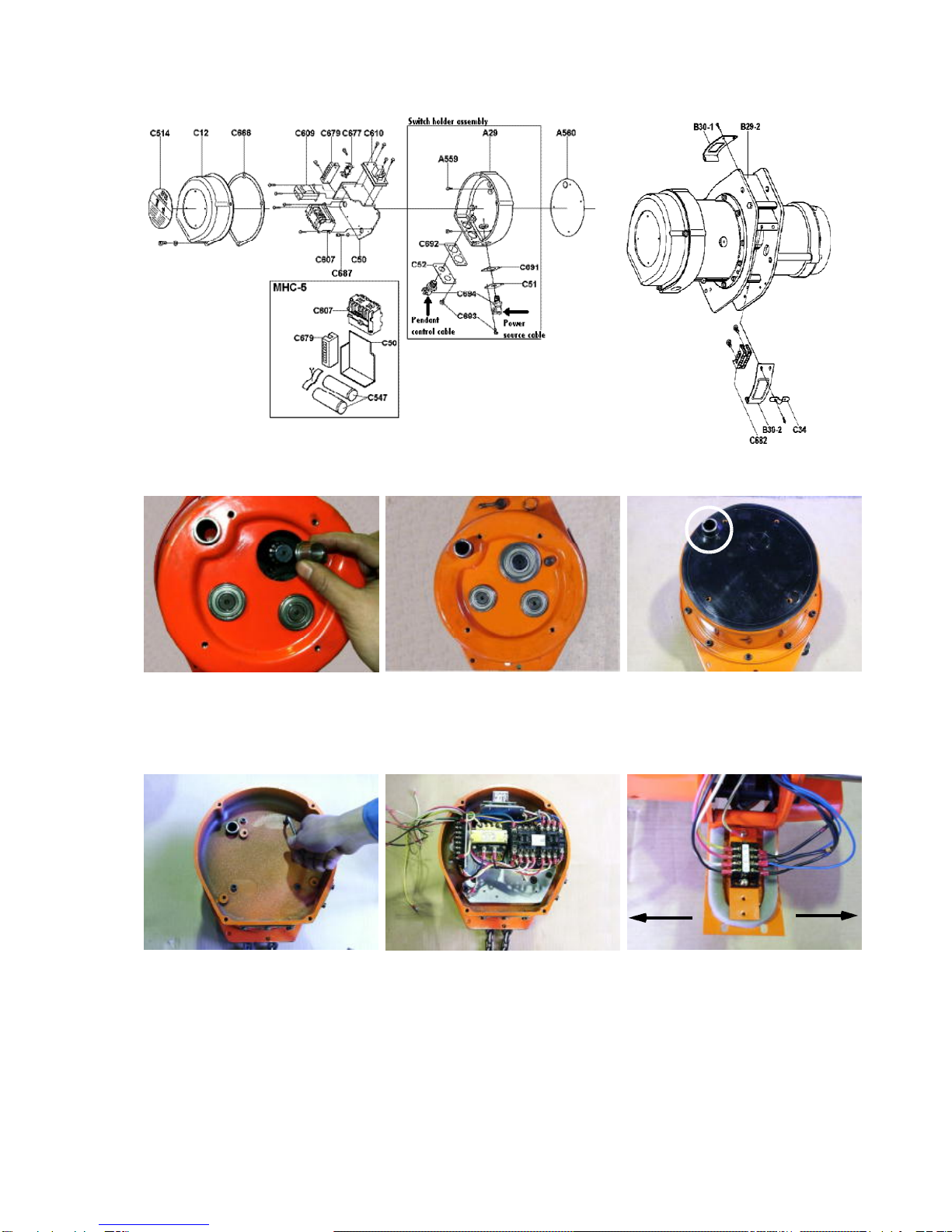

Nitchi MH-5 User manual

Other manuals for MH-5

1

This manual suits for next models

2

Table of contents

Popular Industrial Electrical manuals by other brands

Eaton

Eaton VacClad-W Instructions for installation, operation, maintenance

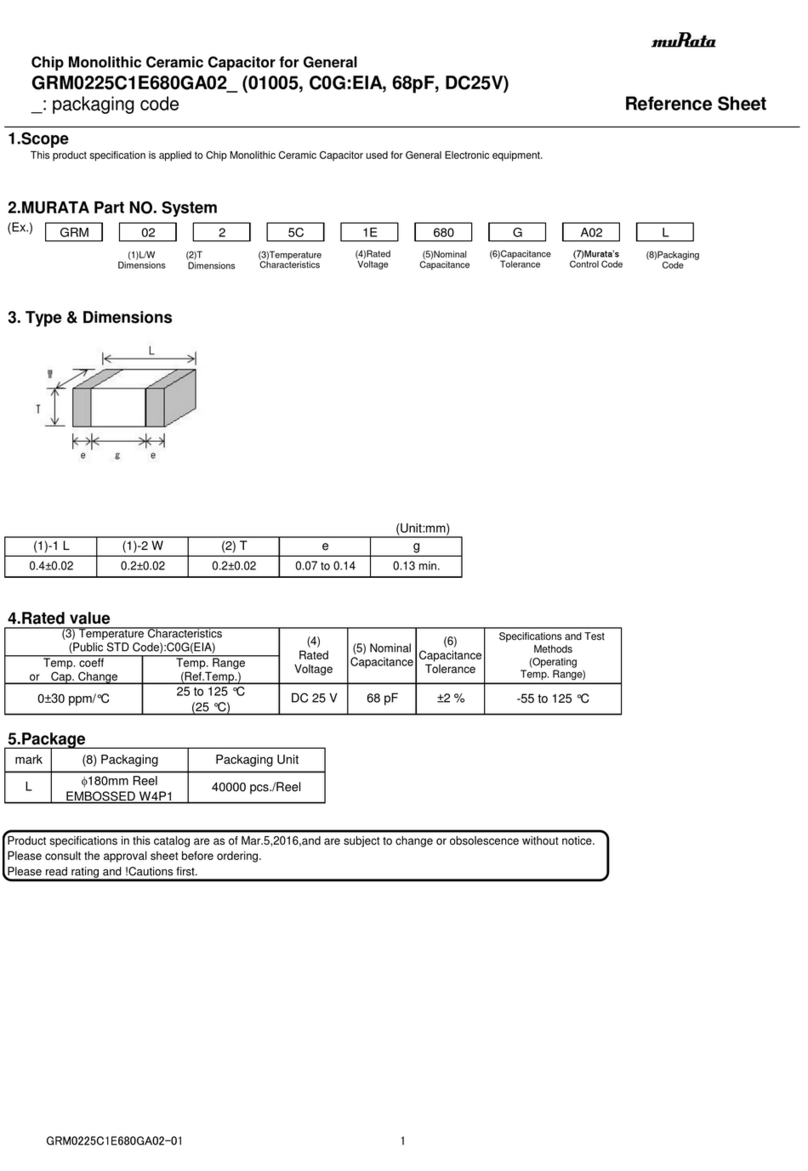

Murata

Murata GRM0225C1E680GA02 Series Reference sheet

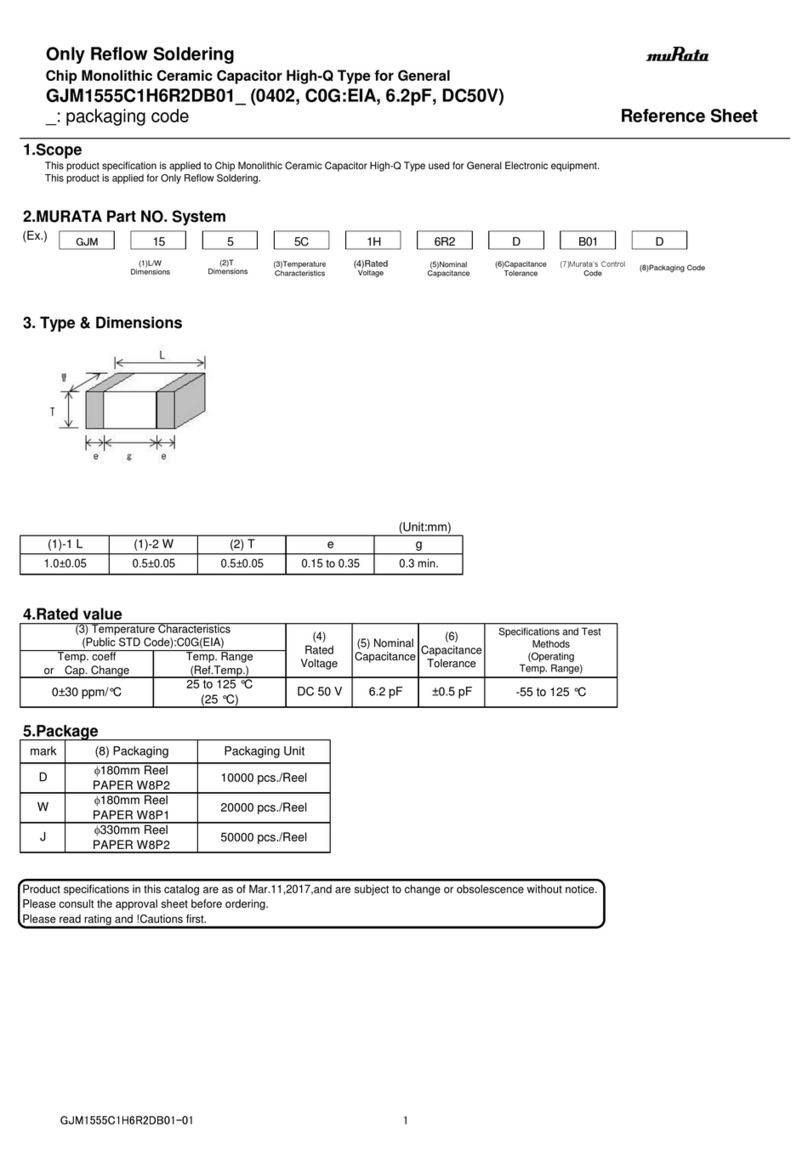

Murata

Murata GJM1555C1H6R2DB01J Reference sheet

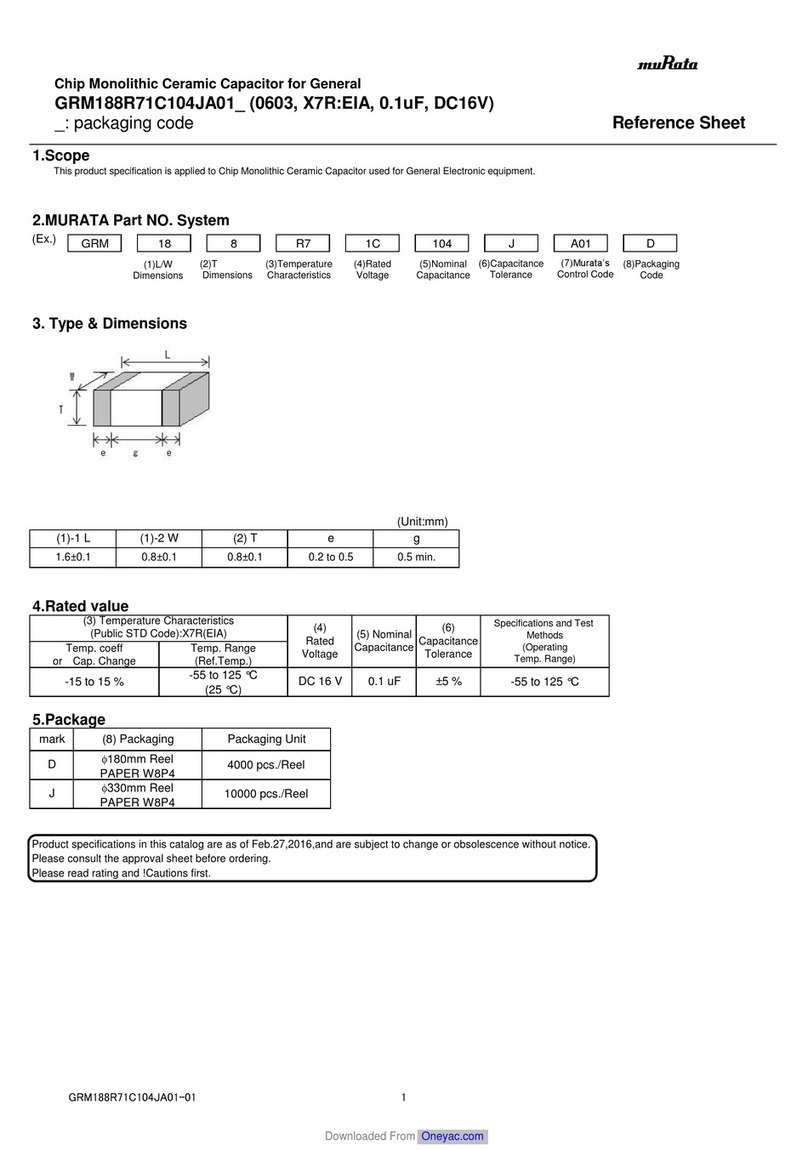

Murata

Murata GRM188R71C104JA01 Series Reference sheet

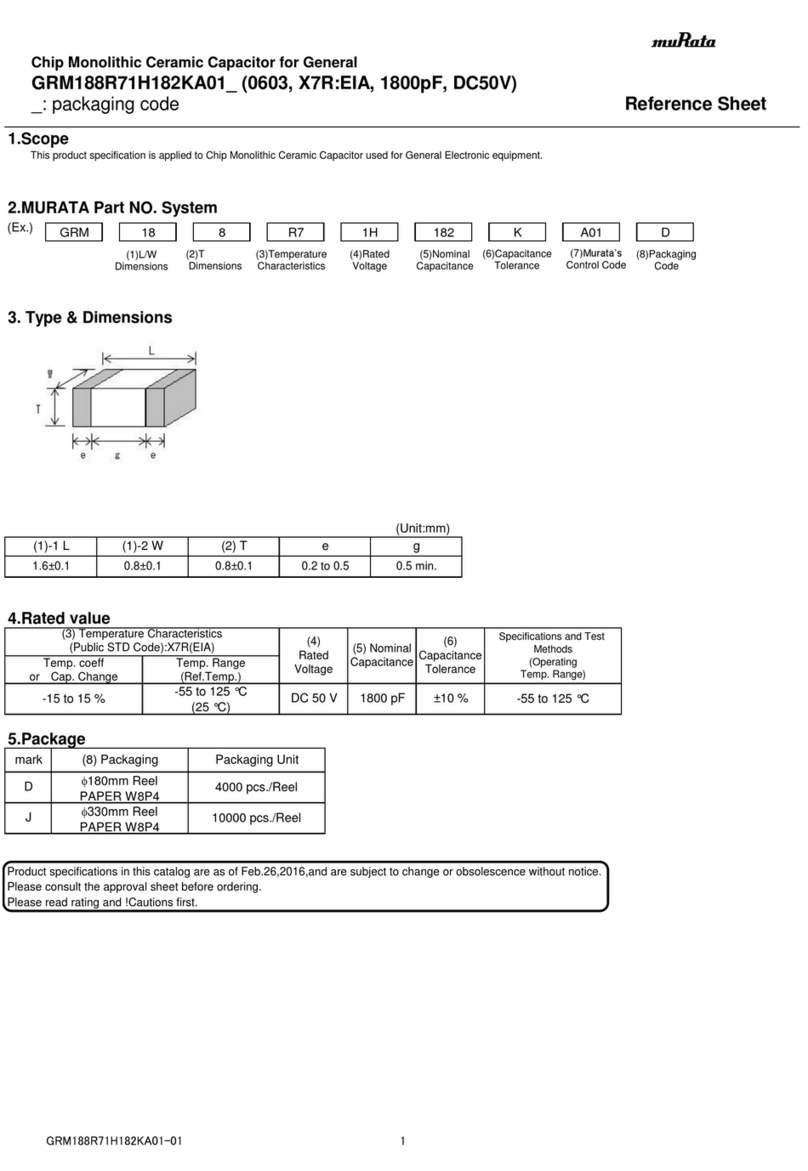

Murata

Murata GRM188R71H182KA01 Series Reference sheet

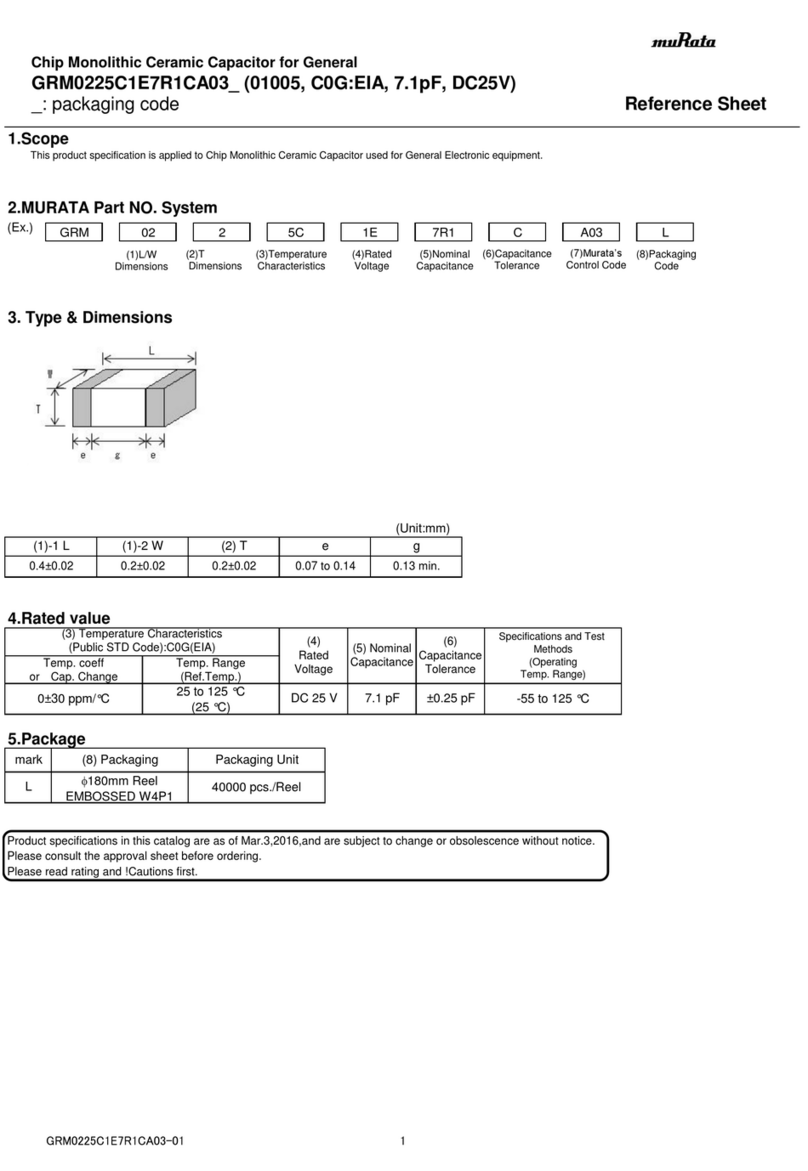

Murata

Murata GRM0225C1E7R1CA03 Series Reference sheet

Toshiba

Toshiba HCV-7HA instruction manual

Graphic Whizard

Graphic Whizard Finishmaster 100 Reference manual

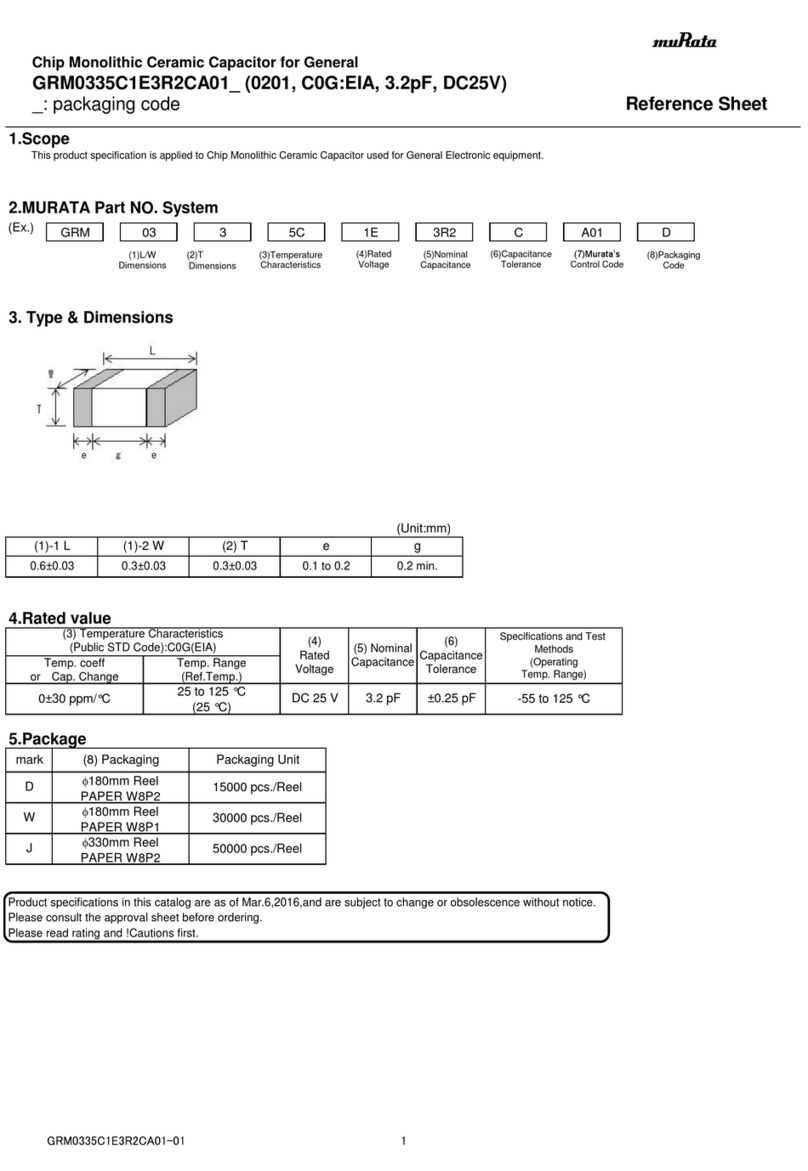

Murata

Murata GRM0335C1E3R2CA01 Series Reference sheet

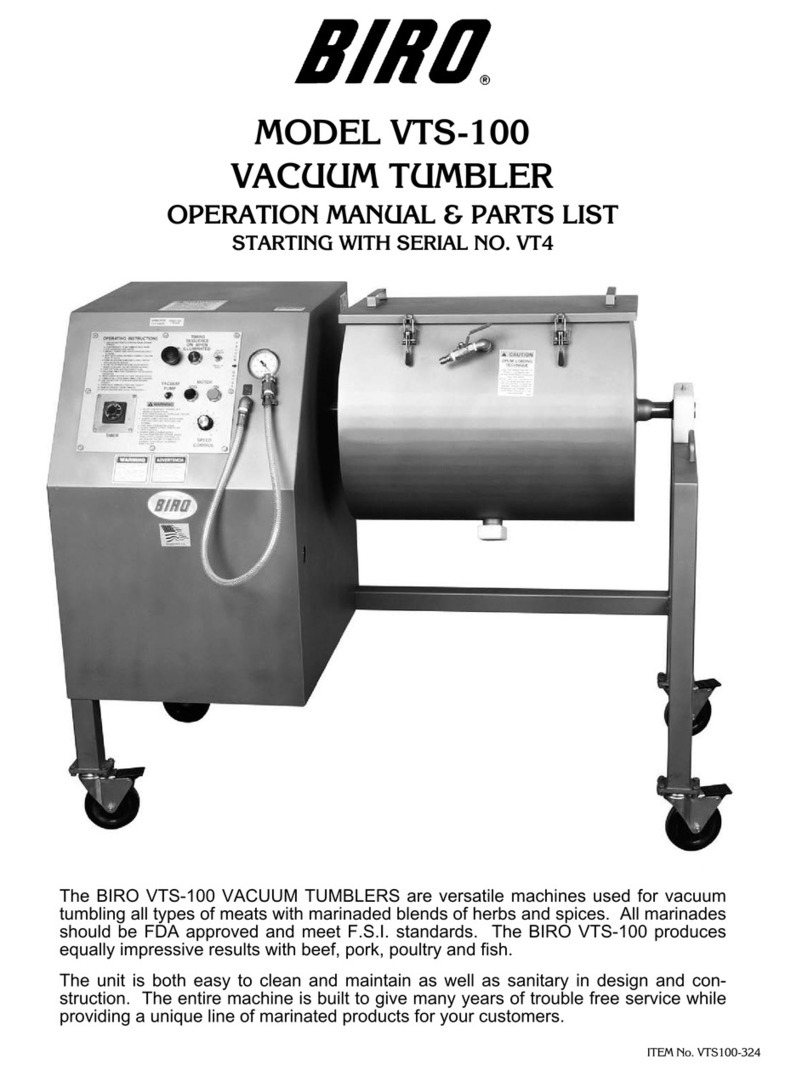

BIRO

BIRO VTS-100 Operations manual & parts list

Vertiv

Vertiv Liebert Maintenance Bypass Cabinet Installer/user guide

Murata

Murata GRM155R60J105KE19 Series Reference sheet

Huawei

Huawei SUN2000-4.95KTL-JPL0 quick guide

AST

AST 40 installation instructions

Siemens

Siemens SIMATIC ET 200SP operating instructions

Gewiss

Gewiss RESTART PRO installation instructions

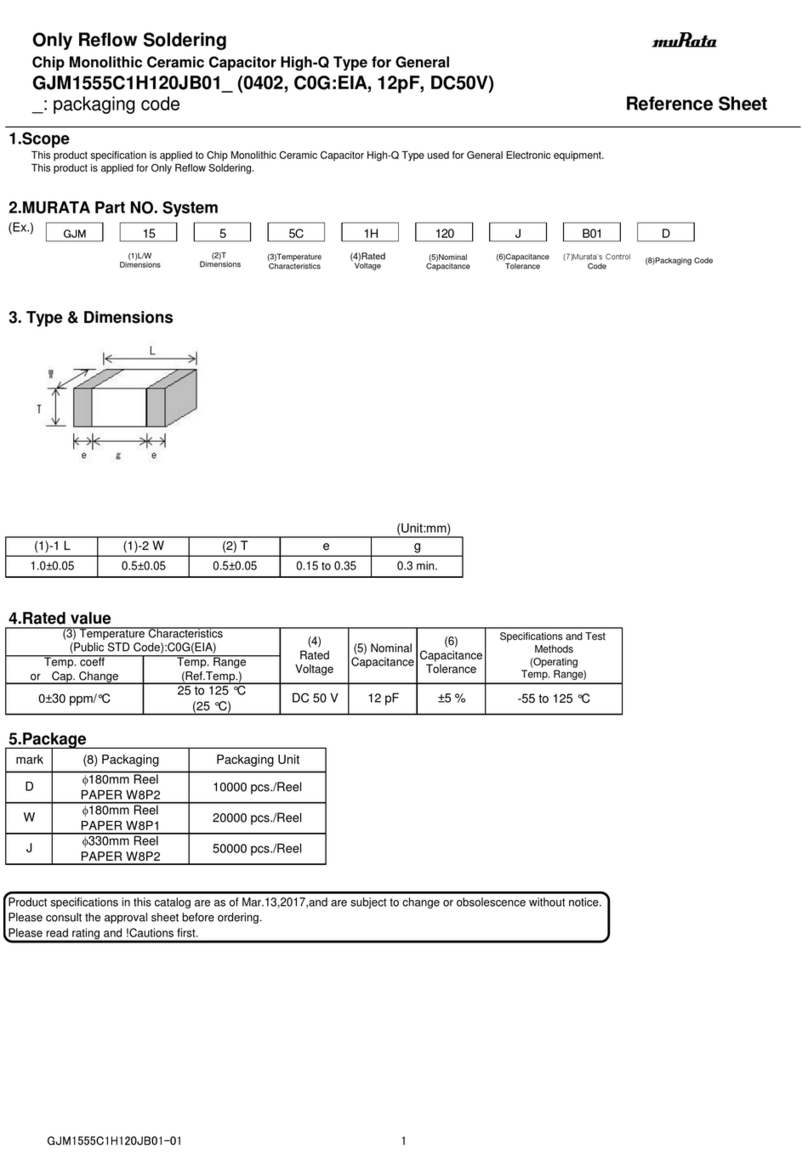

Murata

Murata GJM1555C1H120JB01 Series Reference sheet

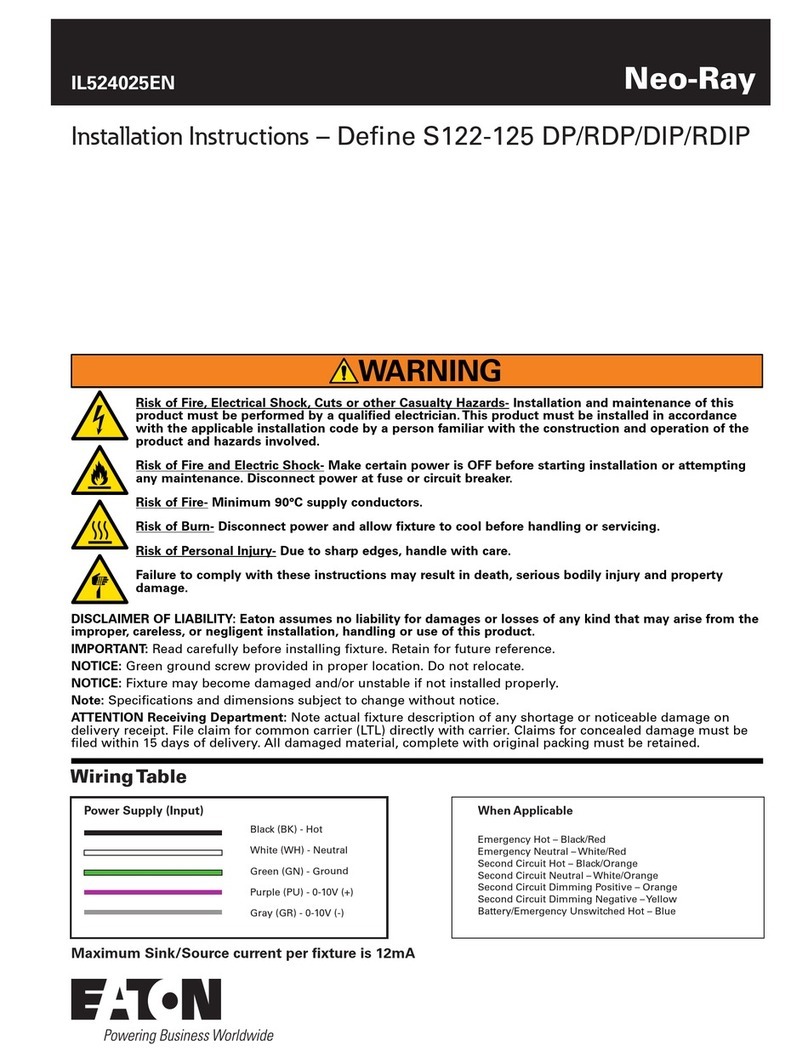

Eaton

Eaton Neo-Ray Define S122-125 DP installation instructions