4

NORDYNE also offers water heaters, fire-

places and ventilating systems specifically de-

signed for manufactured housing applications.

Ask your manufactured home retailer, your

heating and cooling contractor, or your dis-

tributor for more information. Write directly to

the factory (PO Box 46911, St. Louis, MO

63146) if you are unable to locate a source for

NORDYNE manufactured housing products in

your area.

1. Furnace Location

The furnace area and the vicinity of any other

gas appliance must be kept clear and free of

combustiblematerials,gasoline,andotherflam-

mable vapors and liquids. Do not store or use

flammable items such as paint, varnish, or

strippers in the vicinity of the furnace.

Do not use the furnace closet or area next to

the furnace as a storage area. This area must

be kept clear, clean, and free of lint. The

furnace must also be kept clear of loose or

exposed insulation materials. Examine the fur-

nace area when the furnace is installed or

when insulation is added. Some insulation

materials may be combustible.

Do not use this furnace if any part has been

under water. Immediately call a qualified ser-

vice technician to inspect the furnace and to

replace any part of the control system and any

gas control which has been under water.

Familiarize yourself with the controls that shut

off the gas and electrical power to the furnace.

Ifthefurnaceistobeshutdownforanextended

periodoftime,turnoffboththegasandelectrical

power. For your safety always turn off both the

gas and electrical power before performing

service or maintenance on the furnace.

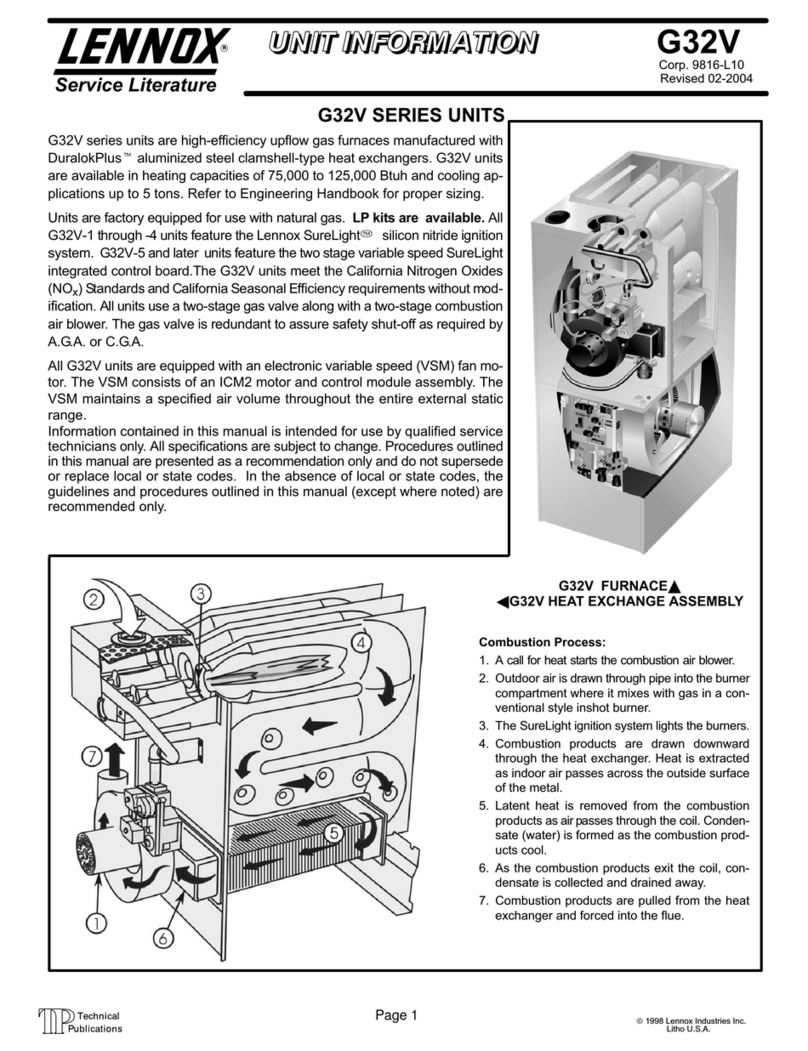

2. Combustion Air Supply

A furnace needs an adequate supply of com-

bustion and ventilation air for proper and safe

operation. Follow the installation instructions

included with the furnace to properly vent air to

the combustion air inlet and exhaust the prod-

ucts of combustion to the outside from the

exhaust vent.

If the furnace is operated with a restricted com-

bustion air supply, the pressure switch will

open, turning off the gas supply to the burners.

(See Figure 1). DO NOT install a jumper wire

across this switch to defeat its function. If this

switch must be replaced, use only authorized

replacement parts from your authorized dis-

tributor.

If the furnace is operated with inadequate

combustion air supply, due to sooting of the

heat exchanger, or partial blockage of the vent

or air intake pipe, the flame roll-out control

switch located above the burners may open,

turning off the gas supply to the burners. The

flame roll-out control is a manually resettable

device (See Figure 1). If the flame roll-out

control opens again after once reset, DO NOT

install a jumper wire across this switch to

defeat its function. DO NOT reset the control

without identifying and correcting the fault con-

dition which caused the control to trip. If this

switch must be replaced, use only authorized

replacement parts from your authorized dis-

tributor.

Airopeningsinwarmairregisters,andreturnair

grilles must not be restricted.

!

CAUTION:

Combustion air must not be drawn

from occupied spaces.

To maximize heat exchanger life, the combus-

tion air must be free of chemicals which form

corrosive acidic compounds in the combustion

gases. Some examples of these chemicals are

chlorine, fluorine, and sulphur. Some common

sources of these chemicals are detergents,

bleaches,aerosolsprays,cleaningsolvents,and

a wide variety of commercial and household

products.

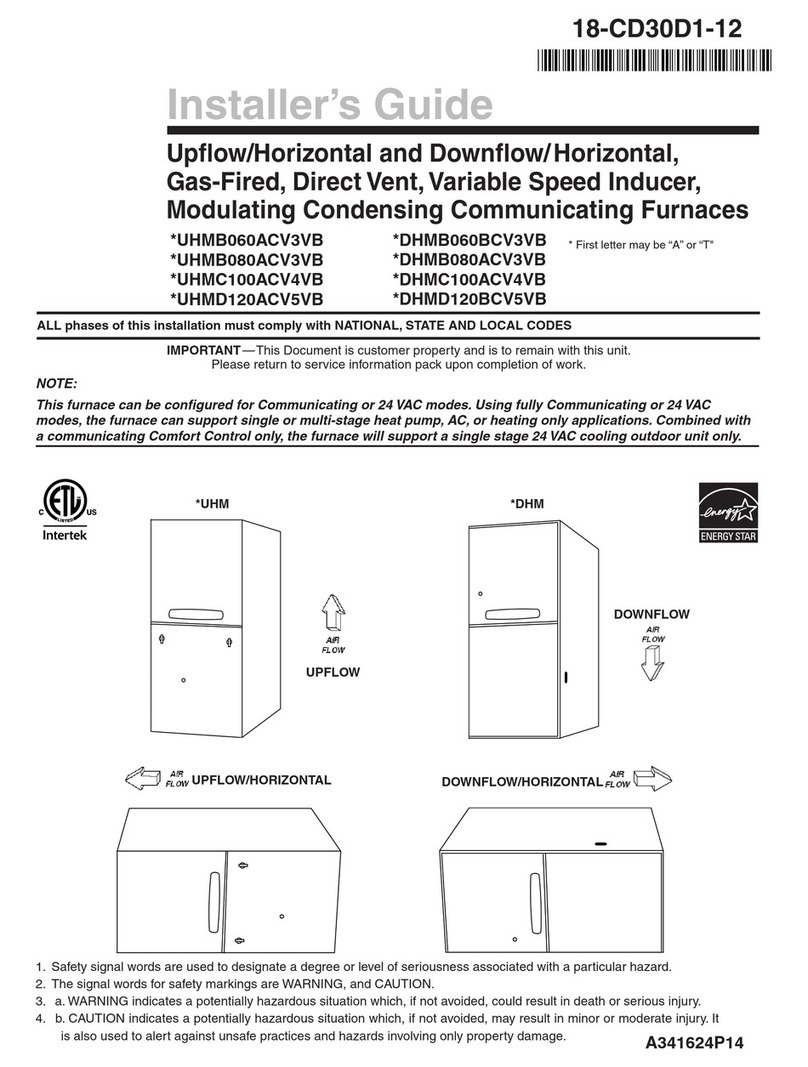

3. Return Air Supply

ForM3models,thereturnairopeningislocated

at the front of the furnace. The floor or platform

on which the furnace is mounted must provide

sound physical support of the furnace with no

gaps, cracks, or sagging between the furnace

andfloororplatform. Thecirculatingairductwork

must not be connected to any other heat pro-

ducing device such as a fireplace insert, stove,

etc. Doing so may result in fire, explosion,

personal injury, carbon monoxide poisoning, or

property damage.