CONTENTS

1. GENERAL ............................................................................................................ 4

2. SAFETY WARNINGS ........................................................................................... 4

2.1. Usage and installation warnings ........................................................................... 4

2.2. Personal safety warnings...................................................................................... 5

2.3. Transport, storage and handling warnings............................................................ 6

2.4. Freeze protection warnings .................................................................................. 6

3. SYSTEM DESCRIPTION ..................................................................................... 7

4. INSTALLATION .................................................................................................... 8

4.1. General points for installation engineer ................................................................ 8

4.1.1.Preparation before installation .............................................................................. 8

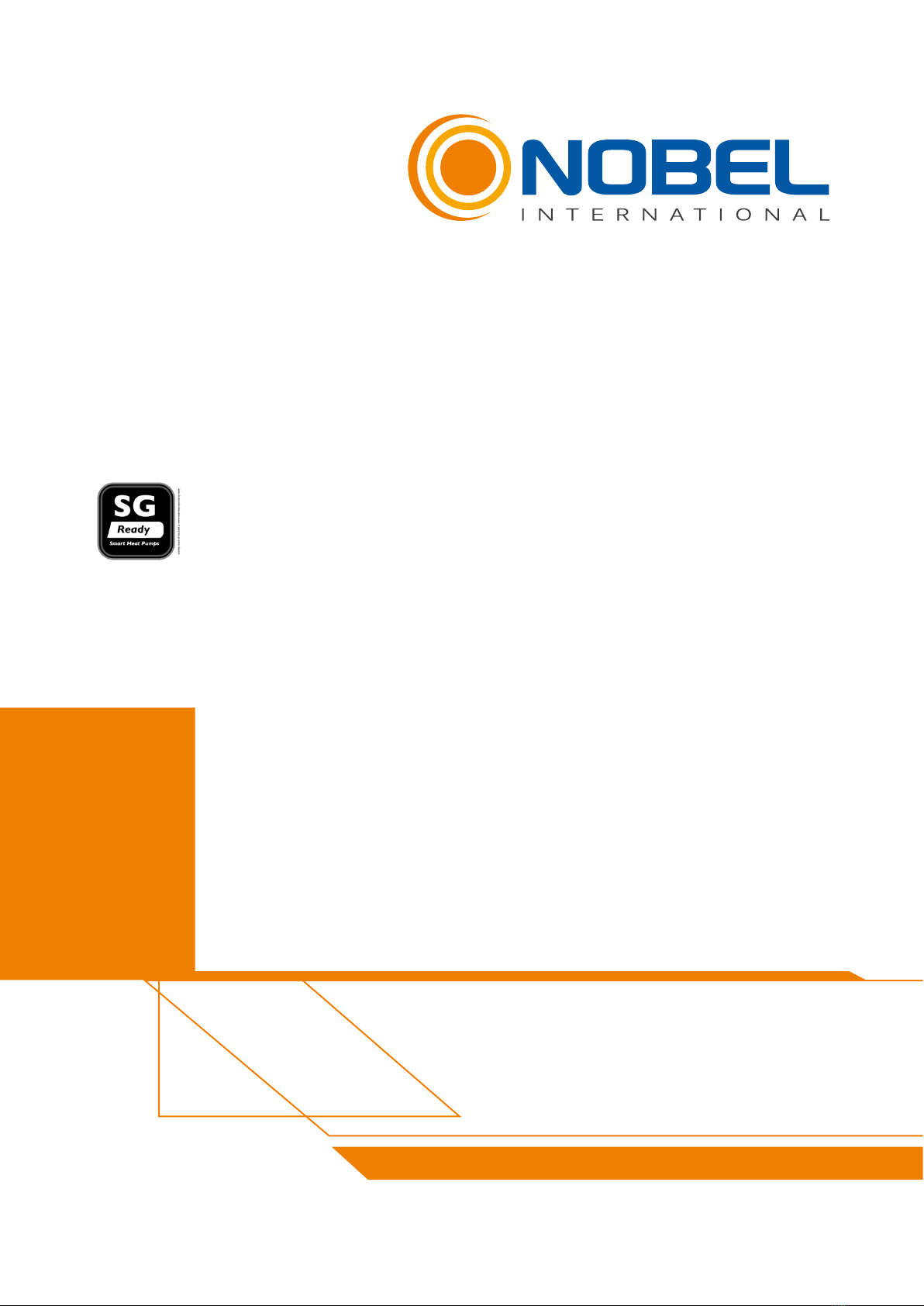

4.1.2.Sitting the heat pump............................................................................................ 8

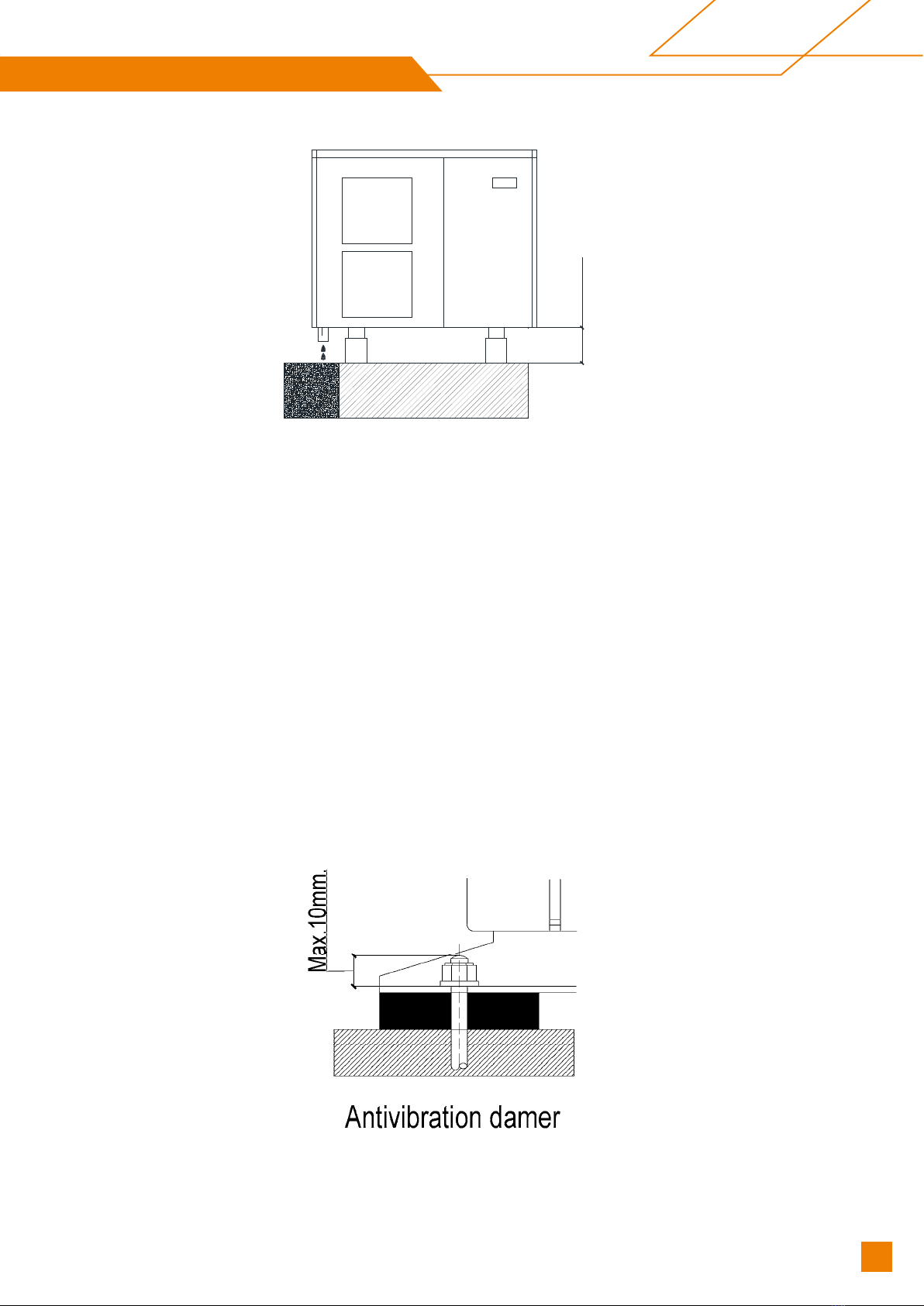

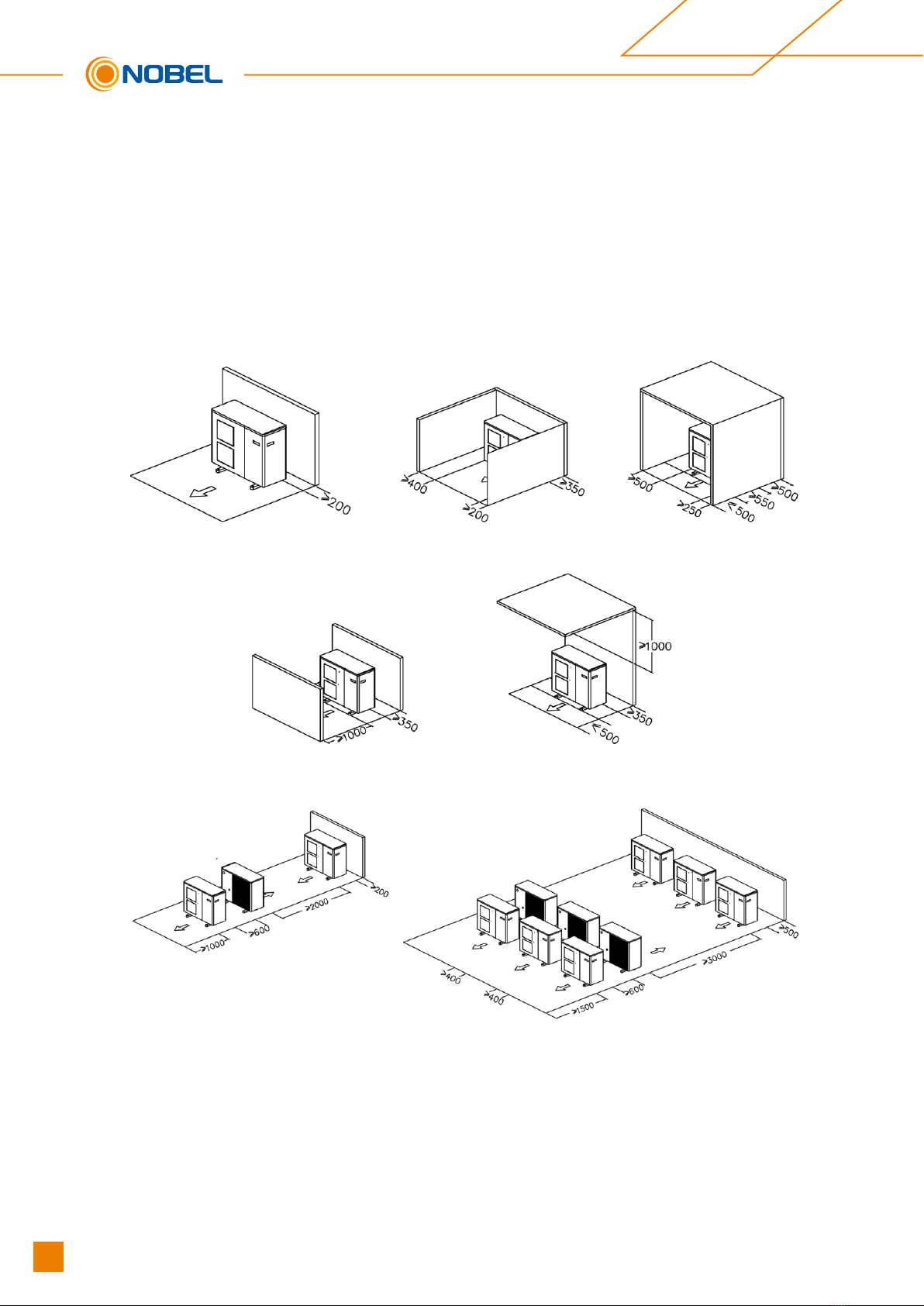

4.1.3.Location requirements between machine and building....................................... 10

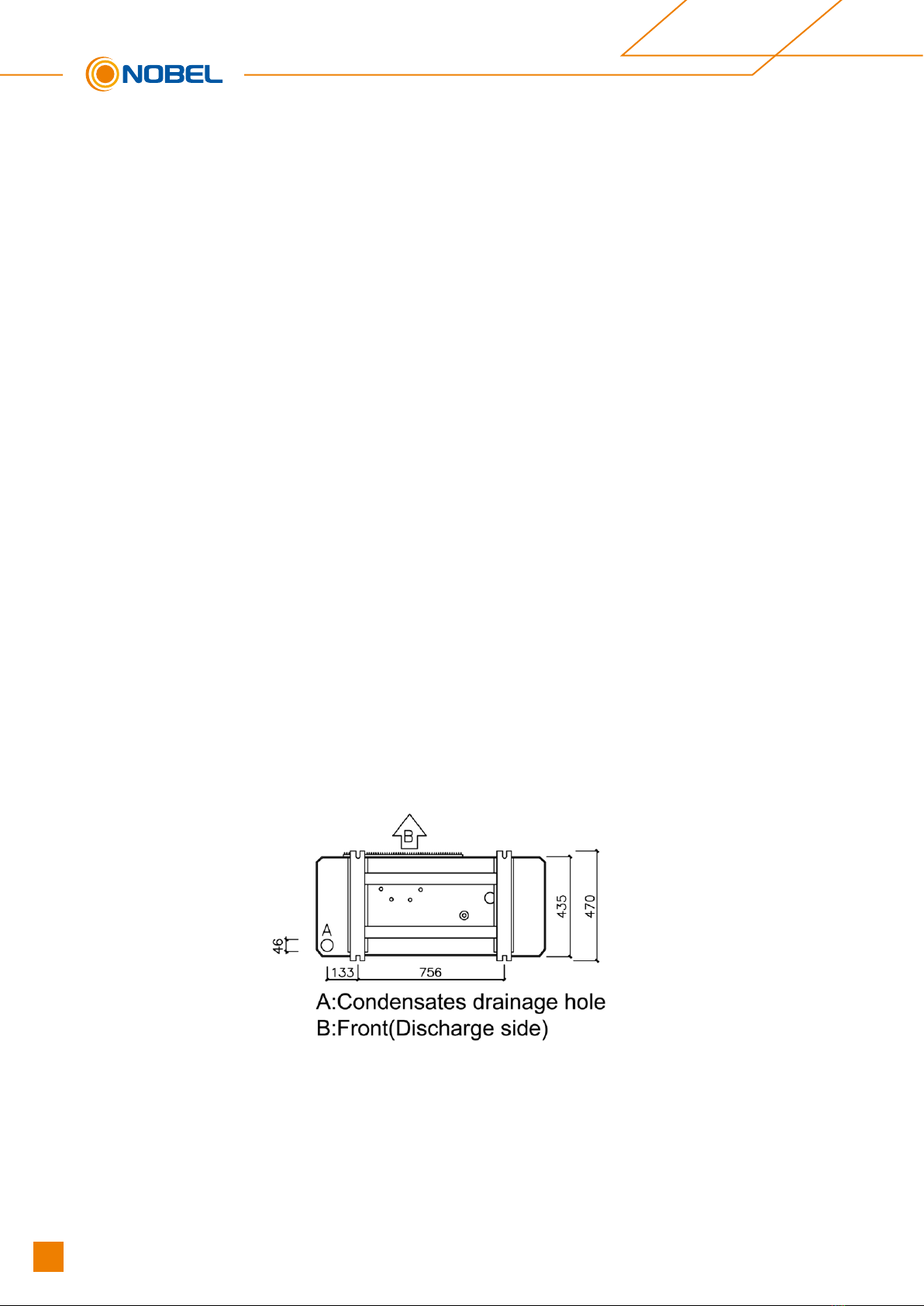

4.1.4.Condensate drainage ......................................................................................... 12

4.1.5.Accessories supplied .......................................................................................... 13

4.1.6.Controller ............................................................................................................ 13

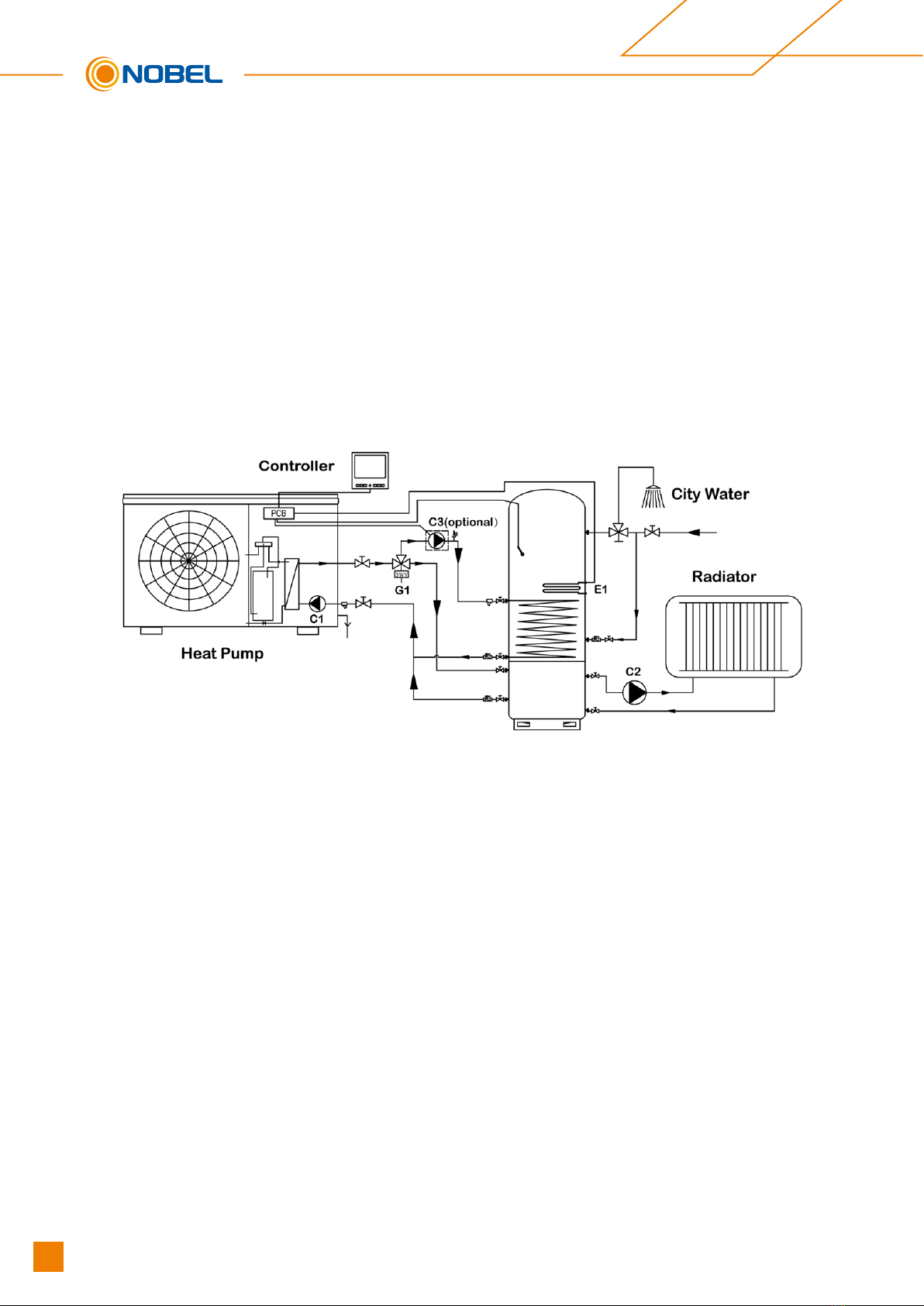

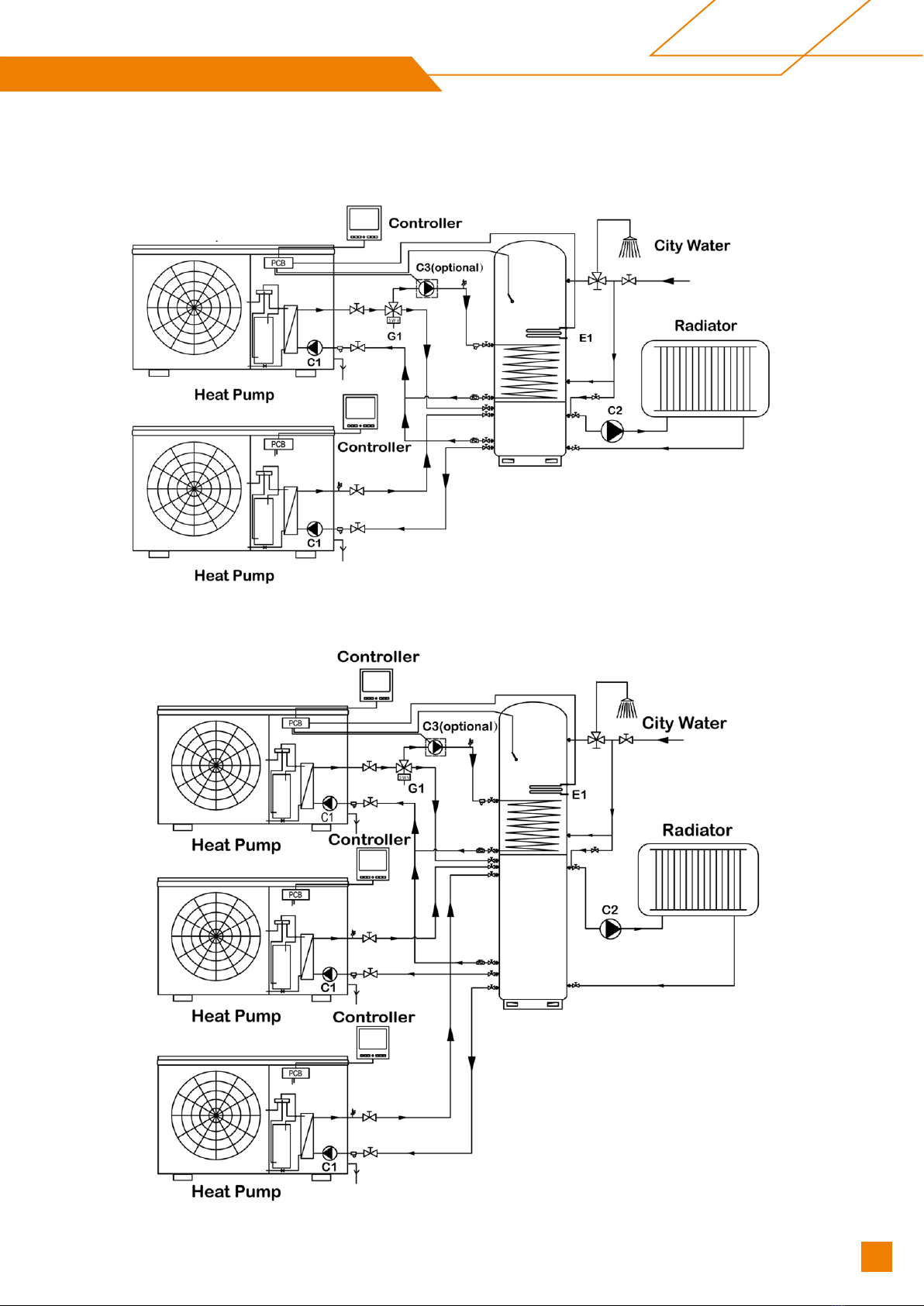

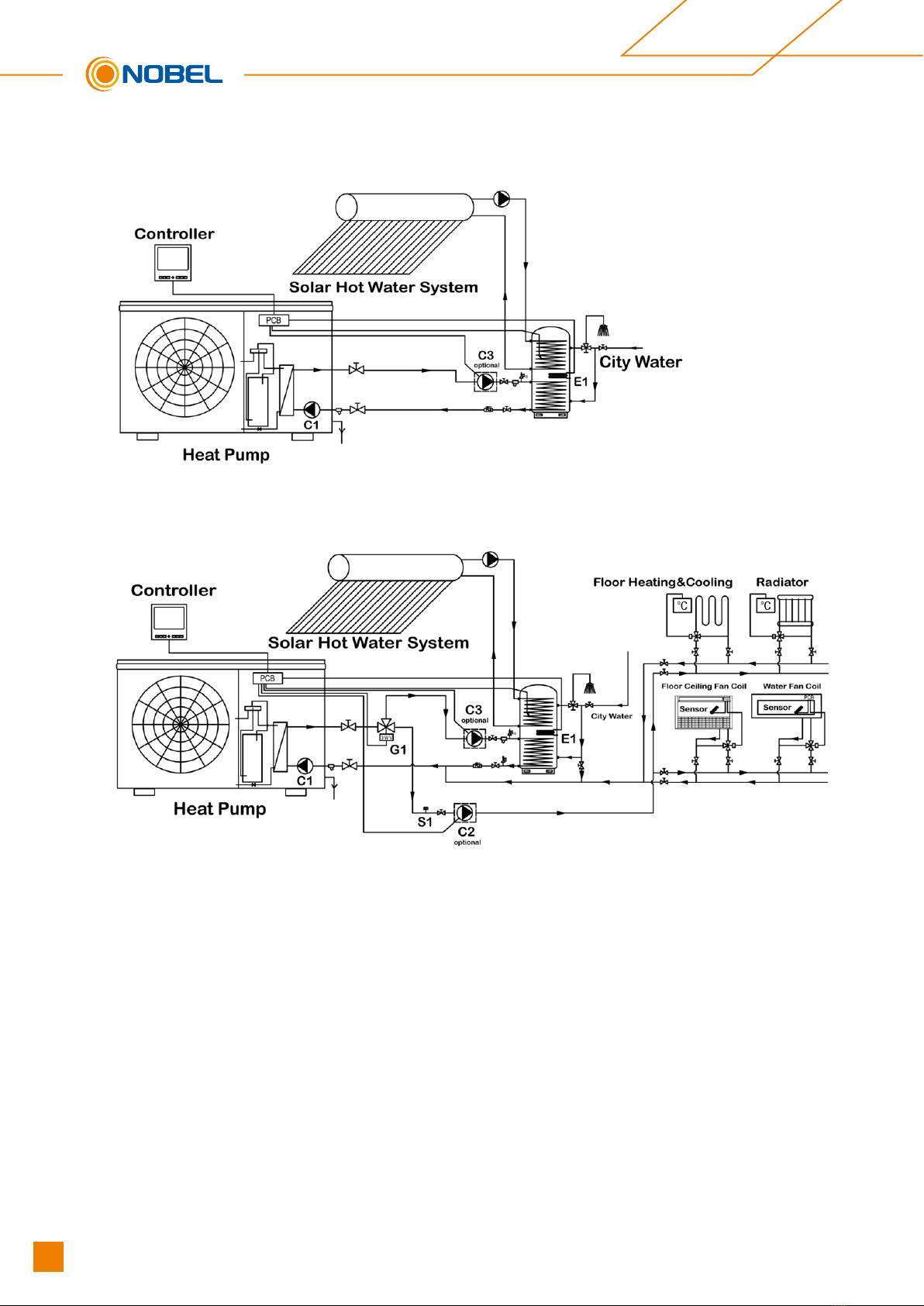

4.2. Installation design ............................................................................................... 14

4.3. Pipe connection .................................................................................................. 17

4.4. Electrical connection........................................................................................... 18

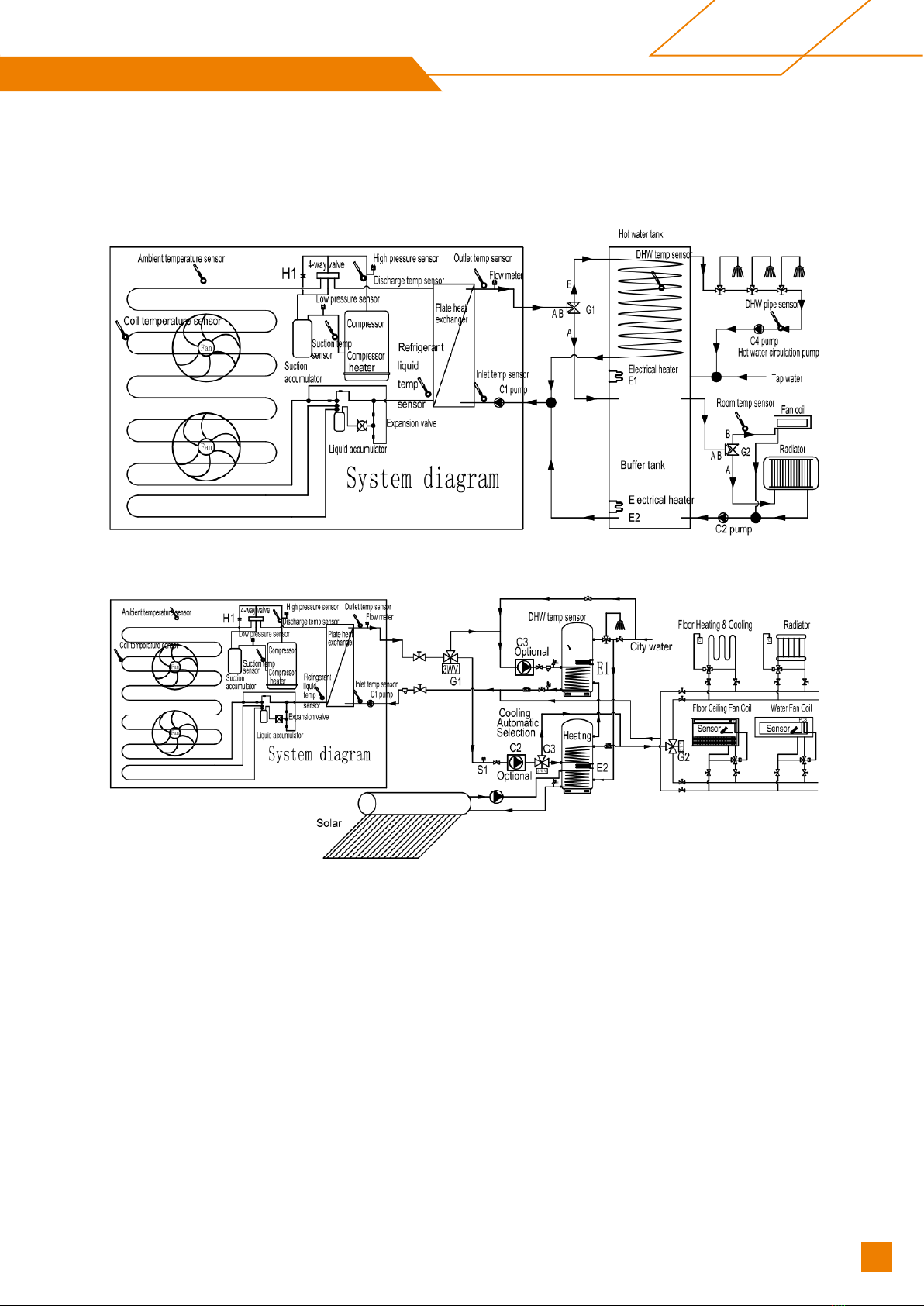

4.4.1.System diagram.................................................................................................. 19

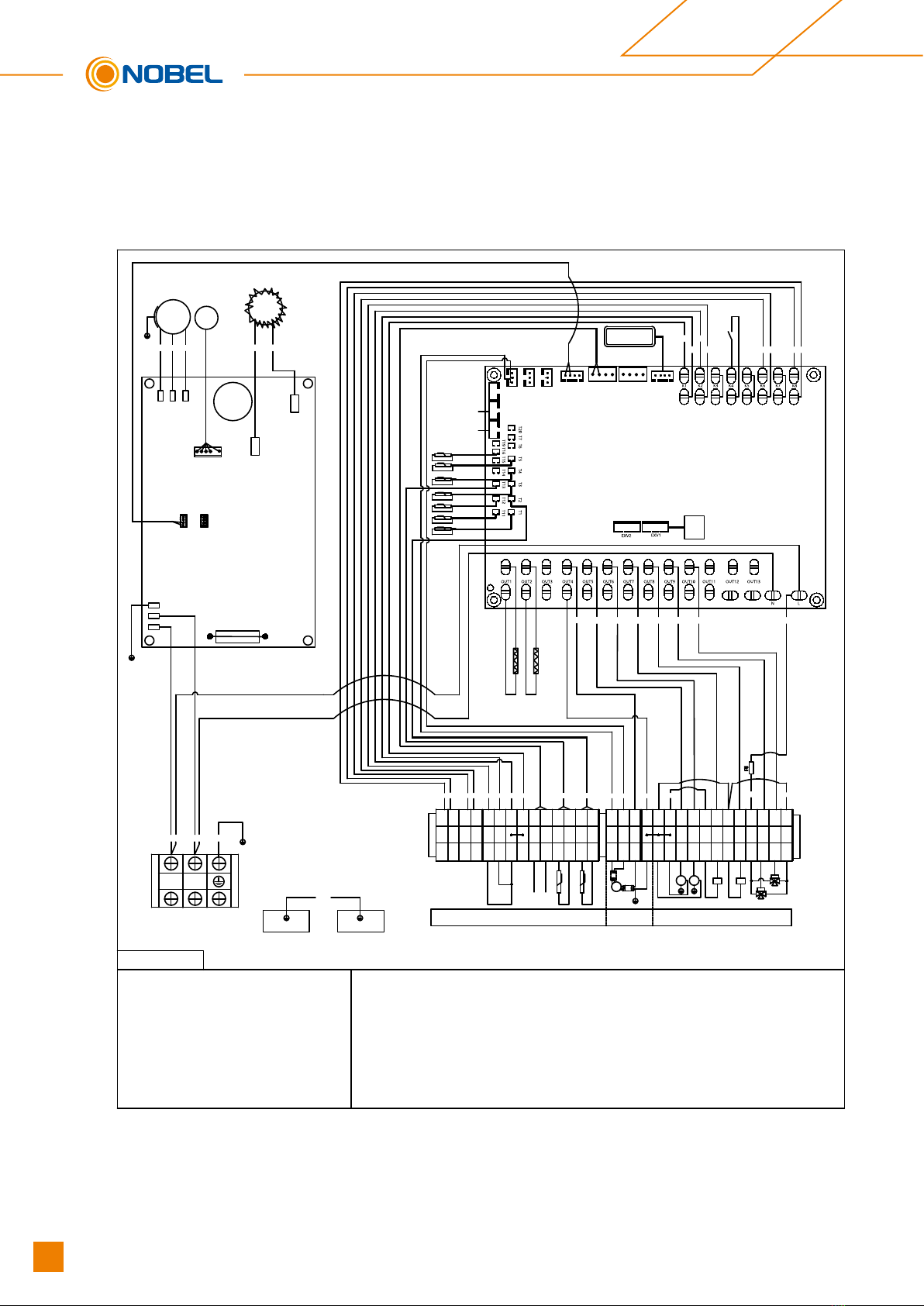

4.4.2.Wiring diagram.................................................................................................... 20

4.4.3.Auxiliary electrical heater connection ................................................................. 24

4.4.4.Installation drawing ............................................................................................. 24

4.4.5.DHW anti-freeze ................................................................................................. 26

4.4.6.AC anti-freeze..................................................................................................... 26

4.5. Commissioning ................................................................................................... 26

4.5.1.Preparations ....................................................................................................... 26

4.5.2.Inspection before start up ................................................................................... 27

4.5.3.Start up and commissioning ............................................................................... 27

5. CONTROLLER................................................................................................... 28

5.1. Electric parts control program working theory .................................................... 28

5.2. Operating mode principle.................................................................................... 29

5.3. Wired controller................................................................................................... 30

5.3.1.Main interface ..................................................................................................... 30

5.3.2.Buttonsdenitionandaction............................................................................... 31

5.4. Night mode ......................................................................................................... 43

5.5. Communication with controller............................................................................ 43

5.6. Denitionofabbreviationdisplayedinthecontroller .......................................... 43

6. TECHNICAL SPECIFICATION........................................................................... 45

6.1. Internalview........................................................................................................ 45

6.2. System drawing .................................................................................................. 47

6.3. Dimensions(mm)................................................................................................. 48

6.4. Specication ....................................................................................................... 49

7. MAINTENANCE ................................................................................................. 50

8. HOW TO GET THE MOST OUT OF YOUR HEAT PUMP ................................. 51

Appendix I: WI-FI operation ............................................................................. 52

Multifunctional Heat Pump R290

3

Technical Manual - Multifunctional Heat Pump R290