T.M. C173285-3

1 DECEMBER 1997

i

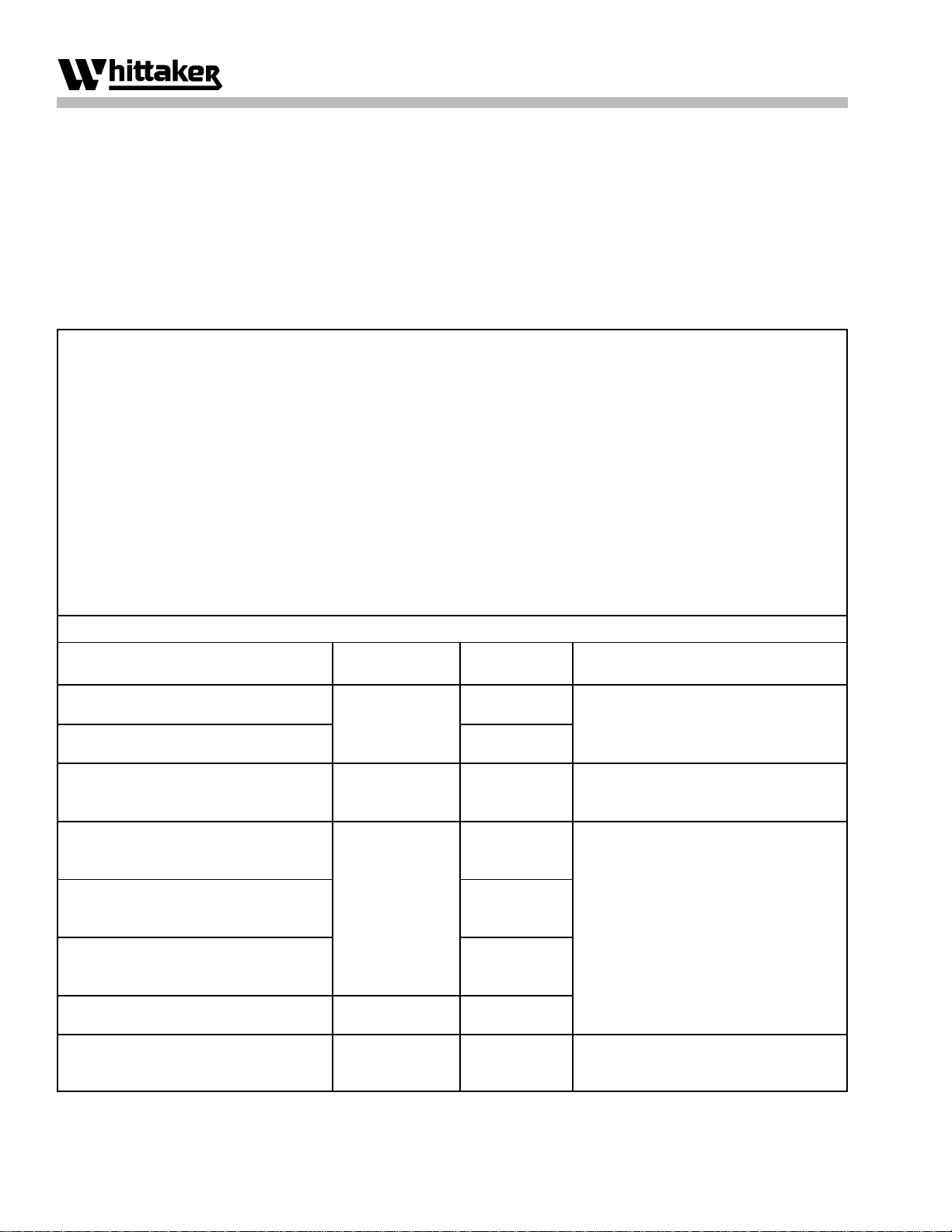

TABLE OF CONTENTS

Section Paragraph/Title Page Section Paragraph/Title Page

SAFETY SUMMARY ................. iii

IINTRODUCTION ...................1-1

1-1. Purpose of Manual .............1-1

1-4. Scope of Manual ..............1-1

1-7. Symbols and Abbreviations ......1-1

II SYSTEM DESCRIPTION AND

OPERATION ......................2-1

2-1. General .....................2-1

2-3. Fuel Metering Skid ............2-1

2-5. Motor Controllers .............2-1

2-7. Operation ....................2-5

2-9. DLE Engine Skid Settings ......2-5

2-11. SAC Engine Skid Settings ......2-5

2-13. System Operation .............2-5

2-17. Gas Isolation Shutoff Valves

(SOV1 and SOV2) ...........2-5

2-20. Inter-Shutoff Vent Valve

(GVV) .....................2-7

2-22. Gas Supply Temperature

Transmitter (TT1/TT2) ........2-7

2-23. SAC/DLE Manual Selector

Valve (SOV4) ...............2-9

2-27. Fuel Metering Valves (FMVB

FMVP, FMVO and FMVI) .....2-9

2-30. DLE Absolute Pressure

Transducer (GP1/GP2) ......2-11

2-32. SAC Absolute Pressure

Transducer (GP1B) .........2-12

2-34. Motor Controllers (MCB, MCI,

MCO and MCP) ............2-12

III INSTALLATION ....................3-1

3-1. General .....................3-1

3-3. Mechanical Interfaces ..........3-1

3-5. Gas Inlet Supply Flange .......3-1

3-7. DLE Engine Outlet Flanges ....3-1

3-9. SAC Engine Outlet Flange .....3-1

3-11. Seal Vent Interface Flange .....3-1

III 3-13. Electrical Interfaces ............3-1

3-14. PE Grounding Connection ......3-1

3-16. Main Junction Box

Connectors ..................3-1

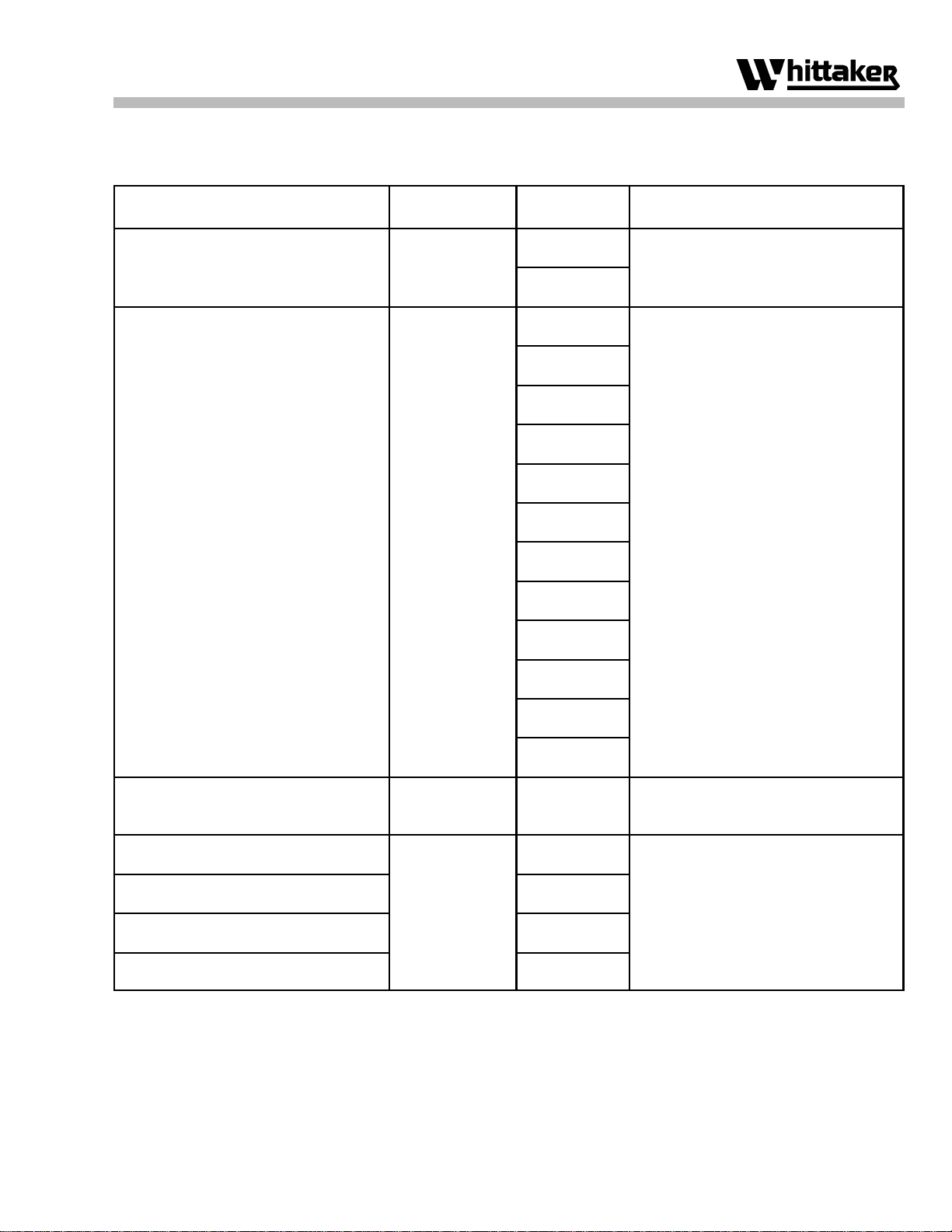

IV FAULT ISOLATION ................. 4-1

4-1. General .....................4-1

4-2. Fault Isolation –Gas Isolation

Shutoff Valve (SOV1 or SOV2) ..4-1

4-3. Position Indication ...........4-1

4-4. Position Indicator Moves

Normally –Possible Position

Indicating Switch Fault ........4-1

4-5. Position Indicator Will Not

Move –Possible Solenoid

Fault ......................4-1

4-6. Gas Supply Temperature

Transmitter (TT1/TT2) .........4-2

4-8. SAC Gas Supply Absolute

Pressure Transducer (GP1B) ...4-2

4-10. DLE Gas Supply Absolute

Pressure Transducers

(GP1/GP2) ..................4-2

4-12. SAC/DLE Manual Selector

Valve (SOV4) ................4-3

4-13. Position Indication ...........4-3

4-14. Inter-Shutoff Vent Valve (GVV) ..4-3

4-15. Valve Will Not Operate .......4-3

4-16. Motor Controllers (MCB, MCI,

MCO and MCP) ..............4-3

4-19. Motor Controller Enable .......4-3

4-21. Error Code Fault Isolation ......4-7

4-22. Fuel Metering Valves (FMVB,

FMVI, FMVO and FMVP) ......4-7

4-23. Valve Position ..............4-7

4-24. LVDT Position Indication ......4-7

4-25. Actuator Motor Control or

Position Problems ...........4-9

4-27. Fuel Metering Valve Motor

Controller Enable ...........4-10