Page 4 TABLE OF CONTENTS

SAFETY .................................................................................................................................................. 1

INTRODUCTION ..................................................................................................................................... 6

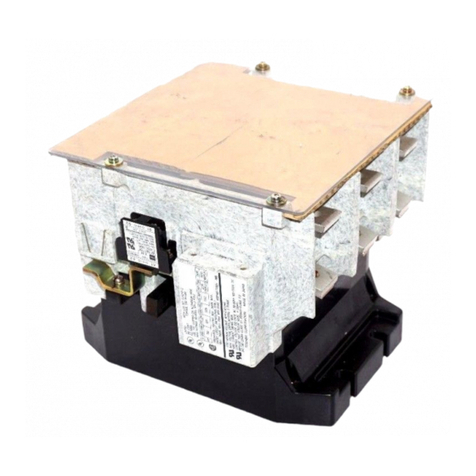

GENERAL DESCRIPTION...................................................................................................................... 7

Components ....................................................................................................................................................7

Indicators Provided ..........................................................................................................................................7

Figure 1 – Contactor Structure ........................................................................................................................7

RECEIVING, INSPECTION AND HANDLING ......................................................................................... 8

Receiving and Unpacking................................................................................................................................8

Acceptance Inspection ....................................................................................................................................8

Handling and Moving .......................................................................................................................................8

Figure 2 – Wear Gauge ...................................................................................................................................8

INSTALLATION ...................................................................................................................................... 9

Ambient Conditions .........................................................................................................................................9

Mounting the Contactor ...................................................................................................................................9

Main Circuit Cable Connections ......................................................................................................................9

Ground Connections........................................................................................................................................10

Control Circuit Connections.............................................................................................................................10

Figure 3 – Control Voltage Selection for Closing Coils ...................................................................................10

PRE-ENERGIZATION CHECK................................................................................................................ 11

General ............................................................................................................................................................11

Electrical Checks .............................................................................................................................................11

OPERATION ........................................................................................................................................... 12

Figure 4 – Drive Unit Block Diagram ...............................................................................................................12

Figure 5 – Internal Connection of the Magnetically Held Type .......................................................................13

Figure 6 – Internal Connection of the Mechanically Latched Type .................................................................13

Figure 7 – Typical Control Circuit for Magnetically Held Type ........................................................................14

Figure 8 – Typical Control Circuit for Mechanically Latched Type 125VDC-250VDC Trip .............................15

Figure 9 – Typical Control Circuit for Mechanically Latched Type 24VDC-48VDC Trip .................................16

MAINTENANCE ...................................................................................................................................... 17

Maintenance Program .....................................................................................................................................17

Maintenance Record .......................................................................................................................................17

Servicing Equipment........................................................................................................................................17

Recommended Inspection and Maintenance Types .......................................................................................18

Table 1 – Tightening Torque ...........................................................................................................................18

Table 2 – Check Points for Periodic Inspection...............................................................................................19

Table 3 – Gap/Wipe Standard Values (contactor in new condition)................................................................20

Vacuum Check ................................................................................................................................................21

Figure 10 – Toshiba Portable Vacuum Checker .............................................................................................21

Figure 11 – Application of Test Voltage for Vacuum Check............................................................................22

Electrical Service Life ......................................................................................................................................23

Mechanical Service Life...................................................................................................................................23

Figure 12 – Wipe Measurement ......................................................................................................................23

Service Life – Capacitor Switching ..................................................................................................................23