Nicotra Gebhardt EKE 10-0070-5E-IM User manual

Operating Manual

EN

Motor Controller

BA-EKE 1.04 –03/2020

EKE 10-0070-5E-IM

EN - 2 of 39

Warning

Before installing and commissioning the EC-Controller, you must read all

safety instructions and warnings carefully including all the warning labels

attached to the equipment. Make sure that the warning labels are kept in a

legible condition and replace missing or damaged labels.

NICOTRA Gebhardt reserves the right to change without notice.

Information is also available from:

Nicotra Gebhardt GmbH

Gebhardstraße 19-25 Phone: +49 (0)7942 / 101 - 0

74638 Waldenburg E-Mail: info.ng.de@regalbeloit.com

Germany URL: www.nicotra-gebhardt.com

EN - 3 of 39

Definitions and Warnings

Warning

For the purpose of this documentation and the product warning labels,

"Warning" indicates that death, severe personal injury or substantial damage

to property can result if proper precautions are not taken.

Caution

For the purpose of this documentation and the product warning labels,

"Caution" indicates that minor personal injury or material damage can result if

proper precautions are not taken.

Note

For the purpose of this documentation, "Note" indicates important information

relating to the product or highlights part of the documentation for special

attention.

Qualified personnel

For the purpose of this Instruction Manual and product labels, a "Qualified

person" is someone who is familiar with the installation, mounting, start-up and

operation of the equipment and the hazards involved.

He or she must have the following qualifications:

•Trained and authorized to energize, de-energize, clear, ground and tag

circuits and equipment in accordance with established safety procedures.

•Trained in the proper care and use of protective equipment in accordance

with established safety procedures.

•Trained in rendering first aid.

Use for intended purpose only

The equipment may be used only for the application stated in the manual and only in

conjunction with devices and components recommended and authorized by

Nicotra Gebhardt GmbH.

EN - 4 of 39

Approvals

European Low Voltage Directive

The EC-Controller complies to the requirements of the Low Voltage Directive 2006/95 EC.

European EMC Directive

The EC-Controller is supplied exclusively in connection with products of the company

Nicotra Gebhardt. The unit is fully integrated in the corresponding products or will be

delivered together with the products. After correct installation it complies to the requirements

of the EMC directive, according to the EMC product standard for electrical drives with

variable speed EN 61800-3.

EN - 5 of 39

Safety Instructions

The following warnings, cautions and notes are provided for your safety and as a means of

preventing damage to the product or components at the connected machines. This section

lists warnings, cautions and notes, which apply generally when handling the

Nicotra Gebhardt EC-Controller, classified as General, Transport & Storage,

Commissioning, Operation and Repair.

Specific warnings, cautions and notes that apply to particular activities are listed at the

beginning of the relevant chapters and are repeated or supplemented at critical points

throughout these sections.

Please read the information carefully, since it is provided for your personal safety and

will also help prolong the service life of your EC-Controller and the equipment you

connect to it.

General

Warnings

This equipment contains dangerous voltages and controls potentially

dangerous rotating mechanical parts. Non-compliance with these warnings or

failure to follow the instructions contained in this manual can result in loss of

life, severe personal injury or serious damage to property.

Only suitable qualified personnel should work on this equipment, and only

after becoming familiar with all safety notices, installation, operation and

maintenance procedures contained in this manual. The successful and safe

operation of this equipment is dependent upon its proper handling, installation,

operation and maintenance.

Children and the general public must be prevented from accessing or

approaching the equipment!

Risk of electric shock!

The DC link capacitors remain charged after mains supply has been switched

off. It is not permissible to open the equipment until 10 minutes after the mains

supply has been removed.

Caution

This equipment may only be used for the purpose specified by the

manufacturer. Unauthorized modifications and the use of spare parts and

accessories that are not sold or recommended by the manufacturer of the

equipment can cause fires, electric shocks and injuries.

Notes

Keep these operating instructions within easy reach of the equipment and

make them available to all users. Whenever measuring or testing has to be

performed on live equipment suitable electronic tools should be used.

Before installing and commissioning, please read these safety instructions and

warnings carefully and all the warning labels attached to the equipment.

Make sure that the warning labels are kept in a legible condition and replace

missing or damaged labels.

EN - 6 of 39

Transport & Storage

Warning

Correct transport, storage, erection and mounting, as well as careful operation

and maintenance are essential for proper and safe operation of the

equipment.

Caution

Protect the inverter against physical shocks and vibration during transport and

storage. Also be sure to protect it against water (rainfall) and excessive

temperatures.

Commissioning

Warnings

Work on the device/system by unqualified personnel or failure to comply with

warnings can result in severe personal injury or serious damage to material.

Only suitably qualified personnel trained in the setup, installation,

commissioning and operation of the product should carry out work on the

device/system.

This equipment must be grounded.

The following terminals can carry dangerous voltages even if the

EC-Controller is inoperative:

•the power supply terminals L1, N

•the motor terminals U, V, W

Operation

Warnings

The EC-Controller operates at high voltages.

Certain parameter settings may cause the inverter to restart automatically

after an input power failure.

The MaxSpeed Parameter must be accurately configured for motor overload

protection to operate correctly.

Repair

Warning

Repairs on equipment may only be carried out by Nicotra Gebhardt.

Before opening the equipment for access, disconnect the power supply and

wait for at least 5 minutes until the DC-link capacitor is completely

discharged!

Table of content EN - 7 of 39

Table of Contents

1Overview....................................................................................................................... 8

1.1 General Information................................................................................................. 8

1.2 Features.................................................................................................................. 8

2Installation.................................................................................................................... 9

2.1 Ambient Operating Conditions................................................................................. 9

2.2 Mechanical Dimensions .........................................................................................10

2.3 Optional Fan...........................................................................................................11

2.4 Overview Connectors and Operating Elements......................................................12

2.5 Assembling ............................................................................................................15

2.6 Electrical Installation...............................................................................................16

3Commissioning ...........................................................................................................24

3.1 Reset to Factory Default.........................................................................................24

3.2 Motor Identification.................................................................................................25

3.3 Fan Selection.........................................................................................................27

3.4 Analogue/Digital Inputs ..........................................................................................28

3.5 Change Motor PWM Frequency.............................................................................31

3.6 Error Handling........................................................................................................32

4Technical Data.............................................................................................................33

4.1 Electrical Characteristics........................................................................................33

4.2 Performance Characteristics..................................................................................33

4.3 Mechanical Characteristics.....................................................................................33

4.4 Ambient Conditions................................................................................................33

4.5 Modbus RTU Specification.....................................................................................34

5Electro-Magnetic Compatibility (EMC).......................................................................38

5.1 EMC Evaluation Basics..........................................................................................38

5.2 EMC Evaluation .....................................................................................................38

6Notes............................................................................................................................39

Overview EN - 8 of 39

1 Overview

1.1 General Information

The Nicotra Gebhardt EC-Controller EKE10-0070-5E-IM is an inverter for controlling the

speed of motor-impeller-units with BLDC or induction motors (IM).

Due to its sensorless field oriented control algorithm the motors are driven in any duty point

at the optimum field angle. This always results in good efficiency.

The EC-Controller provides active Power Factor Correction (PFC) and inverter and motor

overload protection. The EC-Controller EKE10-0070-5E-IM can be used in both stand-alone

applications as well as in large fan systems using the integrated network interface (Modbus

RTU) for controlling and monitoring purposes.

1.2 Features

1.2.1 Main Characteristics

•Supply voltage 230Vac ±10%

•Easy installation and commissioning

•Simple cable connection with cage clamps

•Integrated network interface (Modbus RTU)

•Sensorless Airflow Control

•Integrated analogue-/digital interface (3x programmable analog/digital inputs, 2x

programmable dry contacts)

1.2.2 Performance

•Sensorless field oriented speed control

•Acceleration and deceleration ramp

•High efficiency

•up to 2000W input power (depending on cooling)

•Power Factor >98%

•Harmonic currents <8% THD (integrated active PFC)

1.2.3 Protection

•Mains voltage monitoring (Brown-out)

•Overload and overheat protection controller

•Impeller blocking protection

•Adjustable maximum speed according to the impeller size

•Safe Operating Area (speed, power and current limitation according to the selected fan

type)

Speed

Power

Limit

Current

Limit

V

p

Installation EN - 9 of 39

2 Installation

Warnings

Work on the device/system by unqualified personnel or failure to comply with

warnings can result in severe personal injury or serious damage to material.

Only suitably qualified personnel trained in the set-up, installation,

commissioning and operation of the product should carry out work on the

device/system.

This equipment must be grounded.

The following terminals can carry dangerous voltages even if the EC-

Controller is inoperative:

•the power supply terminals L1, N

•the motor terminals U, V, W

2.1 Ambient Operating Conditions

Protection Class

IP 54

Humidity Range

90% Non-condensing

Altitude

If the inverter is to be installed at an altitude > 1000m, derating is required.

Shock

Do not drop the inverter or expose it to sudden shock.

Vibration

Do not install the inverter in an area where it is likely to be exposed to constant vibration.

Installation

Warnings

The device is designed to be exposed partly to the fan air stream with

maximum medium temperature of 40°C to achieve full power load at all fan

sizes.

Alternatively, a forced cooling can be realized in any other way, for instance by

additional blower. Otherwise, if the operating conditions cause overheating,

the controller would automatically perform self-derating to operate at the

allowed temperature limit, indicating warning "Temperature derating".

Do not cover the device during operation!

Installation EN - 10 of 39

2.2 Mechanical Dimensions

Figure 1: Device dimensions

Figure 2: Drill pattern

Installation EN - 11 of 39

2.3 Optional Fan

The EKE10 provides the possibility to mount an additional fan if the cooling may not be

enough inside the application.

Figure 3: EKE10 with optional fan mounted

Figure 4: Required fan size

Note

It is recommended to use a fan with minimum 25 m3/h (15 cfm).

When using a 230 Vac supplied fan, the power can be taken from EKE10

power connector X1 using one cable gland.

If the fan cooling is not sufficient, the device will perform automatic derating.

Installation EN - 12 of 39

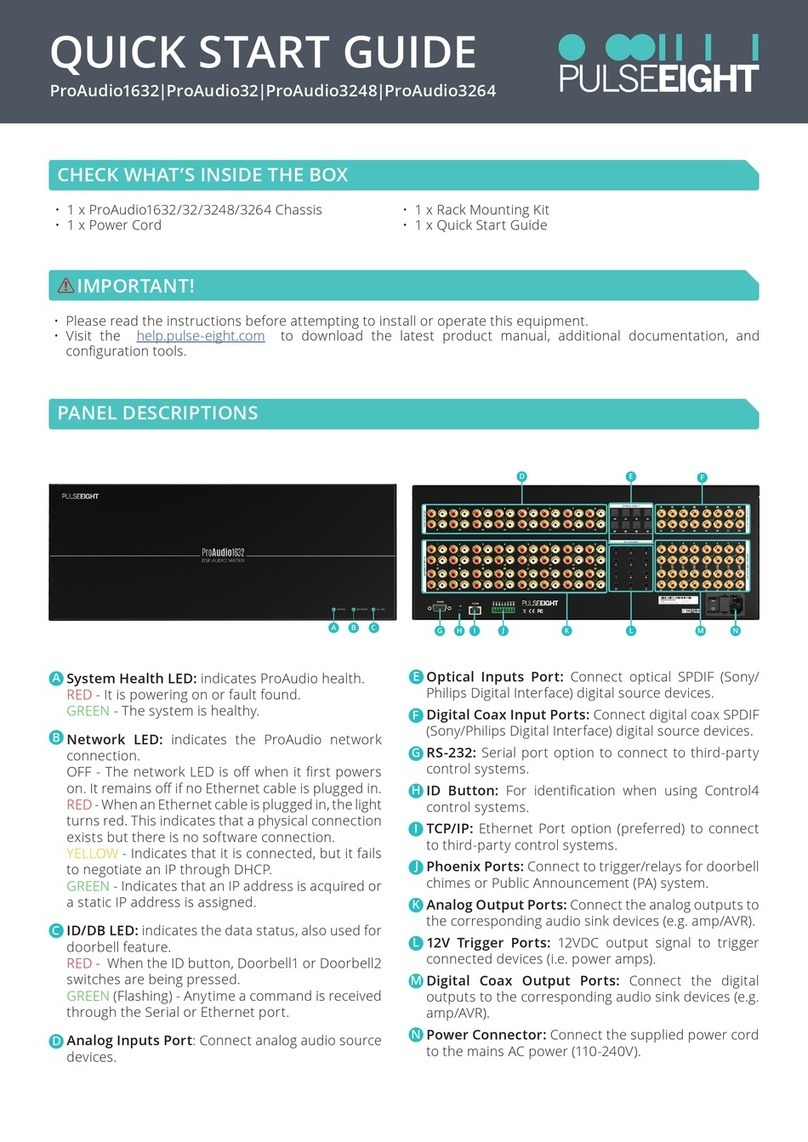

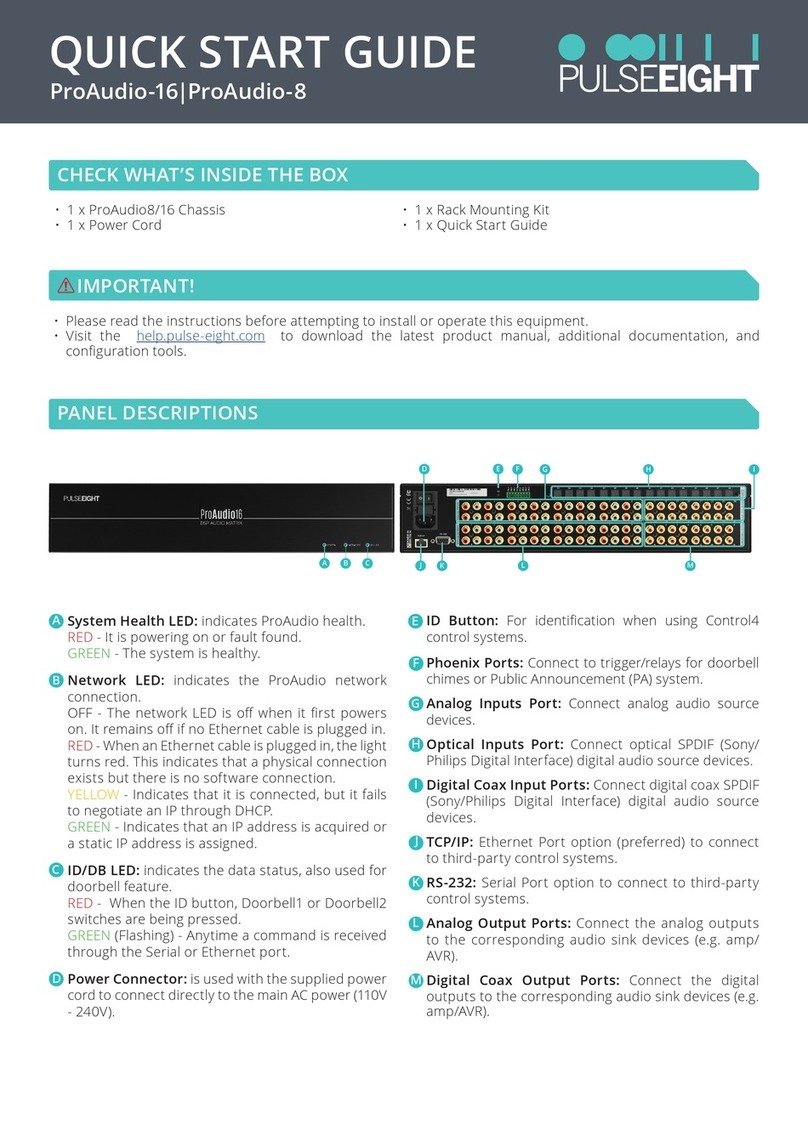

2.4 Overview Connectors and Operating Elements

2.4.1 Connectors

Power

X1

X2 X3

X4

Control

Modbus

Motor

LED

Figure 5: Connector overview

Installation EN - 13 of 39

2.4.2 DIP Switches

The interface PCB provides DIP switches for fan selection purpose and to enable special

funtions.

Figure 6: Position of DIP switches

Position

DIP

Additinal Conditions

Function

1..5

DIP6 OFF

Fan selection

6

This switch must be OFF during normal operation!

•Analogue input

less than 50%

•Power-ON

Reset to factory default.

•Analogue input

more than 50%

•Power-ON

Trigger motor identification

Table 1: DIP switches for fan selection and special functions

Note

All DIP adjustments will become valid even after power-ON.

Installation EN - 14 of 39

2.4.3 Status LED

To indicate the device status the EKE10 provides a dual colour LED (red and green):

Status LED

Function

Indication

State

Green

Ready

slow flashing (1s period)

Device ready (speed= 0)

ON

Device ready (speed>0)

fast flashing (0,1s period)

Loading of motor parameters

Yellow

(green and red

together)

Warning

OFF

no warning

ON (motor n>0)

Device is working at limit (voltage,

current, power)

slow flashing (1s period)

Warning temperature high

Motor identification

fast flashing (0,1s period)

Motor identification in progress

Software update

ON (motor n=0)

Software update initialized

Red

Software update

Periodical flashing

(1s period, 3x flash)

Software update in progress

Error

OFF

no error

ON

Error

slow flashing (1s period)

Internal communication error

Red

Green

Wink

changing red-green

flashing (1s period)

„Wink“ command received

Table 2: Status indication

Installation EN - 15 of 39

2.5 Assembling

Warnings

Work on the device/system by unqualified personnel or failure to comply with

warnings can result in severe personal injury or serious damage to material.

Only suitably qualified personnel trained in the set-up, installation,

commissioning and operation of the product should carry out work on the

device/system.

This equipment must be grounded.

The following terminals can carry dangerous voltages even if the EC-

Controller is inoperative:

•the power supply terminals L1, N

•the motor terminals U, V, W

Before opening the equipment for access, disconnect the power supply and

wait for at least 5 minutes until the DC-link capacitor is completely

discharged!

2.5.1 Working Steps

1. Preparation of the device

If the EKE10 is not delivered pre-mounted on a fan it

must be mounted on a grounded conducting metal plate.

To open the device unfasten the 4 screws on top lid.

2. Insertion of cable

The device is partly equipped with cable glands

If these glands are not enough it is possible to add more

using the holes removing the blind plugs

When shield motor cable is used, the plastic gland must

be exchanged by an EMI gland to connect the shield

properly with device ground.

3. Connection

See Chapter 2.3

4. Adjustment of DIP switches

See Chapter 3.3

5. Check ground connection

This equipment must be grounded.

Check if the protective earth wire of mains and motor

cable is connected properly.

6. Close cover

Close the device with the top lid using the 4 screws.

Table 3: Working steps for device mounting

Installation EN - 16 of 39

2.6 Electrical Installation

Warning

The inverter must always be grounded. If the inverter is not grounded

correctly, extremely dangerous conditions may arise within the inverter, which

could be potentially fatal. Make sure that the grounding connection between

PCB and basic housing part is applied correctly!

To ensure the safe operation of the equipment, it must be installed and

commissioned by qualified personnel in full compliance with the warnings laid

down in these operating instructions.

Take particular note of the general and regional installation and safety

regulations regarding work on dangerous voltage installations (e.g. EN50178),

as well as the relevant regulations regarding the correct use of tools and

personal protective equipment (PPE).

After electrical wiring and DIP-switch setting the housing needs to be closed

before the mains is switched on.

In case a permanent magnet synchronous motor (PMSM) is connected, the

motor wires and the EKE10 itself can carry dangerous voltage due to back

EMF when motor is turning by air pressure. Make sure to prevent the motor

from revolving during installation or maintenance work is in progress.

All terminals and PCB parts can carry dangerous voltages even if the inverter

is inoperative; wait 5 minutes to allow the unit to discharge after switching

off before the housing is being opened.

The following terminals can carry dangerous voltages even if the EC-

Controller is inoperative:

•- the power supply terminals L1, N

•- the motor terminals U, V, W

Warning

The EKE10 contains no fuse! It needs to be protected by a sufficient external

fuse (slow characteristic) inserted to the L supply wire.

Fuses and cable cross section must be shoosen carefully according tho the

power consumption and number of connected devices.

Motor cable must not be switched or removed duting operation!

Warning

High leakage current!

When using the EKE10 inside an application the device has to be connected

to protective ground by additional wire.

Installation EN - 17 of 39

2.6.1 Pin Assignment

2.6.1.1Power Connector X1

Type

Pin

Name

Function

Screw or cage clamp

maximum 2,5mm2 (13 AWG)

1

PE

Protective earth

2

N

Neutral N

3

L

Phase L

Table 4: Power connection with X1

2.6.1.2Motor Connector X2

Type

Pin

Name

Function

Screw or cage clamp

maximum 2,5mm2 (13 AWG)

1

PE

Protective earth

2

U

Motor phase U

3

V

Motor phase V

4

W

Motor phase W

Table 5: Motor connection with X2

2.6.1.3Interface Connector X3

Typ3

Pin

Name

Function

Screw or cage clamp

maximum 1,3 mm2(16 AWG)

1

GND

Ground

2

ADIN1

Analogue/digital input 1

(Speed set point 0..10V)

3

+10V

+10V output

4

OUT2B

dry contact 2

(running indication)

5

OUT2A

dry contact 2

(running indication)

6

OUT1B

dry contact 1

(error indication)

7

OUT1A

dry contact 1

(error indication)

8

ADIN3

Analogue/digital input 3

(not preconfigured)

9

ADIN2

Analogue/digital input 2

(not preconfigured)

10

GND

Ground

Table 6: Interface connection with X3

2.6.1.4Modbus RTU Interface X4

Type

Pin

Name

Funktion

Screw or cage clamp

maximum 1,3 mm2(16 AWG)

1

GND

Ground

2

Net A

Bus A

3

Net B

Bus B

Table 7: Modbus interface connection with X4

Installation EN - 18 of 39

W

V

U

PE

X2

Motor

4

3

2

1

GND

ADIN2

ADIN3

OUT1A

OUT1B

OUT2A

OUT2B

+10V

ADIN1

GND

Net B

Net A

GND

10 9 8 7 6 5 4 3 2 1

3 2 1

3 2 1

N L PE

Power

X1

X3

X4

Control

Modbus

Figure 7: Configuration of connectors

2.6.2 Application Examples

2.6.2.1Connection of Power and Motor

3 2 1

N L PE

Power

X1

1~230VAC

50/60Hz

PE

L

N

F

Figure 8: Mains connection

Installation EN - 19 of 39

W

V

U

PE

X2

Motor

4

3

2

1

M

Figure 9: Motor connection

2.6.2.2Analogue Interface

The analogue interface can be operated by two ways:

•External voltage 0..10 Vdc

•Potentiometer (using the 10Vdc source of the EKE10)

Caution

When using external voltage signal, the voltage must not exceed the limits

given at the Technical Data page.

GND

ADIN2

ADIN3

OUT1A

OUT1B

OUT2A

OUT2B

+10V

ADIN1

GND

10 9 8 7 6 5 4 3 2 1

3 2 1

3 2 1

X3

nc

24Vdc

REGPOT1

ohne STOP

Minimal-

wert Sollwert

V- V+

5k

IN

Figure 10: Connection of a potentiometer

Installation EN - 20 of 39

GND

ADIN2

ADIN3

OUT1A

OUT1B

OUT2A

OUT2B

+10V

ADIN1

GND

10 9 8 7 6 5 4 3 2 1

3 2 1

3 2 1

X3

nc

24Vdc

Figure 11: Speed control by external voltage signal

GND

ADIN2

ADIN3

OUT1A

OUT1B

OUT2A

OUT2B

+10V

ADIN1

GND

10 9 8 7 6 5 4 3 2 1

X3

24Vdc

Enable

Figure 12: Touch mode, all 3 inputs configured as digital input

Table of contents

Other Nicotra Gebhardt Controllers manuals