5-8 Preparing the Cutting Oil

Safety Notes on Cutting Oil should be observed.

WARNING

(1) Application and Usage Limitations

・Use only as cutting fluid. Not for use in ordinary

households.

(2) Precautions on Handling Cutting Oil

・Thisliquidcontainsamines.Itshouldnotbemixed

with rust preventives containing nitrite.

・May cause inflammation if it enters the eyes.

Protective eye-wear should be used when handling to

prevent entry into the eyes.

・Skin contact may cause inflammation. Protective

gloves should be worn when handling to prevent

contact with the skin.

・May cause discomfort if mist or vapor is inhaled.

Breathing apparatus should be used when handling so

that mist or vapor should not be inhaled.

・Dilution should be carried out in accordance with the

Instruction Manuals.

・Keep it out of reach of children.

・Do not drink it.

(3) Emergency Treatment

・If it has entered eyes, immediately open the eyelids as

wide as possible and wash thoroughly with water for

atleast15minutes.Ifthereisinammation,consulta

physician and follow the instructions.

・If it has contacted the skin, wash immediately with

soap and water. Soiled clothing should be removed

and laundered thoroughly before re-use. If there is

inflammation, consult a physician and follow the

instructions.

・If mist or vapor has been inhaled, immediately transfer

the patient to fresh air, cover his/her body with a

blanketandkeepwarmandquiet.Consultaphysician

and follow the instructions.

・If it has been ingested, immediately give copious water

and induce vomiting. Consult a physician and follow

the instructions. If the patient is unconscious, do not

administer water or induce vomiting.

(4) In Case of Fire

・Forareinthevicinity,wearprotectiveequipmentand

extinguishthereapproachingfromthewindwardside

with foam, powder or CO2reextinguishers.

(5) Method of Storage

・Seal after use to prevent admixture with dirt and/or

water.

・Store in a cool dark place away from direct sunlight

and rain.

(6) Method of Disposal

・Disposal of undiluted and diluted fluid should be

handledaswasteuidinaccordancewiththelawby

a waste disposal specialist.

・WashwatershouldbetreatedbypHadjustment,

flocculation and settling, activated sludge treatment,

activated carbon absorption, etc., and discharged in

accordance with municipal standards.

・Since empty containers contain dregs, they should be

handled with care.

(7) Other

・If transferred to other containers for use, the names

of chemicals used in the workplace and the labeled

contents should be displayed and kept together with

the Instruction Manuals ready for immediate perusal.

・Anyonewishingtohavefurtherdetailsmayrequest

product safety data sheets from manufacturer.

・The inscribed details are based on currently available

information and data and updated by new knowledge.

・Items to be noted are aimed at normal handling.

Where special handling is involved, safety measures

appropriate to the application and method of handling

should be implemented.

・The inscribed details are submitted for your information

and do not imply assurances or acceptance of

responsibility.

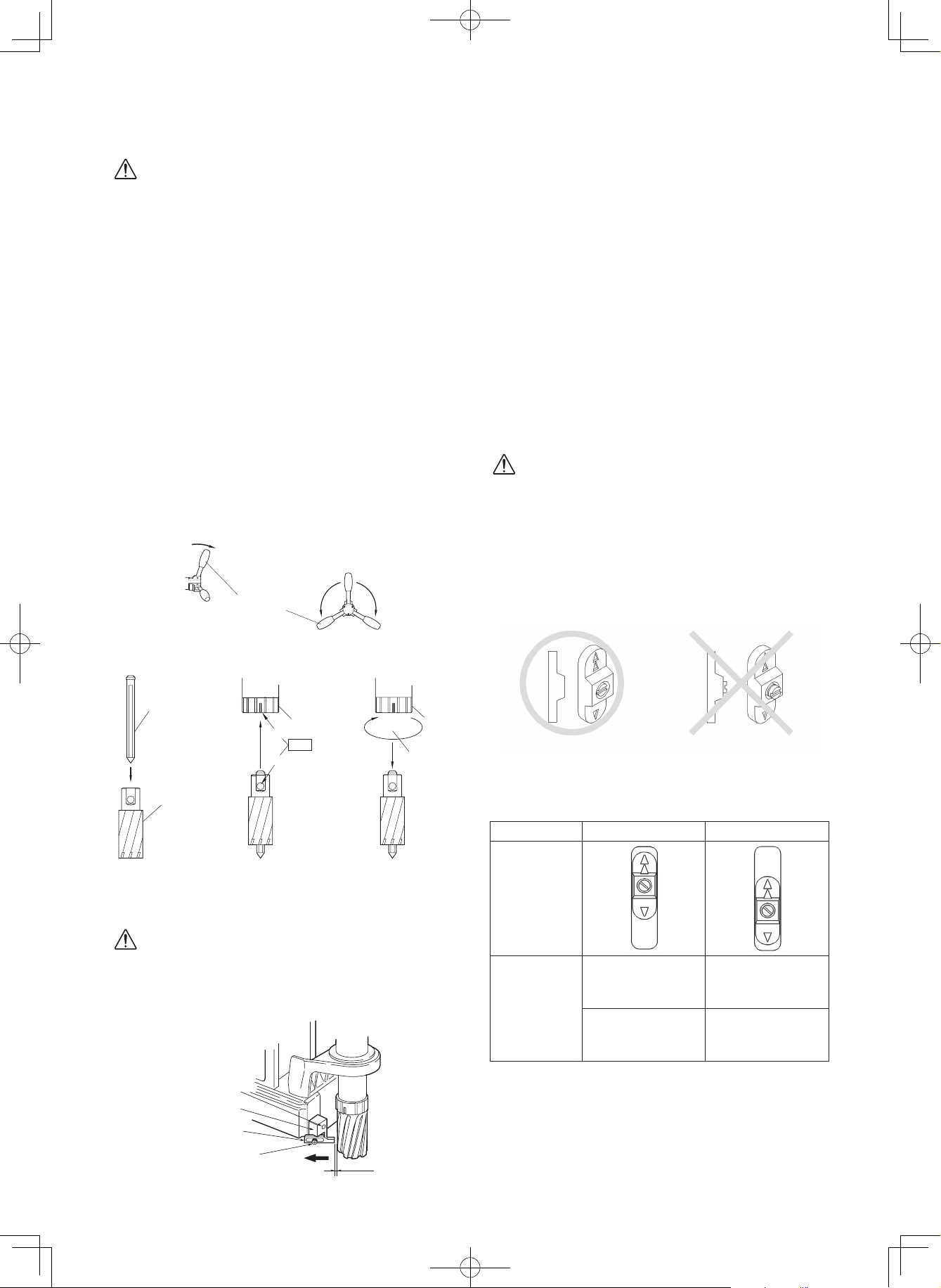

5-8-1 Preparing the Cutting Oil

(1) Use Nitto genuine blue Cutting Oil.

Cutting performance and life may be reduced when other

Cutting Oils are used.

(2) Dilute the Cutting Oil in the proportion of eight to ten

times with tap water.

Do not use well water for dilution.

(3) Remove Rubber Cap from Oil Tank.

Fill in Oil Tank with Cutting Oil to the sideline on the Tank.

Careful not to spill the oil on the machine.

5-8-2 Oil Flow Control

After installed cutter and Pilot Pin, press the Pilot Pin on

to the workpiece, and oil flow starts when P-Cock is

opened.Suchowisrecommendedthatthecutterchips

be kept constantly wet during drilling and free from

discoloration due to overheat burn. Drilling without

enough oil causes longer cycle time and shorter cutter

life.