NLS PM-452 User manual

Non-Linear Systems

PM-452

DIGITAL PANEL METERS

INTRODUCTION

The Model PM-452 is a highly accurate, four and

one-half digit, fixed range, miniature digital panel

meter with automatic polarity indication for making

DC voltage measurements. DC current can also be

measured using external shunt resistors. The

instrument is available in any one of four ranges:

2V, 20V, 200V or 1000V F.S.

System accommodations include multiplexed BCD

outputs, a busy/done output and a hold input. The

instrument also has display enable and polarity

enable capabilities.

Modification from any one range to another is easily

accomplished by changing one or two resistors.

Calibration is accomplished by adjusting a

potentiometer accessible at the rear panel.

The PM-452 has a 0.3 inch high LED numeric

readout. The readout also includes LED + and -

polarity signs and decimal points for each decade.

An active filter at the signal input provides high

normal -mode refection.

For operation, an external +5VDC ±5% power

supply is required. See figure 1 for a typical power

supply circuit.

Figure 1: Power Supply Schematic

SPECIFICATIONS

RANGE: 0 to 2 Volts

0 to 20 Volts

0 to 200 Volts

0 to 1000 Volts

ACCURACY: ±0.02% F.S. (23°C ±2°)

SPEED: 3 Rdg/Sec, nominally

OPERATING TEMP: 0°C to +50°C

POWER: +5 VDC ±5% @ 140 mA, max.

DISPLAY: LED, red, 0.3" high

TURN ON TIME: 10 seconds to ±0.05%

accuracy

TEMPERATURE COEFFICIENT:

±(0.01% Rdg + 0.001% F.S.)/°C

INPUT Z: 2V range, 1000 MΩ; 20V range, 1 MΩ

; 200V and 1000V

ranges, 10 MΩ

METHOD of A to D CONVERSION:

Dual slope

SETTLING TIME: 2 seconds, including

polarity change

COMMON-MODE VOLTAGE:

SIGNAL LO may be anywhere in the range from

-0.1V to +1V with respect to power supply

common. Note that if the power for the meter is

supplied from an isolated power supply, the

effective common-mode voltage is the isolation

voltage rating of the power supply.

COMMON-MODE REJECTION:

80 dB, min.

NORMAL-MODE REJECTION:60 dB

typical, 40 dB minimum @ 50-60 Hz

INPUT CURRENT: 250 pA, maximum

DECIMAL LOCATION:

May be positioned by a jumper to any of four

locations, X . X . X . X . X

INPUT VOLTAGE PROTECTION:

±100 VDC or peak VAC, 2V range; ±350 VDC or

peak VAC, 20V range; ±1000 VDC or peak VAC,

200V and 1000V ranges.

OVERLOAD INDICATION: On all ranges

except the 1000v range, an input exceeding full

scale is displayed as four flashing zeros.

WEIGHT: Approximately 3 ounces

INSTALLATION

1. Mount the PM-452 as follows:

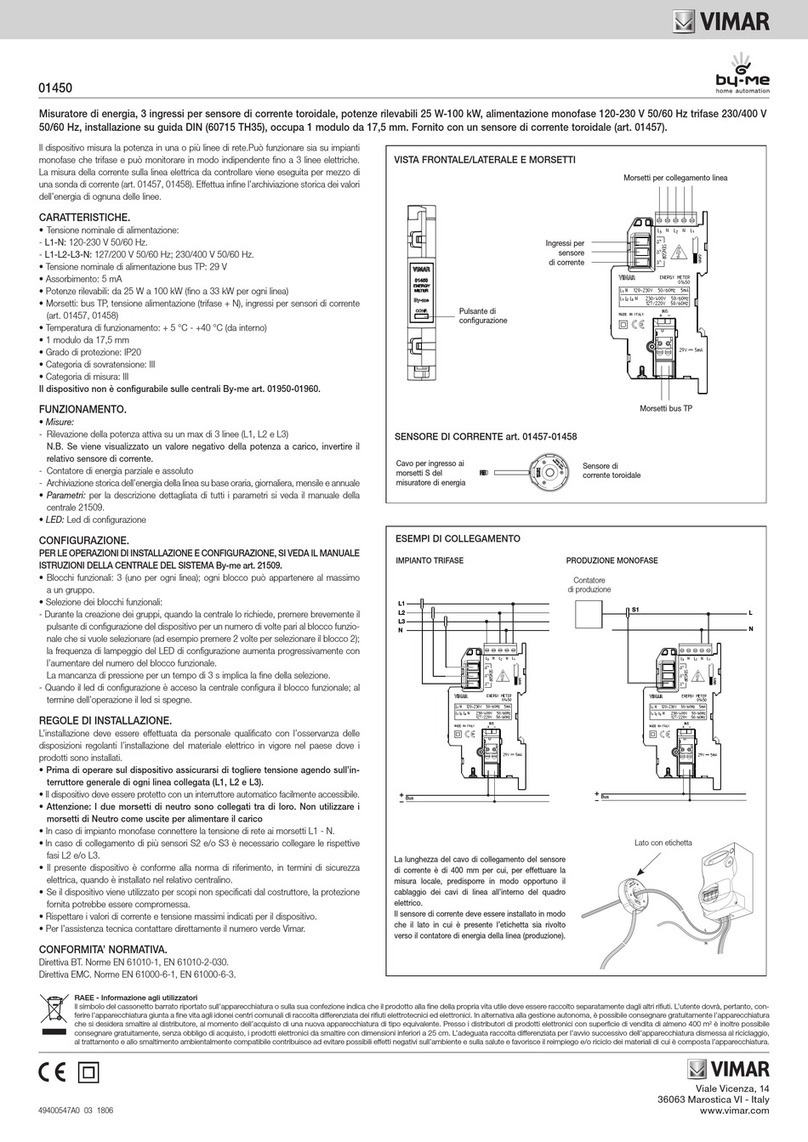

a. Cut a hole in panel (Figure 2).

b. Slide trim plate over meter housing, facing

beveled edge of trim plate forward.

c. Insert meter through opening in panel form

front of panel.

d. Fit mounting clips (2) into slots at sides of

instrument. Foot of clip should face forward.

e. Thread screws (2) into clips and tighten screw

against rear surface of panel.

2. The optional connector should be NLS part

number 39-195, or equivalent. See Figure 3 for

connector pin information.

Panel Thickness 1/16” to ¼”

Panel Cutout

w /Trim Plate

Center Line

w ithout Trim

Pla te

Center Line

w /Trim Plate

Cutout For Multiple

Mounting w ithout Trim

Pla te

A2 17/32

B31/32

C15/16 1 3/16 min

D3 1/8 min 3 1/8 min

ENumber of units x 15/16

Figure 2. Outline Drawing

OPERATION

POWER AND SIGNAL CONNECTIONS

1. Connect power supply common to pins K and L

on the edge connector.

2. Connect +5VDC power to pin 9.

3. Connect the DC voltage to be measured to pin 5

and H of the connector (SIGNAL HI to pin H and

SIGNAL LO to pin 5).

NOTE:

In an electrically noisy environment it may be

desirable to use a shielded lead for this

connection. If a shielded lead is used, the

shield should be connected to SIGNAL LO of

the DC voltage to be measured.

4. Connect the negative terminal of the power

supply to SIGNAL LO of the DC voltage to be

measured. For maximum accuracy and stability,

this connection should be made at the source

and not on the connector.

5. Polarity is enabled from factory. To remove the

polarity sign, remove R2 (see figure 4).

6. Connect pin 8, display enable, to pin 9 (+5VDC).

7. Decimal Point indication if desired is connected

from pin 1 (Decimal Common) to pin A, B, C or D

depending upon which decimal point is to be

illuminated.

Decimal Location: X . X . X . X . X

Connector Pin: D C B A

If decimal point is not desired, omit the jumper.

Top of Board

Bottom of Board

Dec Com 1

A 10°DEC/Enable

Busy/Done 2

B 10¹DEC/Enable

Hold 3

C 10²DEC/Enable

Polarity 4

D 10³ DEC/Enable

SIGNAL LO 5

E BCD 1

BCD 4 6

F BCD 8

BCD 2 7

H SIGNAL HI

Display Enable 8

J Digit 5 Enable

+5 VDC Power 9

K Power Ground

N/C 10

L Power Ground

Figure 3. Connector Pin Wiring

HOLD FUNCTION: Pin 3 is a control input for the

reading hold function which can be controlled from

either a logic level (0V or +5V) or a contact-closure.

A low logic state or contact-closure to ground will

cause the meter to cease making measurements

and hold the reading of the measurement on

progress. A high logic level or open contacts will

cause the meter to resume repetitive

measurements.

DISPLAY DIMMING AND BLANKING: The

display and polarity enable functions are used for

dimming and blanking the display by controlling the

supply voltage to the readouts. Connecting pin 8,

the display enable function, to pin 9, the +5VDC

supply, illuminates the numerals at full brightness.

Polarity enable is provided separately so that

polarity sign can be blanked (remove R2) for

measurements having no polarity. The entire

readout can be dimmed to any convenient

brightness by connecting a resistor or rheostat

between the +5VDC power (pin 9) and the enable

line (pins 8).

BINARY CODED DECIMAL (BCD)

OUTPUTS: The 1, 2, 4, and 8 multiplexed BDC

outputs are available on connector pins E, 7, 6 and

F, respectively. When digit 5 enable (pin J) goes to

a "low" logic level (zero), the 1, 2, 4 and 8 BCD

outputs represent digit 5, the most significant digit.

When digit 4 enable (pin D) goes "low", the BCD

outputs represent digit 4 and so on, to the least

significant digit. For connector pin information refer

to Figure 3. Digits are scanned from most significant

to least significant digit. Each digit goes "low" for

approximately 1-2/3 milliseconds, and there is no

gap between successive digit enables except when

the meter goes into overload. For the BCD outputs,

"high” = true = +5VDC.

BUSY: (pin 2) When the meter is in the process of

making a measurement, the "busy" output is "high"

(+5VDC). When the measurement is completed, the

"busy" output goes "low" (0V).

POLARITY OUTPUT: When the polarity of the

input signal is positive, pin 4 goes "High" (+5V).

When the polarity of the input signal is negative, pin

4 goes "Low". This output becomes valid at

integrate and remains correct until it is re-validated

for the next measurement. It is valid when the

"busy" output is low.

RANGE MODIFICATION

The range of the meter can be changed as follows:

1. Insert the blade of a small screwdriver between

case and rear cover, midway on case above

printed circuit connector, and pry gently outward.

Remove rear cover.

2. Slide meter assembly form case. Observe that

read filter is a loose piece and will be required for

reassembly.

3. Observe resistor values for R4 and R6 and

compare to Table I and Figure 4. Install resistors

of values specified in Table I to obtain desired

range.

4. If a decimal point is desired, refer to instruction 7

under "Operation".

5. Clean all solder joints and adjacent areas on

printed circuit board to minimize leakage paths.

6. Reassemble meter.

7. A range modification resistor set for

PM-452 is available from your distributor, specify

NLS part number 39-356.

TABLE I: RANGE RESISTOR VALUES

Range

R4

R6

2 V

JUMPER

OMIT

20 V

909 KΩ1%

100 KΩ1%

200 V

10 MΩ1%

100 KΩ1%

1000 V

10 MΩ1%

10 KΩ1%

Figure 4. Component Location

CALIBRATION

To calibrate the instrument, perform the following

steps:

1. Allow the meter to warm up for at least

five minutes.

2. Set the power supply voltage to +5V ±2%.

3. Apply DC input signal voltages as follows:

RANGE OF

INSTRUMENT

CALIBRATION

VOLTAGE

2 V

+1.9990 V

20 V

+19.990 V

200 V

+199.90 V

1000 V

999.0 V

4. Adjust potentiometer at rear of meter until display

agrees with input.

5. Disconnect calibration voltage and power supply

input.

CURRENT MEASUREMENT

DC current measurements can be made using an

externally mounted shunt resistor. Use meter in the

2 Volt range and connect shunt resistor between

pins 5 and H of the edge connector.

If the current being measured enters pin 5 and exits

from pin H, the polarity displayed will be positive.

The value of the shunt resistor should be chosen as

set forth in table II. Note that at full scale, the voltage

drop across the shunt resistor is 1.9999 Volts. The

measuring circuit should be carefully examined to

insure that this voltage drop does not introduce

excessive error into the measurement.

WARNING: This meter is frequently used

on the high side of the current source to be

measured. This arrangement may cause a

short between the circuit high side and

ground with possible damage to the meter

and circuit. To prevent such a short, an

isolated meter power supply is

recommended.

TABLE II: SHUNT RESISTOR VALUES for

Current Measurement

FULL SCALE

CURRENT

SHUNT

RESISTOR

20 µA

100 KΩ

200 µA

10 KΩ

2 mA

1 KΩ

20 mA

100 Ω

200 mA

10 Ω

2 A

1 Ω

MAINTENANCE

Due to the solid-state construction and 100%

test and calibration of your PM-452 is an

extremely reliable instrument. However in the

event of trouble, the LED readouts and the

major integrated circuit are plug-in. They can

be easily replaced without soldering.

Specifications Subject to Change without Notice

NON-LINEAR SYSTEMS

Originator of the Digital Voltmeter

San Diego, CA

Phone: (619) 521-2161

Fax: (619) 521-2169

Email: sales@nonlinearsystems.com

11-15

Other NLS Measuring Instrument manuals