NOTE: For the majority of the assembly of

this building a minimum of two persons are

required.

Remove all travel protection blocks from the

bottom edge of panels (This is the edge

where the cladding extends beyond the

framework).

1. Ensure that your base is firm and

absolutely level.

2. Lay the two floor panels upside down on

your base. Make sure that the open ends of

the floor are facing outwards (Both 2390mm

sides touching). Pre-drill through one of the

2390 mm floor bearers and screw through

into the other using 4 x 80mm screws. Turn

the completed / joined floor over (NOTE: The

join between the floor panels runs from the

front to the back of the building. The front and

back panels sit inside the side panels.)

3. Pre drill a back panel through the frame-

work on both sides (longest sides) in 3

places, top, bottom and middle.

4. Place the left side back panel onto the floor

ensuring that the lip on the cladding has over-

hung the floor. (NOTE: The side panels are to

be placed so that they are flush with the back

edge of the floor and overhanging the floor at

the front). While holding the side panel up-

right, place the pre-drilled back panel on the

back edge of the floor next to the left side

back panel ensuring that the lip on the clad-

ding has overhung the floor. From inside the

building, align the touching framework on

both panels and join the back panel to the

side panel by screwing through the pre-drilled

holes using 3 x 80 mm screws.

5. Pre drill the left side front panel (window)

and place next to the left side back panel

ensuring that the lip on the cladding has over-

hung the floor. Align the touching framework

on both panels and join the back panel to the

side panel by screwing through the pre-drilled

holes using 3 x 80 mm screws.

6. Place the remaining back panel into posi-

tion along the back of the floor ensuring that

the lip on the cladding has overhung the floor.

Using the pre-drilled holes in the first back

panel, align the touching framework and

screw together using 3 x 80 mm screws. Pre

drill the second back panel through the ex-

posed framework on the side that will be

screwed to the other side panel. 3 places,

top, bottom and middle.

7. Place the right side back panel in position

along the side of the floor ensuring that the lip

on the cladding has overhung the floor. From

inside the building. align the touching frame-

work on both panels and join the back panel

to the side panel by screwing through the pre-

drilled holes using 3 x 80 mm screws.

8. Pre drill the right side front panel (window)

and place next to the right side back panel

ensuring that the lip on the cladding has over-

hung the floor. Align the touching framework

on both panels and join the back panel to the

side panel by screwing through the pre-drilled

holes using 3 x 80 mm screws.

9. Pre drill both of the front window panels

through the framework on both sides (longest

sides) in 3 places, top, bottom and middle.

10. Place one front window panel in position

at the front of the floor next to a side panel

ensuring that the lip on the cladding has over-

hung the floor. Note: the window panel frame-

work should be adjacent to the exposed

framework on the side panel. The window

panel should be fixed so that it sits behind the

edge of the boarding to the inside face of the

wings on the side panel. Secure the window

panel o the side panel by screwing through

the pre-drilled holes using 3 x 80 mm screws.

11. Place the other front window panel in

position at the front of the floor next to a side

panel ensuring that the lip on the cladding

has overhung the floor. Note: the window

panel framework should be adjacent to the

exposed framework on the side panel. The

window panel should be fixed so that it sits

behind the edge of the boarding to the inside

face of the wings on the side panel. Secure

the window panel o the side panel by screw-

ing through the pre-drilled holes using 3 x 80

mm screws.

12. Place the door panel in position between

the two window panels. Using the pre-drilled

holes in the both window panels, align the

touching framework and screw together using

3 x 80 mm screws on both sides.

The roof is made up of two large 1600 x 2420

mm roof panels (these are handed) and a

3200 x 520 mm panel that creates the roof

overhang. Note: A temporary prop or an extra

helper may be required during the assembly

of the roof. Ensure the roof panels sit square

to the building prior to screwing.

Lift and place the roof overhang panel at the

front of the building, on top of the projecting

wings on the side panels, using the slots at

either end for location. Note: The front edge

of the roof overhang panel is the side where

the framework and plywood are flush.

1. Pre-drill through the rear framework of the

roof overhang panel (the framework that now

should sit adjacent to the front of the building)

In four places. Screw the roof overhang

panel to the window and door panels using 4

x 80mm screws.

2. Pre-drill through the side framework of the

roof overhang panel (the framework that now

should sit adjacent to the inner boarded face

of the side panel wings) in two places. Screw

the roof overhang panel to the side panels

using 2 x 80mm screws at each end.

3. Lift and place one of the roof panels on top

of the side and back wall panels.

NOTE: The two roof panels are handed and

can only fit in the correct side. On the roof

panels, the back edge is the side with the two

pieces of framework separated by a gap of

approximately 70mm (This sits over the back

wall with the inside framework piece flush to

the inside edge of the back wall panel and the

outer piece of framework sitting outside the

building). The front edge framework piece

sits inside the building adjacent to the inside

edge of the window and door panels.

4. Lift and place one of the second roof panel

in to position on top of the other side and

back wall panels. NOTE: If the roof panels

are placed correctly, framework on each

panel should be touching along a central join

that runs from the front to the back of the

building.

5. Pre drill through the framework on one roof

panel along the middle where they are touch-

ing in 3 places, front, back and middle. Ensur-

ing that the framework on the two panels is

aligned, join the two roof panels together by

screwing through the pre-drilled holes using 3

x 80 mm screws.

6. From inside the building pre drill through

both the front and back framework, on both

roof panels in 3 places, to enable fixing to the

framework on the front and back wall panels.

7. Using the pre-drilled holes in the roof panel

framework, screw the roof panels the back

panels using 3 x 80 mm screws per roof

panel and screw the roof panels to the front

window and door panels using 3 x 80 mm per

roof panel. (12 No. screws in total).

8. From outside the building secure the roof

panels to the side walls by nailing down

through the plywood on the roof panel into the

framework of the side walls below using 3 x

40 mm nails per side. Note: This should be 90

mm in from the outer roof panel edge.

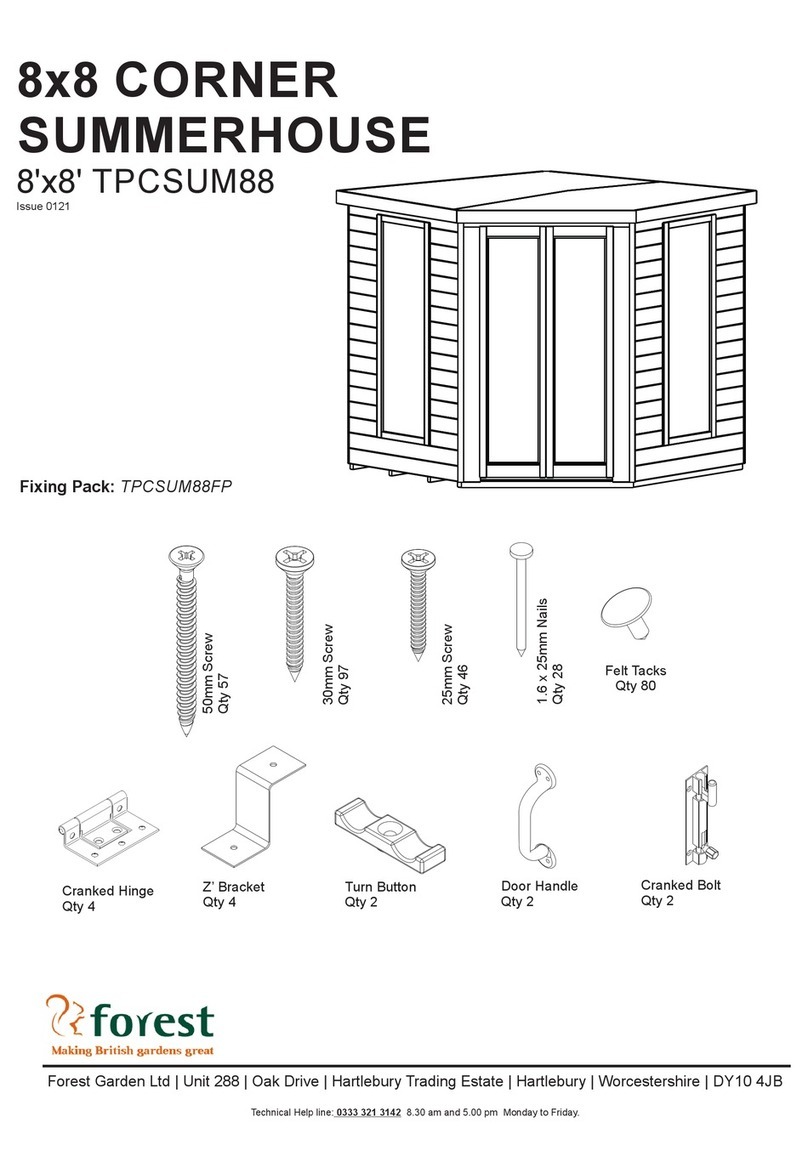

A Floor & Walls

B Roof Assembly