NJ-COMMERCE LTD Domino-302 User manual

Instruction Manual

Built-in Gas Hob

Model Domino-302

www.fontron.com

NOTE: This User Instruction Manual contains important information, including safety &

installation points, which will enable you to get the most out of your appliance.

Please keep it in a safe place so that it is easily available for future reference; for you or any

person not familiar with the operation of the appliance

1

2

Contents

1. Close-up View........................................................................................03

2. How To Use Your Appliance................................................................03

3. How to Keep Your Cooktop in Shape.................................................04

4. Practical Advice....................................................................................05

5. Is there a problem?...............................................................................06

6. Installation Instructions for built-in...................................................07

7. Table1 Burners and Nozzle Specifications .......................................11

8. Table2 How to convert gas source.......................................................12

9. Table3 Adapting to different types of gas ......................................13

10. Table4 Gas source and national comparison table................................15

11. NOTICE ....................................................................................................15

3

Congratulations on choosing appliance, which you will find is dependable and easy to use. We recommend

that you read this manual for best performance and to extend the life of your appliance. Thank you.

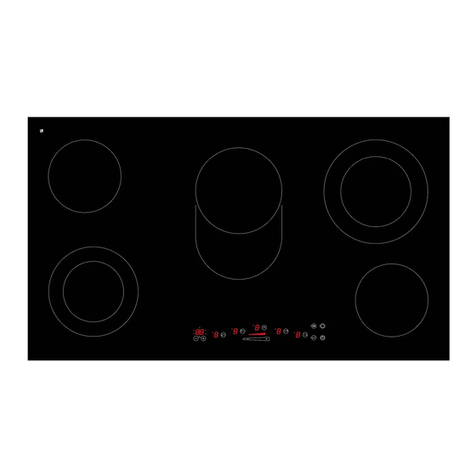

Close-up View

1.Auxiliary Burners

2. Semi-rapid burner

3. Rapid burner

4. Triple ring wok burner

5. Ignitor for Gas Burners (only on certain models)

6. Safety Device (only on certain models) - Activates if the flame accidentally goes out (spills, drafts, etc.),

interrupting the delivery of gas to the burner.

7. Control Knobs for Gas Burners and Electric Hot Plates

NOTICE

The stainless steel grease pan and the cast-iron grill, located in the burner and grate packing box, must be

installed, respectively, below and above the electric heating element so that tile element is enclosed

between the two.

How To Use Your Appliance

The position of the corresponding gas burner or electric hot plate (if present) is indicated on each control

knob.

Gas Burners

The burners differ in size and power. Choose the most appropriate one for the diameter of the cookware

being used.

The burner can be regulated with the corresponding control knob by using one of tile following settings:

OFF

High

Low

4

To turn on one of the burners, place a lighted match or lighter near the burner, press the knob all the

way in and turn in the counter-clockwise direction to the "High" setting.

On those models fitted with a safety device (F), the knob must be pressed in for about 6 seconds

until the device that keeps the flame lighted warms up.

On those models fitted with an ignitor (D), the "E" ignition button, identified by the symbol,

must first be pressed and then the corresponding knob pushed all the way in and turned in the

counter-clockwise direction to the "High" setting.

Some models are equipped with an ignition switch incorporated into the control knob. If this is the case, the

ignitor (D) is present, but not the "E" switch (the symbol is located near each knob).

To light a burner, simply press the corresponding knob all the way in and, then, turn it in the

counter-clockwise direction to the High setting, keeping it pressed in until the burner lights.

Caution: If the burner accidently goes out, turn off the gas with the control knob and try to light it again

after waiting at least 1 minute.

To turn off a burner, turn the knob in the clockwise direction until it stops (it should be on the "." setting).

How to Keep Your Cooktop in Shape

Before cleaning or performing maintenance on your appliance, disconnect it from the electrical power

supply.

To extend the life of the cooktop, it is absolutely indispensable that it be cleaned

carefully and thoroughly on a frequent basis, keeping in mind the following:

●The enameled parts and the glass top, if present, must be washed with warm water without using

abrasive powders or corrosive substances which could ruin them;

●The removable parts of the burners should be washed frequently with warm water and soap, making

sure to remove caked-on substances;

●On cooktops with automatic ignition, the end of the electronic ignition device must be cleaned carefully

and frequently, making sure that the gas holes are not clogged;

●Stainless steel can be stained if it remains in contact with highly calcareous water or aggressive

detergents (containing phosphorous) for an extended period of time, it is recommended that these parts

be rinsed thoroughly with water and then dried well, It is also a good idea to clean up any spills;

●Before using the ceramic glass module, the surface must be cleaned, using a damp cloth to remove dust

or food residues. The ceramic glass surface should be cleaned regularly with a solution of warm water and

a non-abrasive detergent, periodically, special products will need to be used to clean the surface. First,

remove all food buildup or grease with a cleaning scraper, e.g.

CERA (not supplied) (Fig. 1).

Clean the cooking surface when it is still warm with a suitable cleaning product and paper towels. Then

rub with a damp cloth and dry. Aluminum foil, plastic items, objects made of synthetic material, sugar or

foods with a high sugar content that have melted onto the surface must be removed immediately with a

scraper while the cooking surface is still hot. Special cleaning products for ceramic glass surfaces form a

transparent protective layer which fights dirty buildup. This also protects the surface from damage caused

by food with a high sugar content. Do not use abrasive sponges or cleaning products under any

circumstances. This holds true for chemically aggressive cleaners, like oven sprays and stain removers

(Fig.2);

5

Fig.1 Fig.2

●When cleaning the grill, it is recommended that you do so while it is still hot, using the handles provided

to move it from the cooktop to the sink. To remove the pan beneath the grill, it is a good idea to wait until

the heating element has cooled (roughly after 15 minutes)

Greasing the Gas Valves

Over time, the gas valves may stick or become difficult to turn. If this is the case, they must be cleaned on

the inside and then regreased

N.B.:This procedure must be performed by a technician authorized by the

manufacturer.

Practical Advice

Practical Advice on Using the Burners

For best performance, follow these general guidelines:

●Use the appropriate cookware for each burner (see table) in order to prevent the flame from reaching the

sides of the pot or pan;

●Always use cookware with a flat bottom and keep the lid on;

●When the contents come to a boil, turn the knob to "Low".

Burner

Ø Cookware diameter (cm)

Semi–rapid burner 16 - 20

Auxiliary burner 10- 14

Rapid burner 16 - 20

Triple ring wok burner

24 - 26

To identify the type of burner, refer to the designs in the section entitled, "Burner and Nozzle Specifications".

Practical Advice on Using the Half Fish-Kettle Burner

The two central burners, or Half Fish-Kettle burners, are elliptic in form and can be turned up to 90°.This

makes the cooktop more flexible in terms of how it can be used.

To turn the two central burners 90~, proceed as follows:

●Make sure that the burners are cool;

●Lift the burner completely out of its housing;

●Replace it in its housing in the position desired;

●Make sure that the burners are positioned correctly before use.

In addition, the two central burners can be used in tandem or separately with cookware of different

For best performance, keep in mind the following:

6

●All types of casseroles can be used on the ceramic glass cooking surface. However, it is important that

the bottom be perfectly flat. Casseroles with thicker bottoms distribute heat more evenly.

Use cookware the diameter of which is at least as large as the cooking area so that all of the heat produced

by the heating element is used.

●Make sure that the bottom of tile pot is always dry and clean to insure good contact between the

cookware and the cooking surface. This will also increase the life of the pots and of the ceramic glass

surface as well.

●Do not use the same cookware that you use for gas burners because the concentrated heat they

produce can deform the bottom of the pot. Therefore, you will not achieve best results when using these

pots on the ceramic glass surface.

Notice: The glue used to seal the glass surface may leave traces on the appliance. We recommend that the

module be cleaned with a non-abrasive cleaner before being used

the first time. During the first few hours of use, you may detect the smell of rubber; this will disappear after a

short time.

Is there a problem?

It may occur that the cooktop does not function or does not function properly. Before calling customer

service for assistance, let’s see what can be done.

First of all, check to see that there are no interruptions in the gas and electrical supplies, and, in particular,

that the gas valves for the mains are open.

The burner does not light or the flame is not uniform around the burner.

Check to make sure that:

●The gas holes on the burner are not clogged;

●All of the movable parts that make up the burner are mounted correctly;

●There are no draughts around the cooking surface.

The flame does not stay lighted on the model with the safety device.

Check to make sure that:

●You press the knob all the way in;

●You keep the knob pressed in long enough to activate the safety device.

●The gas holes are not clogged in the area corresponding to the safety device.

The burner does not remain on when set to "Low".

Check to make sure that:

●The gas holes are not clogged.

●There are no draughts near tire cooking surface.

7

●Tile minimum has been adjusted correctly (see the section entitled, "Minimum Regulation").

The cookware is not stable.

Check to make sure that:

●The bottom of the cookware is perfectly flat.

●The cookware is centered correctly on the burner or electric hot plate.

●The support grids have not been inverted.

Installation Instructions for built-in

The following instructions are directed at the qualified installer so that the installation and maintenance

procedures may be followed in the most professional and expert manner possible. Important: Unplug the

electrical connection before performing any maintenance or regulation upkeep work.

Positioning for gas hob

Important: this unit may be installed and used only in permanently ventilated rooms according to the British

Standards Codes Of Practice: B.S. 6172 / B.S. 5440, Par. 2 and B.S. 6891 Current Editions. The following

Requirements must be observed:

a) The room must be fitted with a ventilation system which vents smoke and gases from combustion to the

outside.

This must be done by means of a hood or electric ventilator that turns on automatically each time the

hood is operated.

In a chimney stack or branched flue. Directly to the Outside

(Exclusively for cooking appliances)

b) The room must also allow for the influx of the air needed for proper combustion. The flow of air for

combustion purposes must not be less than 2 m³/h per kW of installed capacity. The supply of said air

can be effected by means of direct influx from the outside through a duct with an inner cross section of

at least 100cm² which must not be able to be accidentally blocked. Those appliances which are not

fitted with a safety device to prevent the flame from accidentally going out must have a ventilation

opening twice the size otherwise required, i.e. a minimum of 200 cm² (Fig. 3). Otherwise, the room can

be vented indirectly through adjacent rooms fitted with ventilation ducts to the outside as described

above, as long as the adjacent rooms are not shared areas, bedrooms or present the risk of fire (Fig. 4).

Detail A Adjacent Room Room to be Vented

8

Examples of ventilation holes for comburant air. Enlarging the ventilation slot between window and floor

Fig.3Fig.4

c) Intensive and prolonged use of the appliance may necessitate supplemental ventilation, e.g. opening a

Window or increasing the power of the air intake system (if present).

d) Liquidified petroleum gases are heavier than air and, as a result, settle downwards. Rooms in which

LPG tanks are installed must be fitted with ventilation openings to the outside in order to allow the gas to

escape in the event of a leak. Therefore, LPG tanks, whether empty or partially full, must not be

installed or stored in rooms or spaces below ground level'(cellars, etc.). It is also a good idea to keep

only the tank currently being used in the room, making sure that it is not near sources of heat (ovens,

fireplaces, stoves, etc.) that could raise the internal

temperature of the tank above 50ºC.

Installation of built-in stove tops

The gas hobs are prepared with protection degree against excessive heating of type X, the appliance can

therefore be installed next to cabinets, provided the height does not exceed that of the hob. For a correct

installation of the cooking hob the following precautions must be followed:

a) The hob may be located in a kitchen, a ketone/diner or bed sitting room, but not in a bathroom or shower

room.

b) The furniture standing next to the unit, that is highe1 than the working boards, must be placed at least

110mm from the edge of the board.

c) The cabinets should be positioned next to the hood at a height of at least 420 mm (Fig. 5).

Fig.5

d) Should the hob be installed directly under a cupboard the letter should be at least 700mm (millimeters)

from the worktop, as shown in Fig. C.

e) The dimensions of the room for the furniture must those indicated in the figures in the last two pages the

cover. Fixing hooks are provided which allow place the hob plate on work tops that measure 20 to 40 mm

in thickness (see Fig. 6).To obtain a of the hob plate it is advisable to use all the fixing supplied.

9

Fig.6

Hook position for Hook position for Hook position for

H=30mm top H=40mm top H=20mm top

N.B: Use the hook contained in the "accessories set"

10

f) In the event the cooktop is not installed above a built-in oven, a wood panel must be inserted as insulation.

This panel must be placed at least 20 mm from the bottom of the cooktop itself.

lmportant: When installing the hob above a built-in oven, the oven should be placed on two wooden

strips; in the case of a joining cabinet surface, remember to leave a space of at least 45 x 560 mm at the

back.

When installing on a built-in oven without forced ventilation, ensure that there are air inlets and outlets for

ventilating the interior of the cabinet adequately.

Gas connection for gas hob

The Cooker should be connected to the gas-supply by a corgi registered installer. During installation of this

product it is essential to fit an approved gas tap to isolate the supply from the appliance for the convenience

of any subsequent removal or servicing. Connection of the appliance to the gas mains or liquid gas must be

carried out according to the prescribed regulation in force, and only after it is ascertained that it is adaptable

to the type of gas to be used. If not, follow the instructions indicated in the paragraph headed "Adaptation to

different gas types". In the case of connection to liquid gas, by tank, use pressure regulators that conform to

the regulation in force.

Important: For safety, for the correct regulation of gas use and long life of the appliance, ensure that the

gas pressure conforms to the indications given in table 1 "Nozzle and burner characteristics".

Connection to non-flexible tube

(copper or steel)

Connection to the gas source must be done in such a way as to not create any stress points at any part of

the appliance.

The appliance is fitted with an adjustable, "L" shaped connector and a gasket for the attachment to the gas

supply.

Should this connector have to be turned, the gasket must be replaced (supplied with the appliance).

The feeding connector of the gas to the appliance is threaded 1/2 gas male cylinder.

Connection to flexible steel tube

The gas feed connector to the appliance is a threaded, male 1/2" connector for round gas pipe. Only use

pipes and sealing gaskets that conform to the standards currently in force. The maximum length of the

flexible pipes must not exceed 2000 mm. Once the connection has been made, ensure that the flexible

metal tube does not touch any moving parts and is not crushed.

Check the Seal

11

Once the appliance has been installed, make sure all the connections are properly sealed, using a soapy

water solution. Never use a flame.

Electrical Connection

The cooktops fitted with a tripolar electrical supply cord are designed to be used with alternating current

according to the indications on the rating plate located under the cooktop. The earthing wire can be

identified by its yellow-green color.

In the case of installation over a built-in electric oven, the electrical connections for the cooktop and oven

should be independent, not only for safety purposes, but also to facilitate removal of one or both in the

future.

Electrical Connection for Gas Cooktop

Fit the supply cord with a standard plug for the demand rate indicated on the rating plate or connect it

directly to the electrical mains. In the latter case, a single pole switch must be placed between the appliance

and the mains, with a minimum opening between the contacts of 3 mm in compliance with current safety

codes (the earthing wire must not be interrupted by the switch). The power supply cord must be positioned

so that it does not reach a temperature in excess of 50~C above room temperature at any point.

Before actual connection make sure that:

●The fuse and electrical system can withstand the load required by the appliance;

●That the electrical supply system is equipped with an efficient earth hook-up according to the norms and

regulations prescribed by law;

●That the plug or switch are easily accessible.

Important: the wires in the mains lead are colored in accordance with the following code:

Green & Yellow - Earth

Blue - Neutral

Brown - Live

As the colors of the wires in the mains lead may not correspond with the colored markings identifying the

terminals in your plug, proceed as follows: Connect the Green & Yellow wire to terminal marked "E"

or or colored Green or Green & Yellow.

Connect the Brown wire to the terminal marked "L" or colored Red.

Connect the Blue wire to the terminal marked "N" or colored Black.

Adapting the Cooktop for Different Types of Gas

Table1 Burners and Nozzle Specifications

G20/ G25 G25.1 G27 G2.350 G30 G31

Burner Thermal

power

(kW)

Nozzle

1/100

(mm)

Thermal

power

kW

Nozzle

1/100

(mm)

Thermal

power

kW

Nozzle

1/100

(mm)

Thermal

power

kW

Nozzle

1/100

(mm)

Thermal

power

kW

Nozzle

1/100

(mm)

Nozzle

1/100

(mm)

Nozzle

1/100

(mm)

Thermal

power

(kW)

Nozzle

1/100

(mm)

Auxiliary

(Small) (A) 1.0 71 1.0 75 1.0 79 1.0 98 1.0 52 47 45 1.0 52

Semi rapid

(Medium) 1.80 97 1.80 105 1.80 106 1.80 125 1.8 67 64 59 1.8 67

Rapid (R) 2.40 110 2.40 118 2.40 120 2.40 138 2.40 77 72 67 2.4 77

12

Triple Ring

(TR) 3.40 125 3.40 142 3.40 143 3.40 185 3.40 93 88 82 3.4 93

Supply

pressures 20mbar 25mbar 20mbar 13mbar

30

mbar

37

mbar

50

mbar

37

Mbar

At 15°C and 1013 mbar-dry gas

P.C.I.G20 37.78 MJ/m³ P.C.I.G25.1 32.51 MJ/m³

P.C.I.G25 32.49 MJ/m³ P.C.I.G27 30.98 MJ/m³

P.C.I.G2.350 27.20MJ/ m³ P.C.I.G30 49.47MJ/Kg

Replacement of burner nozzle: loosen the nozzle with a dedicated wrench (7).Fit

the new nozzle, suitable for the required gas type (see table above for

reference) 。

After you have converted the cooktop to another gas type, make sure you have placed a label

containing that information on the appliance.

Adjustment of the reduced valve flow

TABLE2: How to convert gas source

Burners

Flame

Converting the

cooktop from LPG

to natural gas

Converting the

Cooktop from natural

Gas to LPG

Regular burners

Full flame Replace the burner

Nozzle according

To the guidelines in

table 1

Replace the burner

Nozzle according

to the guidelines in

table 1

Saving flame Loosen the adjustment

Spindle (see fig.7 below )

And adjust the flame

Loosen the adjustment

Spindle (see fig.7 below )

And adjust the flame

Valve adjustment

Valve adjustment should be done with the control knob set at Burner ON saving flame position.

Remove the knob, and adjust the flame with a tiny screwdriver (see fig.7 below).

13

Fig.7

Checking the adjusted flame: heat the burner at full open position for 10 minutes. The turn the knob into the saving

setting. The flame should not extinguish nor move to the nozzle. If it goes off or moves over to the nozzle, readjust

the valves.

Note.

It is up to the used to request converting the appliance to another gas type if so required by the local conditions at a

licensed gas fitter/ service.

Flame selection

At the burners adjusted correctly, the flames should be light blue, and the inner cone should be clearly visible. The

size of flame depends on the position of the related burner control knob.

-Burner ON,large flame -Burner ON,small flame(saxing mode)-Burner OFF

Fig.8

See also fig.8 for various operating options (flame size selection); the burner should be set at a large flame during

the initial phase of cooking to bring the food to boiling, and then the knob should be turned to the saving flame

position to maintain the cooking. It is also possible to adjust the flame size stepless.

It is prohibited to adjust the flame in the range between the Burner OFF and Burner ON large flame

positions.

Significant quantities of energy can be saved if the appliance is used correctly, parameters set correctly, and

appropriate cookware is used. The savings can be as follows:

·Up to 60 per cent savings when proper pots are used,

·Up to 60 per cent savings when the unit is operated correctly and the suitable flame size is

chosen.

It is a prerequisite for efficient and energy-saving operation of the cooktop that the burners are kept clean at all times

(in particular the flame slots and nozzles). Adapting to different types of gas

TABLE 3: Adapting to different types of gas

APPLIANCE CATEGORY: I2H I2E I2E+ I2L I2HS I2ELS I2ELW I3+ I3B/P I3B/P I3B/P I3P I2H3+ II2E3B/P II2HS3B/P

II2ELWLS3B/P II2ELL3B/P

Burner Type of Pressure Nozzle Nominal Charge Reduced Charge

14

Gas diameter

mbar 1/100mm g/h l/h kW kcal/h kW kcal/h

Auxiliary

Natural

G20 20 72 — 95 1.0 860 0.40 344

Natural

G25 25 72 — 99.7 1.0 860 0.40 344

Natural

G25.1 25 75 — 99.6 1.0 860 0.40 344

Natural

G27 20 80 — 116 1.0 860 0.40 344

Natural

G2.350 13 97 — 132 1.0 860 0.40 344

Butane G30

30 52 72.6 — 1.0 860 0.40 344

37 47 72.6 — 1.0 860 0.40 344

50 45 72.6 — 1.0 860 0.40 344

Butane G31 37 52 72.6 — 1.0 860 0.40 344

Semi-rapid

Natural

G20 20 97 — 171 1.8 1548 0.60 516

Natural

G25 25 97 — 199.4 1.8 1548 0.60 516

Natural

G25.1 25 105 — 199.4 1.8 1548 0.60 516

Natural

G27 20 106 — 209 1.8 1548 0.60 516

Natural

G2.350 13 124 — 238.2 1.8 1548 0.60 516

Butane G30

30 68 130.8 — 1.8 1548 0.60 516

37 64 130.8 — 1.8 1548 0.60 516

50 59 130.8 — 1.8 1548 0.60 516

Butane G31 37 68 130.8 — 1.8 1548 0.60 516

Rapid

Natural

G20 20 110 — 228 2.4 2064 0.90 774

Natural

G25 25 110 — 265.9 2.4 2064 0.90 774

Natural

G25.1 25 118 — 265.9 2.4 2064 0.90 774

Natural

G27 20 120 — 278.8 2.4 2064 0.90 774

Natural

G2.350 13 138 — 317.6 2.4 2064 0.90 774

Butane G30

30 78 174 — 2.4 2064 0.90 774

37 73 174 — 2.4 2064 0.90 774

50 67 174 — 2.4 2064 0.90 774

Butane G31 37 78 174 — 2.4 2064 0.90 774

15

Triple-ring wok

Natural

G20 20 125 — 323 3.4 2924 1.50 1290

Natural

G25 25 125 — 376.7 3.4 2924 1.50 1290

Natural

G25.1 25 142 — 376.7 3.4 2924 1.50 1290

Natural

G27 20 144 — 395 3.4 2924 1.50 1290

Natural

G2.350 13 185 — 450 3.4 2924 1.50 1290

Butane G30

30 93 247 — 3.4 2924 1.50 1290

37 88 247 — 3.4 2924 1.50 1290

50 82 247 — 3.4 2924 1.50 1290

Butane G31 37 93 247 — 3.4 2924 1.50 1290

TABLE 4: Gas source and national comparison table

Gas group

Supply pressure

Country

I2H G20 20mbar AT, BG, CZ, DK, EE, FI, GR, HR, HU, IS, IE, IT, LV,

LT, NO, PT, RO, SK, SI, ES, SE, CH, TR, GB

I2E

G20 20mbar

DE, LU

I2E+ G20/G25 at 20/25 mbar BE, FR

I2L

G25 25mbar

NL

I2HS

G20/G25.1 25 mbar

HU

I2ELS

G20 20 mbar,G2.350 13 mbar

PL

I2ELW

G20/G27 20 mbar

PL

I3+ G30-G31 (28-30)-37 mbar BE, CY, CZ, EE, FR, GR, IE, IT, LT, LU, LV, PT, RO,

SK, ES, CH, GB

I3B/P

G30 30 mbar

BE, CY, CZ, DK, EE, FI, GR, HR, LV, LT, LU, MT,

NL, NO, SK, SI, SE, TR

I3B/P G30 37 mbar PL

I3B/P

G30 50mbar

AT, DE, HU, CH

I3P

G31 37 mbar

CH,FR,GR,IE,ES,GB

I2H3+

G20 20MBAR,

G30-G31(28-30)-37mbar

GR,IE,IT,PT,ES,GB,CH,CZ,SI,SK

II2E3B/P G20 20mbar,g30 30mbar RO

II2HS3B/P G20/G25.1 25mbar,

G30 30mbar HU

II2ELWLS3B/P G20/G27 20mbar,

G2.350 13mbar,G30 37mbar

PL

II2ELL3B/P

G20 20mbar,G25 25mbar,

G30 50mbar

DE

16

NOTICE:

A.”prior to installation,ensure that the local distribution condition (nature of the gas pressure)

And the adjustment of the appliance are compatible.”

B. “The adjustment conditions for this appliance are stated on the label.”

C. “This appliance is not connected to combustion products evacuation device. It shall be

installed and connected in accordance with current installation regulations. Particular attention shall be

given to the relevant requirement regarding ventilation.”

D. “CAUTION: The use of a gas cooking appliance results in the production of heat, moisture and

products of combustion in the room in which it is installed. Ensure that the kitchen is well ventilated

especially when the appliance is in use: keep natural ventilation holes open or install a mechanical

ventilation device.”

17

Table of contents