NLS X-32 User manual

Non-Linear Systems

X-32 3-Digit

Short Depth

Digital Panel Meter

INSTRUCTIONS

OVERVIEW

The X-32 Digital Panel Meter is a unipolar,

three-digit, fixed-range, DC voltmeter. It

features auto zeroing, eliminating zero drift.

The X-32 is a short depth meter of which

requires only one-half inch to mount behind

panel. Calibration at full-scale can be

accomplished by adjusting a single

potentiometer accessible from the front of

the meter.

A mating connector option provides plug-in

connections of the external leads. This

connector, if required, must be ordered

separately. (Part number 53-106).

The X-32 is built to a standard 1 volt range,

yet is also available in five other ranges.

(Select 100 mV, 10 V, 100 V or 1000 V

range) The factory can make this range

modification, or, you can accomplish this

range change by purchasing the range

change kit. (Part number 53-107)

A current measurement option is available,

permitting measurement of DC current from

100 nano amperes full scale (F.S.) to 1

amperes full scale (F.S.). (Part number

53-108)

An external +5Vdc regulated power supply

is recommended for operation. A typical

configuration for a suitable power supply is:

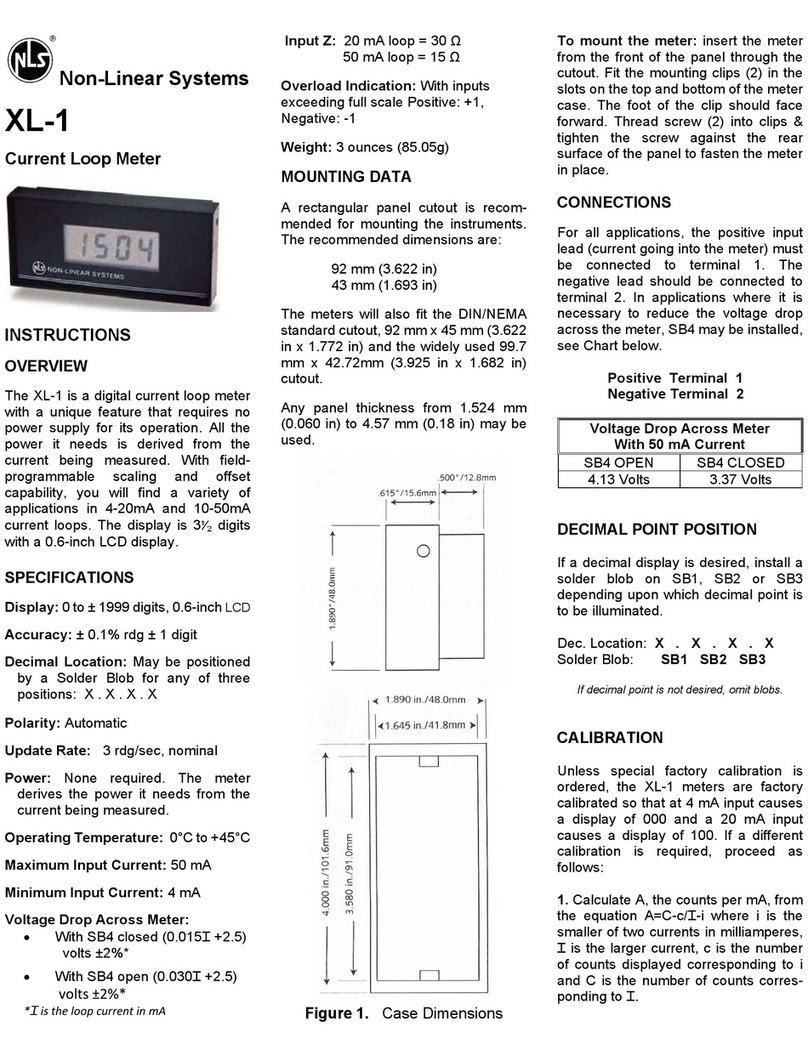

Figure 1: Power Supply Schematic

SPECIFICATIONS

Accuracy: + 0.2% Full Scale

Normal-Mode Rejection:

40 dB minimum.

Common-Mode Rejection:

80 dB minimum.

Common-Mode Voltage:

-1.5V to +4V between signal LO and

negative terminal of power supply.

Display: 0.56" bright Red LED, also

available in yellow, green, or orange

LEDs.

Decimal Location: Positioned by

internal jumper to any one of three

locations: X,X,X, (1V F.S. range

reads mV XXX)

Input Voltage Protection:

+ 250 Vdc on four lowest ranges.

+1200 Vdc on 1000 V range.

Input Z: 100 M

, 100 mV Full Scale,1

M

,1V, 10V, and 100V Full Scale,

4M

, 1000V Full Scale

Measurement Method: Integration;

input integration time - 80 mSec.

Operating Temperature:

0°C to +50°C ambient

Overload or Negative Indication:

Display is blank for inputs exceeding full

scale or for negative polarity input.

Power: +5 Vdc +5% @ 175 mA

Ranges: 0 to 100mV

0 to 1V

0 to 10V

0 to 100V

0 to 1000V

Ratio Operation: Ratio

measurements may be made by

using an external reference.

Settling Time: 1 sec. F.S. input chg.

Update Rate: 3readings/sec nominal

Temp Coefficient: 100ppm/C typical

Warm-up Time: 10 seconds

to + 0.1% accuracy.

Weight: 2 oz (56.7 grams) approx.

Zero Stability: Auto-zeroing

eliminates zero drift.

INSTALLATION

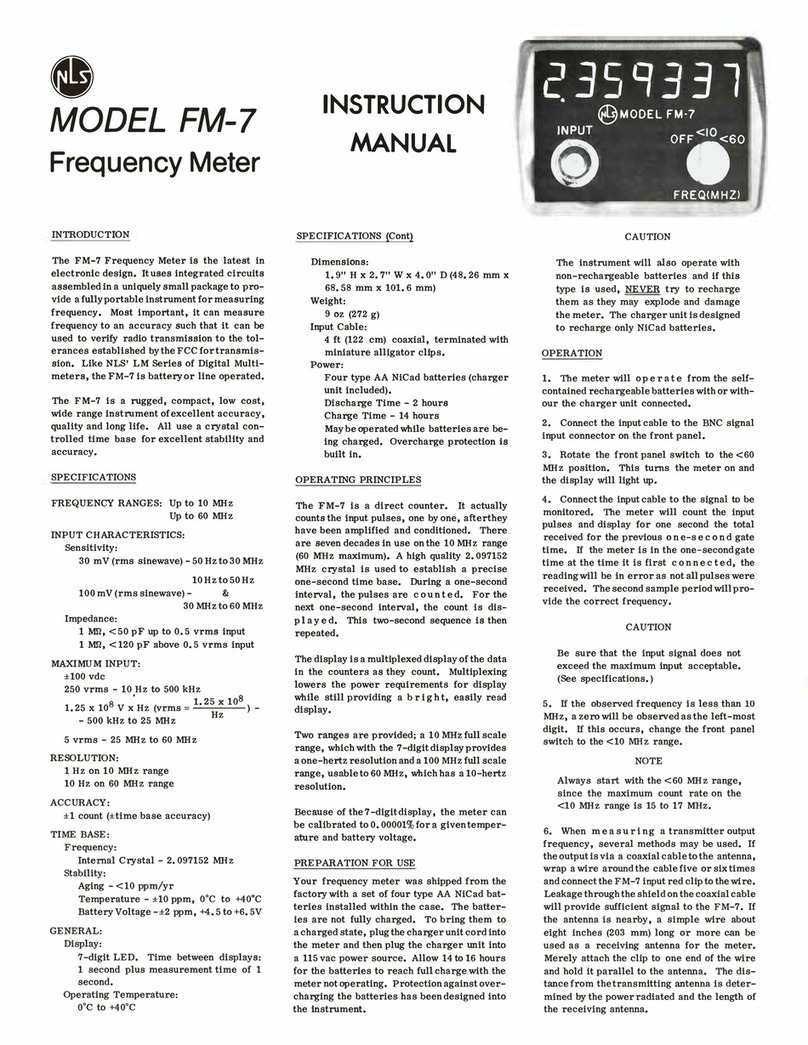

1. Mount the X-32 as follows:

a. Cut hole in panel 3.622" (92mm)

W x 1.693": (43mm) H.

b. Insert meter from the front,

through panel cutout.

c. Fit mounting clips (2) into slots

located on top and bottom of

meter. The foot of the clip should

face forward.

d. Thread screws (2) into clips &

tighten screws against rear

surface of panel.

2. If you have purchased the mating

connector option (NLS P/N 53-106),

install a keying tab in the connector

(Position 2) and attach the hookup

wire to the individual connector

sockets. Insert the sockets into the

connector block making sure the

keying tab and sockets are in the

proper position to latch into the

rectangular holes on the block.

(Refer to Table 1). Positions 3, 4, 5

and 8 do not have sockets.

Figure 2:Outline drawing of X-32 case

Table 1. Connector Pin Information

1. Signal HI 6. Signal LO

2. Key 7. Ground

3. N/C 8. N/C

4. N/C 9. +5Vdc

5. N/C 10. Ext. Ref.

Operation

1. Connector. The connector (purchased

separately) after assembling, is plugged onto

pins at rear of meter. Line up connector key

with missing pin in position 2. Pin 1 in Figure

3 is the pin that's by itself. Pin 2, 3, 4 and 5

are not installed on the PC board of the

meter.

2. Power Supply. Connect the negative

side of the +5 Vdc power supply to pin 7 of

the connector and the positive side to pin 9.

3. Signal. For most applications it is

desirable to have SIGNAL LO (Pin 6)

connected to power ground (pin 7).

As shipped, the meter makes this

connection with a printed circuit trace

labeled "W1." Connect signal HI and signal

LO of the source to pins 1 (HI) and 6 (LO)

respectively of the meter. A shielded cable

may be required if the signal source has a

high resistance. If there is any connection

between source LO and power ground

(other than W1), and if instability is observed

in the least significant digits of the display,

this instability may be improved by cutting

the W1 PC trace.

4. Decimal Location. Depending upon

which decimal point is to be illuminated,

install a jumper wire between circuit board

C and circuit board L, M or R on the inside

of the meter, See below:

Decimal Location X .X . X .

Pad Location L M R

5. Readings. With +5 Vdc power and

positive signal voltage applied (within range

of meter) , the X-32 will display the correct

reading + 0.1% within 10 seconds.

Ratio Operation

For ratio measurement applications, an

external reference voltage may be used as

follows: (In the ratio mode, the calibration

potentiometer, R2, has no effect.)

Remove jumper W2 by cutting

PC trace.

Install jumper W3. (See Figure 3)

Connect an external reference

voltage of +0.1 volt +10% to pin 10.

Voltage Range Modification

The X-32 may be range-changed from

any range to another by the installation

of various precision resistors.

1. Remove faceplate in front of display by

pressing in on sides of bezel and pulling

faceplate out by bowed center. Remove two

screws located at either end of display.

2. Carefully remove meter from front

of case.

3. Observe resistor values that are in meter

and compare to figure 3 and table II. Install

resistors specified in table II to attain desired

range.

Table II.

Resistor Values in

Range Modification Kit

Range 100mV 1V 10V 100V 1000V

R8 - 100k 10k 1k 402

R9 Jumper 909k 1M 1M -

R10 - - - - 1M

R11 - - - - 1M

R12 - - - - 1M

R13 - - - - 1M

4. If a decimal point is desired, see #4 under

Operation.

5. Clean solder joints & adjacent areas on

printed circuit board to minimize leakage

paths.

6. Reassemble meter.

7. Calibrate meter , see Calibration section.

8. Range change modification are available,

(NLS P/N 53-107).

Calibration

1. Set power supply voltage +5Vdc +2%.

2. Allow 5 minutes for warm up.

3. Precision DC power supply voltages:

Range of Recommended

Instrument Calibration Voltage

100 mV 90 mVDC

1 V 900 mVDC

10 V 9.00 VDC

100 V 90.0 VDC

1000 V 900 VDC

4. Adjust potentiometer R2 at side of

meter until readout agrees with input.

Figure 3. Component Location

Current Operation

Current Range Kit NLS P/N 53-108

provides all the resistors required to

measure DC currents. The meter must be in

the 100 mV range to accomplish this. Refer

to Figure 3 & 4 and Table III, for position of

R14. Higher currents are measured by

using an external current shunt. See

Table III for resistor values.

(Call factory for requirements)

Warning: This meter is frequently

used on the high side of the current

source to be measured. This

arrangement may cause a short

between the circuit high side and

ground with possible damage to the

meter and circuit. To prevent this, an

isolated meter power supply is

recommended.

Table III. Shunt Resistor Values

Full Scale Shunt Resistor

Current Range Value

100 Nanoamperes 1 Megohm

1 Microampere 100 Kilohms

10 Microamperes 10 Kilohms

100 Microamperes 1 Kilohm

1 Milliampere 100 Ohms

10 Milliamperes 10 Ohms

100 Milliamperes 1 Ohm

1 Ampere 0.1 Ohm

Figure 4. Current Shunt Location

Specifications Subject to Change

without Notice

Non-Linear Systems

Originator of the digital voltmeter.

San Diego, CA

P: 619-521-2161

F: 619-521-2169

sales@nonlinearsystems.com

11-14

Other NLS Measuring Instrument manuals