FGH 2000 Series Use and care manual

Communications Manual

Series 2000

FGH Controls Ltd

Openshaw Way,Letchworth

Herts. SG6 3ER

Tel:

(

01462

)

686677

Fax:

(

01462

)

480633

SERIES 2000 COMMUNICATIONS MANUAL 1

M41 Issue 1.1

SERIES 2000 COMMUNICATIONS MANUAL.

CONTENTS.

1.0 GENERAL DESCRIPTION. ........................................................................................................................................2

1.1 Specification. ...........................................................................................................................................................2

1.1.1 2-Wire EIA-485 Mode (RS485) .......................................................................................................................2

1.1.2 4-Wire EIA-422-A Mode (RS422)....................................................................................................................2

2.0 CONNECTIONS......................................................................................................................................................2

2.1 General. ...................................................................................................................................................................2

2.2 2 Wire EIA-485 Mode (RS-485).............................................................................................................................3

2.3 4-Wire EIA-422-A (RS-422) ...................................................................................................................................3

2.4 Connection reference table ....................................................................................................................................4

2.5 Software Configuration...........................................................................................................................................4

3.0 COMMUNICATIONS PROTOCOL.............................................................................................................................4

3.1 Message construction .............................................................................................................................................4

3.1.1 Write messages ................................................................................................................................................4

3.1.2 Read messages ................................................................................................................................................5

3.1.3 Set instrument status messages ......................................................................................................................5

3.2 Message header......................................................................................................................................................5

3.3 Instrument address..................................................................................................................................................6

3.3.1 Wildcard addresses ..........................................................................................................................................6

3.4 Message parameter code. ......................................................................................................................................6

3.5 Segment number field (P2000 Only). .....................................................................................................................6

3.6 Message data field ..................................................................................................................................................6

3.7 Controller read/write parameter codes ...................................................................................................................6

3.8 Programmer read/write parameter codes...............................................................................................................8

3.9 Controller Set status codes. ....................................................................................................................................8

3.10 Programmer Set status codes................................................................................................................................9

3.11 Response from read or write ..................................................................................................................................9

3.12 Set status response ................................................................................................................................................9

3.13 Controller error responses....................................................................................................................................10

3.13.1 Corrupt message response ..........................................................................................................................10

3.13.2 Syntax error response....................................................................................................................................10

3.14 Data fields .............................................................................................................................................................10

3.14.1 Data field type 1..............................................................................................................................................10

3.14.2 Data field type 2.............................................................................................................................................11

3.14.3 Data field type 3.............................................................................................................................................11

3.14.4 Data field type 4 (P2000 Only) ......................................................................................................................13

3.14.5 Data field type 5 (P2000 Only) ......................................................................................................................13

3.14.6 Data field type 6 (P2000 Only) ......................................................................................................................13

3.15 Coded data fields. .................................................................................................................................................14

3.15.1 Alarm type codes. ..........................................................................................................................................14

3.15.2 Setpoint type codes........................................................................................................................................14

3.15.3 Ratio limit reference type codes.....................................................................................................................14

3.15.4 Hold type codes (P2000 Only) .......................................................................................................................15

APPENDIX A - BASIC COMMUNICATIONS PROGRAM.................................................................................................16

2 SERIES 2000 COMMUNICATIONS MANUAL

M41 Issue 1.1

1.0 GENERAL DESCRIPTION.

The FGH S2000 controller or P2000 programmer all have serial communications fitted as

standard. This takes the form of 2 way serial asynchronous communication with a

computer.

Messages consist entirely of ASCII characters and may or may not contain spaces as

desired.

All messages are terminated with a carriage return, <CR>.

2-Wire EIA-485 (RS-485) or 4-Wire EIA-422-A (RS-422) serial communication standards

are supported.

1.1 Specification.

1.1.1 2-Wire EIA-485 Mode (RS485)

Transmission standard: EIA-485 (RS-485)

Data rates: 1200, 2400, 4800 and 9600 baud.

Data format: 1 start, 7 data, odd parity, 1 stop bit.

Implementation: 2 wire half duplex.

Max drivers per line: 32

Max receivers per line: 32

Max cable length: 1200 metres/3937 feet

1.1.2 4-Wire EIA-422-A Mode (RS422)

Transmission standard: EIA-422-A (RS-422)

Data rates 1200, 2400, 4800 and 9600 baud.

Data format 1 start, 7 data, odd parity, 1 stop bit.

Implementation 4 wire half duplex.

Max drivers per line 1

Max receivers per line 10

Max cable length 1200 metres/3937 feet

2.0 CONNECTIONS.

2.1 General.

The series 2000 may be connected to any computer or device which supports the RS422

or RS485 interface standards. This includes any other communicating instruments such

as the series 1000 or any other instrument using the FGH standard protocol.

The instrument uses a balanced voltage communications system which will perform well

under most situations provided some simple guidelines are adhered to.

1. The communications wiring should be implemented using screened cable comprising

one or two twisted pairs. The cable screen should be earthed at one point only.

2. The cable should be routed well away from sources of electrical noise such as motors,

contactors and any other high voltage wiring.

SERIES 2000 COMMUNICATIONS MANUAL 3

M41 Issue 1.1

3. The network should be wired as a daisy chain, taking the wires in to one instrument

and hence on to the next. Wiring spurs should be avoided. Take care to continue the

cable screen on to the next instrument.

4. For long cable runs or noisy environments it may be necessary to fit a terminating

resistor to the network. The terminator ( a 220Ωresistor ) should be fitted between

RX+ and RX- on both the computer and the furthest instrument. For two wire networks

this resistor should be fitted at the computer end only. Only one such resistor should

be fitted on each wire pair.

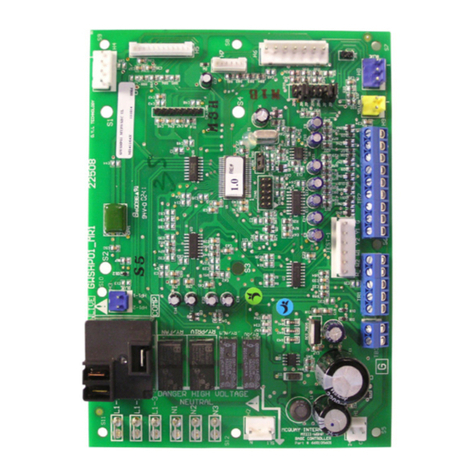

2.2 2 Wire EIA-485 Mode (RS-485)

This diagram shows the connection for EIA-485 mode. Note the use of screened cable. This

connection method may be continued on to other instruments up to the maximum allowed.

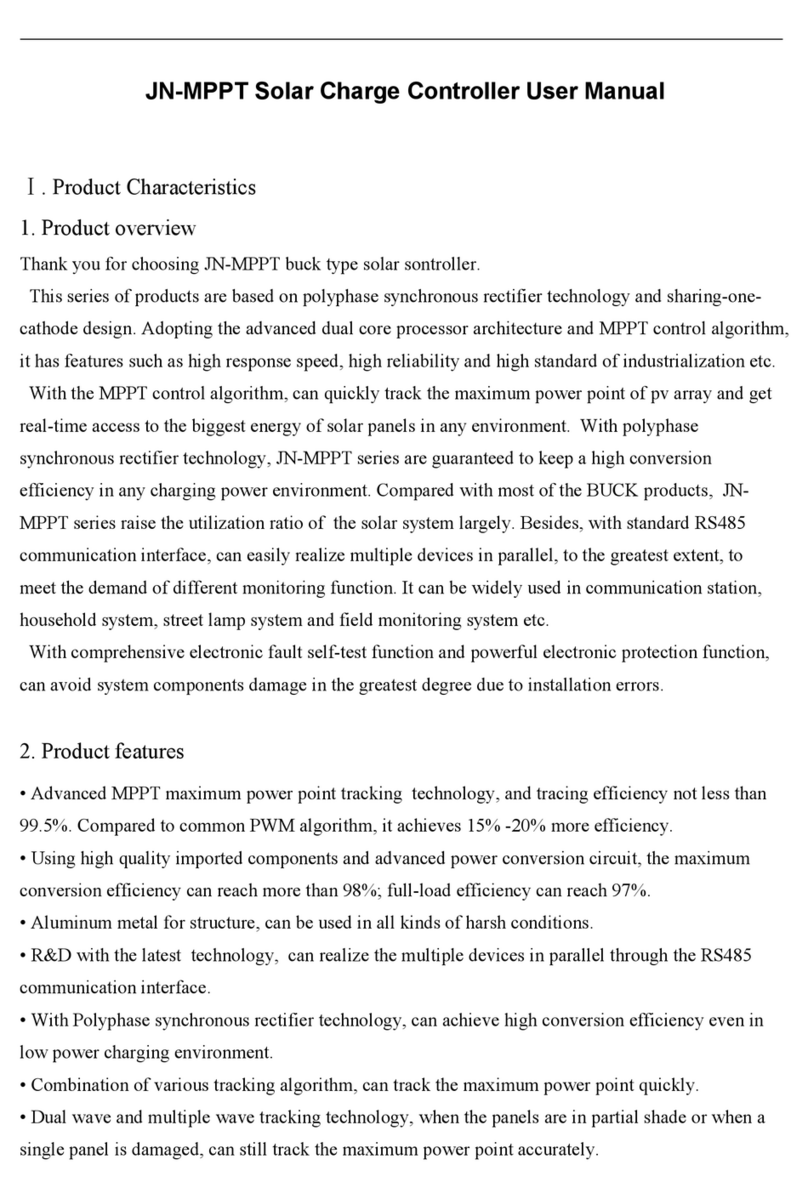

2.3 4-Wire EIA-422-A (RS-422)

This diagram shows the connection for EIA-422 mode. Note the use of screened cable.

This connection method may be continued on to other instruments up to the maximum

allowed.

4 SERIES 2000 COMMUNICATIONS MANUAL

M41 Issue 1.1

2.4 Connection reference table

Instrument

Terminal

Function EIA-485 EIA-422-A

13 TX- TX-/RX- TX-

14 TX+ TX+/RX+ TX+

15 RX+ TX+/RX+ RX+

16 RX- TX-/RX- RX-

1 EARTH N/C or

SCREEN

N/C or

SCREEN

2.5 Software Configuration.

Software configuration of the instrument may be performed once the instrument has been

placed in 'E mode'. This is done by removing the instrument from its sleeve and setting the

'E mode' switch to ON. The instrument is then replaced in its sleeve and power re-applied.

Use the scroll button (>) to scroll through elements until the ConS group is reached. Press

the star button to access the group.

Scroll to the element bAUd and select the baud rate required from 1200, 2400, 4800 or

9600 using the up/down keys

Scroll to the element AddrS. This is the controller instrument address and may be set

between 0 and 99 using the up/down keys. If the instrument is a P2000 programmer then

the controller part of the instrument will have an address as set by this parameter and the

programmer part of the instrument will have an address which is the controller address plus

16.

3.0 COMMUNICATIONS PROTOCOL

3.1 Message construction

Messages to and from the instrument vary in form depending on, amongst other things, the

type of message and its contents. There are three basic message types:-

3.1.1 Write messages

Write messages to the instrument take the following form.

WAAPSSD..D<CR>

where W= write message header

AA = instrument address

P= parameter code

SS = segment number field (P2000 Only)

D..D = numeric data field

SERIES 2000 COMMUNICATIONS MANUAL 5

M41 Issue 1.1

messages to the instrument may have the fields separated by spaces. These spaces will be

ignored. Messages from the instrument will not contain spaces. Eg.

W 45 C 0123 <CR>

will attempt to write 123 to the local set point as well as

W45C0123<CR>

The <CR> at the end of the message is a carriage return. (Hex 0D). Each message written

to the instrument must be terminated with, and each message from the instrument will be

terminated with a carriage return.

3.1.2 Read messages

Read messages to the instrument take the following form.

RAAPSS<CR>

where R= read message header

AA = instrument address

P= parameter code to be read

SS = segment number (P2000 Only)

Again the message must be terminated with a <CR>, and spaces may be included if

desired.

3.1.3 Set instrument status messages

Set messages to the instrument take the following form.

SAAC<CR>

where S= set message header

AA = instrument address

C= set parameter code to be performed

Again the message must be terminated with a <CR>, and spaces may be included if

desired.

3.2 Message header.

This may be;

ASCII Rsignifying a Read

ASCII Wsignifying a Write

ASCII Ssignifying a Set.

The Rheader is used whenever data is being read from the instrument. When this header

is used the data field is absent. The Wheader is used to write data to the instrument. The

Sheader is used to set the status of the instrument.

6 SERIES 2000 COMMUNICATIONS MANUAL

M41 Issue 1.1

3.3 Instrument address.

Each instrument must be given a unique address between 0 and 99. This is set when the

instrument is in E mode. The address field of the message, consisting of two ASCII

characters determines to which instrument the message is directed. The instrument ignores

the message unless it corresponds to its own address.

For serial communications purposes, the programmer and controller parts of the

instrument are treated as separate instruments. The controller part will recognise

messages whose address field corresponds exactly with the address programmed in

engineers mode. The programmer part will recognise the programmed address plus 16.

This fact should be borne in mind when assigning controller addresses on the network.

3.3.1 Wildcard addresses

If desired, a group of instruments can be written to together by using a wildcard character

(large X) in place of one or both of the address characters. eg.

W6XC0100<CR>

would result in all instruments on that communication line with addresses of 60 to 69 having

their local set point set to 100.

Instruments written to with wildcard addresses do not reply.

3.4 Message parameter code.

The parameter code field of the message is a single ASCII character. In a write message

this corresponds to one of the control parameters listed in paragraph 4.6, 'parameter codes'.

In the case of set messages, this is still a single ASCII character, but corresponds to one of

the 'set status codes' listed in paragraph 3.7.

3.5 Segment number field (P2000 Only).

This field is used to specify the segment number reference required for some messages to

the profile generator. The segment number should be a two digit field, left padded with a

zero if required.

3.6 Message data field

The message data field consists of between four and eight ASCII characters and carries the

data associated with the specified parameter. There are six types of data field, the type

depending on the particular parameter being accessed. The parameter code tables in

section 3.7 and 3.8 specify the data field format for each parameter.

3.7 Controller read/write parameter codes

Each parameter within the controller is assigned a single alpha code. The meaning of this

code may vary according to the controller action type, eg. heat/cool, motorised valve etc.

SERIES 2000 COMMUNICATIONS MANUAL 7

M41 Issue 1.1

Please note that some parameters use coded data fields, the code meanings are listed

after the table.

Code R/W Parameter Scroll

Element

Data field

type

@ R/W Comms remote setpoint - 1

A R Measured variable - 1

B R/W Output in 0.1%

Desired valve position

OP

OP

1

1

C R/W Local setpoint SP-L 1

D R/W Propband in 0.1%

Ratio in 0.1%

ProP

rAt

1

1

E R/W Integral action time in S

Ratio low setpoint output limit

IAt

LoOP

1

1

F R/W Derivative action time in S

Ratio low thermal head limit

dAt

tHLo

1

1

G R/W Derivative approach band in Xp

Ratio approach band

APr

bAnd

1

1

H R/W Heat high power limit in 0.1%

Ratio high air setpoint limit

H-PL

HiOP

1

1

I R/W Heat TP cycle time in S

Ratio positive reference type

HCyC

rEFH

1

1

J R/W Alarm 1 level ALr1 1

K R/W Alarm 2 level ALr2 1

L R Controller status - 2

M R/W User Retransmit value - 1

N R Resultant (control) setpoint - 1

O R/W Setpoint type code StyP 1

P R/W Alarm 1 type code A1ty 1

Q R Instrument type code - 3

R R Analogue remote setpoint value - 1

S R/W Alarm 2 type code A2ty 1

T R/W Heat low power limit in 0.1%

Cool high power limit in %

Ratio max thermal head

L-PL

C-PL

tHHi

1

1

1

U R/W Setpoint ramp rate in digits/hour rAtE 1

V R/W Cool TP cycle time in S

Valve action time in S

Ratio negative reference type

CCyC

VAt

rEFL

1

1

1

W R/W Cool relative prop band in 0.1 rEL 1

X R/W Heat/Cool deadband in 0.1%

Motor valve deadband in 0.1%

dbnd

dbnd

1

1

Y R/W Auxiliary setpoint 1 SP1 1

Z R/W Auxiliary setpoint 2 SP2 1

8 SERIES 2000 COMMUNICATIONS MANUAL

M41 Issue 1.1

3.8 Programmer read/write parameter codes

The table below shows the meaning of all the parameter codes available in the profile

generator.

PARAMETER

CODE

SS

FIELD

MEANING READ

ONLY

DATA

FIELD

C N/A Profile setpoint YES TYPE 1

D N/A Delay start time in mins NO TYPE 1

E N/A Segment Elapsed time in mins YES TYPE 1

H N/A Profile hold band in digits NO TYPE 1

I N/A Profile hold type NO TYPE 1

(coded)

J N/A Profile repeats NO TYPE 1

K N/A Number of repeats remaining YES TYPE 1

L YES Segment target level in digits NO TYPE 1

M N/A Current event status YES TYPE 4

N N/A Ready mode event status NO TYPE 4

P N/A Profile pointer NO TYPE 1

Q N/A Profile status YES TYPE 5

R YES Segment event outputs NO TYPE 4

T YES Segment time in minutes NO TYPE 6

X N/A Profile currently running YES TYPE 1

3.9 Controller Set status codes.

Writing a set command to the instrument with a parameter as follows will produce the

specified action if the address field matches the address of the instrument. In the examples

given the instrument address is assumed to be 20.

CODE MESSAGE REPLY MEANING

M S20M<CR> *20M<CR> Set controller to Manual mode

A S20A<CR> *20A<CR> Set controller to Auto mode

P S20P<CR> *20P<CR> Turn on the pretuner

T S20T<CR> *20T<CR> Turn on the adaptive tuner

O S20O<CR> *20O<CR> Turn off pretuner and adaptive tuner

U S20U<CR> *20U<CR> Unlatch any latched alarms

SERIES 2000 COMMUNICATIONS MANUAL 9

M41 Issue 1.1

3.10 Programmer Set status codes.

Programmer set commands are signified by the Sheader as they are for the controller.

There are only four set parameter codes and their meanings are given below.

CODE MESSAGE REPLY MEANING

S S36S<CR> *36S<CR> Start profile pointed to by profile pointer

R S36R<CR> *36R<CR> Reset currently running profile

H S36H<CR> *36H<CR> Holds (pauses) execution of profile

F S36F<CR> *36F<CR> Frees hold allowing profile to continue

3.11 Response from read or write

The response of the instrument to a satisfactory read or write message with the correct

address will be as follows (unless an address wildcard is used, see para 3.3.1):

*AAPSSD..D<CR>

The instrument will respond with a string of ASCII characters. The header will consist of '*'

(Hex 2A).

The AA, Pand SS fields will be exactly the same as in the message which prompted the

response. The SS field will only be present for some messages to and from the profile

generator part of the instrument.

The format of the data field D..D is specific to the parameter code used and these field types

are described in section 3.14.

3.12 Set status response

The response of the controller to a satisfactory 'set status' message with the correct address

will be as follows (unless a wildcard address is used):

*AAP<CR>

The controller will respond with a string of ASCII characters. The header will consist of '*'

(Hex 2A). The header will be followed by an address (AA) showing the address of the

responding instrument in ASCII, 00 to 99.

after the address is a single ASCII character showing the 'set status' mnemonic used

This is followed by a <CR> to complete the message return.

10 SERIES 2000 COMMUNICATIONS MANUAL

M41 Issue 1.1

3.13 Controller error responses

Two sorts of error in a received message may be detected by the controller, these are:

3.13.1 Corrupt message response

Noise or interference during the transmission of the message causing corruption of one or

more characters so that it was no longer valid. The receiver within the instrument detects

this, and as long as it was not the address that was corrupted, the controller responds as

follows;

?AAC<CR>

where AA is the address of the instrument responding

C= Pfor detected parity error

Ffor detected overflow error

Ofor detected receiver overrun

3.13.2 Syntax error response

Messages that were correctly received but don't make sense, as long as the address part

was o. k. generate the following response;

?AANN<CR>

where AA = address of the instrument responding

NN = two digit ASCII HEX error code

Error code binary weightings:

bit7 = Illegal trailer

bit6 = Tx buffer overflow

bit5 = Illegal number of characters

bit4 = Illegal data

bit3 = Illegal parameter code

bit2 = Rx buffer overflow

bit1 = Illegal header

bit0 = Write to read only parameter

3.14 Data fields

There are six different type of data fields used on the Series 2000.

3.14.1 Data field type 1

This is the most common of the data field types and is used for simple numeric data.

The data field consists of 4 numeric characters preceded by an optional minus sign.

For example to write to the local setpoint on instrument address 3.

The computer would send W03C-0100<CR>

SERIES 2000 COMMUNICATIONS MANUAL 11

M41 Issue 1.1

The instrument would respond *03C-0100<CR>

Note that the data field is padded out to 4 characters in both the query and response

messages.

3.14.2 Data field type 2.

This data field type is reserved for the controller status obtained by reading parameter L.

The instrument will respond with:

*NNLABCD<CR>

Where NN is the instrument address.

A= Digital inputs = 0 Both off or unused

= 1 Input 1 on, 2 off or unused

= 2 Input 2 on, 1 off or unused

= 3 Both digital inputs are on.

B= alarm condition = 0 Both alarms off

= 1 Alarm 1 on, alarm 2 off

= 2 Alarm 2 on, alarm 1 off

= 3 Both alarm 1 and 2 are on

C= Tuner status = 0 pretune and atune are off

= 1 pretune is on, atune is off

= 2 atune is on, pretune is off

= 3 pretune and atune are on

D= Auto/Man = 0 Automatic

= 1 Manual

3.14.3 Data field type 3

This data type is reserved for the instrument type code. The instrument type code may be

read from the controller by reading parameter code Q. The controller will respond with;

*NNQABCD<CR>

Where A= Input 2 = 0 Controller with remote setpoint

= 1 Controller without remote setpoint

= 3 Programmer/Controller

BC = Input = 00 Type S, degrees C

type = 01 Type R, degrees C

= 02 Type J, degrees C

= 03 Type K, degrees C

= 04 Type T, degrees C

= 05 Type E, degrees C

= 06 Type B, degrees C

12 SERIES 2000 COMMUNICATIONS MANUAL

M41 Issue 1.1

= 07 Type N, degrees C

= 08 Type W, degrees C

= 09 Type W3, degrees C

= 10 Type W5, degrees C

= 11 Type NM, degrees C

= 12 Type L, degrees C

= 13 Type K10, degrees C

= 14 Type T10, degrees C

= 15 Type RT10, degrees C

= 16 Type RT, degrees C

= 17 Type S, degrees F

BC = Input = 18 Type R, degrees F

type = 19 Type J, degrees F

= 20 Type K, degrees F

= 21 Type T, degrees F

= 22 Type E, degrees F

= 23 Type B, degrees F

= 24 Type N, degrees F

= 25 Type W, degrees F

= 26 Type W3, degrees F

= 27 Type W5, degrees F

= 28 Type NM, degrees F

= 29 Type L, degrees F

= 30 Type K10, degrees F

= 31 Type T10, degrees F

= 32 Type RT10, degrees F

= 33 Type RT, degrees F

= 34 Type Linear

= 35 Type Root

D= Control = 0 None

action = 1 Heat only

= 2 Heat and Cool

= 3 Motorised Valve

= 4 Ratio output

SERIES 2000 COMMUNICATIONS MANUAL 13

M41 Issue 1.1

3.14.4 Data field type 4 (P2000 Only)

This data field consists of 8 data digits and is used solely for event output data. Each data

digit may be either a '1' (signifying event ON), or '0' (signifying event OFF).

For example, To read the current event output status from instrument address 4.

The message R20M<CR>

May be answered *20M10010000<CR>

Indicating that events 1 and 4 are currently on and the rest are off.

3.14.5 Data field type 5 (P2000 Only)

This data field type is used for profile status only, and consists of 4 digits some of which may

be alpha characters.

For example, reading the profile status of instrument address 4.

The message R20Q<CR>

May invoke the reply *20QR'dy<CR>

indicating that the programmer is in ready mode.

Or *20Q02<CR>

Indicates that segment 2 is currently running.

Or *20Q03HM<CR>

Indicates that segment 3 is running, the Hindicates that the programmer is in hold and the

Mindicates the programmer is recovering from a mains failure.

3.14.6 Data field type 6 (P2000 Only)

This data field type is only used for parameter code T (segment time). It consists of 4

numeric data digits preceded by an optional alpha character.

For example reading the segment 12 target time from instrument address 4.

(Note the use of the SS field to specify the segment number).

The message R20T12<CR>

May invoke the reply *20T124000<CR>

Indicating that the segment time is 4000 minutes.

Or *20T12E0000<CR>

Indicating that the segment is programmed as an END.

Or *20T12G0008<CR>

Indicating that the segment is programmed as GOTO program 8.

14 SERIES 2000 COMMUNICATIONS MANUAL

M41 Issue 1.1

3.15 Coded data fields.

3.15.1 Alarm type codes.

Reading and writing the controller alarm types is possible by use of parameters P(alarm 1)

and S(alarm 2) where the data field of the message is coded as follows.

DATA FIELD S2000 ALARM TYPE P2000 ALARM TYPE

0000 HIGH ALARM HIGH ALARM

0001 LOW ALARM LOW ALARM

0002 INDEXED ALARM INDEXED ALARM

0003 INDEXED HIGH ALARM INDEXED HIGH ALARM

0004 INDEXED LOW ALARM INDEXED LOW ALARM

0005 MANUAL ACK' RELAY MANUAL ACK' RELAY

0006 REMOTE SP ACK' RELAY REMOTE SP ACK' RELAY

0007 INVALID PROGRAM RELAY

0008 INVALID READY RELAY

0009 INVALID UP RAMP RELAY

0010 INVALID DOWN RAMP RELAY

0011 INVALID SOAK RELAY

3.15.2 Setpoint type codes.

The setpoint type (parameter code O) is coded as follows.

DATA FIELD SETPOINT TYPE

0000 HIGH CLAMPED SETPOINT

0001 LOW CLAMPED SETPOINT

0002 INDEXED SETPOINT

0003 REMOTE SETPOINT

0004 INTERNAL SETPOINT

3.15.3 Ratio limit reference type codes.

The ratio limit 1 reference (parameter code I) is coded as follows.

DATA FIELD RATIO REFERENCE TYPE

0000 LIMIT IS OFF

0001 LOAD

0002 SETPOINT

SERIES 2000 COMMUNICATIONS MANUAL 15

M41 Issue 1.1

3.15.4 Hold type codes (P2000 Only)

Programmer parameter code I (Hold type) uses coded data of the following form.

DATA FIELD HOLD TYPE

0000 NO INTERNAL HOLD

0005 HOLD ON RAMPS, ABOVE SETPOINT ONLY

0006 HOLD ON RAMPS, BELOW SETPOINT ONLY

0007 HOLD ON RAMPS, ABOVE AND BELOW SETPOINT

0009 HOLD ON DWELLS, ABOVE SETPOINT ONLY

0010 HOLD ON DWELLS, BELOW SETPOINT ONLY

0011 HOLD ON DWELLS, ABOVE AND BELOW SETPOINT

0013 HOLD ON RAMPS & DWELLS, ABOVE SETPOINT ONLY

0014 HOLD ON RAMPS & DWELLS, BELOW SETPOINT ONLY

0015 HOLD ON RAMPS & DWELLS, ABOVE AND BELOW SETPOINT

16 SERIES 2000 COMMUNICATIONS MANUAL

M41 Issue 1.1

APPENDIX A - BASIC COMMUNICATIONS PROGRAM

1000 REM DEMO PROGRAM FOR S2000 COMMUNICATIONS (GW-BASIC V3.23)

1010 ON ERROR GOTO 6000

1020 GOSUB 2000 'INITIALISE

1030 GOSUB 3000 'DRAW SCREEN

1040 WHILE PAUSED=0 'Main loop

1050 KEY (7) STOP:KEY (8) STOP

1060 FOR I=1 TO MAXPRM

1070 KEY (5) STOP:KEY (6) STOP

1080 LOCATE 5+I,1

1090 GOSUB 4000 'Send read question and get answer

1100 GOSUB 5000 'Display answer

1110 KEY (5) ON:KEY (6) ON

1120 NEXT I

1130 KEY (7) ON:KEY (8) ON

1140 WEND

1150 GOTO 1040

2000 REM ***** INITIALISE *************

2010 ON KEY (5) GOSUB 7000 : KEY (5) ON 'Write

2020 ON KEY (6) GOSUB 10000 : KEY (6) ON 'Address

2030 ON KEY (7) GOSUB 11000 : KEY (7) ON 'Pause

2040 ON KEY (8) GOSUB 12000 : KEY (8) ON 'Cont

2050 ON KEY (10) GOSUB 9000 : KEY (10) ON 'Break

2060 WHILE PRAM$(MAXPRM) <>"END"

2070 MAXPRM = MAXPRM+1

2080 READ PRAM$(MAXPRM)

2090 READ PRMCODE$(MAXPRM)

2100 READ PRMMUL(MAXPRM)

2110 READ PRMUNITS$(MAXPRM)

2120 WEND

2130 MAXPRM = MAXPRM-1

2140 OPEN "COM1:1200,O,7,1,DS0,CS0,CD0" AS #1

2150 ADDRESS$= "55" 'Initial controller address

2160 RETURN

2170 REM DATA TABLE. TEXT(18 MAX),PARAMETER LETTER,1/UNIT VALUE,UNITS

2180 DATA "MEASURED VALUE","A",1,"DEG"

2190 DATA "OUTPUT","B",10,"%"

2200 DATA "LOCAL SET POINT","C",1,"DEG"

2210 DATA "PROPBAND","D",10,"%"

2220 DATA "INT ACTION TIME","E",1,"SEC"

2230 DATA "DER ACTION TIME","F",1,"SEC"

2240 DATA "DER APPROACH BAND","G",10,"XP"

2250 DATA "END","",0,""

2260 RETURN

3000 REM ***** DRAW SCREEN ************

3010 SCREEN 0,0:WIDTH 80

3020 CLS

3030 KEY 5,"WRITE"

3040 KEY 6,"ADDR'S"

3050 KEY 7,"PAUSE"

3060 KEY 8,"CONT"

3070 KEY 9,""

3080 KEY 10,"QUIT"

3090 LOCATE 2,24

3100 PRINT "F:G:H S2000 SERIES COMMS DEMO"

3110 LOCATE 4,1

3120 PRINT TAB(4)"Parameter"TAB(23)"Question"TAB(33)"Answer" TAB(52)"Result"

3130 RETURN

4000 REM ***** READ AND GET ANSWER ***

4010 PRINT "->";

4020 TX$="R"+ADDRESS$+PRMCODE$(I)+CHR$(13)

4030 PRINT #1,TX$;

4040 GOSUB 8000 'GET RX$

4050 RETURN

5000 REM ***** DISPLAY QUESTION AND ANSWER

5010 PRINT TAB(4) PRAM$(I); 'Text parameter title

5020 PRINT TAB(23) "R"ADDRESS$+PRMCODE$(I);" = ";RX$ SPACE$(5);

5030 VALUE$=RIGHT$(RX$,5)

SERIES 2000 COMMUNICATIONS MANUAL 17

M41 Issue 1.1

5040 IF (LEFT$(VALUE$,1))>"-" THEN VALUE$=RIGHT$(VALUE$,4)

5050 PRINT TAB(48)" = ";

5060 IF (RX$="TIMEOUT") OR (LEFT$(RX$,1)<>"*") THEN GOTO 5090

5070 PRINT VAL(VALUE$)/PRMMUL(I);PRMUNITS$(I);" ";

5080 GOTO 5100

5090 PRINT " ERROR"SPACE$(10);

5100 LOCATE CSRLIN,1:PRINT " ";

5110 RETURN

6000 REM ***** ERROR HANDLER *************

6010 GOSUB 13000 'Position cursor

6020 PRINT " Error Type " ERR "At line "ERL

6030 LOCATE CURY,CURX:RESUME NEXT

7000 REM ***** WRITE TO CONTROLLER ******

7010 GOSUB 13000 'Position cursor

7020 PRINT "Write Parameter ? ";

7030 WPRAM$=INKEY$:IF LEN(WPRAM$)=0 THEN 7030

7040 PRINT WPRAM$;

7050 LINE INPUT;" New Data [-]NNNN ";WDAT$

7060 WTX$="W"+ADDRESS$+WPRAM$+WDAT$

7070 PRINT #1,WTX$+CHR$(13);

7080 GOSUB 8000 'GET RESPONSE RX$

7090 PRINT " "WTX$" = "RX$;

7100 LOCATE CURY,CURX

7110 RETURN

8000 REM ***** GET RESPONSE RX$ *****

8010 RX$="":IN$=""

8020 TIMLIMIT=300 'TIMEOUT LIMIT

8030 TIM=0:TIMOUT=0:RXEND=0

8040 WHILE (RXEND=0) AND (TIMOUT=0)

8050 WHILE NOT EOF(1)

8060 IN$=INPUT$(1,#1)

8070 IF IN$=CHR$(13) THEN RXEND=1 ELSE RX$=RX$+IN$

8080 TIM=0

8090 WEND

8100 TIM=TIM+1

8110 IF TIM>TIMLIMIT THEN TIMOUT=1

8120 WEND

8130 IF TIMOUT <>0 THEN RX$="TIMEOUT"

8140 RETURN

9000 REM *******BREAK - KEY 10 ************

9010 LOCATE 23,1:END

10000 REM ***** CHANGE ADDRESS ***********

10010 GOSUB 13000 'Position cursor

10020 LINE INPUT;" New Address NN ";ADDRESS$

10030 LOCATE CURY,CURX

10040 RETURN

11000 REM ***** PAUSE **********************

11010 GOSUB 13000 'Position cursor

11020 PAUSED=1:PRINT " ** Paused ** "

11030 LOCATE CURY,CURX:RETURN

12000 REM ***** CONT ***********************

12010 GOSUB 13000 'Position cursor

12020 PAUSED=0:PRINT " ** Continue ** "

12030 LOCATE CURY,CURX:RETURN

13000 REM ***** TALK WITH OPERATOR *******

13010 CURX=POS(0):CURY=CSRLIN 'Current curser posn

13020 LOCATE 22,2:PRINT STRING$(77,32):LOCATE 22,2

13030 RETURN

This manual suits for next models

2

Table of contents

Other FGH Controllers manuals