7

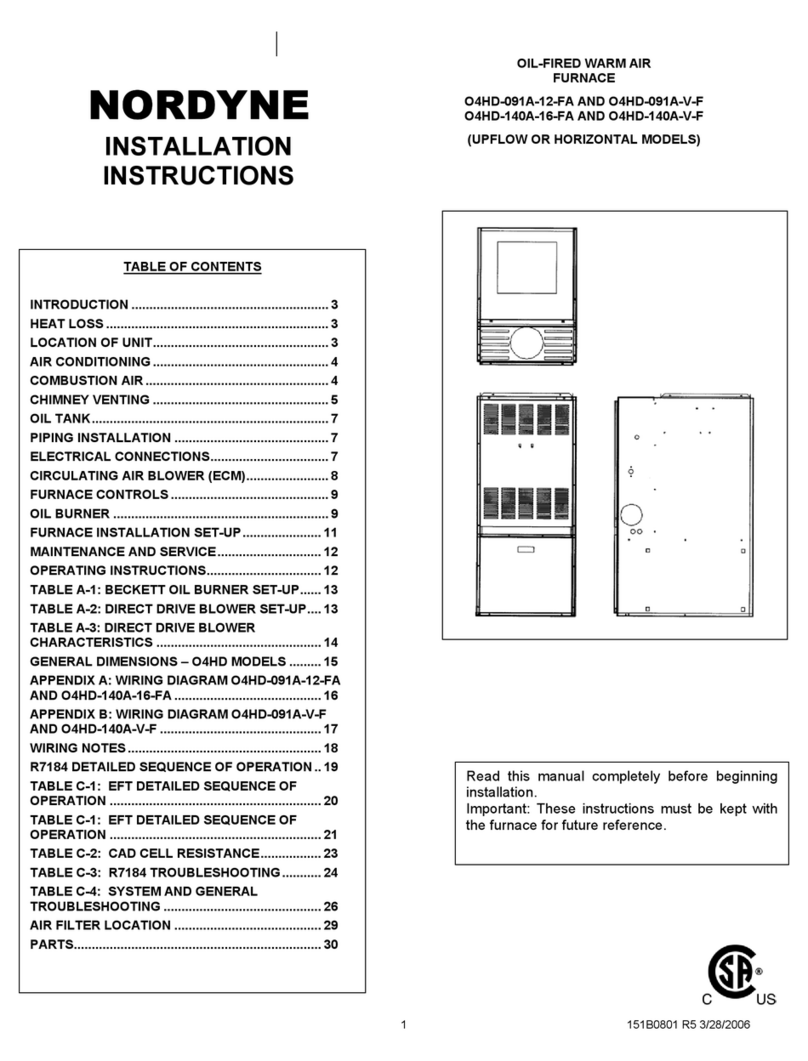

GENERAL INFORMATION

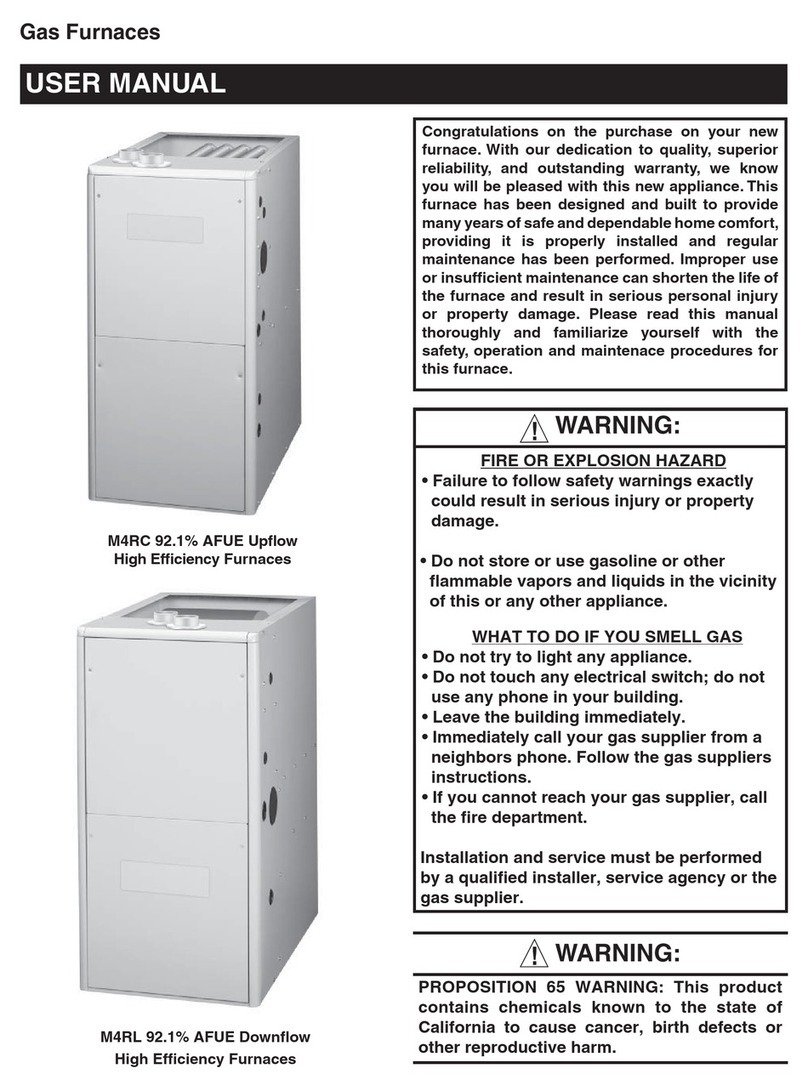

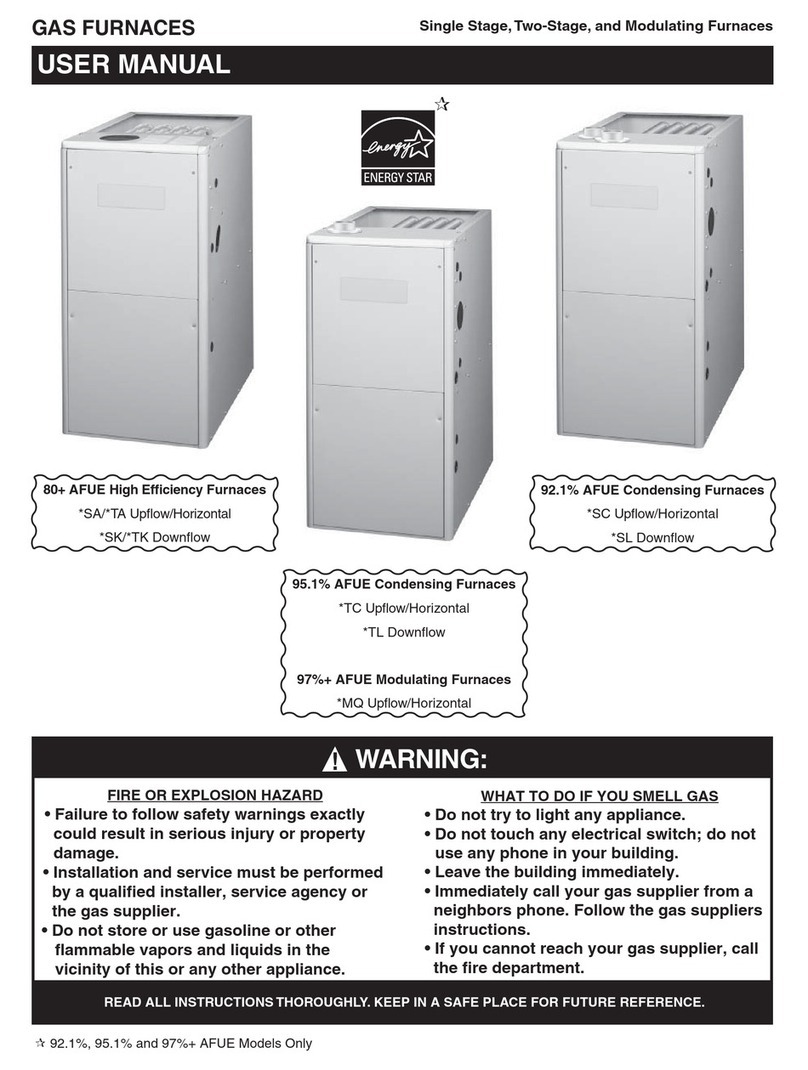

This furnace has been designed and built to

provide many years of safe and dependable

home comfort, providing it is properly installed

and maintained. With regular maintenance, this

furnacewilloperatesatisfactorilyyearafteryear.

Abuse, improper use, and/or improper mainte-

nance can shorten the life of the furnace and

createhazardsforyou. Pleasereadthismanual

carefully to familiarize yourself with operation,

maintenance, and safety procedures for this

furnace.

A regular service and maintenance schedule

should be established to insure efficient and

safe operation of the furnace. See Section 5 for

maintenance procedures and schedules.

Devices attached to the flue or vent for the

purposeofreducingheatlossupthechim-

ney have not been tested and have not

been included in the design certification

of this furnace. We, the manufacturer, can

not and will not be responsible for injury

1. Safety Information

The furnace area and the vicinity of any other

gas appliance must be kept clear and free of

combustible materials, gasoline, and other

flammable vapors and liquids. Do not store or

use flammable items such as paint, varnish, or

strippers in the vicinity of the furnace.

Donotusethefurnace closetor areanext tothe

furnace as a storage area. This area must be

kept clear, clean, and free of lint. The furnace

must also be kept clear of loose or exposed

insulation materials. Examine the furnace area

when the furnace is installed or when insulation

is added. Some insulation materials may be

combustible.

For proper and safe operation, the furnace

needsairforcombustionandventilation.Donot

blockor obstructairopenings on thefurnace, or

any air openings where the furnace may be

installed, including any surrounding spaces.

Should the gas supply fail to shut off or if

overheatingoccurs,shutoffgasvalvetothe

furnacebeforeshuttingoffelectricalsupply.

Do not use this furnace if any part has been

under water. A flood-damaged furnace is

extremelydangerous.Attempstousethefurnace

canresultinfireorexplosion.Aqualifiedservice

agency should be contacted to inspect the

furnace and to replace all gas controls, control

system parts, electrical parts that have been

wet or the furnace if deemed necessary.

Familiarize yourself with the controls that shut

off the gas and electrical power to the furnace.

Ifthe furnace is tobeshut down for anextended

periodoftime,turnoffboththegasandelectrical

power. For your safety always turn off both the

gas and electrical power before performing

service or maintenance on the furnace.

2. Combustion Air Supply

A furnace needs an adequate supply of

combustion and ventilation air for proper and

safe operation. Follow the installation

instructions included with the furnace to

properly vent air to the combustion air inlet

and exhaust the products of combustion to

the outside from the exhaust vent.

For 90+ and 93+ Models: If the furnace is

operatedwitharestrictedcombustionairsupply,

thepressureswitchwillopen,turningoffthegas

supply to the burners. (See Figures 2 and 3).

DO NOTinstall a jumper wire across this switch

to defeat its function. If this switch must be

replaced,useonlythereplacementpartspecified

in the Replacement Parts List.

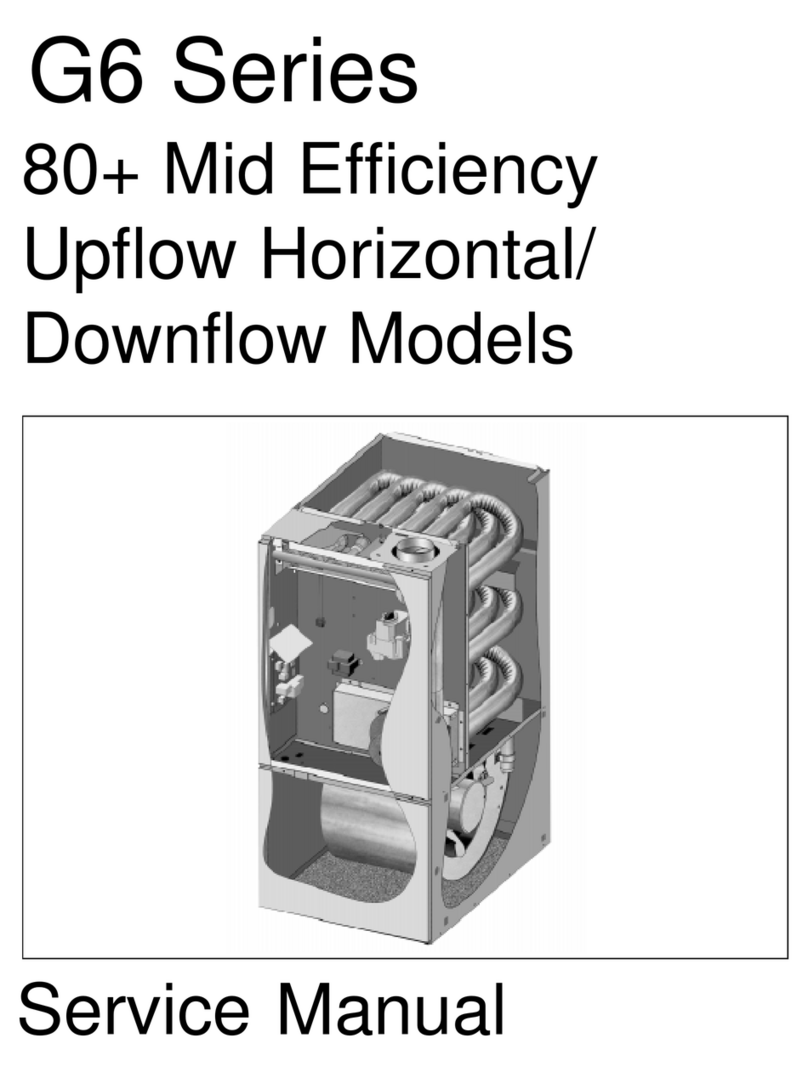

For 80+ Models: If the furnace is operated with

inadequatecombustion air supply,theflame roll-

outcontrolswitchlocatedabovetheburnersmay

open, turning off the gas supply to the burners.

Theflameroll-outcontrolisamanuallyresettable

device (See Figure 1 and 4). DO NOT install a

jumperwireacrossthisswitchtodefeatitsfunction.

DO NOT resetthe control without identifying and

correcting the fault condition which caused the

controltotrip. Ifthisswitchmustbereplaced,use

only the replacement part specified in the

Replacement Parts List.

Airopeningsinwarmairregisters,andreturnair

grilles must not be restricted.

!

CAUTION:

Combustion air must not be drawn

from a corrosive atmosphere.