Nissei GTR-AR User manual

<Read this manual before using the product.>

NISSEI CORPORATION

Battery powered driver SD type

Instruction Manual

・Be sure to carefull

y

read the contents described in this instruction manual and

to understand how to use

p

roduct correctl

y

before usin

g

it.

・The extent of hazard/damage expected to occur in the case of improper handling

are classified and indicated in ranks of “DANGER”, ”WARNING”, and ”CAUTION.”

The definitions and indications are as follows.

■

D

escr

i

pt

i

on o

f

t

h

e sym

b

o

l

■

Th

e types o

f

contents to

b

e o

b

serve

d

are exp

l

a

i

ne

d

w

i

t

h

c

l

ass

ifi

cat

i

on

b

y grap

hi

ca

l

sym

b

o

l

s

b

e

l

ow.

Indicates "Fire Hazard." Indicates "Ground Connection."

If the product is used in an application such as a personnel transport device, make sure to install a

protective device for safety purposes. Failure to implement safety measures may result in personal

injury, death, and/or damage to the application.

If the product is used in an elevator, install a safety device on the application to prevent it from

falling. Failure to implement safety measures may result in personal injury, death, and/or damage to

the application due to the falling of the elevator.

Do not use the product under the explosive atmosphere. Failure to follow this precaution may result

in explosions, ignition of fire, fire, electric shock, injury, and/or damage to the application.

Danger

Cases where it is expected that a degree of danger is extremely high such that improper

handling possibly causes a dangerous situation to occur, which may lead to death or

serious injury.

Indicates

"What You Must Pay Attention To." Indicates "What You Must Not Do."

Introduction

Thank you very much for purchasing our product.

Safety Precautions

Even items described in “CAUTION” may lead to a serious results depending on the situation.

Be sure to observe every instruction which deals with important contents.

Indicates "Burn Hazard." Indicates "Do Not Disassemble."

Warning

Cases where improper handling possibly causes a dangerous situation to occur, which

may lead to death or serious injury.

Caution

Cases where improper handling possibly causes a dangerous situation to occur, from

which a minor or medium degree of injury may be incurred.

Indicates "Electric Shock Hazard." Indicates "What You Must Do."

Danger

■General

■Wiring

Do not change the wiring while the product is energized. Failure to follow this precaution may result

in fire, electric shock, and/or damage to the application.

Install a fuse and a circuit breaker on the power supply side to immediately stop the operations and

cut off the power supply in the event of current overflow.Negligence may cause accidents leading to

fire, electric shock, damage to the device, and/or other accidents.

Make sure the temperature of driver surface should not exceed 80℃.Failure to follow this

precaution may result in damage of the product and/or burn injury.

Caution

■General

Never perform operations with wet hands. Failure to follow this precaution may result in electric

shock.

Use the specified combination of the motor and driver. Negligence may cause fire and damage to

the equipment.

■Operation

Be sure not to approach to the application after a power failure.

Otherwise, sudden power recovery may cause injury.

Correctly connect the positive and negative sides of input voltage to this driver. Negligence may

cause failure/damage to the driver or accidents.

When the operation has stopped due to the occurrence of error or activated safeguards, do not re-

start the operation until the causes of error are determined and countermeasures are taken. Failure

to follow this precaution may result in damage to the application, injury, fire, electric shock, and/or

burns.

Warning

■General

The operators in charge of installation, piping, wiring, operation, handling, maintenance, and

inspection should have enough knowledge and technical skill related to the product. Failure to

follow this precaution may result in fire, electric shock, injury, and/or damage to the application.

This driver is not equipped with the function to prevent inrush current when power is supplied.

When power is supplied repeatedly at a frequency of once/hour or more or when inrush current

becomes a problem for the instrument, the customer is requested to take appropriate treatment.

Negligence may cause malfunction of/damage to the driver or accidents.

■Wiring

When changing the setting of the built-in trimmer, use a slotted screwdriver made of resin.

Negligence may cause electric shock or burns.

Input voltage to this driver must be within the allowable range. Using the driver with voltage outside

this range may cause failure/damage to the driver or accidents.

Regenerative energy is supplied to the power supply unit through this driver. When using a load

that generates regenerative energy, the customer is required to take measures appropriate for the

power supply unit. Negligence may cause malfunction of/damage to the driver or accidents.

Do not cut connection with the battery when the motor is regenerative running buring motions of

lowering and reducing speed and the main power supply(+) and controlled power supply(⊕) are

connected.

Failure to follow this precation may cause failure/damage to the driver and accidents.

Do not repair, disassemble or remodel the product. Failure to observe this precaution may result in

injury, fire, electric shock, and/or burns.

■Installation

Do not operate the product where it is exposed to water, corrosive atmosphere, flammable gas

atmosphere, and near the combustible material. Failure to follow this precaution may result in fire

and/or accident.

Do not remove the nameplate.

Operate the product under the conditions specified in this instruction manual. Failure to follow this

precaution may result in damage to the application and/or injury.

Do not expose the product to strong impacts/shocks. Failure to observe this precaution may result

in failure of the product and/or injury.

The contents of this manual are subject to change without notice.

We have made every possible effort to make the contents of this manual easy to understand. If there is anything that

is unclear or hard to understand, please feel free to contact us.

Do not touch the rotating part of the gearmotor. Failure to follow this precaution may result in injury.

Important

When disposing of the product, dispose of it as a general industrial waste. Please follow local laws and regulations if

any apply and take care of the waste accordingly.

Notice

We shall assume no responsibility or liability for any troubles caused by use that violates the cautions above.

Ensure that the wires to the power supply, motor, and driver are connected properly and securely.

Negligence may cause malfunction of the equipment, resulting in injuries.

■Operation

Immediately stop the operation if there is any abnormality. Failure to follow this precaution may

result in electric shock, injury, and/or fire.

Do not touch the gearmotor when the power is on or immediately after turning off the power, as

their surfaces may be hot for a while. Failure to follow this precaution may cause burns.

■Wiring

Be careful not to cause damage to the cable nor pull it strongly. Failure to follow this precaution

may result in injury, fire, and/or electric shock.

Do not put any combustible material near the product. Failure to follow this precaution may result in

fire.

Do not put any object that may prevent air from being circulated around the product. Failure to

follow this precaution may cause burns due to abnormal overheating, and/or fire.

Do not allow any foreign materials to enter the driver. Negligence may cause burns, fire and/or

electric shock.

Do not stand on or place any heavy object on the product. Failure to follow this precaution may

result in injury.

■Installation

Caution

Introduction

Safety precautions

1. Part number and Model Configuration P.6

2. Section Names P.7

3. External Dimensions P.10

4. Installation P.11

5. Wiring Diagrams P.12

6. External I/F Specifications P.16

7. I/O Terminal Wiring

7-1 Control input P.18

7-2 Control output P.19

7-3 External analog input P.19

8. User Constants

8-1 Setteing of Constants P.20

8-2 Constant list P.20

8-3 Constants explained P.25

9. Safeguards

9-1 Driver error list and display method P.40

9-2 Causes and countermeasures when safeguards P.41

are activated

9-3 Troubleshooting P.42

10. Specifications P.43

11. Accessories P.44

12. Conformity to Safety Standards (CE, KC) P.45

13. Storage, Warranty P.46

Contact Us P.47

Related Instruction Manual and Software P.48

Table of contents

■Driver model

The contents of Driver Model's codes are as follows.

Make sure the Driver Model on nameplate is consistent with your order.

■Model confi

g

uration

[1]

[2]

[4]

Motor power

80

[2]

Motor Ver

SD

[3]

Motor

classification

NB

A

SD

[1]

Series

A

[6]

Auxiliary code

X

[5]

Voltage

L4

ー

ー

Motor classification

Motor power

Voltage

Series

Motor Ver

Empty

080

L4

Motor power Voltage

0.75kW

DC48V

Driver model

0.75kW DC48V A-SDNB080L4

1. Part number and Model Configuration

X

[6] Auxiliary code Standard specifications

Designates a special option

[3]

[4]

[5]

GTR-AR

Brushless Motor SD type

Common to Motor and Brakemotor

NB

6

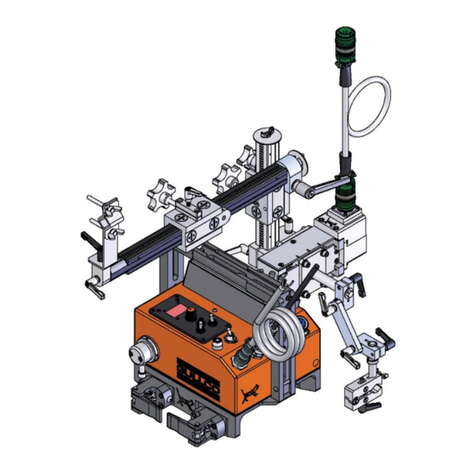

■Name

p

late Detail

Name No. NameNo.

2. Section Names

1 Main circuit terminal block (M5) 8 Nameplate(attached to the side face)

2 Mounting hole 9 Heat Sink

3 Connector for control signal (CN1) 10 Built-in trimmer 3 (VR3)

Status display LED lamps 1 ~ 3

(red/yellow/green) Built-in trimmer 4 (VR4)114

5 Connector for communication (CN8) 12 Built-in trimmer 2 (VR2)

6 Connector for motor signal (CN6) 13 Built-in trimmer 1 (VR1)

7 Built-in switch (SW1) 14 Cooling fan

No. Description No. Description

1 Model Name 5 Safety Standards

2 Input specifications 6 Software version

3 Output specifications 7 Hardware version

4 Serial number

7

■Built-in switch

When you enter a control signal, choose to use internal power supply(+15V) or external power supply.

【Settin

g

Built-in Switch

(

SW1

)

】

■Status dis

p

la

y

LED lam

p

s

The status of the driver is shown with LED lamps. LED lamps turn on as below.

■LED lamp layout

LED2

LED3

Yellow

Green

Lights up when operating in overloaded conditions (operation above motor rated current).

Turns off when the overload condition is no longer present or when an alarm is activated.

Stays lit while the controlled power is supplied.

Lights up or blinks when an alarm is issued. The alarm type can be determined

by the number of blinks.

Code

LED1

Color

Red

Specification

Lights up when an alarm is activated

Description

Disconnect from the internal power supply.

Add 15V to each input terminal I1~I8.

Code Setteings

SW1

External power supply

(Default)

Internal power supply

CN1

CN8

LED 1 (red) Alarm

LED 2 (yellow) Warning for overload

LED 3 (green) Controlled power supply

Internal power supply(I)

External power supply(O)

(Default position)

Switch lever

8

■Built-in trimmer

There are four built-in trimmers on the driver. The following settings can be changed by adjusting the trimmers.

*2 Speeds of up to 5000 [r/min] can be set by the trimmer, but the available motor speed is only up to 3000 [r/min].

■Trimmer ad

j

ustment reference

VR2

VR4 Built-in trimmer 4 Not used -

*1 The function of the built-in trimmer 1 is not active upon shipment. Change the user constant (Pn000)

to “4” per p.18 to activate built-in trimmer 1. The default is set to external analog command.

Default

Description

Turning the trimmer clockwise increases the speed. *1

Speed Range: 0 ~ 4000 [r/min]

The maximum speed value for this trimmer can be changed with

Pn040. *2

Function name

VR1 Built-in trimmer 1

(Speed Control)

Code

VR3

Full

Clockwise

Built-in trimmer 3

(Torque Limit)

Turning the trimmer clockwise increases the torque limit value.

Range: 0 ~ 200%

Full

Clockwise

Turning the trimmer clockwise increases the

acceleration/deceleration time.

Range: 0.00 ~ 5.00 [s]

The standard speed for acceleration/deceleration time setting made

by the trimmer can be changed with Pn025.

The initial value of the standard speed is 3000 [r/min].

Full

Counter-

Clockwise

Built-in trimmer 2

(Accelaration/

Deceleration Time)

Counter-clockwise Clockwise

9

■

A

-SDNB080L4

App

roximate Wei

g

ht=0.73k

g

3. External Dimensions

10

■Installation Environmen

t

*When installin

g

the driver,

p

lace it in a switchboard or the like to

p

revent forei

g

n materials from enterin

g

.

■Mountin

g

direction

There is no restriction on the mounting direction of the driver,

but please provide a gap of 30mm or larger at the top and bottom of the driver.

4. Installation

Ambient Temperature

Ambient Humidity

Altitude

Atmosphere

-10~50℃

95%RH or less (no condensation)

1,000m or lower

A place with no corrosive/explosive gas, vapor, etc.

A well-ventilated place without any dust.

Vibration

Installation Place

2.0G or less

Indoors

30mm or larger

30mm or larger

11

■Sink connection exam

p

le

(

when usin

g

external

p

ower su

pp

l

y)

When using the external power supply,

set the built-in switch lever of the driver (SW1) as shown on the right.

5. Wiring Diagrams

BK(W) Black

12V〜24V

2

3

4

5

6

7

8

9

1

Main power supply (+)

Main power supply (-)

I1

I2

I3

I4

I5

I6

I7

I8

IN-COM

RD(U) Red

WT(V) White

CN6

B

Ry

CN1

CN8

M

19

20

21

22

10

11

12

13

14

15

16

17

C1

E1

C2

E2

C3

E3

C4

E4

+5V

AIN

AOUT

TGND

Ry

*4

Built-in switch (SW1)

When using internal

power supply (I)

When using external

power supply (O)

Motor drive output

W-phase

Motor drive output

V-phase

Motor drive output

U-phase

Controlled power supply ()

Input common

Multi-function input 1

(CW driving command)

Multi-function input 2

(CCW driving command)

Multi-function input 3

(Speed command selection 1)

Multi-function input 4

(Speed command selection 2)

Multi-function input 5

(Acceleration/deceleration time selection)

Multi-function input 6

(Torque limit value selection)

Multi-function input 7 *2

(Alarm reset, emergency stop)

Multi-function input 8

(Pulse frequency speed command)

Ground for external equipment *3

Multi-function output 1 *2

(Error detection)

Multi-function output 2

(During operation)

Multi-function output 3

(Rotation pulse)

Multi-function output 4

(Overload)

External analog 5 V power supply

External analog input

Analog output

30 V or less

Motor signal line

Surge

protector

Personal computer

(RS-232C)

+

-

⊕

*1

*1 Do not cut connection with the battery when the motor is regenerative running buring motions of

lowering and reducing speed and the main power supply(+) and controlled power supply(⊕) are connected.

Cut off only the main power supply(+) when you unavoidably turn off power.

*2 The polarity is reversed in the initial state for safety.

*3 See "Caution for wiring" on page 15 and Wire.

*4 This wiring example is for using with brake.

12

■Source connection exam

p

le

(

when usin

g

external

p

ower su

pp

l

y)

When using the external power supply,

set the built-in switch lever of the driver (SW1) as shown on the right.

10

11

12

13

14

15

16

17

Ry

2

3

4

5

6

7

8

9

1IN-COM

CN6

B

CN1

CN8

M

19

20

21

22

C1

E1

C2

E2

C3

E3

C4

E4

+5V

AIN

AOUT

Built-in switch (SW1)

When using internal

power supply (I)

When using external

power supply (O)

Main power supply (+)

Main power supply (-)

Controlled power supply ()

Motor drive output

W-phase

Motor drive output

V-phase

Motor drive output

U-phase

BK(W) Black

RD(U) Red

WT(V) White

Motor signal line

Ry

Surge

protector

Personal computer

(RS-232C)

12V〜24V

I1

I2

I3

I4

I5

I6

I7

I8

TGND

Input common

Multi-function input 1

(CW driving command)

Multi-function input 2

(CCW driving command)

Multi-function input 3

(Speed command selection 1)

Multi-function input 4

(Speed command selection 2)

Multi-function input 5

(Acceleration/deceleration time selection)

Multi-function input 6

(Torque limit value selection)

Multi-function input 7 *2

(Alarm reset, emergency stop)

Multi-function input 8

(Pulse frequency speed command)

Ground for external equipment *3

Multi-function output 1 *2

(Error detection)

Multi-function output 2

(During operation)

Multi-function output 3

(Rotation pulse)

Multi-function output 4

(Overload)

External analog 5 V power supply

External analog input

Analog output

30 V

or less

*4

*1 Do not cut connection with the battery when the motor is regenerative running buring motions of

lowering and reducing speed and the main power supply(+) and controlled power supply(⊕) are connected.

Cut off only the main power supply(+) when you unavoidably turn off power.

*2 The polarity is reversed in the initial state for safety.

*3 See "Caution for wiring" on page 15 and Wire.

*4 This wiring example is for using with brake.

+

-

⊕

*1

13

■Sink connection exam

p

le

(

when usin

g

internal

p

ower su

pp

l

y)

When using the internal power supply,

set the built-in switch lever of the driver (SW1) as shown on the right.

19

20

21

22

10

11

12

13

14

15

16

17

2

3

4

5

6

7

8

9

1

C1

E1

C2

E2

C3

E3

C4

E4

+5V

AIN

AOUT

CN6

B

CN1

CN8

M

Ry

Built-in switch (SW1)

When using internal

power supply (I)

When using external

power supply (O)

Main power supply (+)

Main power supply (-)

Controlled power supply ()

Motor drive output

W-phase

Motor drive output

V-phase

Motor drive output

U-phase

BK(W) Black

RD(U) Red

WT(V) White

Motor signal line

Ry

Surge

protector

Personal computer

(RS-232C)

IN-COM

I1

I2

I3

I4

I5

I6

I7

I8

TGND

Input common

Multi-function input 1

(CW driving command)

Multi-function input 2

(CCW driving command)

Multi-function input 3

(Speed command selection 1)

Multi-function input 4

(Speed command selection 2)

Multi-function input 6

(Torque limit value selection)

Multi-function input 7 *2

(Alarm reset, emergency stop)

Multi-function input 8

(Pulse frequency speed command)

Ground for external equipment *3

Multi-function output 1 *2

(Error detection)

Multi-function output 2

(During operation)

Multi-function output 3

(Rotation pulse)

Multi-function output 4

(Overload)

External analog 5 V power supply

External analog input

Analog output

*4

30 V or less

Multi-function input 5

(Acceleration/deceleration time selection)

*1 Do not cut connection with the battery when the motor is regenerative running buring motions of

lowering and reducing speed and the main power supply(+) and controlled power supply(⊕) are connected.

Cut off only the main power supply(+) when you unavoidably turn off power.

*2 The polarity is reversed in the initial state for safety.

*3 See "Caution for wiring" on page 15 and Wire.

*4 This wiring example is for using with brake.

+

-

⊕

*1

14

■Caution for Wirin

g

When the TGND and main power supply(-) are connected outside of the driver,

the current flows in both the main power supply(-) and TGND side. Each current value depends

on the wiring resistance.

In case of flowing the current over 2A in the TGND side, it may cause damege to the driver and control device.

Wire with the following conditions.

Connectin

g

wire to the TGND︓Diameter 0.4mm

(

AWG26

)

and under

Connectin

g

wire to the main

p

ower su

pp

l

y(

-

)

︓Diameter 1.6mm

(

AWG14

)

and over

Control

device

22

TGND

CN1

Main power supply(-)

Wire length of TGND

Wire length of main power supply

Wire length of TGND≧Wire length of main power supply

15

I/F is not isolated from the main power supply. Pay extreme attention when wiring.

■Connector specifications

■Layout of terminal bloc

k

* Pay attention to the wiring of the motor phases. If the wiring is incorrect, the motor will not operate.

■I/O connector layout (CN1)

*1 The I/O polarity is reversed by default.

*2 Multi-function outputs 3 and 4 are compatible with high-speed pulse output. When selecting the output functions

of rotation pulse, clockwise rotation pulse and counterclockwise rotation pulse, please assign the functions

to multi-function outputs 3 and 4.

*3 This is the power supply output terminal. Do not connect an external power supply.

*4 See "Caution for wiring" on page 15 and Wire.

6. External I/F Specifications

Terminal symbol

⊕

-

+

RD(U)

WT(V)

BK(W)

Function name

Controlled power supply (+)

Main power supply (-)

Main power supply (+)

Motor drive output U-phase

Motor drive output V-phase

Motor drive output W-phase

Description

Plus side of the controlled power supply

Minus side of the controlled/main power supply

Plus side of the main power supply

Connected with motor *

CN6 J.S.T.MFG.CO.,LTD. S05B-XASK-1 Applicable housing: XAP-05V-1

22 TGND Ground for external equipment *4 ―

20 AIN External analog input Speed command

21 AOUT Analog output Speed (output actual speed of motor)

18 ―Not used ―

19 +5V External analog 5 V power supply *3 ―

16 C4 Multi-function feature output 4

(Correspond to high-speed pulse output) Overload

17 E4

14 C3 Multi-function output 3

(Correspond to high-speed pulse output) Rotation pulse

15 E3

12 C2 Multi-function output 2 During operation

13 E2

10 C1 Multi-function output 1 Error detection *1

11 E1

8 I7 Multi-function input 7 Alarm reset, emergency stop *1

9 I8 Multi-function input 8 Pulse frequency speed command

6 I5 Multi-function input 5 Acceleration/deceleration time selection

7 I6 Multi-function input 6 Torque limit value selection 1

4 I3 Multi-function input 3 Speed command selection 1

5 I4 Multi-function input 4 Speed command selection 2

2 I1 Multi-function input 1 CW driving command

3 I2 Multi-function input 2 CCW driving command

Terminal No. Terminal name Function nam

e

Initial settin

g

1 IN_COM Input common ―

CN8 J.S.T.MFG.CO.,LTD. S4B-XH-A Applicable housing: XHP-4

Applicable crimping terminal: SXH-001T-P0.6N

CN1 J.S.T.MFG.CO.,LTD. S22B-PUDSS-1 Applicable housing: PUDP-22V-S

Applicable crimping terminal: SPUD-001T-P0.5

Code Manufacturer Type Remarks

Terminal block

(TM1 ~ 6) --

Tightening torque︓1.6 ~ 2.0 N·m (M5)

Applicable crimping terminal: SXA-001T-P0.6

16

■I/O connector

p

in arran

g

ement(CN1)

■Layout of motor signal connector (CN6) *1

*1 The maximum extension length is 5 m.

*2 Not to be connected with Main supply (-).

■Layout of communication connector

(

CN8

)

* Not to be connected with Main supply (-).

3 RxD Data receipt

4 GND Ground *

Terminal No. Terminal name Function name

1 +5V Power supply 5 V

2 TxD Data transmission

3 HALL_V Hall sensor input V-phase

4 HALL_W Hall sensor input W-phase

5 GND Ground *2

Terminal No. Terminal name Function name

1 +15V Power supply 15 V

2 HALL_U Hall sensor input U-phase

Terminal #1 notch

PCB

CN1

22

21

2

1

17

■When usin

g

external

p

ower su

pp

l

y

(set SW1 to the side of external

p

ower su

pp

l

y(

O

)

・default *1)

【Sink connection】【Source connection】

■When usin

g

internal

p

ower su

pp

l

y

(set SW1 to the side of internal

p

ower su

pp

l

y(

I

)

*1)

【Sink connection】*1Built-in switch

(

SW1

)

settin

g

*2 IN-COM is not used when usin

g

internal

p

ower su

pp

l

y.

*3 See "Caution for wirin

g

" on

p

a

g

e 15 and Wire.

7. I/O Terminal Wiring

7-1 Control input

1

2〜9 5.1kΩ

2kΩ

+15V

SW1

IN-COM

I1〜I8

1

2〜9 5.1kΩ

2kΩ

+15V

SW1

IN-COM

I1〜I8

External power supply(O)

(Default)

1

2〜9 5.1kΩ

2kΩ

+15V

SW1

IN-COM

I1〜I8

TGND

22

*2

*3

External

power

supply

+12 ~ 24 V

Driver

External

power

supply

+12 ~ 24 V

Driver

Driver

Switch lever

Internal power supply(I)

18

■Maximum rated value of control out

p

ut

【Sink connection】【Source connection】

By using the AIN terminal (external analog input) to input a DC voltage, a speed or torque limit value can be enabled.

* The DC voltage reference differs depending on the external speed setting unit and the DC voltage control.

Connect wires according to the following wiring examples.

■External s

p

eed settin

g

unit wirin

g

exam

p

le

The external speed setting unit is available from us as an option.

When sourcing a unit from another vendor, select one with a range of 1k to 20kW.

■DC volta

g

e control wirin

g

exam

p

le

When an analog output unit or the like is used, the one having insulated output is recommended.

7-3 External analog input

7-2 Control output

Max voltage between C and E 30V

Max current C1/E1, C2/E2 100mA

C3/E3, C4/E4 50mA

E1〜E4

10,12,14,16

11

,

13

,

15

,

17

0V

C1〜C4

E1〜E4

10,12,14,16

11

,

13

,

15

,

17

0V

C1〜C4

19

20

21

22

+5V

AIN

AOUT

TGND

3

2

1

1k~20kΩ

CN1

19

20

21

22

+5V

AIN

AOUT

TGND

DC0~+5V

or

DC0~+10V

⊕

⊖

CN1

Load

Load

Driver Driver

External

power supply External

power supply

External speed setting unit

Insulated analog output unit

19

The user constant can be changed using PC software “ACD-PSTool.”

* “ACD-PSTool” can be downloaded from our website for free.

* The communication cable between PC (RS-232C) and the driver is an optional accessory (sold seperately).

■The “ACD-PSTool” is compatible with the following operating systems.

Windows7®, Windows8®, Windows8.1® and Windows10®

■Attribute

Each constant has an attribute. Refer to the explanation below.

■Command constants

A

ttribute S:Chan

g

eable when motor is sto

pp

ed or

p

ower is su

pp

lied a

g

ain. D:Alwa

y

s chan

g

eabl

e

Pn001 Speed command 1 Set the speed command 1. r/min 80~4000

8. User Constants

8-1 Setteing of Constants

8-2 Constant list

Pn000 Speed command

source selection

Selects the speed command method.

1: External analog command

2: PWM speed command

3: Pulse frequency speed command

4: Built-in trimmer 1

5: Speed command 1 (Pn001)

―1~5

No. Name Description Unit Setting range

P

Attribute

When the constant is changed, the setting becomes effective after the motor stops or

power is supplied again.

The previous setting is maintained while the motor is operating.

Attribute

S

D

Pn003 Speed command 3 Set the speed command 3. r/min 80~4000

Pn002 Speed command 2 Set the speed command 2. r/min 80~4000

Pn005 Speed command 5 Set the speed command 5. r/min 80~4000

3000 D

Pn004 Speed command 4 Set the speed command 4. r/min 80~4000

3000

D

Pn006 Speed command 6 Set the speed command 6. r/min 80~4000

Pn008 Speed command 8 Set the speed command 8. r/min 80~4000

Pn007 Speed command 7 Set the speed command 7. r/min 80~4000

Pn021 Acceleration time 1

Sets the acceleration time 1 which is from

0 [r/min] to the acceleration/deceleration

time standard speed (Pn025).

s 0.00~5.00

Pn020

Acceleration/

deceleration time

command source

selection

Selects the command method for

acceleration/deceleration time.

1: Built-in trimmer 2

2: Acceleration time 1, deceleration time 1

―1~2

Pn022 Deceleration time 1

Sets the deceleration time 1 which is from

the acceleration/deceleration time

standard speed (Pn025) to 0 [r/min].

s 0.00~5.00

When the constant is changed, the setting becomes effective after power is supplied again.

The previous setting is maintained until power is supplied again.

Description

D

D

D

D

When the constant is changed, the new setting becomes effective immediately.

0.1 D

1

0.1

S

D

3000

3000

D

S

Initial value

1

3000

3000

3000

3000

D

20

Table of contents