15

theductsystem.Caremustbetakentomaintaintheproper

maximum pressure rise across the furnace, temperature

riseandflowrate.Thismaymeanincreasingtheductsize

and/orreducingtheblowerspeed.Thesetreatmentsmust

beconstructedandinstalledinaccordancewithNFPAand

SMACNAconstructionstandards.Consultwithlocalcodes

for special requirements. For best sound performance,

install all the needed gaskets and grommets around

penetrationsintothefurnace,suchasforelectricalwiring.

FURNACE INSTALLATION

NOTE: These Installation procedures are suggested for

typical furnace installations. Since each installation is

different, the sequence of instructions may differ from

the actual installation.

ONLY QUALIFIED HVAC TECHNICIANS SHOULD

INSTALL THIS FURNACE.

The installer must be familiar with and comply with all

codes and regulations applicable to the installation of

these heating appliances and related equipment. In

the absence of local codes, the installation must be in

accordance with the current provisions of one or more of

the following standards.

• FederalManufacturedHomeConstructions&Safety

Standard (H.U.D. Title 24, Part 3280.707[a][2])

• The Standard for Manufactured Home Installations

(ManufacturedHomeSites,Communities,andSet-Ups)

ANSI A225.1 and/or CAN/CSA-2240 MH Series).

• AmericanNationalStandard(ANSI-119.2/NFPA-501C)

for all recreational vehicle installations.

• AmericanNationalStandard(ANSI-Z223.1/NFPA-54)

and/orCAN/CGAB149forallgas-firedfurnacemodels.

• AmericanNationalStandard(ANSI-C1/NFPA-70)and/or

CSA22.1CanadianElectricCodePart1forallelectrical

field wiring.

AboutTheFurnace

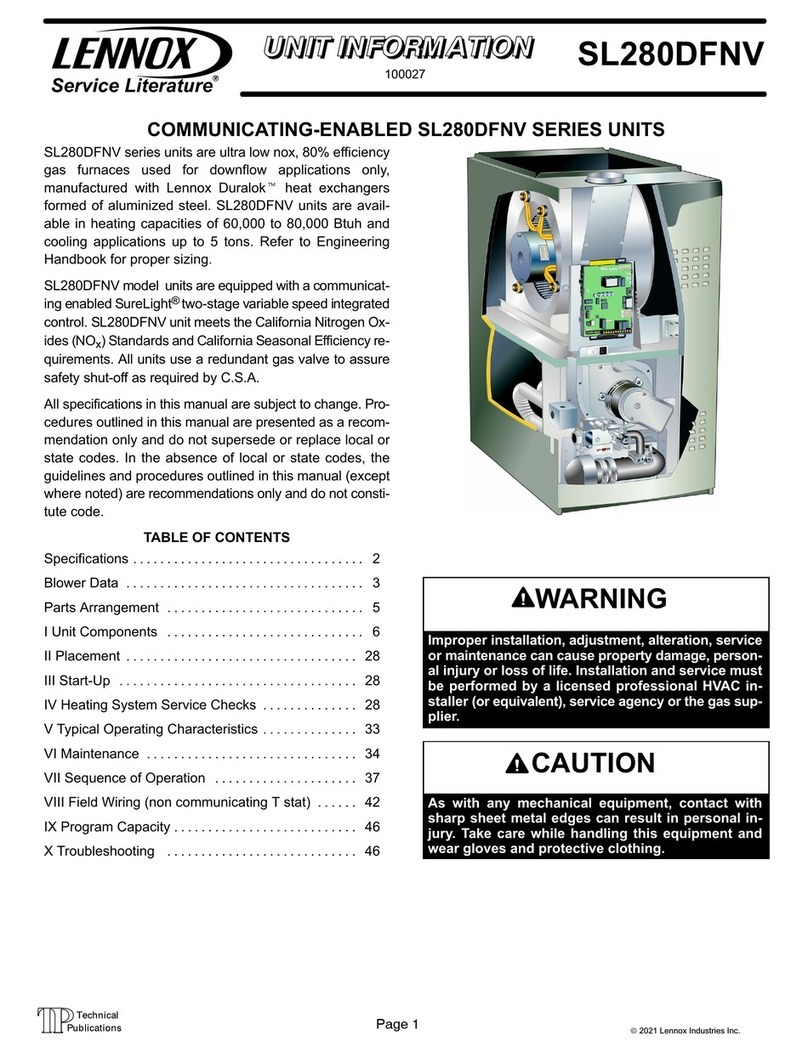

The *M4 Series furnace is designed only for indoor

installationsandcanbereadilyconnectedtothehighstatic

duct system of a home. Units are approved for single/

multistory residential or mobile/modular/manufactured

structures in freestanding/closet/alcove downflow only

configurations.

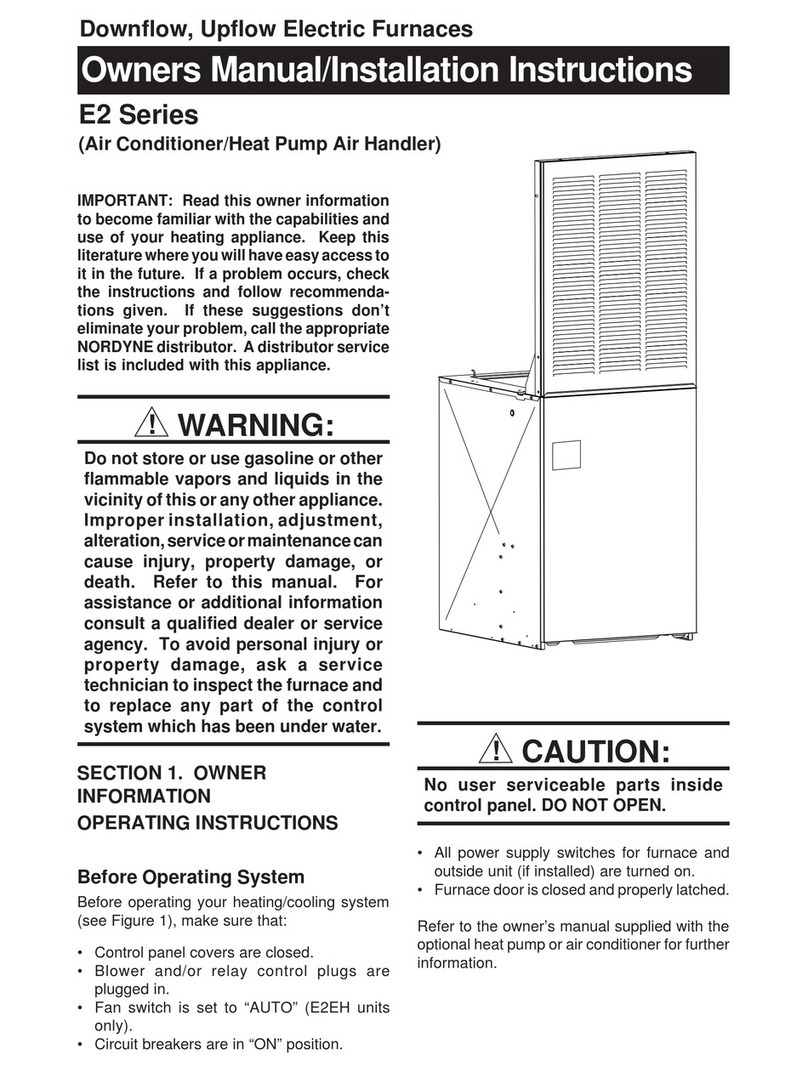

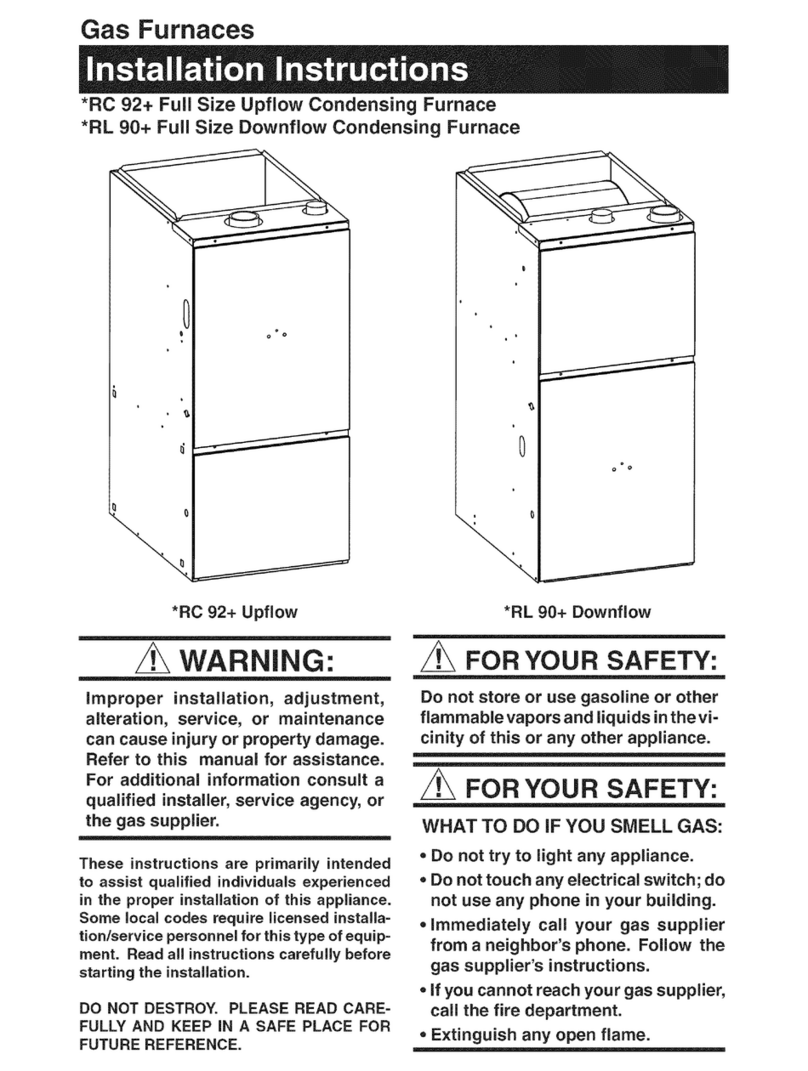

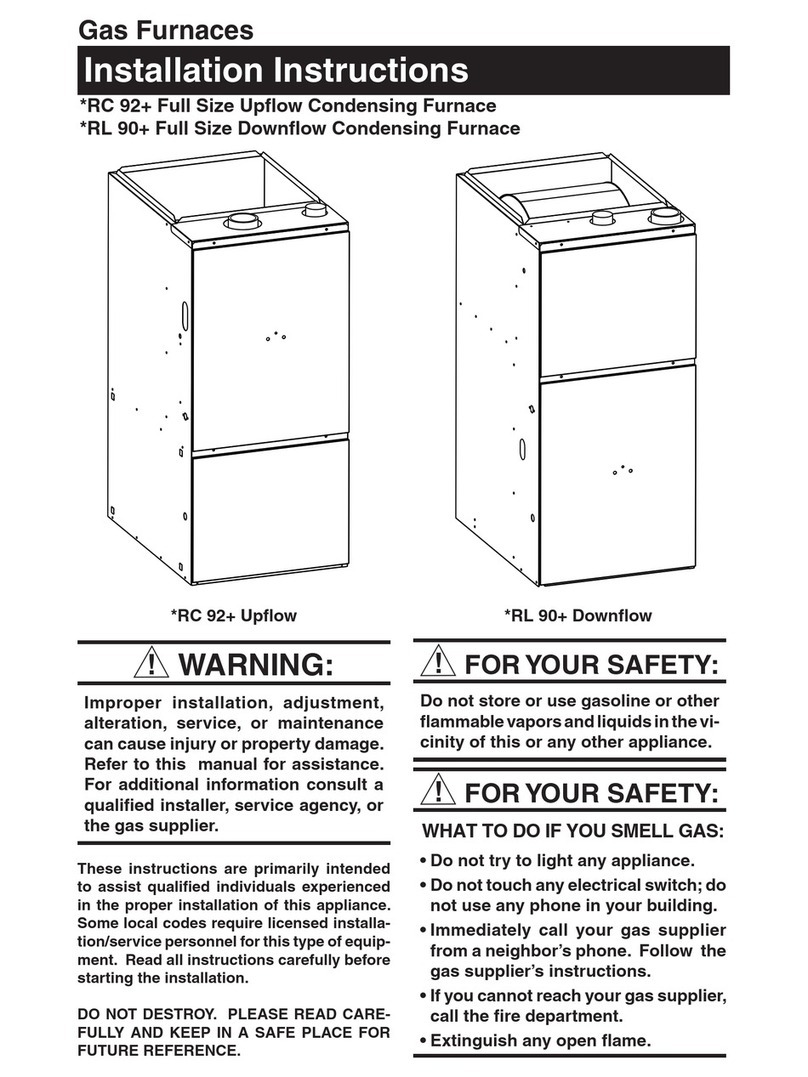

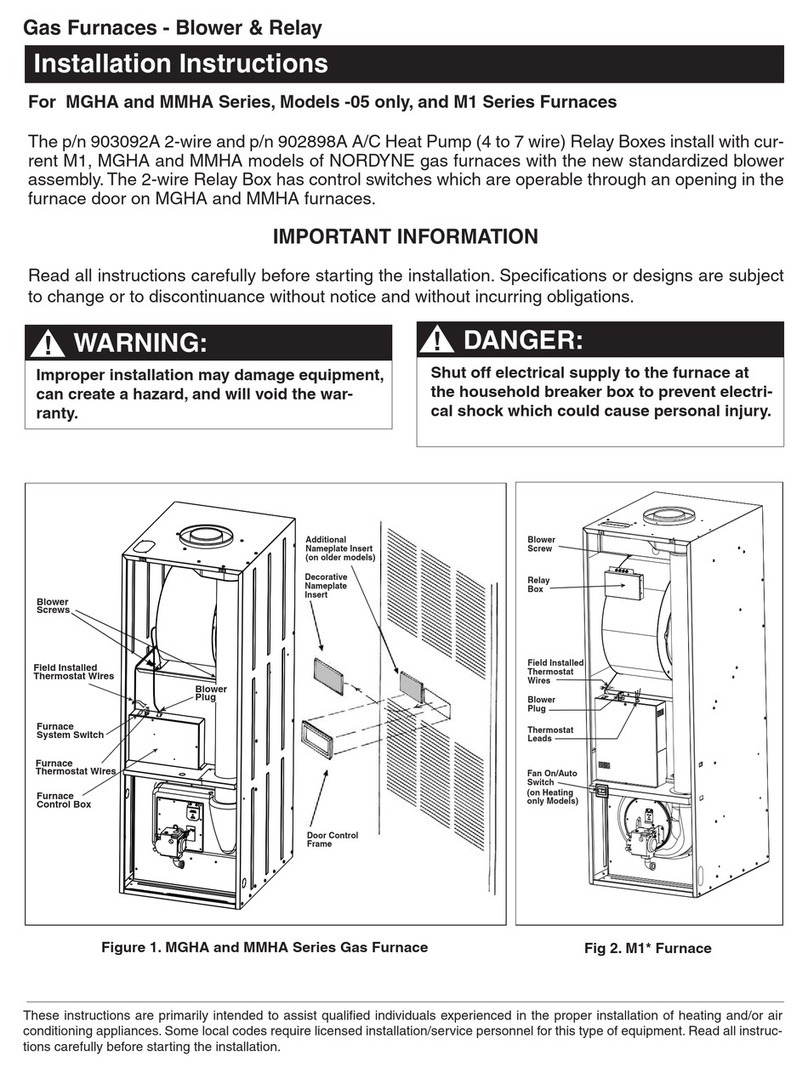

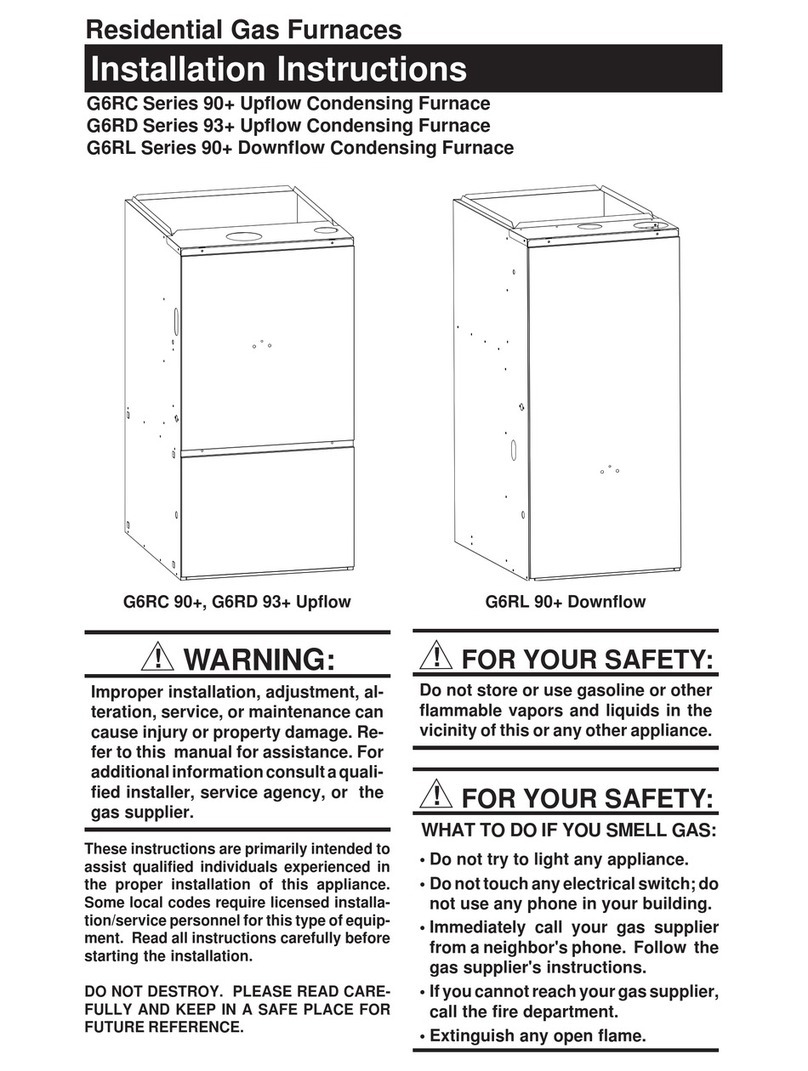

*RCseriesgasfurnacesareshippedreadyforinstallation

intheupflowpositionwithupflowreturnair.*RLseriesgas

furnaces may only be used for downflow operation. See

Figure 1 (page 5) for the required clearances needed

to move the furnace to its installation point (hallways,

doorways, stairs, etc).

Upflow and downflow models must be installed with

the Nordyne A/C coil box which are listed according to

the cabinet size of the furnace: “B” cabinet - 920169,

“C” cabinet - 920171, and “D” cabinet - 920172.

Approved installation, operation, and maintenance of

this appliance must be in accordance with the listed

specifications contained in these instructions and other

documents supplied with the furnace and/or optional air

conditioningequipment.Unlessitisnoteddifferentlyinthis

manual,onlyusefactoryauthorizedkitsandaccessorieson

thisappliance.Refertolocalauthoritieshavingjurisdiction

for further information.

BeforeYouInstallthisFurnace

√This equipment is securely packaged at the time of

shipmentanduponarrivalshouldbecarefullyinspected

for damage prior to installing the equipment at the job

site.Claimsfordamage(apparentorconcealed)should

be filed immediately with the carrier.

√Checkthe electricalsupply andverify thepower supply

isadequateforunitoperation.Thesystemmustbewired

and provided with circuit protection in accordance with

localbuildingcodes.Ifthereisanyquestionconcerning

the power supply, contact the local power company.

√Verify the air delivery of the furnace is adequate to

handle the static pressure drop of the coil, filter, and

duct work.

LocatingtheFurnace

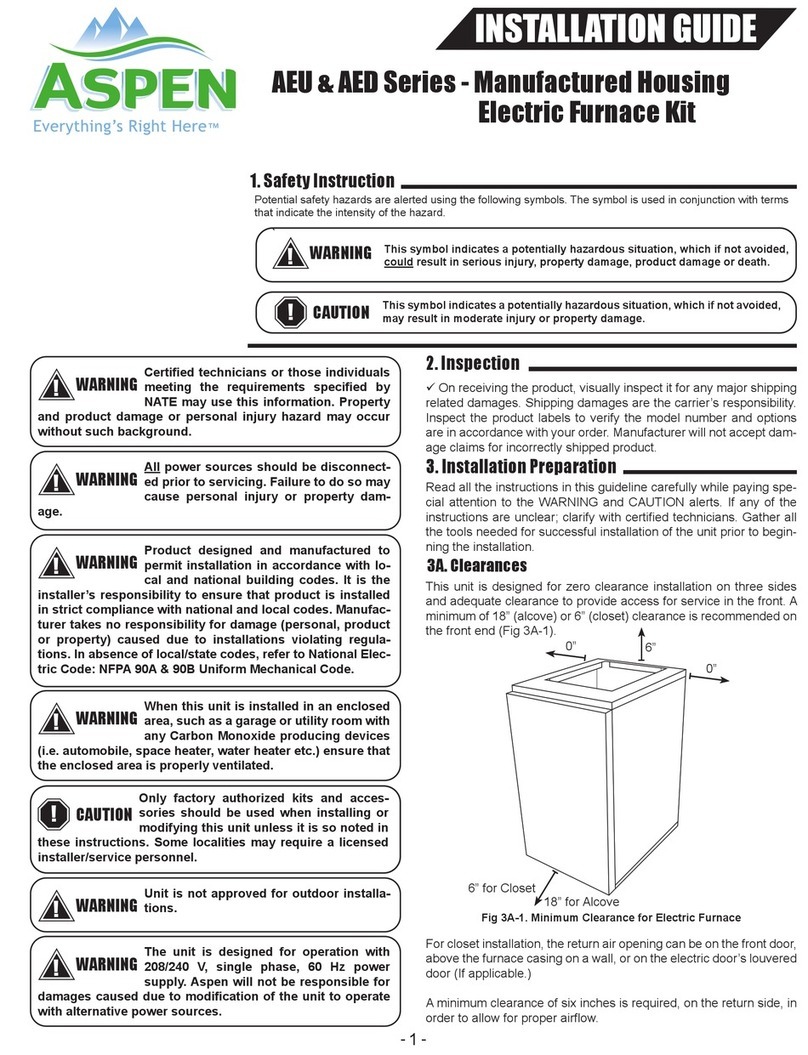

• Thedimensionsoftheroomoralcovemustbeableto

accommodate the overall size of the unit and required

clearances to combustible materials listed in Figure 1

(page 5). Access for positioning and servicing must

alsobeconsideredwhenlocatingtheunit.Todetermine

the required clearances needed for installation and

combustible materials, refer to Figure 41 (page 37)

for cabinet dimensions.

• Thefurnacemustbeinstalledonasolidsurfaceandmust

belevelfront-to-backandside-to-sideatinstallation.The

surface that the furnace is mounted on must provide

sound physical support of the unit.

• Thefurnaceshouldbeinstalledasclosetothecenterof

the air distribution system as possible and attached to

a properly installed duct system. Donotusetheback

of the furnace for return air. See pages 13 - 14

for circulating air requirements.

• The furnace must be installed so that all electrical

components are protected from water.

• TheplenumattachedtotheA/Ccoilboxandductwork

within 3 ft. of the furnace must be installed so that

surfacesareatleast1/4”fromcombustibleconstruction.

• Wheninstalledinaresidentialgarage,thefurnacemust

be positioned so the burners and the source of the

ignition are located no less than 18 inches above the

floor and protected from physical damage by vehicles.

• This furnace is certied for use on wood ooring or

supports,butmustnotbeinstalleddirectlyoncarpeting,

tile,oranycombustiblematerialotherthanwoodflooring.

NOTE: The furnace may be installed on combustible

flooringwheninstalledonaNordyneductconnector.See

Figure 12 (page 16). This factory supplied accessory

must be installed in the floor cavity and attached to the

supplyairductbeforethedownflowfurnaceisinstalled.

• The furnace must be installed upstream from a

refrigeration system.