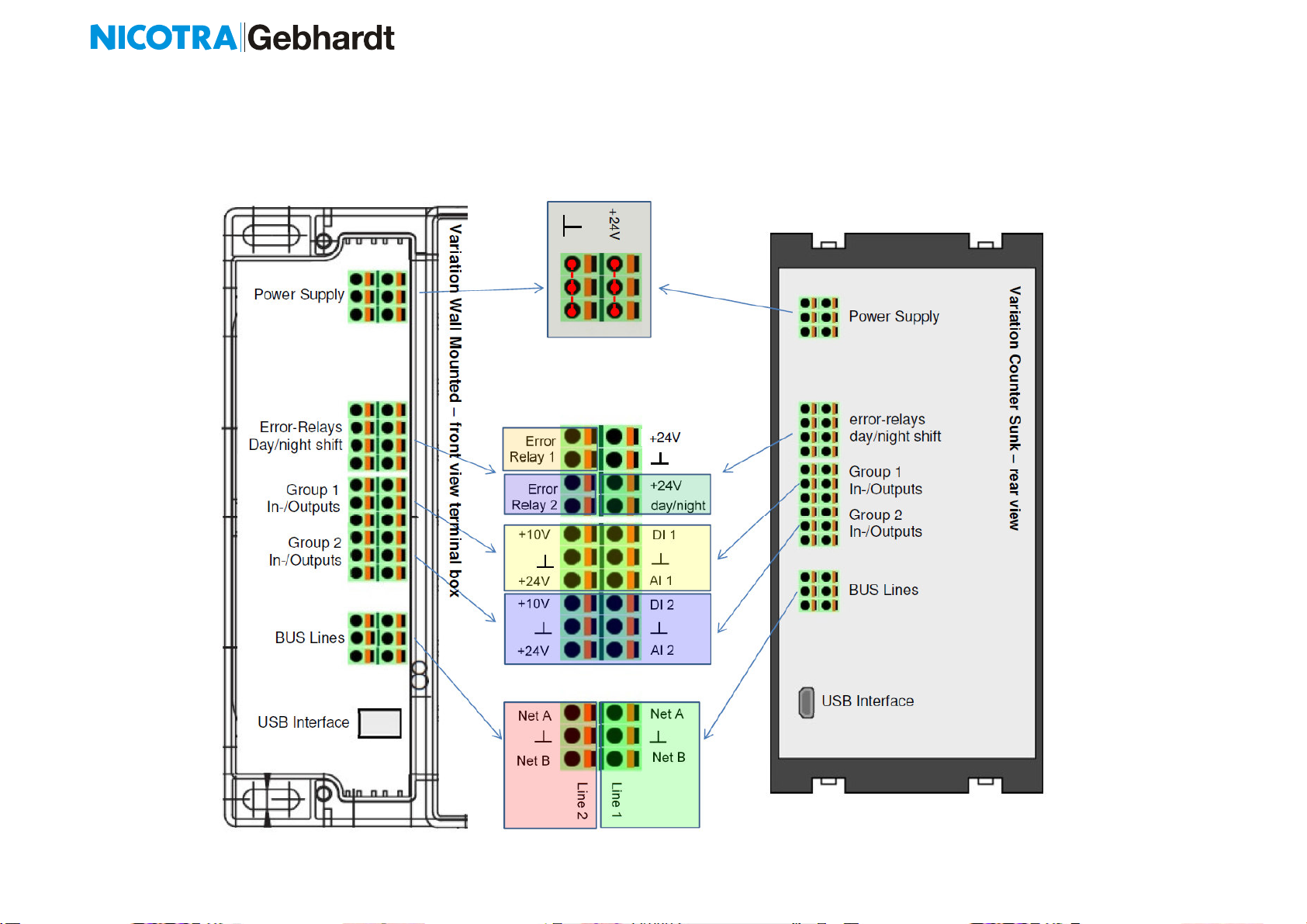

4.3 Electrical nstallation

4.3.1 Connection Overview

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 11 on 24

4.3.2 Description Connection

The terminal assignment of both design ariations Wall-mounted

and Counter sunk is identically.

4.3.3 Connection Details

Power Supply

24V(=) / 100mA

3 clamps each - internal linked

Error

Relays

Error-Relay 1 (1)

for acknowledged, but still existing faults

(new) Error-Relay 2 (2)

for new, unacknowledged faults

programmable as NC or NO

maximum contact load:

60V/500mA (peak AC / DC)

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 12 on 24

Day/Night

Day/Night Shift

Tripping +24V day/night

Group1

In-/Outputs

Group 1

DI1 (tripping +24V DI1)

External enable of control group 1

AI1 (0 … 10V)

analogue measure- or setpoint input

+10V (Power Supply for Sensor / Potentiometer)

maximum load in total (with Group 2)

20mA (peak AC / DC)

+24V (Power Supply Sensor)

maximum load in total (with Group 2)

100mA (peak AC / DC)

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 13 on 24

Group2

In-/Outputs

Group 2

DI1 (tripping +24V DI1)

External enable of control group 2

AI1 (0 … 10V)

analogue measure- or set point input

+10V (Power Supply for Sensor / Potentiometer)

maximum load in total (with Group 1)

20mA (peak AC / DC)

+24V (Power Supply Sensor)

maximum load in total (with Group 1)

100mA (peak AC / DC)

BUS Lines

Line 1

Connect up to 100 subscriber with RS485

Interface

Line 2

Connect up to 100 subscriber with RS485

Interface

WARN NG!

Handling of unused P Ns according to

specification of applied EC-fan supplier!

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 14 on 24

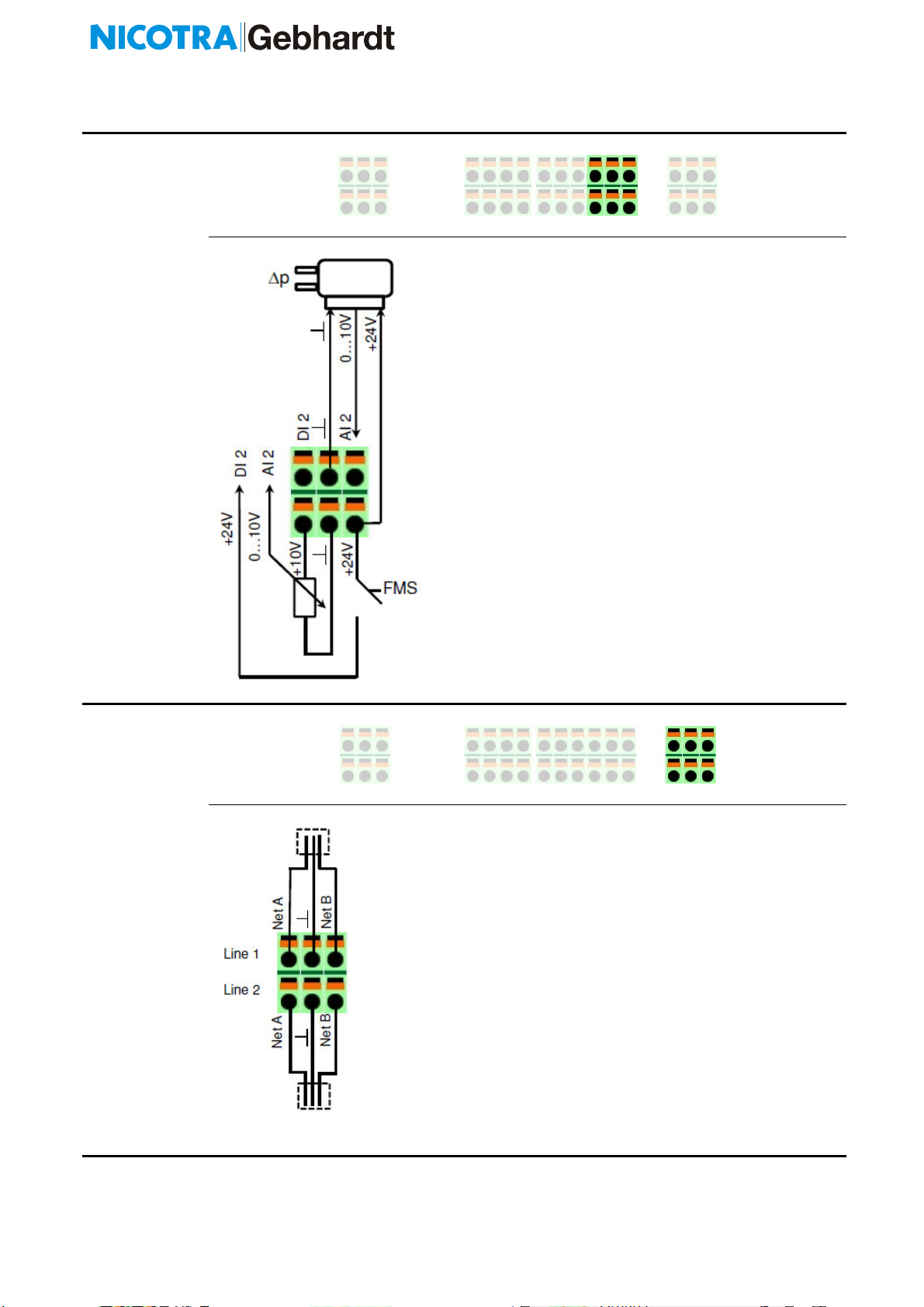

4.3.4 Connection Example

Group 1 – closed loop control pressure

3 fans at line 1

Sensor signal p as 0…10V and 24V(=) power supply

Extern enable of closed loop controller by FMS

Group 2 – speed control by potentiometer

2 fans at line 2

Potentiometer for speed setting by 0…10V

Internal enable of control

General connection

day/night - shift – external timer

Utilization error/new error by costumer FMS with external 24V (~) supply

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 15 on 24

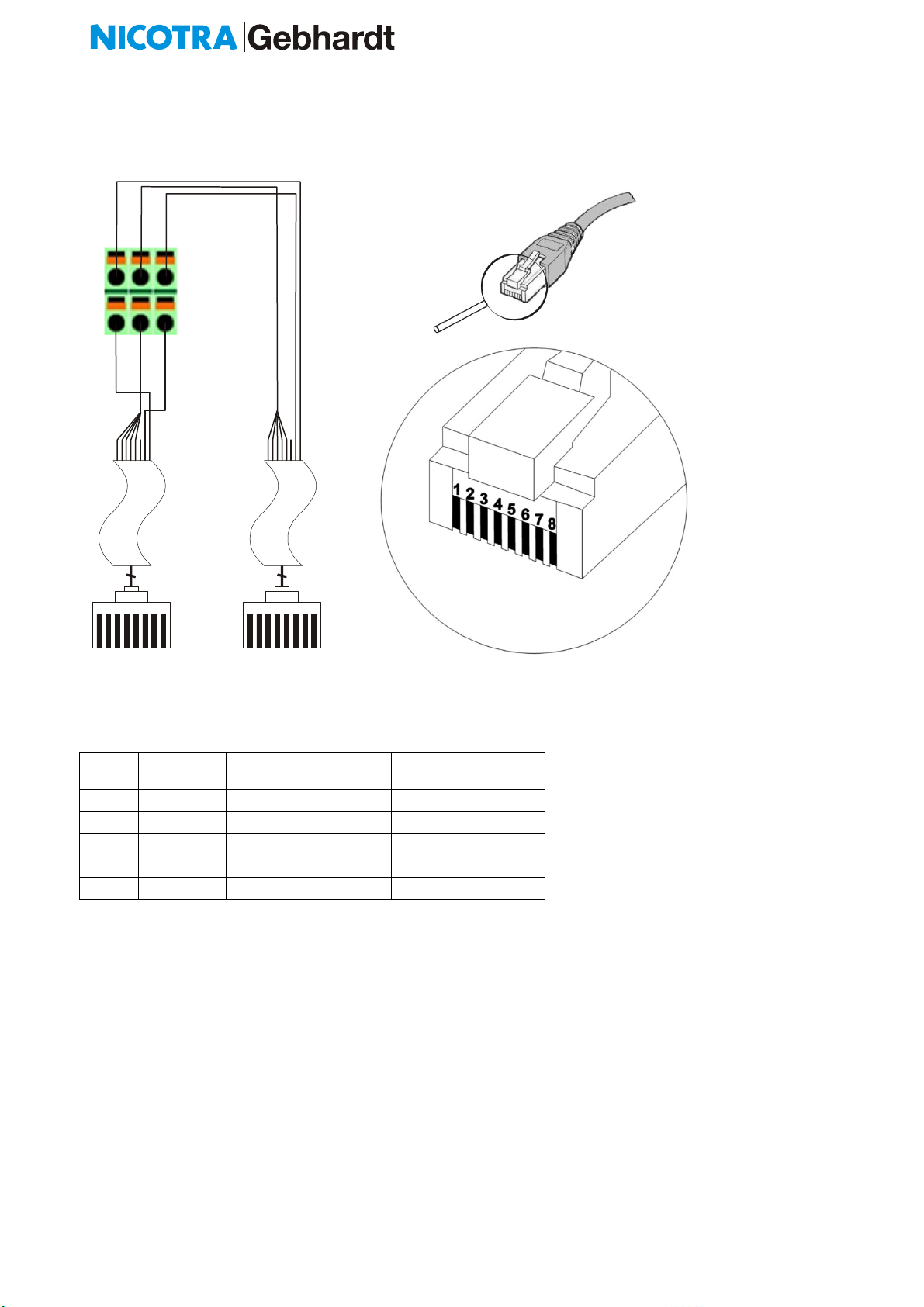

4.3.5 Wiring of Nicotra Gebhardt FFU Controller

Terminal assignment

Wire

Function

colour T A 568B

(mostly Germany)

colour T A 568A

(mostly USA)

1 Net A white / orange white / green

2 Net B orange green

3 Not

used

white / green white / orange

4-8 Ground All other wires All other wires

( iew to the RJ45 plug from front to the contacts)

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

8

8

1

1

8

8

Line 1

Line 2

Net A Net A

Net B Net B

GND GND

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 16 on 24

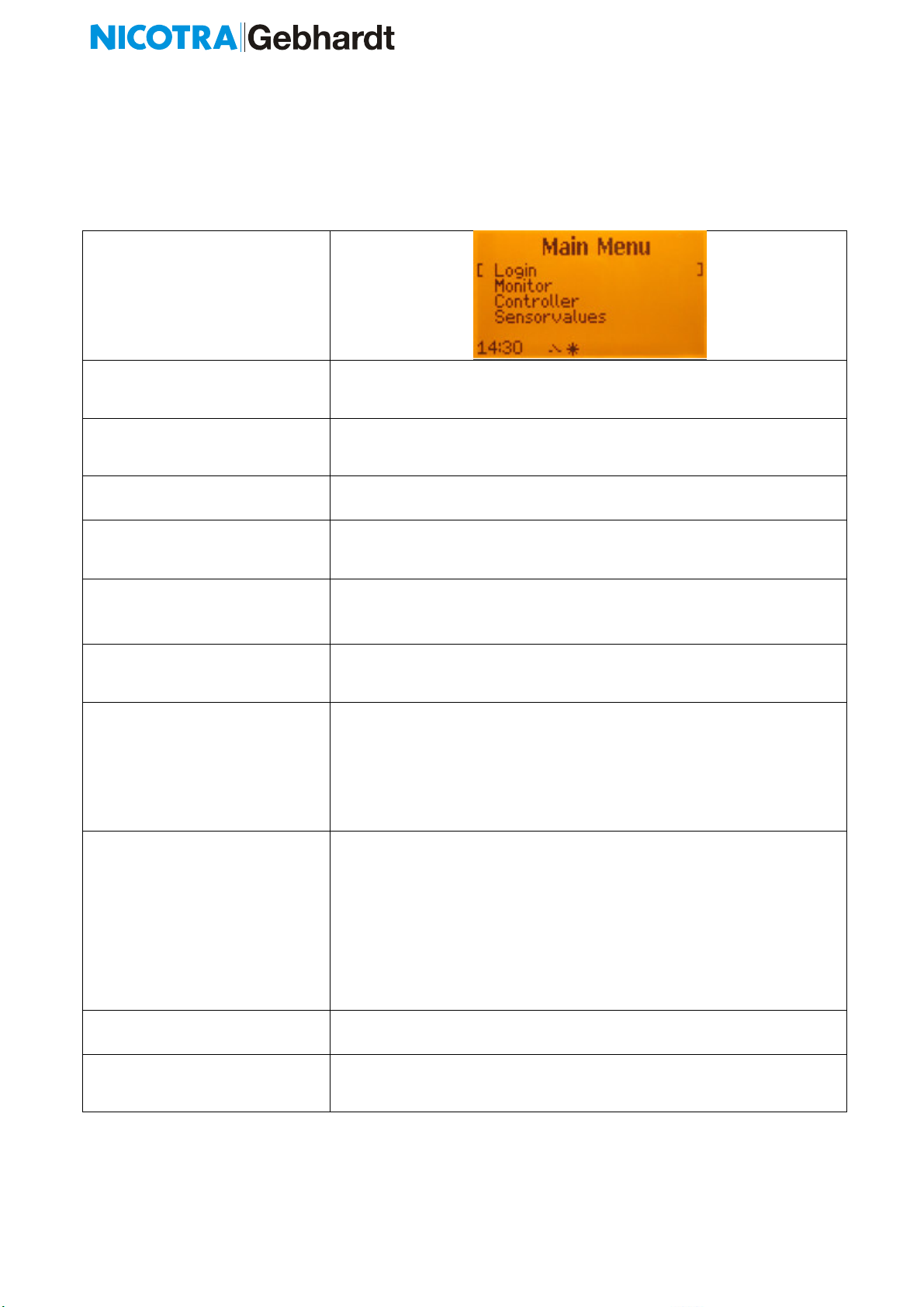

5 Working with the FC 200

5.1 Software

Display

Scan Line Network scan to find all connected de ices with the

chosen protocol

Single Monitor Cyclic scan of single de ice and monitoring of

requested data

Single Control

Control of a single addressable de ice with feedback

Group Control

Control of all fans assigned to one of 20 speed control

groups

Broadcast

Control / Parameterizing of all connected de ices

without feedback (broadcast)

Group Building

up to 20 groups (free definition) for simple speed control and

up to 2 groups for closed loop control mode

Internal PI-Controllers (2) two separate closed loop control circuits

free programmable as temperature, elocity, pressure and %

fixed assigned sensor signal inputs (1/2) and digital inputs

(1/2) to each closed loop control group (1/2)

Error Output as error indication signal and free configurable signal outputs

(high/low acti e) maximum 60V – 500mA

Error 1 red

for acknowledged, but still existing faults

Error 2 red alternating

for new, unacknowledged faults

Operating Le els

3 operating le els (Monitor / Operator / Administrator)

Timer Programmable Scheduler for set-point shift of single fans and

assigned groups

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 17 on 24

5.2 Commissioning

5.2.1 Quick Commissioning – fan driven by speed setting

required: Connection Power supply (24V) / Bus (NetA/NetB)

Mainmenu

Suble el 1

Suble el 2

Suble el 3

1. „Login“ as Administrator

default password „0000“

2. „Database“

used Bus Line (1/2) „Config Line“ choose rele ant Bustyp

„nstall Fan“

„Scan Line“ Found de ices will be installed automatically –

correct fan addressing required!

3. „Configuration“

choose – Single / Line / Group / All

max. speed checked or set correctly

4. „Control“

choose – Single / Line / Group / All

„Speed Day“ set day speed in %

„Start Fan“ Start Control

5.2.2 Quick Commissioning – fan driven by closed loop control

required: Connection Power supply (24V) / Bus (NetA/NetB) / Sensor AI (0…10V)

1. „Login“ as Administrator

default password „0000“

2. „Database“

used Bus line (1/2) „Config Line“ choose rele ant Bustyp

„nstall Fan“

„Scan Line“ Found de ices will be installed automatically –

correct fan addressing required!

„Assign group“ assign (fan) group ( 1 …10) for closed loop control

0 = none group

3. „Configuration“

choose – Single / Line / Group / All

max. speed checked or set correctly

4. „Controller“

„Config Controller“ choose Controller 1 or Controller 2 (acc. connection

of sensor to AI1 or AI2)

„Group“ assign under #2 defined fan group to Controller

if needed adapt further controller settings

„Control Controller“

choose Controller 1 or Controller 2

„Set Day“ Set Control alue in %

„Start Controller“ Start Controller with “Day-setting”

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 18 on 24

6 Technical Data

6.1 Connection

Power Supply 24V (=)

Current Consumption maximum 100mA

rating according load of 24V (=) i.e. by sensors

Connection plugs

Serie

Wire cross section

Wire cross section (AWG)

Cage Clamps

Phoenix FMCD 1,5/ x-ST-3,5

min. 0,2mm

2

/ max. 1,5mm

2

(solid and stranded)

min. 0,25mm

2

/ max. 1,5mm

2

(stranded with ferrule without

plastic collar)

min. 0,25mm

2

/ max. 0,75mm

2

(stranded with ferrule

with

plastic collar)

min. AWG/kcmil 24 / max. AWG/kcmil 16

6.2 Housing

Variation

Wall- ounted with lid

Fibox Cardmaster PC 1716-l3TT

Counter-Sunk

OKW

NEG TYP A 144x72

Dimensions (LxBxH) 166 x 160 x 100mm

144 x 72 x 129nn

Weight appr. 700g

appr. 500g

Protection Class

(DIN EN 60529)

IP65

IP20

Material

Polycarbonate

(UL 94-5V)

Noryl

(UL 94 V-0)

Protection Class (electrical)

(DIN EN 61140)

III

(Safety Extra Low Voltage)

No Protecti e Earth

III

(Safety Extra Low Voltage)

No Protecti e Earth

6.3 Ambient Operating Conditions

usage indoor application

Temperature 0°C … 40°C (32 … 104°F) - Operating

-20°C … 70°C (-4°F … 158°F) - Storage

relati e humidity 0 … 90%, non-condensing

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 19 on 24

6.4 N/- and OUTPUTs

Digital Inputs DI

(day/night; enable group)

+24V DI (Voltage)

10mA (minimum current source capacity)

4 kV (isolating oltage against internal circuit)

Analogue Inputs AI

(Sensor values-, Speed

setting)

0 … 0.5 … 10V (=)

from 0.5V linear

40 k

(internal resistance)

3,75 kV

(isolating oltage against

internal circuit)

Digital Outputs DO

(Error relays)

as low-acti e or high-acti e programmable

60V (max. Voltage as peak AC / DC)

500mA (max. Current as peak AC / DC)

1,5 kV (max. Current as peak AC / DC)

Analogue Outputs AO

Sensor Power Supply

+10V (=)

20mA (max. Current as peak AC / DC)

+24V (=)

100mA (max. Current as peak AC / DC)

min 1kV (isolating oltage across DC/DC con erter)

6.5 Fan Network

Hardware RS485

Maximum Subscriber 200 at 2 Lines

(100 / Line)

Maximum line length 400m (per Line)

Baud rate according type of subscriber

cable (recommended) Cat. 5

isolating oltage against

internal circuit

2,5 kV (o er oltage class 2)

0,5V

0,5V

U

a

nalogue

U

inp

10V

10V

Operating Manual “FAN Commander 200” ECE 03-0200-5E-MG Seite 20 on 24

7 Additional Hints

7.1 Manufacturing

All de ices of the FC 200 series are manufactured according

D RECT VE 2011/65/EU on the restriction of the use of certain hazardous

substances in electrical and electronic equipment

7.2 Packing and Shipping

The shipping is in fitting indi idual packing.

For export the FC 200 is categorized to the following HS code

85176200

Machines for the reception, con ersion and transmission or regeneration of oice,

images or other data, incl. switching and routing apparatus (excl. telephone sets,

telephones for cellular networks or for other wireless networks)

All claims for damage must be reported immediately.

7.3 Service

Technical queries about the FC 200 under:

Nicotra Gebhardt GmbH

Gebhardtstraße 19-25 Telephoneon: +49 (0)7942 / 101 - 0

74638 Waldenburg

Table of contents

Other Nicotra Gebhardt Controllers manuals