Nobel NBL-HPM-NT-AC012-V1 User manual

Technical Manual

Installation, maintenance & use instructions

Multifunctional

Heat Pump R32

2Technical Manual - Multifunctional Heat Pump R32

CONTENTS

1. GENERAL ........................................................................................................................... 3

2. SAFETY WARNINGS......................................................................................................... 3

2.1. Usage and installation warnings .................................................................................... 3

2.2. Personal safety warnings............................................................................................... 3

2.3. Transport, storage and handling warnings..................................................................... 4

2.4. Freeze protection warnings ........................................................................................... 4

3. SYSTEM DESCRIPTION ................................................................................................... 5

4. TECHNICAL SPECIFICATION ......................................................................................... 6

4.1. Internal View .................................................................................................................. 6

4.2. Dimensions (mm)........................................................................................................... 9

4.3. Specication ................................................................................................................ 10

4.4 . System Drawing............................................................................................................11

5. INSTALLATION ................................................................................................................ 12

5.1. General points for installation engineer ....................................................................... 12

5.1.1. Preparation before installation .................................................................................. 12

5.1.2. Sitting the heat pump................................................................................................ 12

5.1.3. Location requirements between machine and building............................................. 13

5.1.4. Condensate drainage ............................................................................................... 15

5.1.5. Accessories supplied ................................................................................................ 16

5.1.6. Controller .................................................................................................................. 17

5.2 . Installation design ........................................................................................................ 17

5.3. Pipe Connection ........................................................................................................... 21

5.4. Electrical Connection ................................................................................................... 22

5.4.1. Wiring Diagram ......................................................................................................... 23

5.4.2. Auxiliary electrical heater connection........................................................................ 26

5.4.3. Installation Drawing .................................................................................................. 26

5.5. Commissioning ............................................................................................................ 28

5.5.1. Preparations ............................................................................................................. 28

5.5.2. Inspection before Start up......................................................................................... 28

5.5.3. Start up and Commissioning..................................................................................... 28

6. CONTROLLER MANUAL................................................................................................ 29

6.1. Electric Parts Control Program working theory............................................................ 29

6.1.1. Compressor .............................................................................................................. 29

6.1.2. Start up / Shut down Cycle ....................................................................................... 29

6.1.3. 2nd heat source starting ........................................................................................... 29

6.1.3. DHW Auxiliary Electric Heater E1............................................................................. 29

6.1.4. Multifunctional port E2 .............................................................................................. 30

6.1.5. Motorized 3 way Valve G1 ........................................................................................ 30

6.1.6. DHW antifreeze3 ...................................................................................................... 30

6.1.7. AC antifreeze ............................................................................................................ 30

6.2. Operating Mode Principle ............................................................................................ 31

6.3. Wired controller............................................................................................................ 31

6.3.1. Controller .................................................................................................................. 31

6.3.2. Main interface ........................................................................................................... 32

6.3.3. Buttons denition and action..................................................................................... 32

6.3.3-1. Turn on / o ............................................................................................................ 33

7. MAINTENANCE................................................................................................................ 41

7.1. Maintenance and Cleaning for User ............................................................................. 41

8 . HOW TO GET THE MOST OUT OF YOUR HEAT PUMP............................................. 42

Multifunctional Heat Pump R32

3

Technical Manual - Multifunctional Heat Pump R32

- 3-

11 GGeenneerraall

Thank you for choosing a N

N

O

O

B

B

E

E

L

L

heat pump. This is a heat pump capable of providing

the ideal level of comfort for your home, always with a suitable hydraulic installation. The

unit is an air source heat pump for space heating/cooling and sanitary water heater for

houses, apartment blocks and small industrial premises. Outdoor air is used as a heat

source creating free energy to heat your home.

This manual forms an essential part of the product and it must be given to the user.

Read the warnings and recommendations in the manual carefully, as they contain

important information on the safety, use and maintenance of the installation. This

heat pump must be installed by qualified personnel only, in accordance with the

legislation in force and following the manufacturers instructions.

The start-up of this heat pump and any maintenance operations must be carried

only by qualified personnel only.

Incorrect installation of this heat pump could result in damage to people, animals or

property, and the manufacturer will not be held liable in such cases.

2

2

S

S

a

a

f

f

e

e

t

t

y

y

w

w

a

a

r

r

n

n

i

i

n

n

g

g

s

s

2

2

.

.

1

1

U

U

s

s

a

a

g

g

e

e

a

a

n

n

d

d

i

i

n

n

s

s

t

t

a

a

l

l

l

l

a

a

t

t

i

i

o

o

n

n

w

w

a

a

r

r

n

n

i

i

n

n

g

g

s

s

The heat pump must be installed by personnel authorized by the Ministry of Industry, in

compliance with the applicable laws and regulations. The precautions detailed here cover

very important issues. Please be sure to follow them carefully. Read carefully this

instruction manual and keep it in a safe, easily-accessible place. The manufacturer will

not be liable for any damages caused by failure to follow these instructions.

This heat pump is suitable for use in both heating and cooling installations and can be

combined with fan coils, underfloor heating/cooling, low-temperature radiators, and

domestic hot water tanks (optional). It must be connected to a heating/cooling

installation and/or a domestic hot water distribution network and compatible with its

performance and power. Liable under any circumstances for damage caused by

unsuitable, erroneous or irrational use. Remove all the packaging and check the contents

are complete. In case of doubt, do not use the heat pump. Contact your supplier. Keep

the packaging elements out of reach of children, as they can be dangerous.

Improper installation or placement of equipment or accessories may cause electrocution,

short circuit, leakage, fire, or other damage to the equipment. Use only accessories or

optional equipment designed specifically to work with the products presented in this

manual. Do not modify, replace or disconnect any safety or control device without first

consulting the manufacturer. When it is decided not to use any more the heat pump,

disable the parts that could represent a potential hazard.

2

2

.

.

2

2

P

P

e

e

r

r

s

s

o

o

n

n

a

a

l

l

s

s

a

a

f

f

e

e

t

t

y

y

w

w

a

a

r

r

n

n

i

i

n

n

g

g

s

s

Always wear appropriate personal protective equipment (gloves, safety goggles, etc.)

when performing installation and/or maintenance on the unit. Do not touch any switch

with wet fingers. Touching a switch with wet fingers may cause electric shock. Before

accessing the electrical components of the heat pump, disconnect the main power supply

completely. Disconnect all electricity sources before dismantling the cover panel from the

electric panel or before making any connections or accessing electrical parts.

To avoid electrocutions, be sure to turn off the power for 1 minute (or more) before servicing

the electrical parts. Even after 1 minute, always measure the voltage at the terminals of the

main circuit capacitors and other electrical parts before touching them and make sure that the

voltage is equal to or less than 36 V AC/DC. When the cover panels are disassembled, the

energised parts can be easily accessed. Never leave the unit unattended during installation or

during maintenance work when the cover panel is removed. Do not touch the refrigerant

pipes, water piping, or internal parts during and immediately after operation. Pipes and

internal parts may be excessively hot or cold, depending on the use of the unit.

The hands may be burned by cold or heat in case of improperly touching pipes or internal

parts. To avoid injury, wait until the pipes and internal parts return to their normal

temperature. Alternatively, if access is required, be sure to wear appropriate safety gloves.

4Technical Manual - Multifunctional Heat Pump R32

- 5-

2

2

.

.

3

3

T

T

r

r

a

a

n

n

s

s

p

p

o

o

r

r

t

t

,

,

s

s

t

t

o

o

r

r

a

a

g

g

e

e

a

a

n

n

d

d

h

h

a

a

n

n

d

d

l

l

i

i

n

n

g

g

w

w

a

a

r

r

n

n

i

i

n

n

g

g

s

s

The heat pump must be transported, handled and stored vertically. Tipping the machine

may cause the compressor or other components damage.

Do not twist, loosen or pull the external electric cables of the heat pump.

Do not insert any sharp objects through the fan grille or into the fan itself.

Do not wash the interior of the heat pump with water as this may result in electric

shock or fire. For any cleaning and /or maintenance operations, disconnect the main

power supply.

2

2

.

.

4

4

F

F

r

r

e

e

e

e

z

z

e

e

p

p

r

r

o

o

t

t

e

e

c

c

t

t

i

i

o

o

n

n

w

w

a

a

r

r

n

n

i

i

n

n

g

g

s

s

The heat pump is a machine that is installed in the exterior of the house, so that it will

be exposed to the extreme climatic conditions of cold in the periods of frost. Due to

this, it is of paramount importance that this type of machine is protected against such frost.

The freezing of the water inside the heat pump causes the heat pump to breakdown,

with the subsequent interruption of its operation and major economic expenses

involving its repair.

It is mandatory to use a safety system in the installation to prevent the freezing of the

water in the machine. We proposes the use of glycol in the water circuit of the heat

pump, or some antifreeze valve system to empty the installation in conditions of low

temperatures. Carefully read the Freeze Protection section in this manual for more

detailed information on these systems. We will not cover damages caused by the lack

of any of these antifreeze safety systems.

The electronic controller of the heat pump has a function for protection against the

freezing of the water in its interior in periods of frost. For this function to remain active

and on alert, the heat pump must be connected to the mains and have a power supply,

even if it is switched off or not in use.

A water filter should be installed in the installation, in order to avoid obstructions in the water

circuit of the heat pump. It must be installed in the return circuit of the heat pump and MUST

be installed before filling and circulating the water through the installation. The water filter

should be checked and cleaned, if necessary, at least once a year. IN new installations,

however, it is advisable to check it within the first few months of its commissioning.

Multifunctional Heat Pump R32

5

Technical Manual - Multifunctional Heat Pump R32

- 6-

3 System description

The unit is a monoblock (single unit) air/water heat pump, specially designed for the

colder climate. There is no need for bore holes and usually the system can be installed

within 1 day.

The unit can both heat hot water effectively at high outdoor temperatures and give a high

output to the heating system at low outdoor temperatures. If the outdoor temperature drops to

a level lower than minus 0℃ (factory setting), the auxiliary heater switches on to ensure the

heat pump unit works normally. The unit is also capable of cooling in the summer. The heat

pump controller is an intelligent wired system. The unit is rated as 6KW/9KW/12KW/18KW.

The Material/components are chosen to provide a long service life and to fully withstand

harsh outdoor conditions.

The unit has two different installation options:

1). Space heating/cooling + DHW (Domestic hot water)

2). Space heating/cooling only or DHW only

6Technical Manual - Multifunctional Heat Pump R32

- 7-

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21

Top cover Evaporator

Electrical box

Right side support

Electrical box support

Plate type heat exchanger

Base plate

Plate type heat exchanger support

Front plate

Mid-support plate

Fan motor

Left side pore plate 22

Evaporator

Behind plate

Expansion vessel

Compressor

Water pump

Right side service plate

Front service plate

Fan grille

Fan blade

Fan motor support

Left side support

4

4

T

T

e

e

c

c

h

h

n

n

i

i

c

c

a

a

l

l

s

s

p

p

e

e

c

c

i

i

f

f

i

i

c

c

a

a

t

t

i

i

o

o

n

n

4

4

.

.

1

1

I

I

n

n

t

t

e

e

r

r

n

n

a

a

l

l

V

V

i

i

e

e

w

w

NBL-HPM-NT-AC006-V1 / AC009-V1

Multifunctional Heat Pump R32

7

Technical Manual - Multifunctional Heat Pump R32

- 8-

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

Evaporator

Behind plate

Expansion vessel

Compressor

Water pump

Base plate

Plate type heat exchanger support

Front plate

Mid-support plate

Fan motor

Left side pore plate

23

Top cover Evaporator

Electrical box

Right side support

Electrical box support

Gas-liquid separator

Plate type heat exchanger

Right side service plate

Front service plate

Fan grille

Fan blade

Fan motor support

Left side support

NBL-HPM-NT-AC012-V1 / AC012-V3

8Technical Manual - Multifunctional Heat Pump R32

- 9-

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

Evaporator

Behind plate

Expansion vessel

Compressor

Water pump

Right side service plate

Plate type heat exchanger support

Front plate

Mid-support plate

Fan motor

Left side pore plate

23

Top cover Evaporator

Electrical box

Right side support

Electrical box support

Gas-liquid separator

Base plate

Plate type heat exchanger

Front service plate

Fan grille

Fan blade

Fan motor support

Left side support

NBL-HPM-NT-AC018-V1 / AC024-V3

- 10-

4

4

.

.

2

2

D

D

i

i

m

m

e

e

n

n

s

s

i

i

o

o

n

n

s

s

(

(

m

m

m

m

)

)

A

B L

D

C

EE

G

H

F

I

K

J

N

Units A B C D E F G H I J K L N

6/9kW 898 1115 485 415 180 150 470 429 38 60 128 472 62.5

12kW 982 1115 485 415 180 180 470 450 38 60 128 472 62.5

18/23kW 1330 1115 485 415 180 180 470 770 38 60 128 472 62.5

Multifunctional Heat Pump R32

9

Technical Manual - Multifunctional Heat Pump R32

4.3 Specification

Model In

Heating Capacity Range kW 1.2-7.0 2-10 4-14 4-14 6-20 6.5-25

Rated Heating Capacity kW 6.40 9.14 12.20 12.2 18.50 23.00

Rated Heating Input kW 1.34 2.04 2.73 2.73 4.00 5.00

Rated Heating Current A 5.83 8.87 11.87 4.61 17.39 8.44

COP W/W 4.78 4.49 4.47 4.47 4.63 4.60

Rated Cooling Capacity kW 6.25 8.99 11.00 11.00 17.82 21.00

Rated cooling Input kW 1.54 2.41 3.08 3.08 4.92 5.66

Rated cooling Current A 6.70 10.48 13.39 5.20 21.39 9.56

EER W/W 4.05 3.73 3.57 3.57 3.62 3.71

Start Current A 0.5 0.5 1.5 1.5 3.0 5.0

Rated voltage/Frequency/phase V/Hz 230/50/1 230/50/1 230/50/1 380/50/3 230/50/1 380/50/3

Maximum input power kW 2.76 3.45 3.95 4.00 6.21 7.10

Maximum input current A 12 15 17 7 27 12

High pressure protect MPa 4.50

Low pressure protect MPa 0.10

Brand/Type of Compressor /Mitsubishi / Twin Rotary

Refrigerant / R32 R32 R32 R32 R32 R32

Brand of Water pump WILO or GRUNDFOS

Defrost / Auto defrost with 4 way valve

Waterproof grade / IPX4

Noiseat 1m dB(A) 51 54 54 54 56 58

Max water outlet temperature C 60 60 60 60 60 60

Diameter of water connection / DN25 DN25 DN25 DN25 DN25 DN32

Rating water flow m/h 1.1 1.6 2.1 2.1 3.1 4.0

Water pressure drop at rating flow kPa 22 40 50 50 60 40

Min/Max heating water pressure bar 0.5/3.0 0.5/3.0 0.5/3.0 0.5/3.0 0.5/3.0 0.5/3.0

Main board Fuse A 10 10 10 10 10 10

Ambient operational temp. C -15~45 -15~45 -15~45 -15~45 -15~45 -15~45

Water operation temp.(DHW mode ) C 10~60 10~60 10~60 10~60 10~60 10~60

Water operation temp.(Heating mode) C 10~60 10~60 10~60 10~60 10~60 10~60

Water operation temp.(cooling mode) C 10~30 10~30 10~30 10~30 10~30 10~30

Net Dimensions ( L/W/H ) mm 1115/415/8 1115/415/8 1115/415/9 1115/415/9 1115/415/1 1115/415/1

98 98 82 82 332 332

Net Weight kg 80 82 125 125 175 180

Rated test conditions: Heating: DB/WB 7C/6C, In/Out: 30C/35C. Cooling: DB/WB: 35C/24C, In/Out: 23C/18C

-11-

NBL-HPM-NT-

AC006-V1

NBL-HPM-NT-

AC009-V1

NBL-HPM-NT-

AC012-V1

NBL-HPM-NT-

AC012-V3

NBL-HPM-NT-

AC018-V1

NBL-HPM-NT-

AC024-V3

10 Technical Manual - Multifunctional Heat Pump R32

- 12-

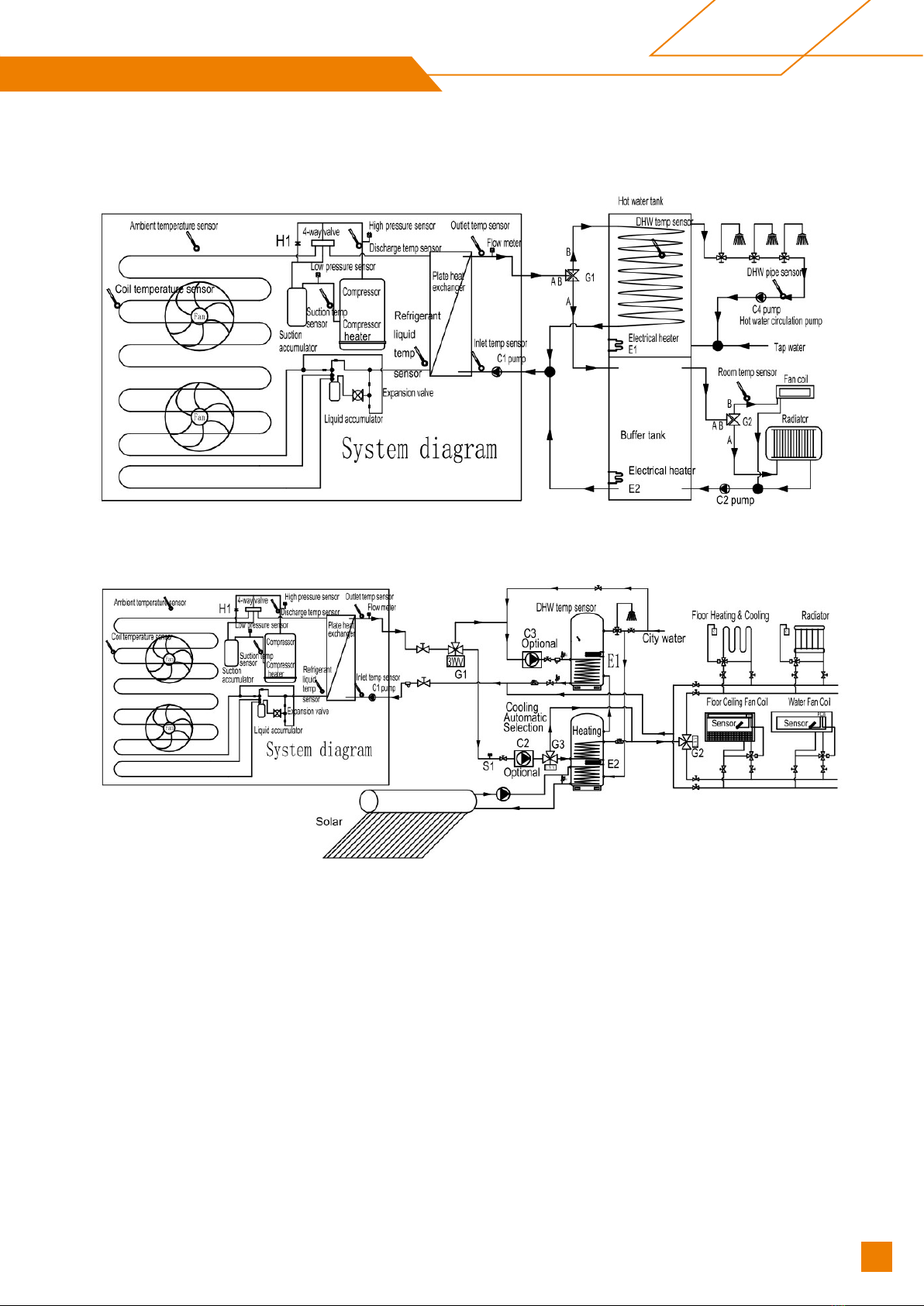

44..44 SSyysstteemm DDrraawwiinngg

P

P

8

8

8

8

=

=

1

1

P

P

6

6

5

5

=

=

1

1

S

S

y

y

s

s

t

t

e

e

m

m

s

s

c

c

h

h

e

e

m

m

a

a

t

t

i

i

c

c

P

P

8

8

8

8

=

=

0

0

P

P

6

6

5

5

=

=

0

0

S

S

y

y

s

s

t

t

e

e

m

m

s

s

c

c

h

h

e

e

m

m

a

a

t

t

i

i

c

c

Multifunctional Heat Pump R32

11

Technical Manual - Multifunctional Heat Pump R32

- 13-

5 Installation

5

5

.

.

1

1

G

G

e

e

n

n

e

e

r

r

a

a

l

l

p

p

o

o

i

i

n

n

t

t

s

s

f

f

o

o

r

r

i

i

n

n

s

s

t

t

a

a

l

l

l

l

a

a

t

t

i

i

o

o

n

n

e

e

n

n

g

g

i

i

n

n

e

e

e

e

r

r

5

5

.

.

1

1

.

.

1

1

P

P

r

r

e

e

p

p

a

a

r

r

a

a

t

t

i

i

o

o

n

n

b

b

e

e

f

f

o

o

r

r

e

e

i

i

n

n

s

s

t

t

a

a

l

l

l

l

a

a

t

t

i

i

o

o

n

n

Make sure the site is large enough to hold all the equipment and has enough

operation space. Measure the hoisting path to ensure that the path to the installation site is

unobstructed and prevent the equipment from reaching the site during installation Confirm

that the power meter capacity and the wire capacity are sufficient and the phase (three-

phase, two-phase) meets the requirements.

Plan the layout of the equipment according to the customers site. And strive to have the

shortest and the most straight water pipe and enough space for operation and maintenance.

For the heat pump with side outlet wind, consider the local wind direction and choose a

reasonable installation direction to avoid the wind direction being opposite. Current

regulations require the heating installation to be inspected before it is commissioned. The

inspection must be carried out by a suitably qualified person and should be documented. If

the heat pump is replaced, the installation must be inspected again. In the event of

installation with unvented (closed) heating systems, Make sure the line has an exhaust valve

(the system comes with an automatic exhaust valve). If necessary, installation engineer may

add additional exhaust valves to the line.

5.1.2 Sitting the heat pump

The heat pump should be firmly fixed to a base, preferably a concrete baseIt is the

most suitable that the right end is 5-10mm higher than the left end .As shown below:

≥100mm

The receiving surface of the device must:

- Allow a solid fixation (preferably concrete).

- Fully support its weight.

- Have a permeable area below the condensate drainage hole

(earth, gravel bed, sand, etc ).

12 Technical Manual - Multifunctional Heat Pump R32

- 14-

- Do not transmit any vibration to the home, recommending the installation of the

anti-vibration dampers supplied with the heat pump.

In case of installing the device on wall mounts, it will be especially important to isolate the

machine from the transmission of vibrations and noise inside the house, it may be necessary

to install more suitable anti-vibration dampers for the wall mount in addition to those supplied

with the heat pump. Nevertheless, the installation on the ground is the most advisable.

Straighten the heat pump well to ensure that the condensate water cannot exit through any

paths other than the intended drain hole.

Fasten it firmly using 4 sets of M12 bolts suitable for the base material, with nuts and

washers (available on the market). Make sure that the protruding distance of the bolt

does not exceed 10mm inside the metallic support of the device(leg).

5

5

.

.

1

1

.

.

3

3

L

L

o

o

c

c

a

a

t

t

i

i

o

o

n

n

r

r

e

e

q

q

u

u

i

i

r

r

e

e

m

m

e

e

n

n

t

t

s

s

b

b

e

e

t

t

w

w

e

e

e

e

n

n

m

m

a

a

c

c

h

h

i

i

n

n

e

e

a

a

n

n

d

d

b

b

u

u

i

i

l

l

d

d

i

i

n

n

g

g

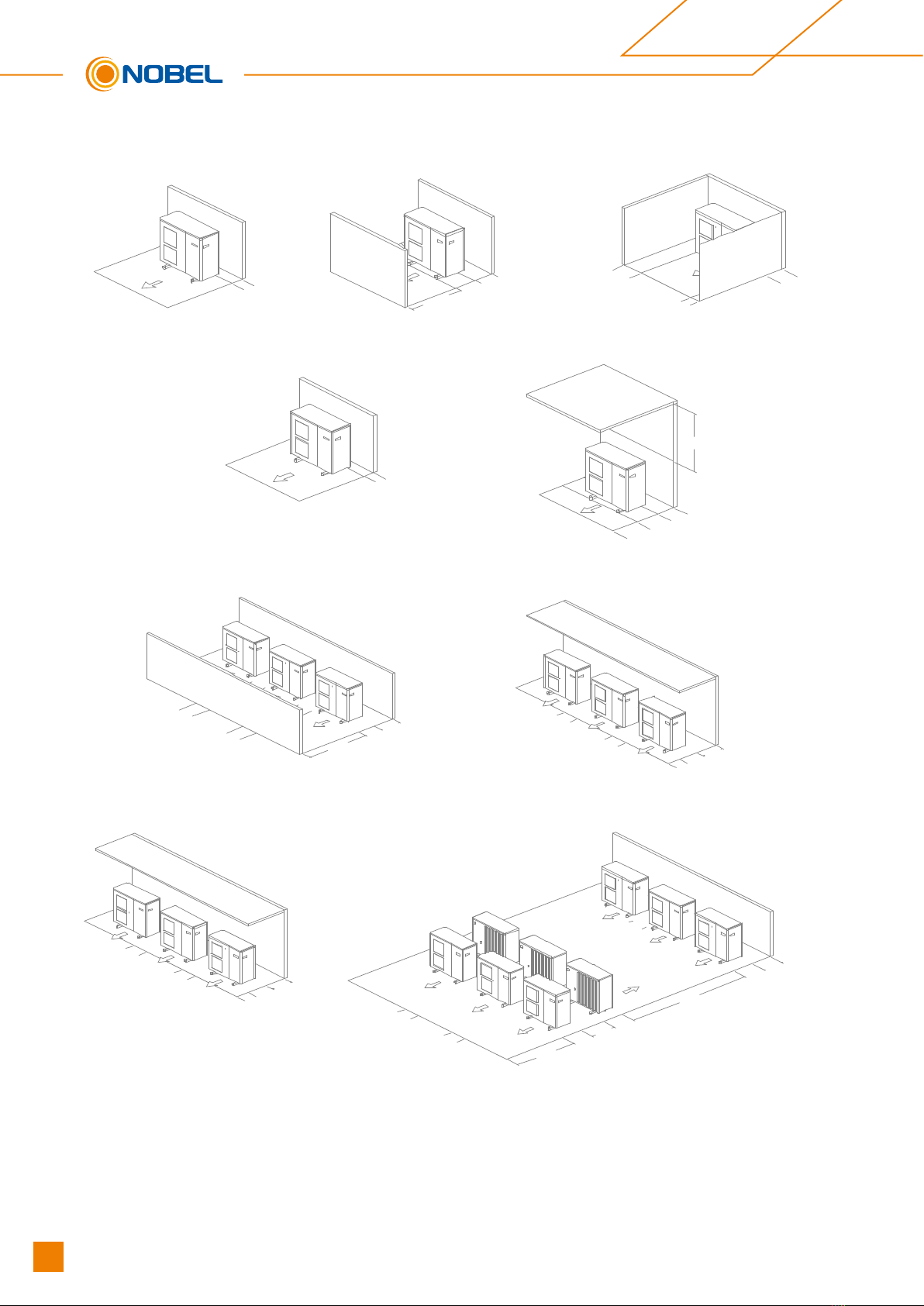

The heat pump must be installed exclusively outside the home and, where possible, in

a completely clear area. If a protection is needed around the appliance, it should

have wide openings on the 4 sides and the installation separations indicated in the

following figure must be respected. No obstacle should prevent the circulation of air

through the evaporator and the fan outlet.

Multifunctional Heat Pump R32

13

Technical Manual - Multifunctional Heat Pump R32

- 15-

≥ 2 00

≥ 3 50

≥ 10 00

≥ 3 50

≥ 4 00

≥ 2 00

≥ 2 00

≥ 3 50

≥ 1000

M a x . 500

Mininum separations for the installation of a unit(mm)

≥ 5 00

≥ 15 00

≥ 4 00

≥ 4 00

≥ 5 00

M a x . 300

≥ 4 00

≥ 4 00

≥ 5 00

M a x . 300

≥ 4 00

≥ 4 00

≥ 15 00

≥ 30 00

≥ 5 00

≥ 6 00

≥ 4 00

≥ 4 00

Mininum separations for the installation of multiple units in the same location(mm)

14 Technical Manual - Multifunctional Heat Pump R32

- 16-

Consult with the user before choosing the location of the device. It should not be

placed next to sensitive walls, such as on the wall next to a bedroom. Make sure that

the location of the heat pump is not disruptive to neighbors (sound level, air currents

generated, low temperature of the air blown with risk of freezing plants in the path,

etc.).

Choose a location that preferably has sunlight and is protected from strong and cold

winds. If the heat pump is exposed to gusts of wind that make it possible to overturn

it, it should be supported by suitable guys, as indicated in the figure.

The device must be sufficiently accessible for subsequent installation and maintenance

work. Make sure that the passage of the hydraulic and electrical connections to the

interior of the house is possible and comfortable. The spacing measures indicated in

the figure above are those strictly necessary to ensure correct operation of the device;

however, sometimes, it will be essential to provide more space for maintenance work.

The heat pump is a device specially designed for outdoor installation. Nevertheless,

avoid installing it in a place where it may be exposed to significant water stains or

spills (e.g. under a faulty gutter, near gas outlets, etc.) . Move the appliance away

from heat sources and flammable products. In areas where abundant and copious

snowfalls occur, special care must be taken to protect the heat pump from possible

obstructions due to accumulation of snow around it. The obstruction of the air inlet and/

or outlet of the machine due to the accumulation of snow may cause malfunction of the

unit and possible breakdowns. The heat pump must be raised at least 100 millimeters

above the maximum expected snow level. In turn, the roof should be protected from

accumulation of snow, by means of a roof projecting from the building or a similar

structure.

5

5

.

.

1

1

.

.

4

4

C

C

o

o

n

n

d

d

e

e

n

n

s

s

a

a

t

t

e

e

d

d

r

r

a

a

i

i

n

n

a

a

g

g

e

e

In normal operation, the heat pump can evacuate large amounts of water, for which the

heat pump provides a hole in the bottom of the appliance. Be sure not to obstruct this

hole during the installation process of the appliance.

Multifunctional Heat Pump R32

15

Technical Manual - Multifunctional Heat Pump R32

- 17-

Preferably install the device in a well-drained place. To do this, it is advisable to

provide a bed of gravel, sand or similar materials below said hole. If the drain hole of

the heat pump is covered by a mounting base or by the floor, lift the unit to leave a

free space of at least 100mm below it.

If it is installed on a terrace or facade, the condensate outlet must be led to a drain to

avoid inconvenience and/or damage caused by the dripping of condensate water. If the

installation is carried out in a region where the temperature can be below 0 for a long

period of time

5

5

.

.

1

1

.

.

5

5

A

A

c

c

c

c

e

e

s

s

s

s

o

o

r

r

i

i

e

e

s

s

s

s

u

u

p

p

p

p

l

l

i

i

e

e

d

d

The following accessories are supplied in the interior of the heat pump. Be fore

proceeding with the installation of the machine, make sure that you receive them and

that they are in good condition.

Documentation:

Inside the machine, open the front door to find the documentation bag, where all the

manuals and documents necessary for the use and installation of the heat pump are

included.

Controller:

It is supplied inside the machine and can be found by removing cover of the electronic

boards. Before connecting the power supply to the machine, the controller should be

installed inside the house. See 6.3.1 for the physical drawing

Drain valve:

It is supplied inside the machine, tied with a flange to one leg of the compressor.

Front

Behind

16 Technical Manual - Multifunctional Heat Pump R32

- 18-

This key must be installed in the drain socket on the back of the heat pump before

filling the water in the heating/cooling circuit.

4x Anti-vibration dampers:

Four units are supplied in a bag stuck on the back of the machine, next to the drain

socket.

5

5

.

.

1

1

.

.

6

6

C

C

o

o

n

n

t

t

r

r

o

o

l

l

l

l

e

e

r

r

The unit is equipped with an external electronic controller that handles all functions

necessary for heat pump operations. Defrosting, stop at max/min temperature,

connection of the compressor heater as well as enabling the aux electrical heater,

monitoring of motor protection and pressure sensors are all controlled.

The number of starts and the operating time after this power-on can also be read. The

controller is set during installation and can be used during a service. Under normal operating

conditions the home owner does not need to have access to the controller. The unit has an

integrated electronic outlet water temperature sensor that limits the outlet temperature up to

60℃.

5

5

.

.

2

2

I

I

n

n

s

s

t

t

a

a

l

l

l

l

a

a

t

t

i

i

o

o

n

n

d

d

e

e

s

s

i

i

g

g

n

n

The unit can be installed in several different ways.

The safety equipment must be installed in accordance with current regulations for all

installation options.

When connecting with the unit, the total water volume in the heat pump pipe system

and buffer tank must be at least 10 liters per 1 kW of output.

Multifunctional Heat Pump R32

17

Technical Manual - Multifunctional Heat Pump R32

- 19-

A

A

)

)

N

N

B

B

L

L

-

-

H

H

P

P

M

M

-

-

N

N

T

T

-

-

A

A

C

C

0

0

0

0

6

6

-

-

V

V

1

1

/

/

A

A

C

C

0

0

0

0

9

9

-

-

V

V

1

1

/

/

A

A

C

C

0

0

1

1

2

2

-

-

V

V

1

1

/

/

V

V

3

3

/

/

A

A

C

C

0

0

1

1

8

8

-

-

V

V

1

1

S

S

p

p

a

a

c

c

e

e

H

H

e

e

a

a

t

t

i

i

n

n

g

g

/

/

C

C

o

o

o

o

l

l

i

i

n

n

g

g

+

+

D

D

H

H

W

W

B

B

)

)

N

N

B

B

L

L

-

-

H

H

P

P

M

M

-

-

N

N

T

T

-

-

A

A

C

C

0

0

0

0

6

6

-

-

V

V

1

1

/

/

A

A

C

C

0

0

0

0

9

9

-

-

V

V

1

1

/

/

A

A

C

C

0

0

1

1

2

2

-

-

V

V

1

1

/

/

V

V

3

3

/

/

A

A

C

C

0

0

1

1

8

8

-

-

V

V

1

1

S

S

p

p

a

a

c

c

e

e

H

H

e

e

a

a

t

t

i

i

n

n

g

g

/

/

C

C

o

o

o

o

l

l

i

i

n

n

g

g

M

M

o

o

d

d

e

e

O

O

n

n

l

l

y

y

18 Technical Manual - Multifunctional Heat Pump R32

- 20-

C

C

)

)

2

2

x

x

N

N

B

B

L

L

-

-

H

H

P

P

M

M

-

-

N

N

T

T

-

-

A

A

C

C

0

0

0

0

6

6

-

-

V

V

1

1

/

/

A

A

C

C

0

0

0

0

9

9

-

-

V

V

1

1

/

/

A

A

C

C

0

0

1

1

2

2

-

-

V

V

1

1

/

/

V

V

3

3

/

/

A

A

C

C

0

0

1

1

8

8

-

-

V

V

1

1

I

I

n

n

s

s

t

t

a

a

l

l

l

l

a

a

t

t

i

i

o

o

n

n

.

.

S

S

p

p

a

a

c

c

e

e

H

H

e

e

a

a

t

t

i

i

n

n

g

g

/

/

C

C

o

o

o

o

l

l

i

i

n

n

g

g

+

+

D

D

H

H

W

W

D

D

)

)

3

3

x

x

N

N

B

B

L

L

-

-

H

H

P

P

M

M

-

-

N

N

T

T

-

-

A

A

C

C

0

0

0

0

6

6

-

-

V

V

1

1

/

/

A

A

C

C

0

0

0

0

9

9

-

-

V

V

1

1

/

/

A

A

C

C

0

0

1

1

2

2

-

-

V

V

1

1

/

/

V

V

3

3

/

/

A

A

C

C

0

0

1

1

8

8

-

-

V

V

1

1

I

I

n

n

s

s

t

t

a

a

l

l

l

l

a

a

t

t

i

i

o

o

n

n

.

.

S

S

p

p

a

a

c

c

e

e

H

H

e

e

a

a

t

t

i

i

n

n

g

g

/

/

C

C

o

o

o

o

l

l

i

i

n

n

g

g

+

+

D

D

H

H

W

W

Multifunctional Heat Pump R32

19

Technical Manual - Multifunctional Heat Pump R32

- 21-

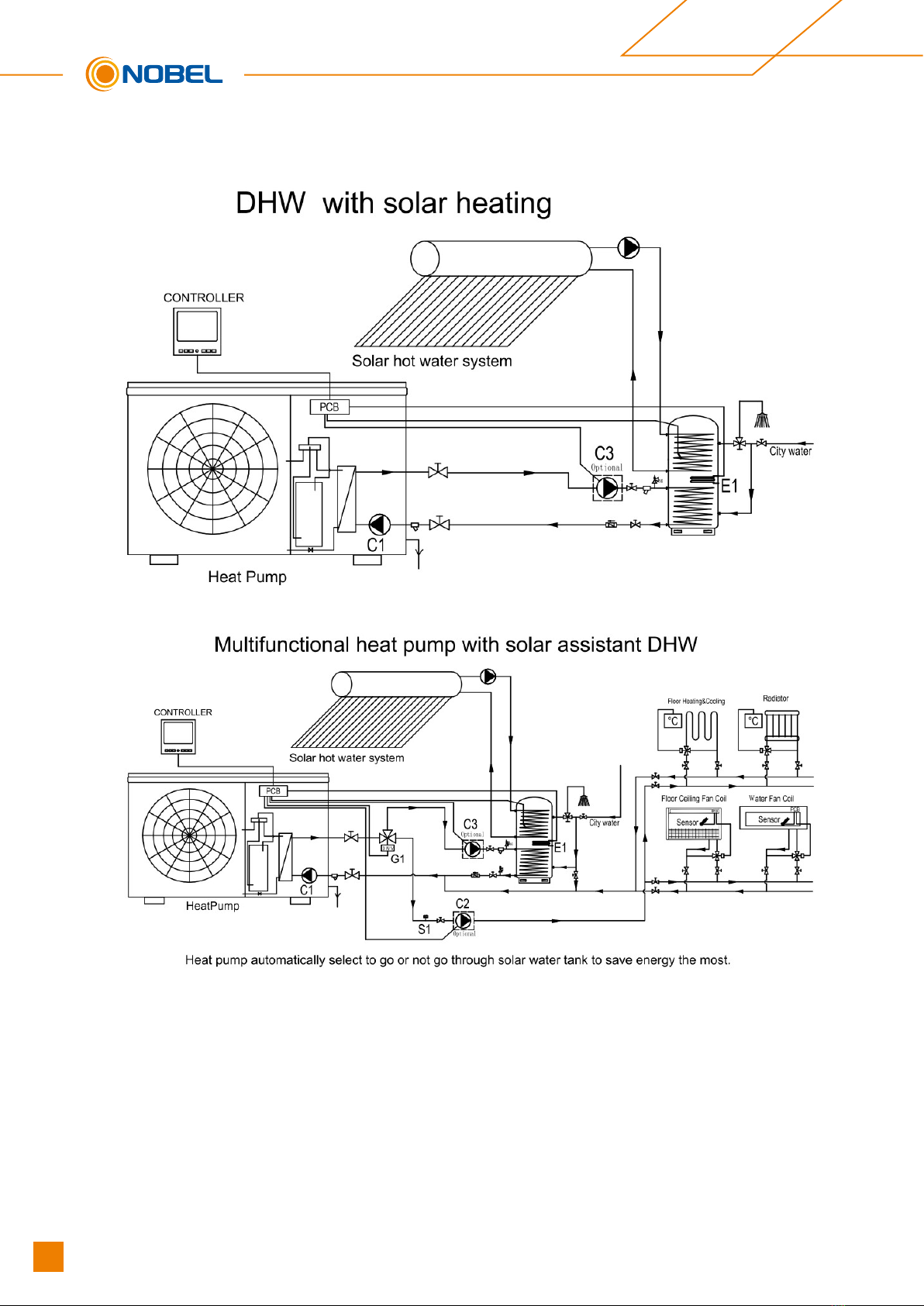

Solar Application 1

Solar Application 2

20 Technical Manual - Multifunctional Heat Pump R32

This manual suits for next models

1

Other Nobel Heat Pump manuals

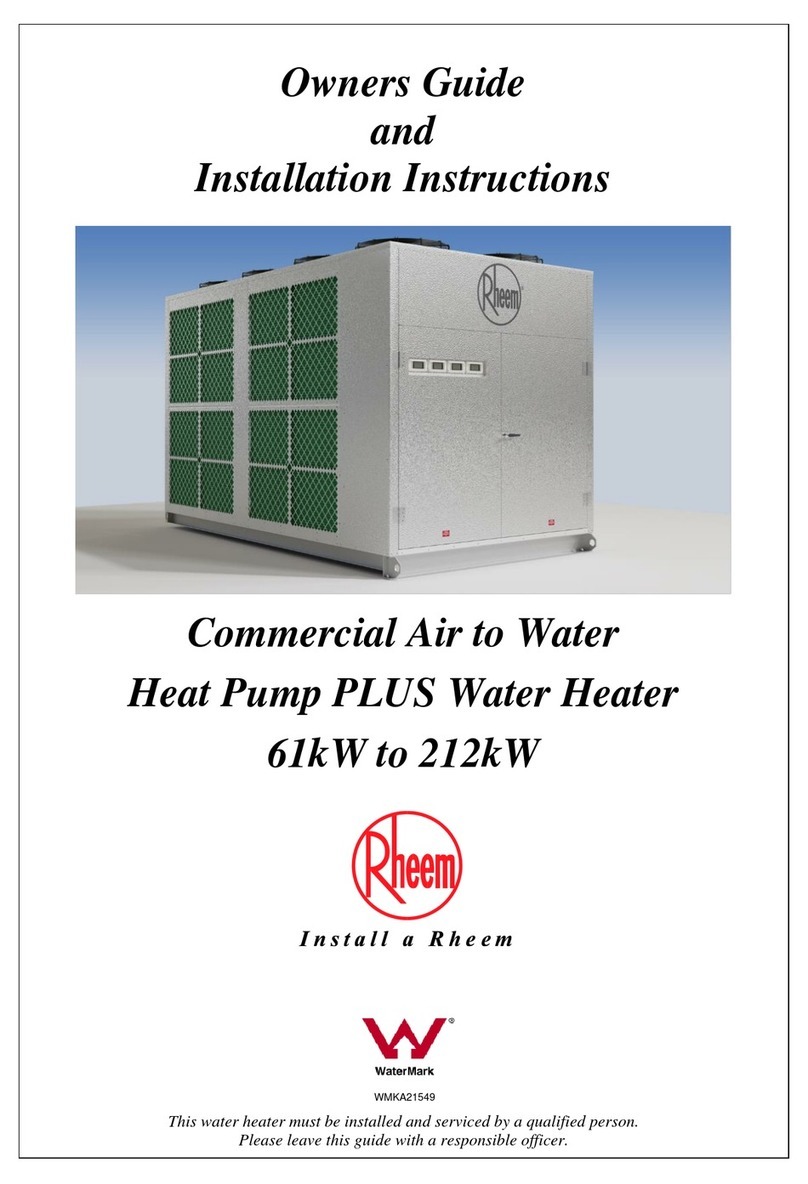

Popular Heat Pump manuals by other brands

Rheem

Rheem 953060DP Owner's guide and installation instructions

Maritime Geothermal

Maritime Geothermal NORDIC W Series Product application, installation and service manual

Kaisai

Kaisai KHY-12PY3 user manual

ANTEK

ANTEK AIR MAGNA 100 Installation and maintenance instructions

Daishiba

Daishiba DSP?45HCA user manual

OEM

OEM DC BWA-SS-9 Installation and maintenance instructions