Nidec-Shimpo FGS-VC Series User manual

All manuals and user guides at all-guides.com

all-guides.com

All manuals and user guides at all-guides.com

Read Manual thoroughly prior to operation.

Use instrument only after reading the complete manual .

Follow all safety precauti ons.

All manuals and user guides at all-guides.com

Safety Precautions

Before Installation, Operation or Maintenance, be sure

to read carefully this Operation Manual and use the

equipment as directed. Use the equipment after carefully reading all the caution item

s, safety information, and

other discriminations. In this User’s Manual, the Sa

fety Awareness Items are divided into three different

categories: “Danger”, “Warning” and “Caution”.

Follow these precautions.

This symbol indicates if you ignore the contents mentioned and improperly

operate, it may lead to serious injury from a potential fire.

This symbol indicates a potential dangerous situation that could produce a

Serious injury if improperly handled.

This symbol indicates a potential situat

ion that could produce a minor injury or

Damage to material if it is improperly handled. However, depending upon

the situation, there coul

d be a possibility that it may cause more serious

results.

P rot e ct io n cat eg or ies ar e ex p lai n ed a nd sepa ra te d b y t he f o llow in g s ymb ol s.

Proceed with Caution.

Not Allowed-Prohibited.

Mandatory-Must Follow

Warning

Heavy! Take sufficient care while

handling.

Ensure stand is placed on a flat, level,

stable surface that can support the unit.

Do not operate in areas where explosive

gases or vapors may be present.

Do not touch the running, inner parts.

Keep appendages and loose clothing

away from running, moving parts.

Caution

Fix object surely.

There is the possibility of damage.

Do not install in a high humidity

environment or near where water may be

present. Electric shock may occur if water

is encountered.

Hold power plug while removing the

power cord. Do not pull or put tension on

the cord. Doing so could result in cord

damage and electric shock

Never carry o r move the FGS-VC with the

AC code.

There is the pos sibility of elec tric shock, a fire and

injury.

Danger

Warning

Caution

All manuals and user guides at all-guides.com

Attention Safety

Warning

Disconnect from the AC outlet during any maintenance of the stand. Also, unplug when not

using for long periods of time.

May cause electric shock, a fire and injury.

Attention before using FGS-VC

Avoid the following.

Place where water, oil, or medicine may splash

Dusty locations

Places where condensation occurs

Places where explosive gases or ignition sources

are present.

Place where high vibration may occur

Places outside of operating temperature range.

32-104°F (0-40°C)

Cleaning with thinner and gasoline, etc.

Make sure the cable is not stuck in the stand.

Install the force gauge after turning off the power

switch.

Adjust the limit switches when the motor stops.

When digital force gauge FGV series is installed

Set "ovEr" in the F06 parameter, which is the parameter of Output Type.

If "ovEr" is not set, FGS-VC does not stop by the overload of the force gauge.

Confirm that the power supply is the

same voltage rating as the displayed

voltage rating on the unit

Do not plug AC connector with wet hand.

There is the possibility of electric shock.

All manuals and user guides at all-guides.com

Index

1. Prior to use ..............................................................................................................................

.................. 1

1.1. Procedure from the Installation of a force gauge to the m easureme nt

........................................... 1

1.2. Confirmation of product packing

...................................................................................................... 1

2. Names of components ..............................................................................................................................

. 2

3. Names and functions of the operation panel

........................................................................................... 2

4. Se tup ..............................................................................................................................

........................... 3

4.1. Installation of force gauge

................................................................................................................. 3

4.2. Connection of force gauge to the stand

............................................................................................. 4

4.3. Connection of PC t o the stand

.......................................................................................................... 5

5. Operation ..............................................................................................................................

.................... 5

5.1. Basic operation flow

.......................................................................................................................... 5

5.2. Operation mode ..............................................................................................................................

... 7

5.3. Manual o peration mode

.................................................................................................................... 8

5.3.1. MANU mode ..............................................................................................................................

. 8

5.3.2. JO G mode ..............................................................................................................................

..... 9

5.3.3. SING mode ................................................................................................................................

11

5.3.4. CONT mode ..............................................................................................................................

14

5.4. Program operation mode

................................................................................................................. 17

5.4.1. PROG mode ..............................................................................................................................

17

5.5. Parameter setting mode

.................................................................................................................. 21

5.6. Changing Engineering units

......................................................................................................... 23

6. Message of status and error

................................................................................................................... 24

7. Dimensions ..............................................................................................................................

............... 25

8. Specifications ..............................................................................................................................

............ 27

9. Troubleshooting ..............................................................................................................................

........ 27

All manuals and user guides at all-guides.com

all-guides.com

- 1 -

1. Prior to use

1.1. Procedure from the Installation of a force gauge to the measurement

FGS-VC can measure various loads using Shimpo's digital for ce gauges which are FGV s eries.

Confirm the following procedures before use.

1.2. Confirmation of product packing

FGS-VC 1 Cable to force gauge 1

Cabl e c lip 1 USB c abl e (2m) 1

Hex-head spanner 1 Bolt (M8 x 8mm) 4

Socket bolt (M6 x 16m m) 2 Set screw (M6 x 20mm) 1

Washer 2 Manual 1

Confirm the parameter

setting of the force gauge Install the force gauge. Connect the cables.

Measure each mode. Troubleshooting

Problem

All manuals and user guides at all-guides.com

- 2 -

2. Names of components

3. Names and functions of the operation panel

No Name Description

1 Emergency switch

Emergency stops when pushing.

Push the switch when FGS-VC acts abnormally or a potentially danger ous

situation is oc curring. Release the emergency stop to restart operation.

2 Speed key (up) Increase or decrease the speed when pushing the up or

down ar rows of the

Speed key. If the up or down arrows

are held, the speed adjusts continuousl y.

3 Speed key (Down)

4 MAX key

Push to override the current speed setti

ng. The speed will ins tantly go to the

maximum capable of the stand. Once released, the speed returns to the

previous speed setting. This key only is functional i n Manu or J og modes.

1

2

3

4 5 97 8

10 11 12

6

Emergency switch Measurement table

Lower limit knob

Force gauge plate Upper limit Knob

Operation panel

All manuals and user guides at all-guides.com

- 3 -

5 MOD E key Change operation modes or function setti ngs.

6 SET k ey The indicated data is set when the key is pushed.

7 START key Start the progr am m ode operati on

8 PUSH k ey Move in the PUSH direction.

9 STO P k ey Stop operation.

10 PULL key Move in the PULL direction.

11 ZERO key Clear distance in Manu and Jog modes.

Clear repeat time in Sing, Cont and Prog modes.

12 LCD display Displays distance, speed and mode, etc.

LCD display

4. Setup

4.1. Installation of force gauge

Force gauge that c an be connected with FGS-VC is F GV series.

Force gauges up to 100kgf are compatible w ith the F GS-220VC.

Force gauges up to 200kgf are compatible w ith the F GS-550VC.

In case of FGS-220VC

The force gauge is fixed to the stand.

The force gauge is set in the mounting plate.

Remove the mounting plate usi ng the

hex-head spanner acces sory.

Set the force gauge in the mounting plate.

Fix the mounting pl at

e with the force

gauge to the stand us in

g

su

pp

lied bolts.

Main display

Sub display

Status display

All manuals and user guides at all-guides.com

- 4 -

4.2. Connection of force gauge to the stand

The connection and confirmation between FGS-VC and a force gauge is the following procedure.

If the connection is wrong, check:

Are the parameter setti ngs of the force gauge correct?

Is the sequence of power on correct?

Is the cable correct?

If no probl em, please contact our technical support.

Parameter setting of the force gaug e

Set the following parameters.

Measurement polarity: +

RS232C baud rate: 19,200 bps

Refer to the manual of the force gauge.

Connect to FGS-VC

Connect the force gauge to FGS-VC by the

attached cable.

Pow er on

Turn on the power of the force gauge.

Next, tu rn on FGS-VC w ith the power switch on

the back.

Confirmation o f the connection

Display of FG S-VC as fol lows:

1. Indi cates "FGS-220VC".

2. Indi cates "MANU"(Manual Mode)

If the connection is wrong,

2. Indic ate "NO FOR CE GAUGE" in 3 seconds, then

indicate "MANU".

All manuals and user guides at all-guides.com

- 5 -

4.3. Connection of PC to the stand

FGS-VC can c onnect to PC for taking force and displacement.

The software is able to be downloaded from Shimpo's website free of charge.

Refer to the software manual .

5. Operation

5.1. Basic operation flow

The procedure of bas ic operation is desc ribed as follows.

Personal computer

USB cable

Cabl e between FGS-VC and force gauge

Force gaug e p ower

Turn on the power of the force gauge.

Keep hands, hair and jewelry away from stand when drive assembly is in motion.

May cause damage or injury.

FGS-VC pow er

Turn on the power of the stand.

Example. Tension test of a wire

A wire

Wedged chuck

Solderless

terminal

Separate hands from the force gauge and FGS-VC

movable parts.

Turn on FGS-VC.

Display appears as below:

All manuals and user guides at all-guides.com

all-guides.com

- 6 -

Select measuremen t mode

Select Manual, Jog, Single, Continuous and Program mode according to the

measurement purpose and the usage.

Mode can be changed by the Mode switch.

Start to measure.

Start each mode by pressing PUSH, PULL or START switch.

Refer to each mode section.

FGS-VC is able to test as follows:

Compression test

Tension test

Welding test

Peel test

Suction test

Repulsion test

Cork test

Open test

Etc.

All manuals and user guides at all-guides.com

- 7 -

5.2. Operation mode

The operation mode consists of manual and program.

The mode is selected by the measurement purpose and the usage.

How to select the mode?

Pres sing MODE switch in the Operation panel, the mode c hanges one by one as follows.

A pres ent operational mode is displayed under the left of LCD.

You wish to t est by PUSH or PULL key.

e.g.,

You want to mov e to the position of PULL limit by

pressing PULL switch.

You want to mov e only while y ou press the

PUSH key.

You want to move the round trip operation many

times between limits of PUSH and PULL.

etc.

Select manual operation

modes :

You wish t o move complex operations.

e.g.,

You want to measure by specifyi ng the positions.

The pos ition of the object to be measured

cannot be specified.

You want to combine a different direction

(PUSH/PULL) of oper ation with a test.

etc.

Select Prog ram op eration mode.

MANU

mode

MODE

Parameter

setting mode

JOG

mode

MODE SING

mode

MODE PR OG

mode

MODE CONT

mode

MODE MODE

All manuals and user guides at all-guides.com

- 8 -

5.3. Manual operation mode

The manual operation modes are MANU, JOG, SING and CONT.

The mode is selected by the measurement purpose and the usage.

5.3.1. MANU mod e

This mode of operation is ideal for m anually recording for ce measurements. The test stand will only operate

between the limits that are s et by the test s tand user. These are manually adjusted distanc e limits.

Contents

The test stand will move i n the downward or upward direction when the respective PU SH or PU LL button is

selected. The stand will continue to move in the s elected direction until one of the following occurs : STOP

button is pushed, one of the l imit stop switches is tripped or the emergenc y reset button is pushed.

MANU mode

When pr essing the PUSH (PULL) key, FGS-VC goes to PU SH (PULL)

limit switch position.

FGS-VC stops if reaching the limit position.

JOG mode

This mode of operation is identic al to MANU, except that the movement

in any direction will onl y occ ur while either the PUSH or PULL key is

depressed.

SING mode

Pres sing PUSH or PU LL k eys, FGS-VC moves for one complete cycle

between mechanical distance limit stops.

CONT mode

Pres sing PUSH or PULL keys, F GS-VC moves repeatedly up and dow n

between the mechanical distance limit stops.

Upper limit

Lower limit

PULL

PUSH

Stop with upper l imit

switch ON

Stop with lower limit

switch ON

All manuals and user guides at all-guides.com

- 9 -

Speed

Speed can be changed by UP or DOWN button of the SPEED.

The speed setting of MANU and JO G mode is common.

Also the speed is able to be changed while moving.

Display

Parameter

The speed of MAN U and JO G modes is adjustable. Pr ess the SET butt

on to enable adjustment via the UP or

DOWN buttons of the SPEED k ey. Then press the SET button to save the new value.

If y ou want to cancel

the setting press the ZERO button.

5.3.2. JOG m ode

Contents

This mode of operation is identical to MANU mode, except that the movement i n any direction will only occ ur

while either the PU SH or PULL button is depres sed.

Speed

Speed can be changed by UP or DOWN button of the SPEED key.

The speed setting of MANU and JO G mode is common.

Also the speed is able to be changed while moving.

Display

Pres ent positi on

Setting speed

Setting speed

The UP or DOWN button of the

SPEED key can be used to

change the speed. The range is

0.40-15.75in/min

(10

to400[mm/min

]

].

Pres ent positi on

Setting speed

All manuals and user guides at all-guides.com

- 10 -

Parameter

The param eter, which is the speed of MANU and JOG mode, is available.

Pres sing SET button, and the speed can be changed by UP or DO WN k ey of the SPEED.

Then press SET button for saving.

If you want to c ancel the setting, press ZER O button.

Setting speed

The UP or DOWN button of the

SPEED key can be used to

change the speed. The range is

0.40-15.75 in/min (10 to

400[mm/min]

All manuals and user guides at all-guides.com

all-guides.com

- 11 -

5.3.3. SING mode

This mode of operation is ideal for completing one cyc le between mechanical, manually

adjusted distance limit

stops. The test stand will onl y oper ate between the limits that are set by the test s tand user.

Contents

The test stand will move dow nward or upward when the respective PUSH or PULL button is selected.

The stand will continue to move until one of the following ev ents occur s: the STOP button is

pushed, one of the

limit switches is tr ipped or the emergenc y reset button is pushed.

Upper limit

Lower limit

PULL

Stop with upper l imit

switch ON with dw ell timer

Stop and complete

with lower limit switch ON

Display alternately

Upper limit

Lower limit

PUSH

Stop and complete with

upper limit switch ON

Stop with lower limit

switch ON with dw ell timer

Display alternately

All manuals and user guides at all-guides.com

- 12 -

Speed

Speed can be changed by UP or DOWN button of the SPEED key.

The speed setting of SING and CONT mode is com mon.

Also the speed is able to be changed while moving.

Display

Repeat count

Incremental count at pressing PUSH or PULL button.

The count is cl ear ed with the ZERO button. When the mode is changed, the count will also be reset to zero.

Pres ent positi on

Setting speed

Repeat count

Moving direction

Status of limit s witch

Setting dwell ti mer

All manuals and user guides at all-guides.com

- 13 -

Parameter

The param eter, which is the dwell ti mer and the speed of pull and push, is avai lable.

Pres sing SET button, the speed can be changed by UP or

DOWN button of the SPEED key. The dwell timer

can be c hanged by STOP.

Finally pr ess SET button for saving.

If you want to c ancel the setting, press ZER O button.

Setting speed

The UP or DOWN button of the

SPEED can be used to change.

The range is o.40- 15.75 in/mi n(10

to 400

[mm/min]

Setting dwell timer

The STO P button of the dwell time

can be used to change.

Pres sing STOP, the dw ell timer is

incremental.

When the dwell timer is 5s, it

returns to 0s pr es sing STO P.

SET

SET

SET

Saving, return to SING mode

All manuals and user guides at all-guides.com

- 14 -

5.3.4. CONT mode

This mode of operation is ideal if the user wants the test stand to repe

atedly cycle up and dow n continuously or

for a us er-programmed number of times. The stand will start in either direc tion depending on

whether PUSH or

PULL button is selected.

Contents

The test stand will start to mov e dow nward or upward w hen the respective

PUSH or PU LL button is selected.

The stand will c ontinue to move until one of the following events occ urs: the STO P

button is pushed, the

emergency reset button is pus hed.

Display alternately

B

A

Upper limit

Lower limit

PULL

Stop with upper l imit

switch ON with dw ell timer

Stop with lower limit

switch ON with dw ell timer

Complete with lower limit

switch ON when the repeat

count is reached.

A

B

Upper limit

Lower limit

PUSH

Stop with upper l imit

switch ON with dw ell timer

Stop with lower limit

switch ON while dwell ti mer

Complete with upper lim it

switch ON when the repeat

count is reached.

A

B

All manuals and user guides at all-guides.com

This manual suits for next models

2

Table of contents

Popular Rack & Stand manuals by other brands

MMT

MMT HYPEBOX product manual

Performance Tool

Performance Tool W5183 owner's manual

Zemic

Zemic BM-8-904 installation manual

PROforma

PROforma PROFORMA460AB manual

Formsprag

Formsprag Long Life Holdbacks Series Service & installation instructions

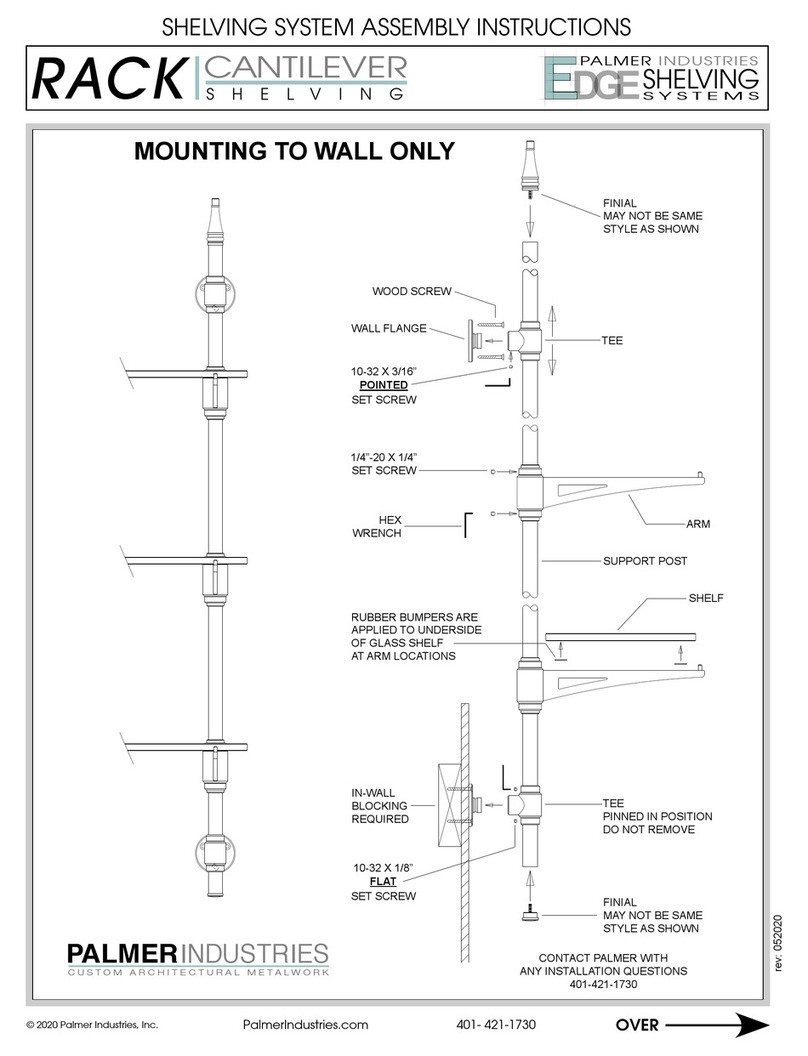

Palmer Industries

Palmer Industries CANTILEVER SHELVING Assembly instructions