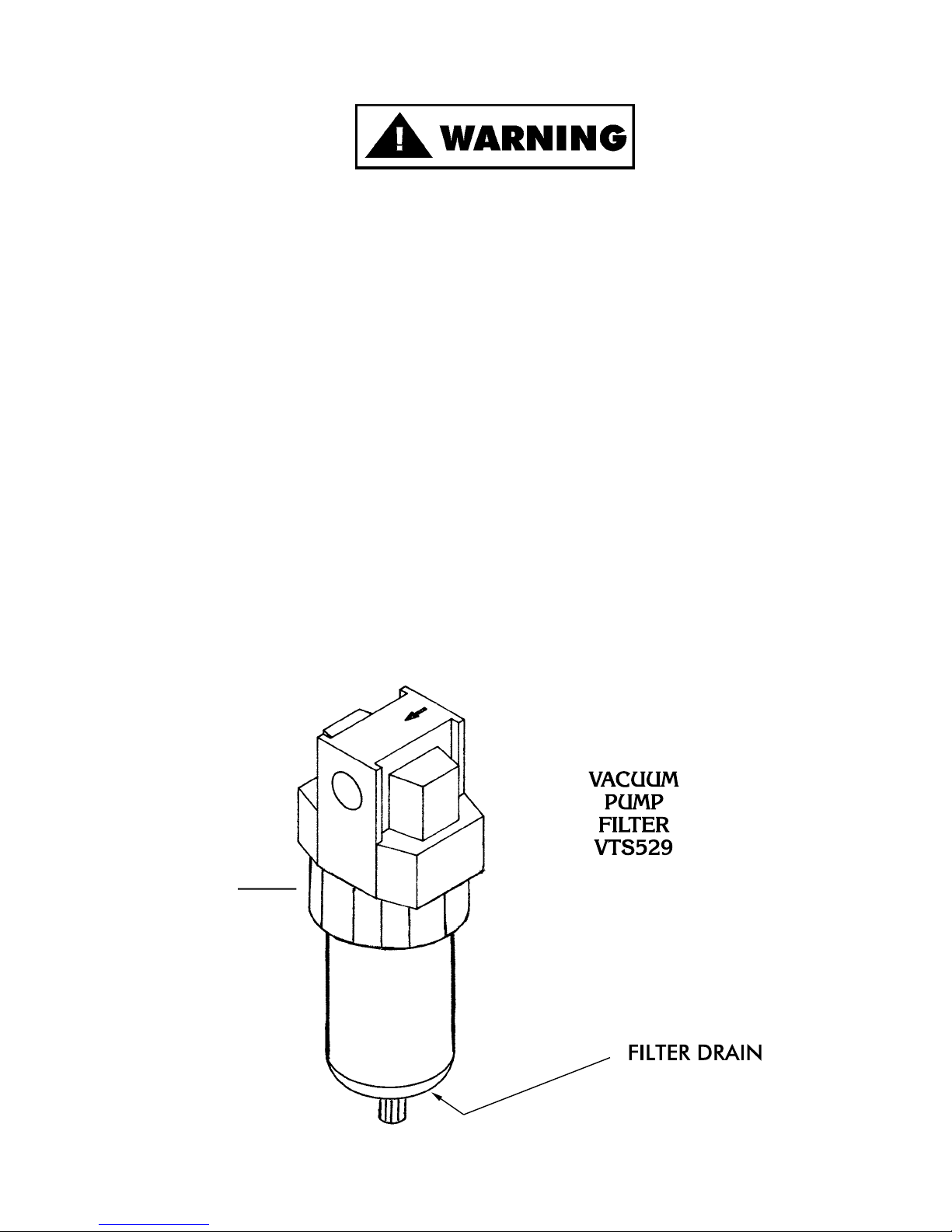

B. VACUUM PUMP

WARNING: MAKE SURE THE ELECTRIC MOTOR IS PROPERLY GROUNDED AND THE WIRING IS DONE BY

A QUALIFIED ELECTRICIAN FAMILIAR WITH NEMA MG2 SAFETY STANDARDS, NATIONAL ELECTRICAL

CODE AND ALL LOCAL SAFETY CODES.

WARNING: THE MOTOR IS THERMALLY PROTECTED AND CAN AUTOMATICALLY RESTART WHEN THE

OVERLOAD RESETS. ALWAYS DISCONNECT FROM POWER SOURCE BEFORE SERVICING. PERSONAL

INJURY COULD BE THE RESULT.

WARNING: DO NOT USE KEROSENE OR OTHER COMBUSTIBLE SOLVENTS TO FLUSH UNIT. USE ONLY

GAST BRAND AH255 FLUSHING SOLVENT OR EQUIVALENT.

1. CONSTRUCTION: The end plate, body, rotor and all mounting brackets are cast iron. Any moisture that

accumulates in the pump will tend to corrode the interior, especially if it stands idle. The muffler box, on the

front of the unit, is made of aluminum. The vanes are made of hard carbon and are precision ground. They

should last many thousand hours depending on degree of vacuum at which the pump is run.

2. STARTING: CAUTION: NEVER LUBRICATE THIS OILLESS AIR PUMP. The carbon vanes and grease

packed motor bearings require no oil. If the motor fails to start or slows down when under load, shut the unit

off and unplug. Check that the supply voltage agrees with the motor post terminals and motor data name

plate. If the pump is extremely cold, allow it to warm to room temperature before starting.

3. FLUSHING: Should excessive dirt, foreign particles, moisture, or oil are permitted to enter the pump the

vanes will act sluggish or even break. Flushing the pump should remove these materials. There are two

options for performing this operation. Option 1: You will need two pipe nipples at least 4" long with 38" NPT

on one end. 1) Remove the filter elements from the front of the muffler box and screw the nipples in through

the same holes. 2) With the pump running allow about 2 tbsp. of flushing solvent to be ingested into the

vacuum side of the unit. CAUTION: WEAR EYE PROTECTION AND FLUSH IN A WELL VENTILATED

AREA. Repeat the flushing procedure. If it does not remedy the situation, remove the end plate for further

examination. Option 2: Remove the filter elements from the front of the muffler box and carefully remove

the five bolts that hold the muffler box in place (be careful not to damage the gaskets and it may be

necessary to replace them). Tap the box with a small hammer to break it loose. DO NOT PRY WITH A

SCREWDRIVER as the gasket will be damaged. This will allow access to the intake and exhaust ports.

4. DISASSEMBLY: If flushing does not eliminate the problem, remove the six bolts holding the end plate to the

body. Now remove the end plate and the four vanes (do not remove the rotor or loosen any electric motor

through bolts). The vanes could be worn or could require further cleaning. The top clearance (between the

rotor and body) may be adjusted by: 1) loosen body bolts, 2) lightly tap on the pump body and turn the rotor

while setting this clearance to assure all points on the rotor clear the body.

PUMP MOTOR

VAC. PRESS. VAC. PRESS. OVERHEATING OVERLOAD

Filter dirty X X at pump X X

Muffler dirty at pump X X

Vacuum line collapsed X at pump X X

Relief valve set too high X X X X

Relief valve set too low X X

Plugged vacuum line X X at pump at pump X X

Vanes sticking X X

Running at too high RPM X X X X

Vanes worn (replace) X X

Shaft seal worn (replace) X X

Dust or offset powder in pump X X X X

Motor not wired correctly X X X

8

LOW HIGH

REASONS FOR PROBLEM