NMJ SKD224 User manual

SKD224 replacement board

Assembly Manual

- Document version 0.1.6 –

© Copyright NMJ 2016

All rights reserved

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 2 of 46

Please read this manual carefully before carrying out the

installation!!! Although our products are very robust, incorrect

wiring may destroy the module!

During the operation of the device the specified technical parameters

shall always be met. At the installation the environment shall be fully

taken into consideration. The device must not be exposed to moisture

and direct sunshine.

A soldering tool may be necessary for the installation and/or

mounting of the devices, which requires special care.

During the installation it shall be ensured that the bottom of the

device should not contact with a conductive (e.g. metal) surface!

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 3 of 46

Content

1. Important Information..............................................................4

2. Required tools..........................................................................4

3. Required materials ...................................................................4

4. Operation principle ..................................................................5

5. Board Connections...................................................................7

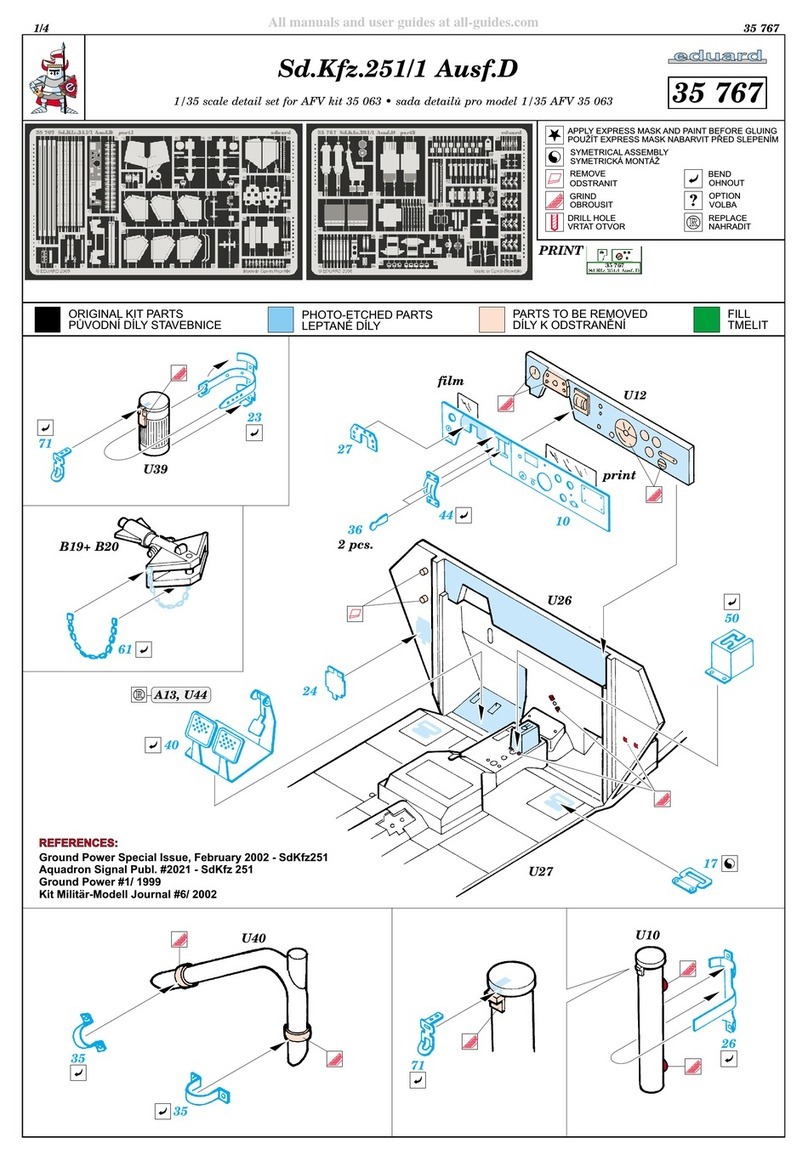

6. Disassembly of the SKD224....................................................9

7. Installing the replacement board............................................13

8. Replacement of the wheels ....................................................18

9. Decoder settings.....................................................................25

10. Programming tips...................................................................26

11. Analog operation ...................................................................28

12. Notes......................................................................................28

13. CV Table................................................................................29

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 4 of 46

1. Important Information

The manual is a guide to assemble the SKD224 replacement

board and gives some decoder setting recommendations and

programming tips. The replacement board is a drop in replacement

for the original board situated inside the SKD locomotives chassis.

The replacement board contains a DCC decoder and a Smart

Power Supply (SPP) and is suitable for DCC operation. The

decoders have installed a dedicated firmware with factory default

parameter values optimized for the SKD224 locomotives. After a

decoder reset, all the decoder parameters are reverted to the factory

default values.

Reference documents: NA

2. Required tools

- tweezer

- screwdriver

- right plier

- cutter

- cutting plier

- soldering station

3. Required materials

- SKD224 replacement board kit containing the replacement axles

- soldering wire

Estimated assembly time: 30-45 minutes

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 5 of 46

4. Operation principle

The SKD224 replacement board contains a smart power pack (SPP)

and is integrating a DCC decoder with BEMF PID motor control and

4 physical (function) outputs. The decoder controls the charging of

the on board 1 Farad capacitor, and ensures switching to the internal

power supply in case of track contact interruption. This guaranties a

trouble free running of the SKD224 even if the contact with the rails

is lost. The SPP is capable to power the locomotive up to 4 seconds

and can run it up to 30-50 centimeters without DCC power

(depending on the speed). This is especially useful for small 2 axle

locomotives like the SKD224, which has only a few current pickup

points, and suffer very often of DCC power interruption.

At start-up, the board will have a current consumption of 250-300

mA for up to 2 minutes, even if the locomotive is stationary. This is

normal, during this time the SPP is charging the internal capacitor.

In case of external power interruption, after the maximum allowed

timeout has been elapsed (this can be changed altering the specific

CV), the locomotive will stop. The operation can be resumed when

the locomotive is powered again over the rails.

Due to the operational principle, the SPP can be used only in DCC. If

the locomotive is used in DC, the SPP will be not activated.

The lights of the SKD224 are wired to the internal SPP circuit, so

even in the case of contact problems while running, during the

switching between external DCC power and internal SPP, the lights

are stable, and no annoying dimming is visible.

Connections for optional front/rear lights and electrical couplers are

available at both ends of the boards.

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 6 of 46

The on board decoder is full of options: is featuring a SUSI

connector for optional sound module connection, contains Zero

Speed and ABC Braking, with penduling (push-pull operation), has

a RailCom transmitter, and is capable of driving different electrical

couplers. Future options can be also integrated with a firmware

upgrade.

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 7 of 46

5. Board Connections

(the color coding is made according to NMRA standards, otherwise noted)

Motor Negative Terminal

Motor Positive Terminal

Coupler

Common

Coupler Output

Coupler Output

Coupler

Common

Right Track Connection

Left Track Connection

Lights

Common

(See note 1)

Lights

Common

(See note 1)

Front

White

(See note 2)

Rear

White

(See note 2)

Front

Red

(See note 2)

Rear

Red

(See note 2)

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 8 of 46

Note 1: The positive common terminal for the optional lights

(brown color in the illustration) is not the same as the coupler

positive common (blue in the illustration). It is forbidden to

connect them together.

The front/rear light outputs (white and yellow color) allows

direct connection of LEDs, so no current limiting resistors are

needed. The resistors are integrated to the boards. The Anode

of the LEDs must be connected to the Lights Common, while

the cathode to the front/rear outputs.

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 9 of 46

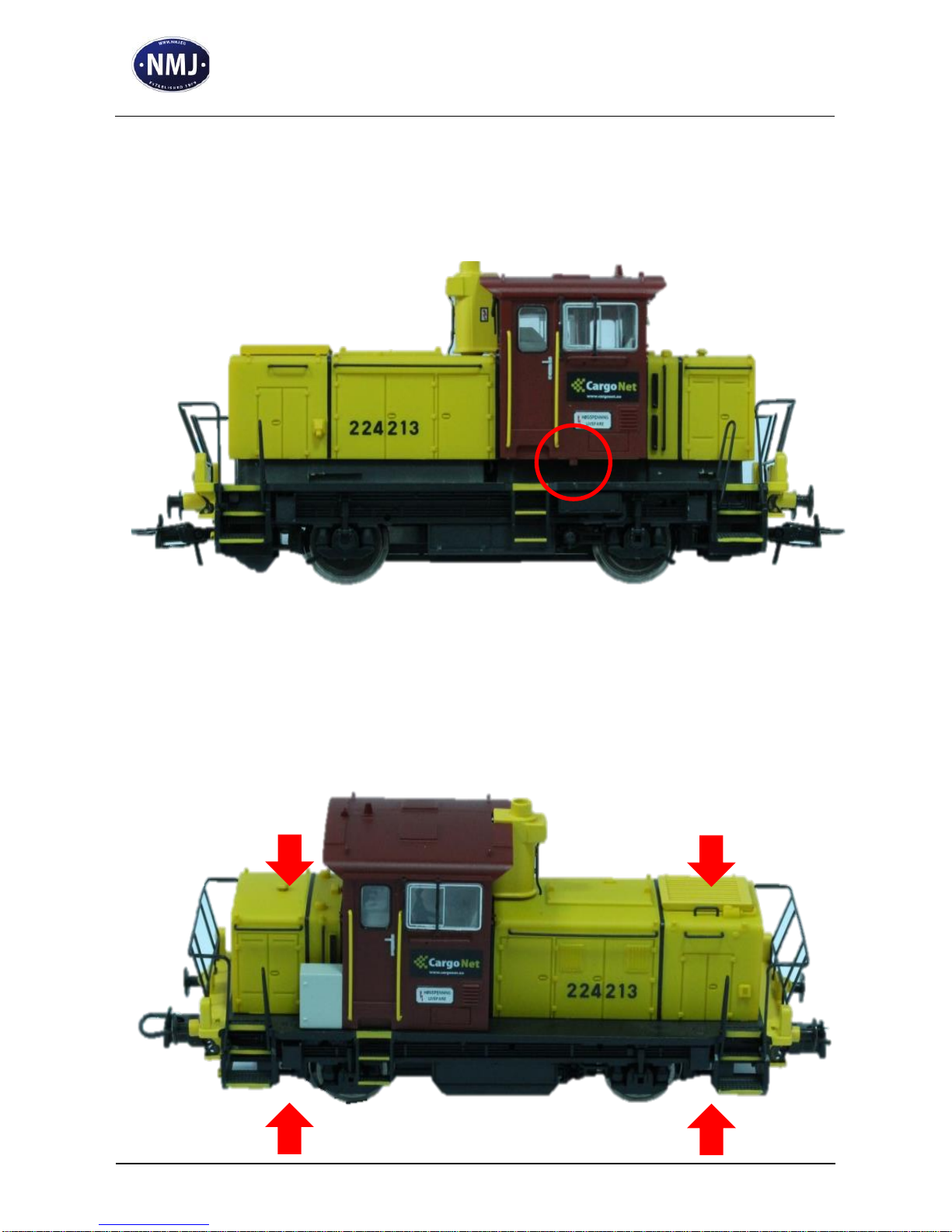

6. Disassembly of the SKD224

Remove the housing from the chassis. Press in the same time on both

ends of the housing (1), and lift (pull) the housing in the upper

direction (2).

The housing has 4 plastic ears (3), which enters in the 4 recess of the

chassis (4). Using a sharp blade (cutter) can help in the extraction.

1

1

2

3

3

4

4

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 10 of 46

Gently remove the housing, and place it on its side near the chassis.

Do not pull it too far, since the cabin lighting has a cable connection

to the chassis (2). The cabin itself also has 2 plastic pins (1), which

fits in the corresponding openings in the base plate located above the

chassis.

2

1

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 11 of 46

Disconnect the cabin lighting by removing the connector from the

chassis printed circuit board.

Localize the track connections (1), motor connections under the

black adhesive tape (2) and the mounting screws (3) on the chassis of

the locomotive.

1

1

2

3

3

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 12 of 46

First, unsolder the connection wires (4 in total).

Remove the 2 screws (1), and lift the printed circuit board. Please

note, that there are 2 mechanical centering pins (2) in the chassis,

which will guide the fit of the replacement board.

2

2

1

1

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 13 of 46

7. Installing the replacement board

Lead the 4 connection wires thru the corresponding holes in the

replacement board, and fit the board to the chassis using the

mechanical centering pins. Screw the board to the chassis.

Solder the wires to the replacement board.

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 14 of 46

All the wires must be pulled back, and arranged under the printed

circuit board. The motor connection wires must be arranged in such a

way to not touch the flywheel.

The track connection can be arranged on both sides of the chassis in

the available cutouts. If needed, a small drop of cyanoacrylate can be

used to fix the wires to the chassis.

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 15 of 46

Half of the small adhesive tape from the original board can be used

to mask the side lighting of the LEDs of the central head lights.

Before reassembling the housing, removal of 2 small inside walls (1)

is necessary to assure the required space for the replacement board.

1

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 16 of 46

This operation has to be performed using a cutter and a small plier.

The 2 interior walls must be cut with extreme care as close as

possible to the housing external wall without damaging it. After the

operation, clear the debris.

Insert the cabin light connector to the counterpart in the replacement

board.

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 17 of 46

Insert the housing over the chassis, and press down until the plastic

ears fit the recesses of the chassis. The plastic ears of the cabin also

have to be fitted to the base plate.

After the housing is in its place, press the base plate in upper

direction while fitting the cabin plastic ears, till there is no distance

between the base plate and the housing.

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 18 of 46

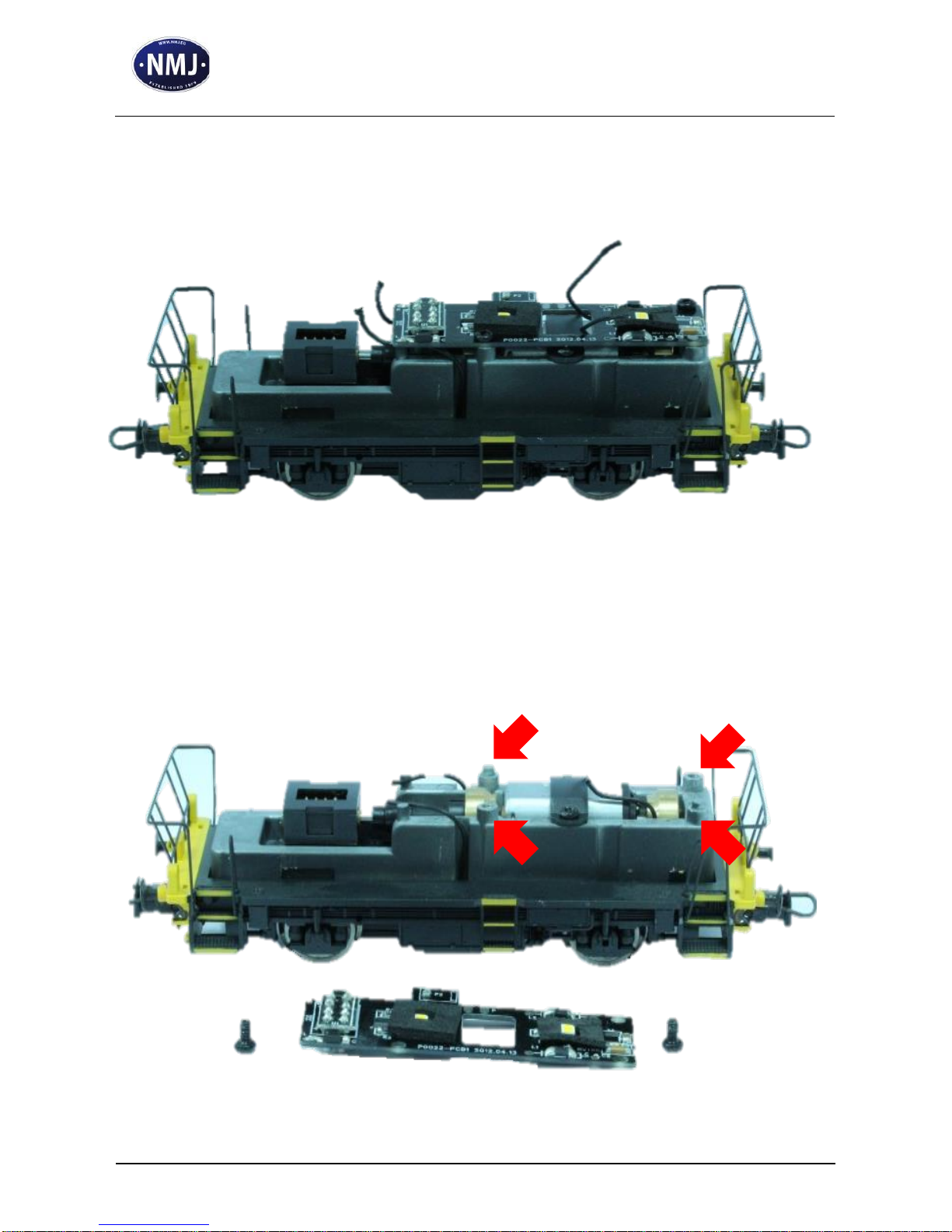

8. Replacement of the wheels

For the wheels/axles replacement, turn the locomotive upside down,

and place it on a stable surface to avoid falling on its side.

Pull the plastic ears on both sides of the base plate with a small

screwdriver to release it from the chassis (1). Lift the base plate in

upper direction (2).

1

1

2

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 19 of 46

Remove the 2 original axles with the plastic toothed wheels from the

chassis. The axle’s assembly keeps the current pickups pressed to the

wheels, while removing them the current pickups will depart from

the chassis.

At this point since there is access to the gearbox, it could be a good

idea to apply some grease over the wheels if needed. However, this

can be done at a later time too. You can use Roco type grease part

number 10905.

SKD224 replacement board

Assembly Manual

Document

Version

0.1.6

Page 20 of 46

In the illustration an exaggerated quantity of grease is applied for

exemplification. Use the grease in a moderate quantity.

Apply it also on the intermediary toothed wheels too.

Insert the replacement axles with the brass toothed wheels. They

must be inserted starting from the inner side of the chassis (1),

moved to the correct position (2) while pressing the elastic current

pickups to touch the wheels from their inner side (3).

2

1

3

Table of contents

Other NMJ Toy manuals