NLR AMS-500 User manual

1

AMS-500 Boost Controller

Overview

The AMS-500 Boost Controller can control 2-Stages and/or levels of boost. The 2-

Stages are controlled by Input1 and Input2. Both of these inputs can be configured using a DIP

Switch for either Ground or +12 volt activation. Input1 may be configured to function as a

“Launch” stage when used in conjunction with Input2. Input2 offers an adjustable ramp rate as

well as boost level settings.

Each stage has a range of adjustment from 0 to 40psi with 1psi resolution and is con-

trolled to within .1psi to target using advanced control algorithms. If a setting greater than

40psi is configured the AMS-500 will default to the maximum 40psi allowed. A setting of 0psi

will turn either stage off.

An optional Safe Mode is available when using a pressure source other than the mani-

fold pressure. The Safe Mode continually checks for the proper pressure increase and will dis-

able the system and open the decrease solenoid in the event of an error condition. When in

Normal Mode of operation the AMS-500 will keep trying to apply pressure to the waste gate

until its target is reached.

For more information on each individual option see the appropriate section listed in the

Table of Contents on Page 2.

IMPORTANT—The AMS-500 controls the pressure on the Waste Gate so the actual

boost level obtained is a combination of the Waste Gate Spring pressure and pressure

applied by the controller.

1 2

O

N

0

5

6

7

8

9

1

2

3

4

0

5

6

7

8

9

1

2

3

4

0

5

6

7

8

9

1

2

3

4

0

5

6

7

8

9

1

2

3

4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

INPUT1

INPUT2

+12 VOLT

SOL+

GROUND

INC SOL

DEC SOL

MAP Sensor Port

1/8 NPT

Stage1 LED

Stage2 LED Power

Input Polarity Select

DIP Switch

Stage1 Programming

Switches 1’s

10’s

10’s 1’s

Stage2 Programming

Switches

Stage2 Ramp Rate

Select Switch

NOTE—The AMS-500 Must be turned OFF and back ON when a change is made to any

switch. If this is not done the new switch settings will be ignored until the next power

on!

2

Table of Contents

Configure AMS-500 Operating Mode Page 3

Configure Stage1 / Input1 Operating Mode Page 4

Setting Input1 and Input2 Activation Polarity Page 5

Setting Stage1 Boost Level Page 5

Setting Stage2 Boost Level and Ramp Rate Page 6

WiringDiagram Page 7

WarrantyInformation Page 8

Notice—It is the responsibility of the purchaser to follow all guidelines and safety procedures

supplied with this product and any other manufactures product used with the AMS-500. It is

also the responsibility of the purchaser to determine compatibility of the AMS-500 with the

vehicle and other components.

NLR, LLC assumes no responsibility for damages resulting from accident, improper

installation, misuse, abuse, improper operation, lack of reasonable care, or all previously

stated reasons due to incompatibility with other manufacturer’s products.

NLR, LLC assumes no responsibility or liability for damages incurred from the use of

products manufactured or sold by NLR, LLC on vehicles used for competition racing.

NLR, LLC neither recommends nor approves the use of products manufactured or sold

by NLR, LLC on vehicles which may be driven on public highways or roads, and assumes no

responsibility for damages incurred from such use.

NLR, LLC does not recommend nor condone the use of its products for illegal street

racing.

Installation of NLR, LLC products signifies that you have read this document and

agree to the terms stated within.

Important Information:

Follow all recommended safety guidelines from this and other manufactures installation

guides. Static suppression ignition wires must be used with this unit! Mount the unit as far

away from secondary ignition components (coil, ignition wires, etc.) as physically possible.

IMPORTANT—The AMS-500 controls the pressure on the Waste Gate so the actual

boost level obtained is a combination of the Waste Gate Spring pressure and pressure

applied by the controller www.nlrsystems.com or

Phone 334-741-7100

3

Configure AMS-500 Operating Mode

Normal Mode—When the AMS-500 is configured for Normal Mode of operation it will

always attempt to reach the target pressure setting by operating the increase solenoid. If there

is not enough pressure in the system to achieve the target level the AMS-500 will keep trying

to apply pressure to the waste gate until its target is reached. When in Normal Mode the Red

LED will be on steady at power to indicate this mode is active.

Safe Mode—When the AMS-500 is configured for Safe Mode of operation it will at-

tempt to reach the target pressure level, if no increase in pressure is detected the system will

turn off the increase solenoid and open the decease solenoid. After one second another at-

tempt will be made to reach the desired target pressure. After three failed attempts the AMS-

500 will flash the Red and Green LED’s to indicate a pressure increase error and open the de-

crease solenoid. It will remain this way until power is turned off and back on to reset the sys-

tem. When in Safe Mode the Red LED will flash 4 times at power up to indicate this mode is

active.

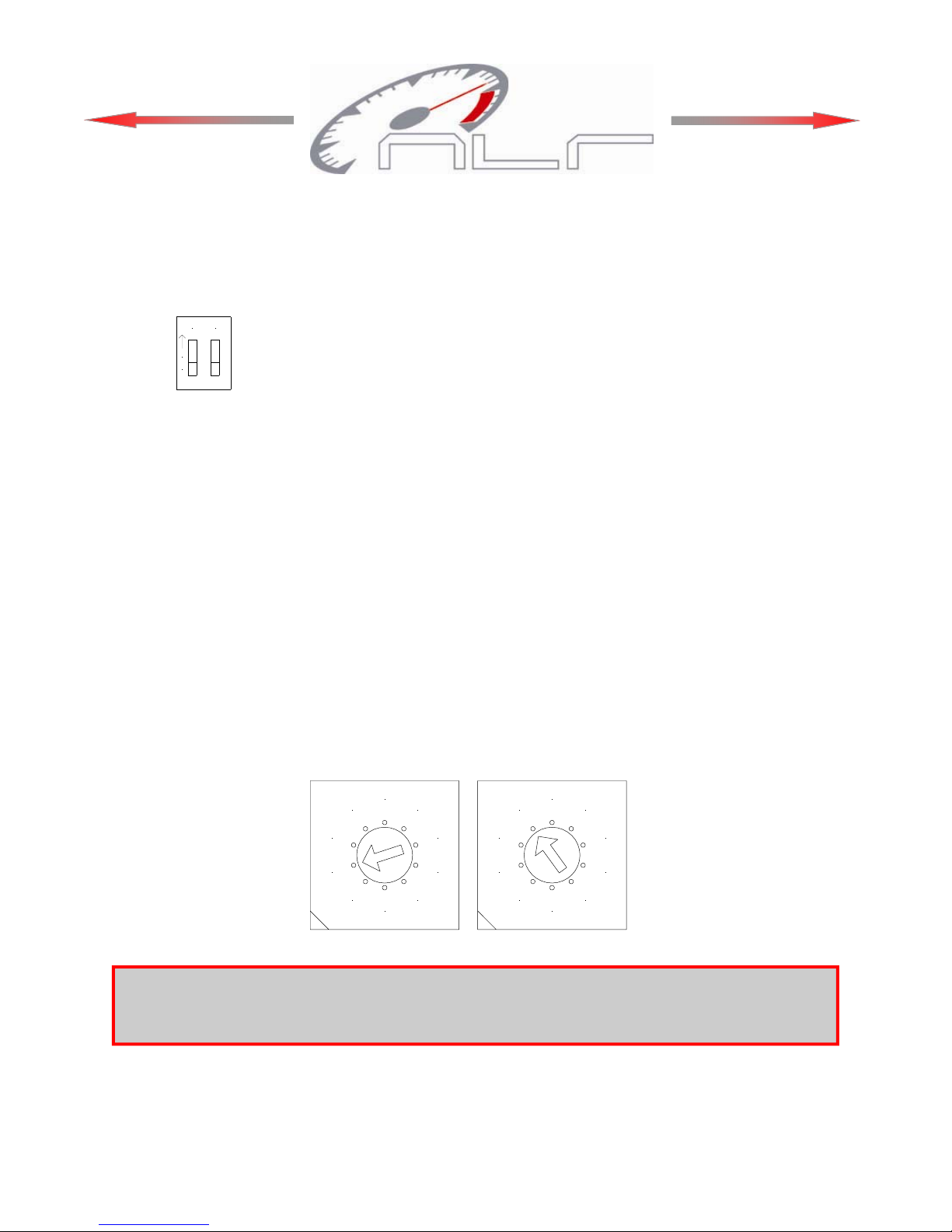

Switching between modes of operation

1—Set all Stage1 and Stage2 switches to 0 including the Ramp Rate switch.

2—Turn AMS-500 on, the Red LED will blink once per second for 10 seconds. To

change operating mode you must wait 10 seconds with the Red LED blinking.

3—After 10 seconds the AMS-500 will automatically switch operating modes. The new

operating mode selected will be indicated by flashing the Red / Green LED’s in the patterns

listed below. Use the LED flash pattern to determine the current mode of operation.

Safe Mode—Red and Green LED’s will blink in a circular pattern.

Normal Mode—Red and Green LED’s will blink in an alternating pattern.

4—Turn power off, set switches for desired target psi and ramp rate for Stage2.

5—Turn power back on and AMS-500 is ready to operate in selected mode.

IMPORTANT—At least one Stage Programming switch must be non-zero for operation.

IMPORTANT—The AMS-500 controls the pressure on the Waste Gate so the actual

boost level obtained is a combination of the Waste Gate Spring pressure and pressure

applied by the controller www.nlrsystems.com or

Phone 334-741-7100

4

Configure Stage1 / Input1 Operating Mode

Normal Mode—When Stage1 and/or Input1 is configured for Normal operation the AMS-500

will immediately apply the pressure selected with the Stage1 Programming switches when Input1 be-

comes active. If Stage2 / Input2 is active the Stage1 setting will override the Stage2 setting.

Example—Stage1 set at 12psi, Stage2 psi set at 8psi. When Stage1 is activated the AMS-500 would ap-

ply 12psi to the system whether Stage2 is active or not. The Stage2 Green LED will blink four times at

power up to indicate this mode is active.

Launch Mode—When Stage1 / Input1 is configured for Launch Mode operation the AMS-500

will ignore the Stage2 / Input2 activation until Input1 is released. This allows a Launch psi to be set for

Stage1 and then Stage2 can be used to Ramp the target pressure up / down after the launch. Typical op-

eration would be to connect Input1 to a clutch and/or trans brake switch and Input2 to a wide open throt-

tle switch. The Stage1 Green LED will blink four times at power up to indicate this mode is active.

Dual Stage Mode—When Stage1 / Input1 is configured for Dual Stage Mode operation the

AMS-500 allows both Inputs/Stages to be combined. Whichever Input is activated first becomes the

First Stage, this Input may remain ON or OFF while the second Input is Activated. The Stage1&2 Green

LED’s will blink four times at power up to indicate this mode is active.

Switching between modes of operation

1—Set Stage1 and Stage2 programming switches to 0. Set Stage2 Ramp Rate select

switch to 1.

2—Turn AMS-500 on, the Stage1 Green LED will blink once per second for 10 sec-

onds. To change Stage1 operating mode you must wait 10 seconds with the Red LED blinking.

3—After 10 seconds the AMS-500 will automatically switch Stage1 operating modes.

The new operating mode selected will be indicated by flashing the either the Stage or Stage2

Green LED. Use the guide below to determine the current Stage1 Mode selected.

Normal Mode—Stage2 Green LED will blink 5 times per second.

Launch Mode—Stage1 Green LED will blink 5 times per second.

Dual Stage Mode—Stage1&2 Green LED’s will blink 5 times per second.

4—Turn power off, set switches for desired target psi and ramp rate for Stage2.

5—Turn power back on and AMS-500 is ready to operate in selected mode.

IMPORTANT—At least one Stage Programming switch must be non-zero for operation.

IMPORTANT—The AMS-500 controls the pressure on the Waste Gate so the actual

boost level obtained is a combination of the Waste Gate Spring pressure and pressure

applied by the controller www.nlrsystems.com or

Phone 334-741-7100

5

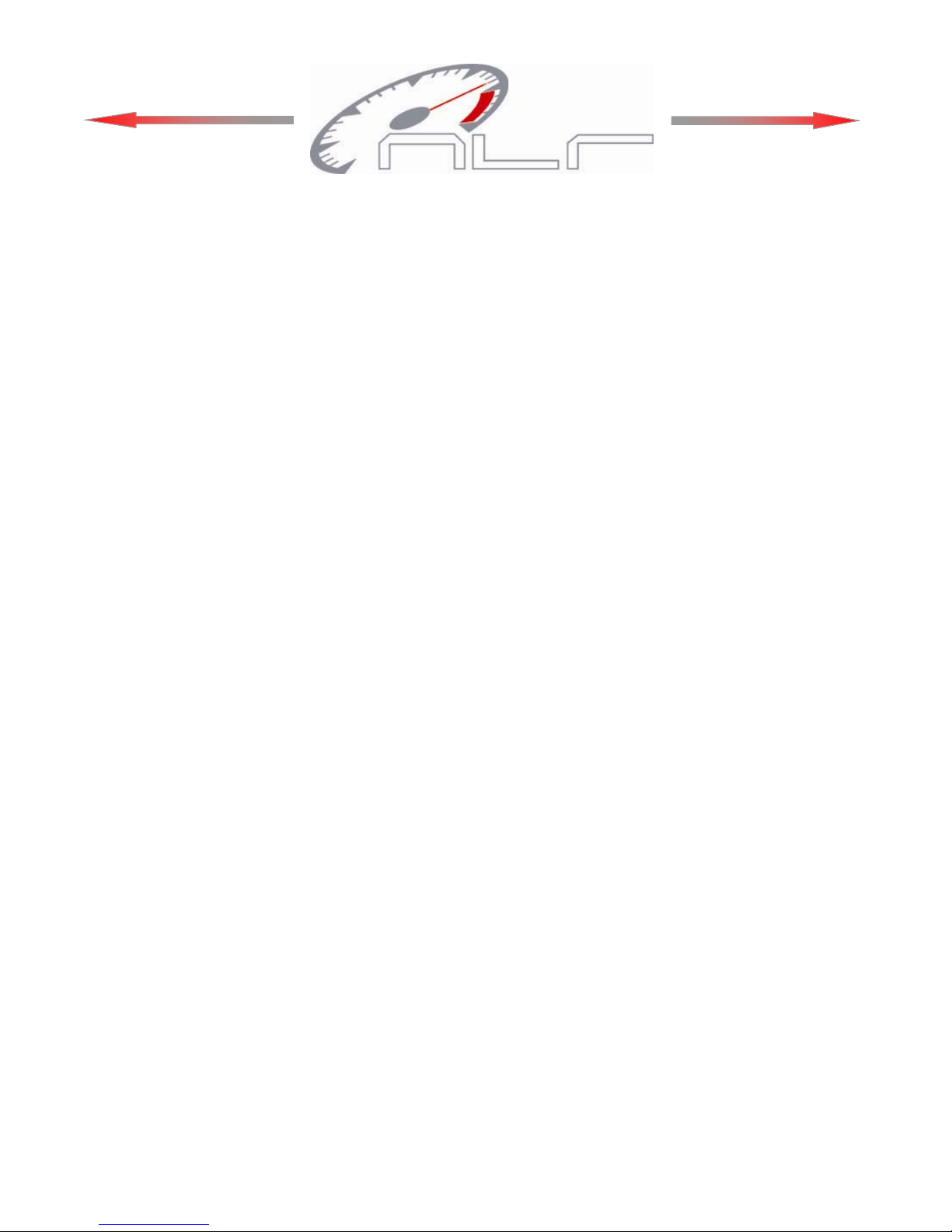

Setting Input1 and Input2 Activation Polarity

Overview—Input1 and Input2 can be configured for either Ground activation or +12

volt activation. This allow the AMS-500 to be used with existing wiring configurations already

installed.

The Inputs are configured using the 2-position Input Polarity Select DIP switch.

Setting Input1 Polarity—DIP Switch #1 OFF for Ground Activation and Switch #1 ON

for +12 volt activation.

Setting Input2 Polarity—DIP Switch #2 OFF for Ground Activation and Switch #2 ON

for +12 volt activation.

Setting Stage1 Boost Level

Overview—The Stage1 Programming switches are used to set the target psi when In-

put1 is active. This setting will either determine Stage1 target psi or Stage1 Launch psi, see

“Configure Stage1 / Input1 Operating Mode” for more information.

Setting Target Psi—There are two Stage1 target psi programming switches. These

are used together to represent the target psi desired. Example—24psi setting, set Stage1, 10’s

switch to 2 and then 1’s switch to 4. If a setting greater than 40psi is used the AMS-500 will

default to a 40psi setting for this stage. Please see diagram below.

1 2

O

N

Stage1 Programming Switches.

10’s Switch 1’s Switch

IMPORTANT—The AMS-500 controls the pressure on the Waste Gate so the actual

boost level obtained is a combination of the Waste Gate Spring pressure and pressure

applied by the controller www.nlrsystems.com or

Phone 334-741-7100

0

5

6

7

8

9

1

2

3

4

0

5

6

7

8

9

1

2

3

4

NOTE—The AMS-500 Must be turned OFF and back ON when a change is made to any

switch. If this is not done the new switch settings will be ignored until the next power

on!

6

Setting Stage2 Boost Level and Ramp Rate

Overview—The Stage2 Programming switches are used to set the target psi when In-

put2 is active. To determine the Ramp Rate of Stage2 see instructions below. When Stage1 is

configured for Launch Mode Input2 activation will be ignored until Input1 is released. See

“Configure Stage1 / Input1 Operating Mode” for more information.

Setting Target Psi—There are two Stage2 target psi programming switches. These

are used together to represent the target psi desired. Example—15psi setting, set Stage2, 10’s

switch to 1 and then 1’s switch to 5. If a setting greater than 40psi is used the AMS-500 will

default to a 40psi setting for this stage. Please see diagram below.

Stage2 Programming Switches.

10’s Switch 1’s Switch

Setting Stage2 Ramp Rate—There are 16 Ramp Rates available for Stage2 boost

control. These are selected using the Stage2 Ramp Rate Select Switch. A setting of 0 will re-

sult in the target pressure being applied immediately when Stage2 is active. See chart below

for other Ramp Rates. The Ramp Rates are defined as psi per second.

Stage2 Ramp Rate

Select Switch

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Psi per second settings.

0 = Maximum ramp rate. 8 = 8psi per second.

1 = 1psi per second. 9 = 9psi per second.

2 = 2psi per second. A = 15psi per second.

3 = 3psi per second. B = 20psi per second.

4 = 4psi per second. C = 30psi per second.

5 = 5psi per second. D = 40psi per second.

6 = 6psi per second. E = 50psi per second.

7 = 7psi per second. F = 60psi per second.

IMPORTANT—The AMS-500 controls the pressure on the Waste Gate so the actual

boost level obtained is a combination of the Waste Gate Spring pressure and pressure

applied by the controller www.nlrsystems.com or

Phone 334-741-7100

0

5

6

7

8

9

1

2

3

4

0

5

6

7

8

9

1

2

3

4

NOTE—The AMS-500 Must be turned OFF and back ON when a change is made to any

switch. If this is not done the new switch settings will be ignored until the next power

on!

7

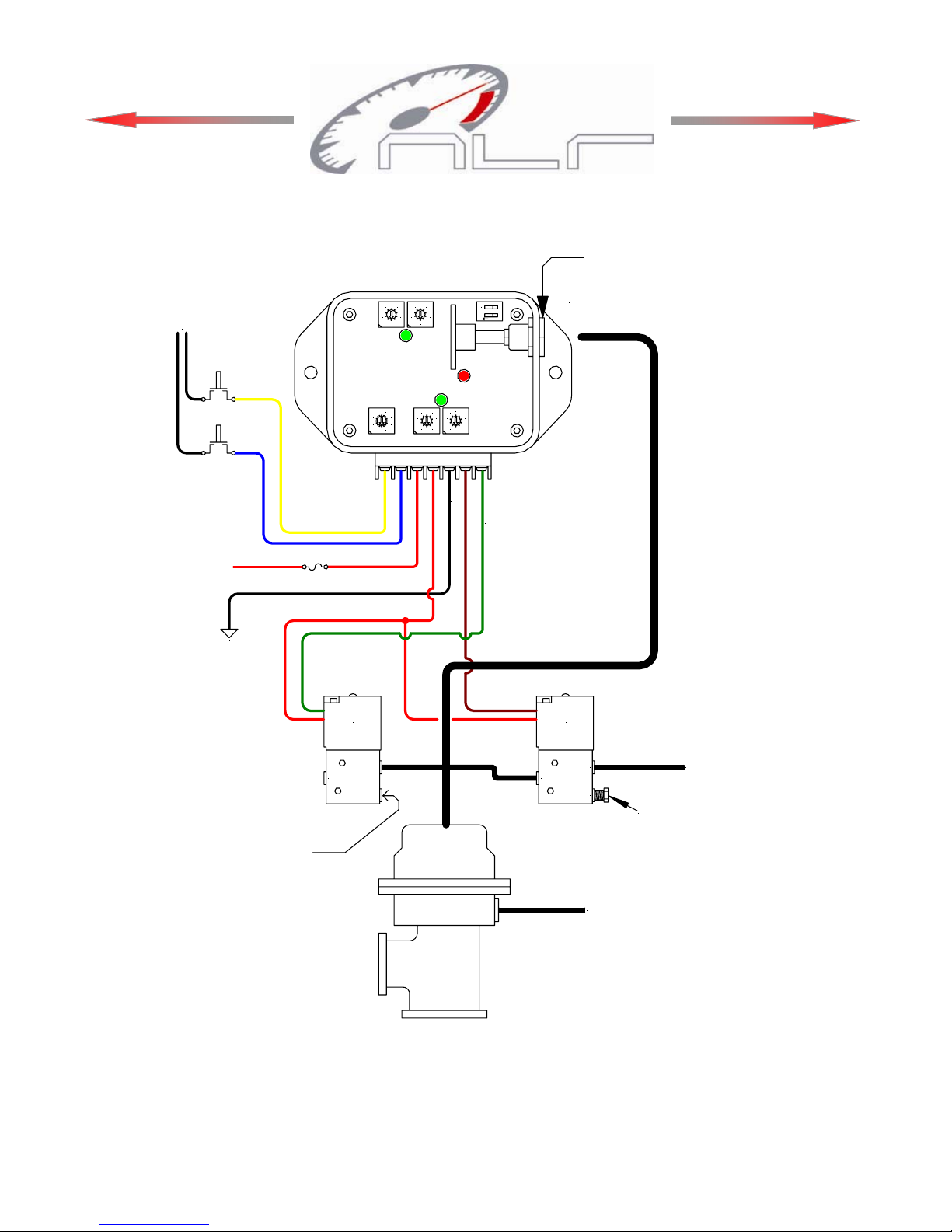

Wiring Diagram

IMPORTANT—The AMS-500 controls the pressure on the Waste Gate so the actual

boost level obtained is a combination of the Waste Gate Spring pressure and pressure

applied by the controller www.nlrsystems.com or

Phone 334-741-7100

OUT EXH

IN OUT EXH

IN

Increase

Solenoid

Decrease

Solenoid

1/8 NPT

Plug

Air Supply or

Manifold Pressure

Wastegate

Manifold Pressure

1 2

O

N

0

5

6

7

8

9

1

2

3

4

0

5

6

7

8

9

1

2

3

4

0

5

6

7

8

9

1

2

3

4

0

5

6

7

8

9

1

2

3

4

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

MAP Sensor port, 1/8 NPT threads. Install

desired fitting here and connect to Solenoids

and Wastegate as outlined below.

GROUND

Decrease Solenoid

Increase Solenoid

Ground

Solenoid +12 Volt

10 Amp Fuse

+12V Switched

Input1

Input2

Connect to +12V

or Ground.

+12 Volt

Do NOT Install Plug

Use proper wrench when installing

pressure line fitting!

8

Warranty Information

NLR warrants to the original purchaser that the AMS-500 Controller Shall be free from defects

in parts and workmanship under normal use for 6 months from the date of purchase.

NLR obligation under this warranty is limited to the repair or replacement of any component

found to be defective when returned postpaid to NLR.

The Controller must be returned with evidence of place and date of purchase or warranty will be

void. The warranty will not apply if the AMS-500 Controller has been installed incorrectly, repaired,

damaged, or tampered with by misuse, negligence or accident.

IMPORTANT—The AMS-500 controls the pressure on the Waste Gate so the actual

boost level obtained is a combination of the Waste Gate Spring pressure and pressure

applied by the controller www.nlrsystems.com or

Phone 334-741-7100

NOTE—The AMS-500 Must be turned OFF and back ON when a change is made to any

switch. If this is not done the new switch settings will be ignored until the next power

on!

Table of contents

Popular Controllers manuals by other brands

Keyautomation

Keyautomation EASY2 Instructions and warnings for installation and use

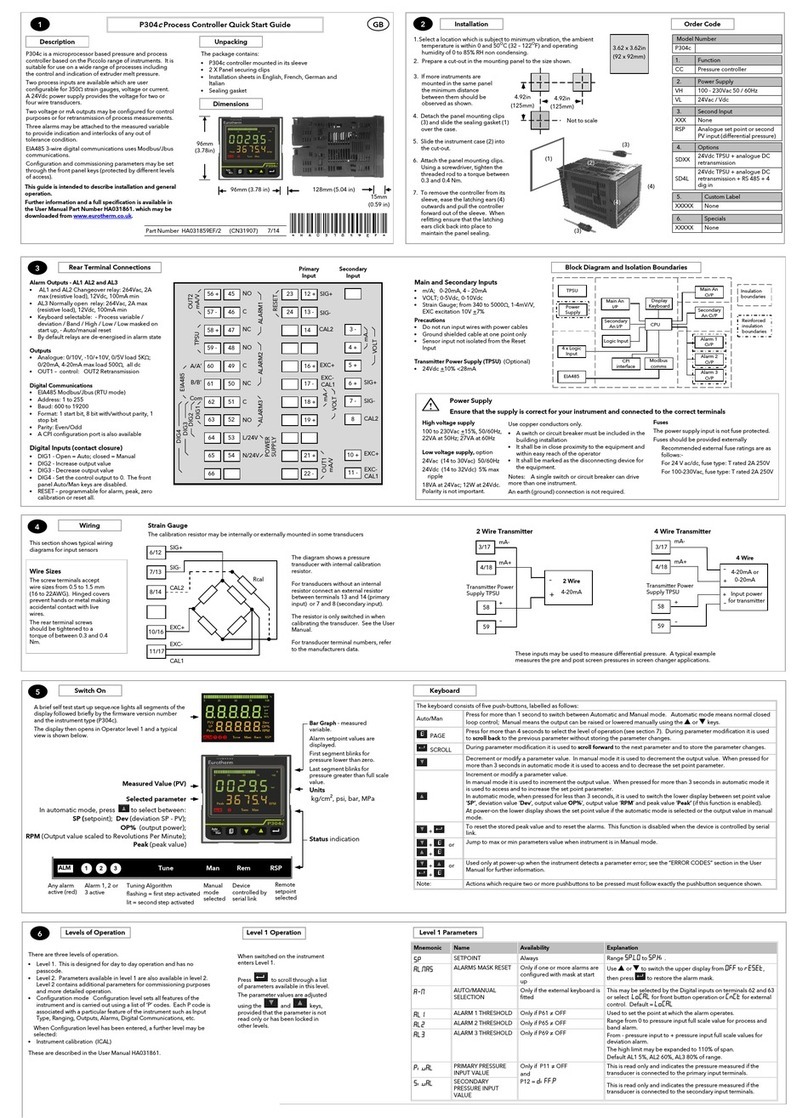

Eurotherm

Eurotherm P304c quick start guide

ATI Technologies

ATI Technologies MetriNet Q52 O & M Manual

Panasonic

Panasonic Minas A4 Series instruction manual

Phidgets

Phidgets 1063 product manual

IAI

IAI ACON-C Operation manual