7

DISPLAY CAPACITY STAGE

C1 Cooling,StageOneCall,Low

C2 Cooling, Stage One Call, Intermediate

C3 Cooling,StageOneCall,LowHigh

C4 Cooling,StageTwoCall,NominalHigh

C5 Cooling, Stage Two Call, Boost

H1 Heating,StageOneCall,Low

H2 Heating, Stage One Call, Intermediate

H3 Heating,StageOneCall,LowHigh

H4 Heating,StageTwoCall,NominalHigh

H5 Heating, Stage Two Call, Boost

0L Startup Delay (5 minutes)

_System Powered but Idle

0F In Defrost

Table 5. Interface Board Operating Codes

For example, with a first stage call in cooling, if the setpoint

was satisfied quickly, the unit will restart the next time at a

lower speed.At a low or intermediate speed, if the setpoint is

not satisfied within 45 minutes, the speed will be increased.

If the unit cycles off after having a speed increase, the entire

next cycle will be at the higher speed. Also, the outdoor fan

will run for an extra minute after the compressor shuts off.

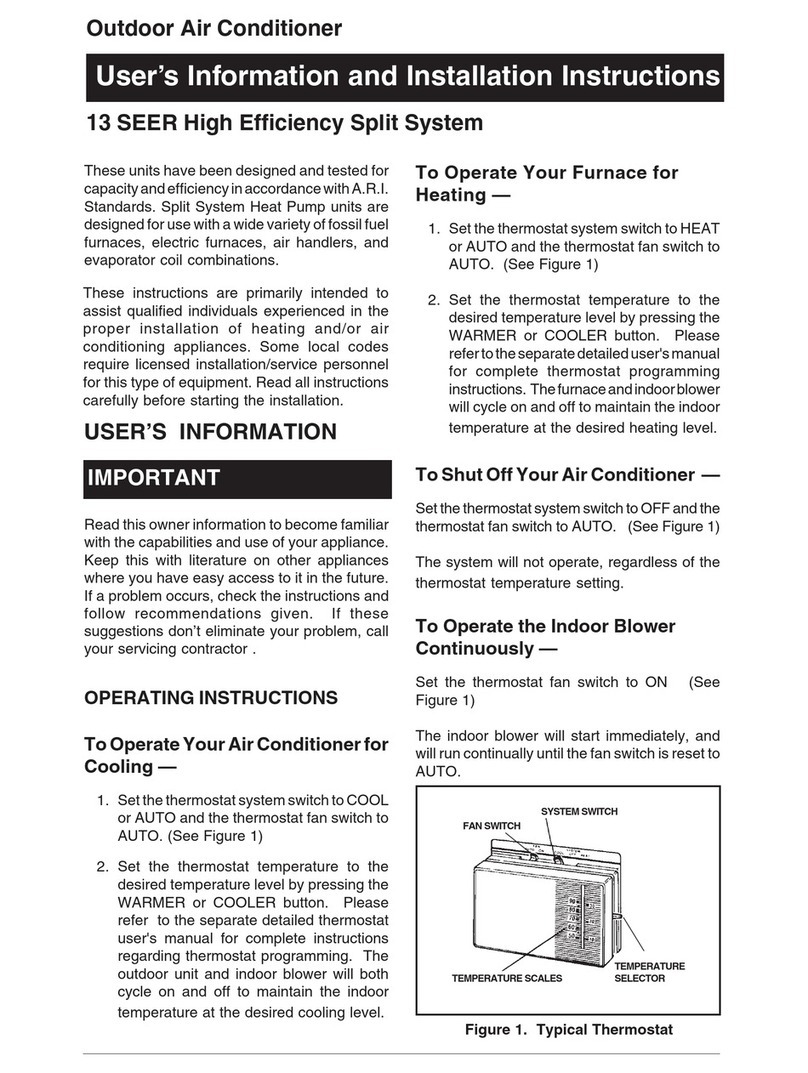

The actual current operating compressor speed can be

determinedbycheckingthe2-characterdisplayontheinterface

board. Refer to Figure 7 (page 12) and Table 5 (page 7).

Control operation is protected under U.S. patent number

US 8,011,199 B1

Blower Flow Rates

Depending on the indoor equipment installed, blower air flow

may be adjustable. When paired with a matching model air

handler or gas furnace, the airflow is set by DIP switches on

the blower control board, providing one flow for second stage

compressorspeedsandalowerflowforfirststagecompressor

speeds.Refertotheindoorequipmentmanualsforinstructions

onhowtoselectthedesiredairflows.Highstageairflowsused

forequipmentratingsareasfollows:

• 2ton-800cfm

• 3ton-1200cfm

• 4ton-1350cfm

• 5ton-1500cfm

Refertoindoorequipmentinstallationinstructionsforoptions,

operation, and field wiring relating to dehumidification and

humidification.

Delay Override

Whenperformingstartuptestsortroubleshooting,the5minute

startup delay can be skipped by shorting the two J4Test pins

indicatedinFigure7forabout1secondwhilethecompressor

is off and waiting to start.NOTE:This will also clear the faults

stored in memory.

Defrost Cycle

Thisequipmentfeaturesanadaptivedemanddefrostinheating

mode, which is enabled when the outdoor coil temperature

is below 35° F. After approximately 35 minutes of operating

in this condition for the first time, a defrost will be forced to

checkthedifferencebetweenthecoiltemperatureandoutdoor

air temperature, with the coil unfrosted.Subsequent defrosts

will be triggered when this temperature difference increases

(coil temperature drops) by an additional 6° F, referenced to

the outdoor ambient at that time.If this has not occurred by 6

hours of operation (with the coil below 35°), a defrost will be

runregardless.Followingeachdefrostsequence,theunfrosted

air-to-coiltemperaturedifferenceisrechecked,andthatvalue

is used to determine the next defrost trigger temperature. In

this way the effect of frosting up is always compared to the

unfrosted performance of the coil in its current condition.

During every defrost cycle the compressor first shuts off, the

reversingvalveshifts,thecyclereversestoheatuptheoutdoor

coil until the coil reaches the defrost termination temperature

setting(70°Fbydefault),thenthecompressorshutsoffagain

forthereversingvalvetoshiftbacktotheheatingmode.During

the following 8 minutes (approximately) the unit will heat at

nominal speed to perform the coil differential temperature

check described above, after which the system will return to

normal heating capacity control.

If a defrost termination temperature setting other than 70° is

desired,itcanbeadjustedbetween50°Fand80°Fbyplacing

ajumper betweenpairs ofpins on J1near the lowerright side

of the interface board inside the control panel (Figure 7). A

jumper is not required, however.

The defrost cycle may be artificially triggered for service and

troubleshooting purposes. With the unit running in heating

mode, simply short together the two J4 Test pins shown in

Figure 7 for about 1 second. NOTE: This will also clear the

faults stored in memory. The 2-character display will show

“0F”whenthedefrostcycleisunderway.

Auxiliary Heat

During the coil heating phase of each defrost cycle, the 18

SEER iQ heat pump will call for auxiliary heat (electric strip

heat or gas furnace). Depending upon the features and

functionality of the installed thermostat, auxiliary heat may

also be turned on in the case of a faulted heat pump, if the

heat pump cannot satisfy heating demand, or if outdoor air

temperatureisbelowa“balancepoint”setting.

Diagnostic Display

The interface board located inside the control panel has a

two character display which provides information regarding

operationalstatusandfaulthistory.When24vaccontrolpower

isprovidedtotheboard,thedisplaywillshowsomecombination

of characters.In order to diagnose a problem with the unit, or

to determine its operational status, remove the control panel

cover, then observe the 2-character lighted display on the

interface board. Refer toTables 5 (page 7) and 6 (page 8).