Norgren B38 Installation and operating instructions

* Outlet pressure can be adjusted to pressures in excess of, and less than, those specified.

Do not use these units to control pressures outside of the specified ranges.

Stainless Steel Instrument Filter/Regulator

B38 - 2★★ - ★★★★

B38

Installation & Maintenance

Instructions

Material

4....Stainless steel

(standard)

5....Stainless steel and

Viton

ADJUSTMENT

1. Before applying inlet pressure to filter/regulator, turn

adjustment (2) counterclockwise to remove all force on

regulating spring (7).

2. Apply inlet pressure, then turn adjustment (2) clockwise

to increase and counterclockwise to decrease outlet

pressure setting.

3. Always approach the desired pressure from a lower

pressure. When reducing from a higher to a lower

setting, first reduce to some pressure less than that

desired, then bring up to the desired pressure.

NOTE

With non-relieving filter/regulators, make pressure

reductions with some air flow in the system. If

made under no flow (dead-end) conditions, the

filter/regulator will trap the over-pressure in the

downstream line.

4. Once required pressure is achieved tighten locknut (3) to

lock setting.

SERVICING

1. For manual drain models, regularly open drain to expel

accumulated liquids. Keep liquids below element retainer

(13).

2. At approximately 6 month intervals it is advisable to

remove the bowl assembly by removing the securing

screws (4) and unscrewing the element retainer (13) to

remove the element (15) for inspection.

Since the direction of air flow is from the inside of the

element to the outside, a clean exterior is not an an

indication of freedom from contamination.

If the filter element shows evidence of blockage, replace

with new element.

Clean the element retainer (13) and the upper and lower

gaskets (14) before replacing the filter element –

avoiding excessive overtightening of the retainer.

Inspect the bowl O-ring (16) for damage and renew if

necessary.

3. Clean or replace filter element when dirty.

DISASSEMBLY

1. Filter/regulator can be disassembled without removal

from air line.

2. Shut off inlet pressure. Reduce pressure in inlet and

outlet lines to zero.

3. Turn adjustment screw fully counterclockwise.

4. Disassemble in general accordance with the item

numbers on exploded view. Do not remove the drains

unless replacement is necessary. Remove and replace

drains only if they malfunction.

CLEANING

1. Rinse and dry parts. Blow out internal passages in body

(30) with clean, dry compressed air. Blow air through

filter element (15) from inside to outside to remove

surface contaminants.

2. Inspect parts. Replace those found to be damaged.

ASSEMBLY

1. Lubricate threads and nose of adjusting screw (2) at

regular intervals with suitable grease eg. Speerol APT2.

2. Lubricate seals (16, 36, 37) with light coat of good

quality grease.

2. Assemble the unit as shown on the exploded view.

3. Torque Table

Item Torque in

Nm (Inch-Pounds)

4 (screws, stainless steel model) 7,3/3,3 (66/30)

TECHNICAL DATA

Fluid: Compressed air

Maximum pressure:

Stainless steel

Manual drain: 31 bar (450 psig)

Automatic drain: 17 bar (245 psig)

Operating temperature*:

-40° to +80°C (-40° to +176°F)

* Air supply must be dry enough to avoid ice formation at

temperatures below +2°C (+35°F).

Particle removal: 5 µm or 25 µm filter element

Air quality: Within ISO 8573-1, Class 3 and Class 5

(particulates)

Typical flow with 7 bar (100 psig) inlet pressure, 1 bar

(15 psig) set pressure and 0,05 bar (1 psig) droop from

set: 8 dm3/s (17 scfm)

Automatic drain connection: 1/4" PTF

Automatic drain operating conditions (float operated):

Bowl pressure required to close drain: Greater than

0,3 bar (5 psig)

Bowl pressure required to open drain: Less than 0,2 bar

(3 psig)

Minimum air flow required to close drain: 1 dm3/s

(2 scfm)

Gauge ports:

1⁄4" as per main ports

Materials:

Body: Stainless steel

Bonnet: Stainless steel

Bowl: Stainless steel

Adjusting screw: Stainless steel

Element

5 µm: Stainless steel

25 µm: Vyon

Elastomers: Synthetic rubber

Diaphragm insert: Acetal resin, stainless steel and nitrile

Other parts stainless steel

REPLACEMENT ITEMS (standard option)

Service Kit (includes items circled on exploded view):

Relieving

2 bar..................................................................R38-100R

4 & 7 bar ...........................................................R38-101R

10 bar................................................................R38-102R

Non relieving

2 bar ...............................................................R38-100NR

4 & 7 bar.........................................................R38-101NR

10 bar .............................................................R38-102NR

Filter section

5 µm stainless steel......................................B38100S(5)

25 µm stainless steel....................................B38100S(25)

5 µm viton and stainless steel......................B38150S(5)

25 µm stainless steel....................................B38150S(25)

Auto drain (replacement) .........................................3000-90

PANEL MOUNTING DIMENSIONS

Panel mounting hole diameter: 42 mm (1,65")

Panel thickness: 0 to 6 mm (0" to 0,24")

INSTALLATION

1. Shut off air pressure. Install filter/regulator in air line -

●vertically (bowl down),

●with air flow in direction of arrow on body,

●upstream of lubricators and cycling valves,

●as close as possible to the device being serviced.

2. Connect piping to proper ports using pipe thread sealant

on male threads only. Do not allow sealant to enter

interior of unit.

3. Install a pressure gauge or plug the gauge ports. Gauge

ports can also be used as additional outlets for regulated

air.

IM-510.315.01 (1/99)

a subsidiary of IMI plc

© Norgren 1999

Port

2....1/4"

Spring (Outlet Pressure Range) *

C....0,04 to 2 bar (0.6 to 30 psig)

F ....0,07 to 4 bar (1 to 60 psig)

K....0,25 to 7 bar (3,6 to 100 psig)

M...0,5 to 10 bar (7.2 to 150 psig)

Thread Form

A....PTF

B....ISO Rc taper

D....ISO G

K....API

Drain

A....Automatic

B....Manual

Element

1....5 µm

2....25 µm

1

2

3

4

5

6

7

8

38

32

36

37

30

16

14

15

14

13

11

17

19

4

4

20

21

18

33

34

35

Options

0....Stainless steel, relieving

1....Stainless steel, non-relieving

2....Stainless steel, relieving with bracket and panel nut

3....Stainless steel, non-relieving with bracket and panel nut

4....Stainless steel, relieving with panel nut

5....Stainless steel, non-relieving with panel nut

6....Stainless steel, relieving with handwheel and panel nut

7....Stainless steel, non-relieving with handwheel and panel nut

8....Stainless steel, relieving with handwheel, bracket and panel nut

9....Stainless steel, non-relieving with handwheel, bracket and panel nut

CAUTION

Water vapor will pass through these units and could

condense into liquid form downstream as air temperature

drops. Install an air dryer if water condensation could have

a detrimental effect on the application.

WARNING

These products are intended for use in industrial

compressed air systems only. Do not use these products

where pressures and temperatures can exceed those listed

under

Technical Data

.

If outlet pressure in excess of the filter/regulator

pressure setting could cause downstream equipment to

rupture or malfunction, install a pressure relief device

downstream of the filter/regulator. The relief pressure and

flow capacity of the relief device must satisfy system

requirements.

The accuracy of the indication of pressure gauges can

change, both during shipment (despite care in packaging)

and during the service life. If a pressure gauge is to be

used with these products and if inaccurate indications may

be hazardous to personnel or property, the gauge should be

calibrated before initial installation and at regular intervals

during use.

Before using these products with fluids other than air,

for non industrial applications, or for life-support systems

consult Norgren.

IM-510.315.02 (1/99)

a subsidiary of IMI plc

© Norgren 1999

B38

Installation & Maintenance

Instructions

Table of contents

Popular Plumbing Product manuals by other brands

Elkay

Elkay Pacemaker PSDKAD2517 Specifications

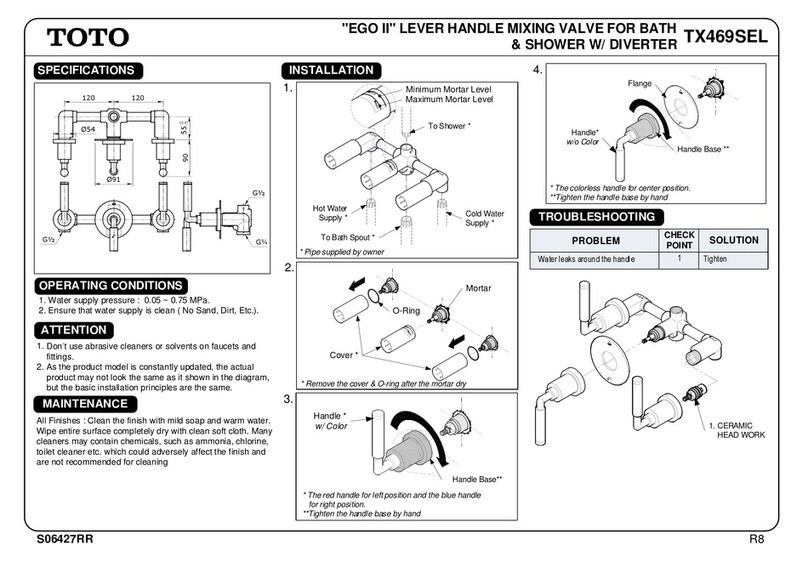

Toto

Toto EGO II quick start guide

Kohler

Kohler K-11550 installation guide

Axor

Axor Clubmaster 28525XX1 Installation instructions / warranty

Hans Grohe

Hans Grohe AXOR Urquiola 11732000 Instructions for use/assembly instructions

Booth & Co

Booth & Co AXBRIDGE BC-AXB-206-CP user guide