North American Tool 8902 User manual

8808902 06/13

14/20 INCH CHAINSAW

CALIFORNIA PROPOSITION 65

WARNING: You can create dust

when you cut, sand, drill or grind

materials such as wood, paint,

metal, concrete, cement, or other

masonry. This dust often contains

chemicals known to cause cancer,

birth defects, or other

reproductive harm. Wear

protective gear.

WARNING: This product or its

power cord may contain

chemicals, including lead, known

to the State of California to cause

cancer and birth defects or other

reproductive harm. Wash hands

after handling.

Important!

When using equipment, a few safety

precautions must be observed to

avoid injuries and damage. Please

read the complete operating manual

with due care. Keep this manual in a

safe place, so that the information is

available at all times. If you give the

equipment to any other person, give

them these operating instructions as

well. We accept no liability for

damage or accidents which arise due

to non-observance of these

instructions and the safety

information herein.

SPECIFICATIONS

Engine Displacement: 45.1 cc

Bar Length: 14in. and 20in.

Idling Speed: 3000 RPMs

Max. Speed with Cutting

Equipment: 10,000 RPMs

Anti-Vibration Function

Chain Brake

Auto Chain Lubrication

CAUTION:

FOR YOUR OWN SAFETY READ

INSTRUCTION MANUAL

COMPLETELY AND CAREFULLY

BEFORE OPERATING THIS

CHAINSAW.

Any failures made in following the

safety regulations and and

instructions may result in an

electric shock, fire and/or serious

injury.

NOTE: Remove the 14”Bar and

Bar Cover from the bottom of the

case by unscrewing the anchor.

SAFETY INSTRUCTIONS

Only allow users who have read

and understand this manual

operate this chainsaw.

Wear protective gear, such as

steel-toed footwear, snugly fitting

clothing, heavy duty gloves, eye

protection (goggles or face

screen), hard hat and ear

protection (ear plugs or mufflers).

Do not wear jewelry and pull long

hair back.

Keep all body parts clear of the

chain while the engine is running.

Do not allow other people or

animals near the saw when it is

running, starting, or being

operated.

You must be mentally alert and in

good physical condition when

operating a chainsaw because the

work is strenuous

Carefully plan your sawing project

before starting. Do not begin until

you are sure the work area is

clean, you have secure footing

and if you are felling trees, that

you have a planned and clear

retreat path.

For Customer Service, please call 1-800-348-5004 or

email feedback@natitools.com 1

Model: 8902,

50969

2

KICKBACK

WARNING: Kickback is the

backward, upward or sudden

movement of the guide bar that

occurs when the guide bar contacts

an object or when the wood closes in

and pinches the saw in the cut. The

saw contacting a foreign object in the

wood can also result in a loss of

control.

Rotational kickback occurs when

the moving chain contacts an object

with the upper tip of the guide bar.

This can cause the chain to dig into

the object, which then stops the

chain for a moment. The result is a

reverse reaction, which kicks the

guide bar up and back towards the

operator.

Pinch kickback occurs when the

woods closes in on the moving chain

along the top of the guide bar. The

sudden stop of the chain results in

the saw to move in the opposite

direction of the rotation and the saw

is driven straight back towards the

operator.

Pull in occurs when the moving

chain comes in contact with a foreign

object in the wood along the bottom

of the guide bar. This sudden stop

pulls the saw forward and away from

the operator and could possibly

cause the operator to lose control of

the saw.

Avoiding Kickback

Be aware of situations or objects that

can cause the material to pinch the

top of or stop the chain.

Do not cut more than one log at a

time.

Do not twist the saw when the bar is

withdrawn from an undercut.

Always begin cutting with the engine

at full speed and with the saw

housing resting against the wood.

Use wedges made of plastic or

wood to hold the cut open. Never

use metal.

Stay alert. Realize kickback can

occur and keep the cutting area free

from foreign objects.

Keep your chain properly tensioned

and sharp, along with properly

maintaining the chainsaw. Failure to

do so can increase the chance of

kickback occurring.

Begin and continue the cut with the

engine running at full speed. Use

caution while re-entering a previous

cut. Do not attempt a plunge cut

(starting a cut with the tip of the

blade).

Maintaining Control of the

Chainsaw

Stand to the left of the saw. Keep

your elbow locked and a firm grip on

the saw.

Keep the thumb on the underside of

the handlebar. Never reverse hand

positions (left hand on handlebar

and right hand on the rear handle).

Stand slightly to the left side of the

saw to keep your body from being in

a straight line with the saw. Stand

with your weight evenly balanced

between both feet.

Do not overreach because you could

be thrown off balance and lose

control of the saw. Do not cut above

shoulder height because it is difficult

to maintain proper control of the saw

at that height.

Chain Brake

The chain brake is designed to stop

the chain from rotating in the event

of a kickback.

WARNING: DO NOT RELY UPON

THE CHAIN BRAKE (OR OTHER

SAFETY FEATURES) TO

PROTECT YOU IN THE EVENT OF

A KICKBACK. Use your chainsaw

properly and under the correct

circumstances to avoid kickback.

ASSEMBLY

Wear protective gloves at all times

during assembly due to the handling

of sharp objects.

Attaching the Bumper Spike

The bumper spike may be used as a

pivot when making a cut.

1) Loosen and remove the bar knob

completely by loosening the two

nuts.

2) Remove the clutch cover.

3) Attach the bumper spike with the

two screws with the spikes pointing

downward.

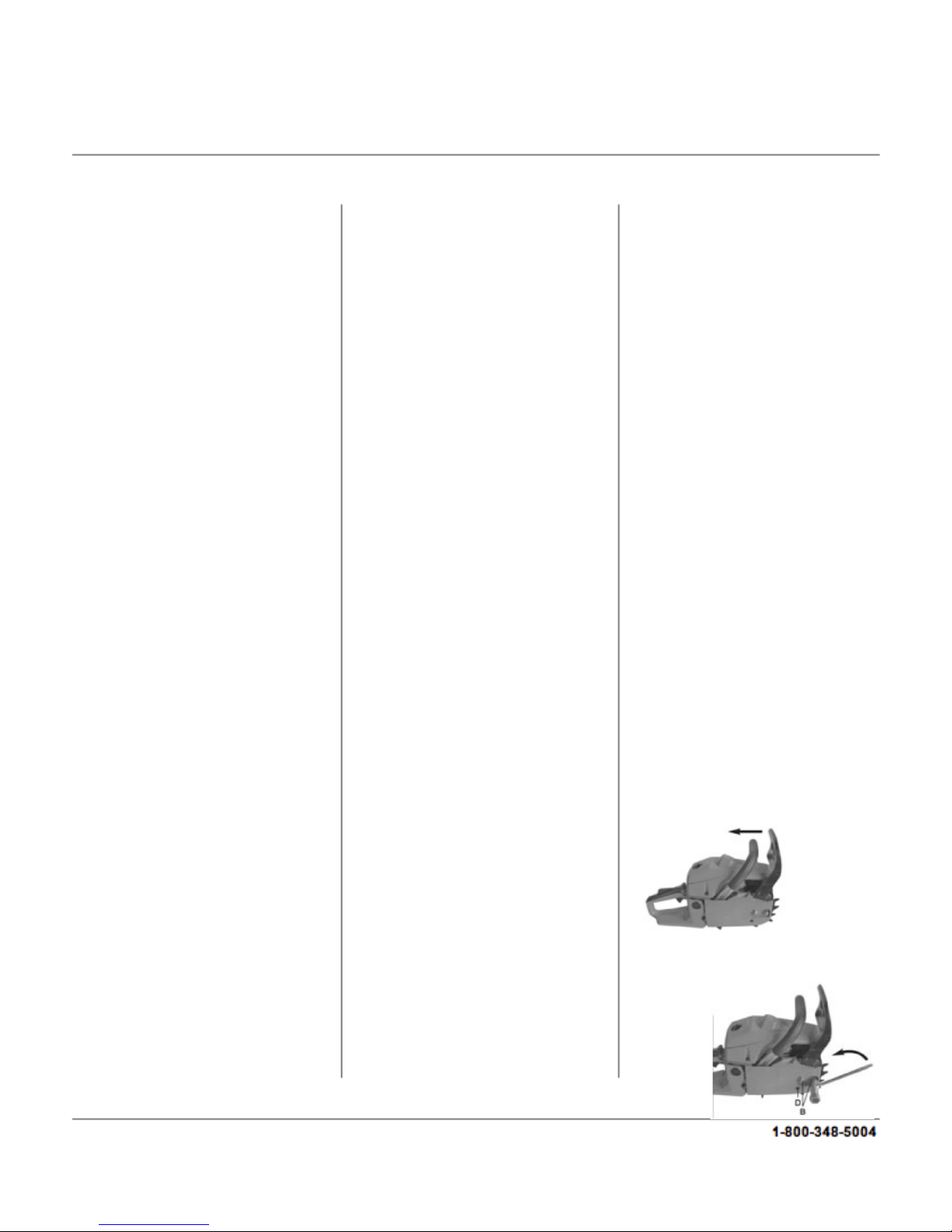

Attaching the Bar and Chain

1) Make sure the saw bottom is

resting on a flat surface. Be sure the

chain brake is pulled back. (Figure1)

Loosen and remove the bar knob

completely by removing the two

nuts. (Figure 2)

feedback@natitools.com

Figure 1

Figure 2

2) Remove the clutch cover.

(Figure 3)

3) Slide the guide bar on the bar

bolts until the guide bar rests against

the clutch drum sprocket. (Figure 4)

4) Hold the chain with the drive links

as shown. The drive links should be

facing inward with the cutters facing

to the right, or direction of rotation.

(Figure 5)

5) Fit the drive links in the clutch

drum sprocket. (Figure 6)

Figure 6

6) Place the chain drive links into the

bar groove.

7) Pull the guide bar forward to

make sure all of the drive links are in

the bar groove.

8) Reinstall the clutch cover. (Figure

3) Make sure the adjusting pin is

aligned with the hole in the guide

bar.

CAUTION: Make sure the

adjustment pin aligns with the hole.

Failure to align the pin and install the

cover properly may result in

damage, possibly permanent, to

your saw.

ADJUSTING CHAIN TENSION

Before adjusting, make sure the bar

knobs are loosened 1 ½- 2 turns.

Adjusting the chain tension with the

knobs tight can cause damage.

Checking the Chain Tension

Check the chain tension by using a

screwdriver to move the chain along

the bar. If it does not rotate, it is too

tight. If it sags below the bar, it is too

loose.

Adjusting the Chain Tension

The chain stretches slightly during

each use, especially the first few

times the saw is used. Always check

the chain tension each time the saw

is used and refueled.

1) Make sure the bar knobs are

loosened 1-1/2 –2 turns.

2) Using a screwdriver, adjust the

tension of the chain. The adjusting

pin is located right below the two bar

knobs.

3

3) Turn the screw to the right to

increase the tension and turn it to

the left to release tension.

4) Using a screwdriver, move the

chain around on the guide bar to

make sure all of the links are in the

bar groove. If the chain does not

rotate, it is too tight and the

adjuster needs to be loosened.

5) Tighten the bar knob securely

after the tension is adjusted.

FUELING AND LUBRICATION

Use regular grade unleaded

gasoline mixed with 40:1 2-cycle

engine oil. Do not use a fuel

mixture that has been stored for

more than 90 days.

The bar and chain require constant

lubrication in order to function

properly. Lubrication is provided by

the oiler system. Lack of oil will

cause damage to the bar and

chain. Smoke coming from the

chain and discoloration on the bar

are signs the oil is low.

Fueling Safety Instructions

1) Do not smoke while fueling or

operating the saw.

2) Do not allow sparks or flame in

the area where the fuel is poured or

mixed. Always allow the engine to

cool before refueling.

3) When refueling, turn the engine

off and let it fuel in a non-

combustible area. Slowly remove

the fuel cap and refuel the saw.

4) Mix and pour the fuel in a well-

ventilated outdoor area. Store the

fuel in a cool, dry place. Wipe up

fuel spills before attempting to start

the saw.

5) Start the engine at least 10 feet

from the fueling site

Figure 3

Figure 4

Figure 5

Figure 7

4

6) Store the saw and fuel in an area

where sparks or open flame will not

reach it.

OPERATING INSTRUCTIONS

Warning: The chain must not move

when the engine is running at an idle

speed. If the chain moves, the

carburetor must be adjusted. Avoid

contact with the muffler because a

hot muffler can cause serious burns

or injury.

Operation Safety Instructions

1) Do not operate a chainsaw with

one hand.

2) Only operate the chainsaw in a

well-ventilated, outdoor area.

3) Make sure that the chainsaw will

not come into contact with any object

while starting the engine. Do not start

the saw when the guide

bar is in the middle of a cut.

4) Do not apply pressure to the saw

at the end of a cut. It can cause you

to lose control of the saw when the

cut is complete.

5) Make sure the engine is stopped

before setting down the saw.

6) Make sure your chainsaw is in

good condition before operating. Do

not operate a saw that is damaged,

improperly adjusted, or not

completely and securely assembled.

7) Do not carry the saw with the

engine running. Carry the saw with

the engine stopped and the muffler

pointing away from you, with the

guide bar and chain facing behind

you. The chain should be covered

with a bar cover to ensure the blade

will not cause harm.

8) Do not run while operating the

chainsaw.

Starting A Cold Engine

Hold the saw firmly against the

ground and make sure the chain is

free to move without contacting any

object.

1) Move the ON/OFF switch to the

ON position.

2) Pull the choke lever out to its full

extent.

3) Pull the starter rope quickly with

your right hand a maximum of 5

times. If the engine sounds as

though it is trying to start before the

5th pull, do not pull any more and

immediately go to the next step.

4) Push the choke lever fully in.

5) Pull the starter rope quickly with

your right hand until the engine

starts.

6) Allow the engine to run for

approximately 30 seconds before

squeezing and releasing the throttle

trigger, which will allow the engine to

return to idle speed.

Starting a Warm Engine

1) Place the ON/OFF switch into the

ON position.

2) Push the choke lever full in.

3) Pull on the starter rope quickly

with your right hand until the engine

starts.

4) After the engine starts, squeeze

and release the throttle trigger, this

will allow the engine to return to idle

speed.

Flooded Engine

If your engine does not start after 10

pulls, it may be flooded. It can be

cleared of the excess fuel by

following the warm engine starting

process. Make sure the

ON/OFF switch is in the ON

position. The amount of flooding in

the engine will determine how many

pulls are necessary for it to start.

Checking the Chain Brake

The chain brake should be checked

several times during use. The

engine needs to be running while

this is done and it is the only time

the saw should be set on the

ground with the engine running.

1) Place the saw on the ground.

2) Grasp the rear handle with your

right hand and the front with your

left.

3) Apply the full throttle with your

right hand.

4) Activate the chain brake by

turning your left wrist against the

hand guard without letting go of the

front handle.

The chain should stop immediately.

If the chain brake fails to activate,

take the saw to an authorized

dealer to have the chain brake

replaced or repaired.

CUTTING METHOD

INSTRUCTIONS

Safety Instructions

Check the chain tension before

using the saw for the first time and

after 1 minute of operation

Do not cut any material other than

wood. Do not cut metal, plastic,

masonry, non-wood building

materials, etc.

If the chain strikes a foreign object,

stop the saw and inspect the chain

for damage. If damage is present,

repair or replace the necessary

parts.

Keep the saw clear of dirt or sand

because even a small amount

could dull the blade and possibly

cause kickback.

Before starting a major project,

practice cutting a few logs.

5

Important Operation Reminders

Allow the engine to reach full speed

before cutting.

Begin cutting with the saw frame

resting against the log.

Keep the engine at full speed the

entire time you are cutting.

Allow the chain to do the work for

you. Do not apply excess pressure.

Forcing the cut may cause damage

to the engine, bar and/or chain.

When the cut is complete, release

the trigger and allow the engine to

return to idle. Running the saw at full

throttle without cutting can cause

wear to the chainsaw.

Do not put pressure on the saw at

the end of a cut in order to maintain

control of the saw.

Stop the engine before setting down

the saw.

Tree Felling

WARNING: Do not cut near buildings

or electrical wires if the direction of

the fall is uncertain. Check for broken

or dead branches, which could fall

while cutting. Do not cut at night or

during bad weather. If the tree falls

onto a utility line, notify the utility

company immediately.

Plan your sawing operation in

advance. Clear the work area in

order to have a secure footing.

Evaluate the natural conditions that

could affect the direction of the fall

such as wind, lean of the tree, weight

and branches on one side,

surrounding trees, decay and rot.

Make sure the tree has enough room

to fall. Keep a distance of at least 2

½tree lengths from the nearest

person or object because engine

noises or the tree falling can drown

out warning calls.

Remove all foreign objects from the

tree where the cuts are going to be

made. Plan a clear retreat path that

is diagonally back from the line

of the fall.

Felling Large Trees (6 in. or larger

in diameter)

A notch is cut into the side of the

tree in the desired falling direction.

After a felling cut is made, the tree

will tend to fall into the notch.

Note: If the tree has large buttress

roots, remove them before making

the notch into the tree. If you use a

chainsaw to remove the roots, keep

the chain from contacting the ground

to prevent the chain from dulling.

1) Make the notch by cutting the top

of the notch first. Cut through 1/3 of

the diameter of the tree. Complete

the notch by cutting the bottom of

the notch. Remove the notch of

wood from the tree once the notch is

cut.

2) After removing the wood, make

the felling cut on the opposite side of

the notch. Make a cut about two

inches higher than the center of the

notch. This will leave a hinge

between the felling cut and the

notch. The hinge will help prevent

the tree from falling in the wrong

direction. It also helps hold the tree

on the stump and control the fall.

Before the felling cut is complete,

use wedges, if necessary, to open

the cut and control the direction of

the fall. Use wood or plastic wedges

to avoid kickback and chain

damage. Never use steel or iron

wedges.

Be alert to signs that the tree is

about to fall, such as cracking

sounds, widening of the felling cut,

or movement in the branches.

As the tree begins to fall, stop and

put down the saw and quickly get

away on your planned retreat path.

Do not cut down a partially fallen

tree. Be cautious when working

around partially fallen trees

because they may be poorly

supported. If a tree does not fall

completely, put the saw aside and

pull down the tree with a cable

winch, block and tackle or a tractor.

Cutting A Fallen Tree (Bucking)

WARNING: DO NOT stand on the

log that is being cut. If the log rolls,

it can cause loss of footing and

control. Do not stand downhill of

the log being cut.

Only cut one log at a time.

Cut shattered wood carefully.

Sharp pieces of wood could

possibly be thrown back towards

the operator.

Never allow another person to hold

a small log for cutting, or use your

leg or foot to hold it. Use a

sawhorse to cut small logs.

Do not cut in an area where logs,

roots and limbs are tangled. Drag

the logs into a clear area before

cutting.

Types of Cutting for Bucking

WARNING: If a saw becomes

pinched in a log, do not try to force

it out. It is possible to lose control

of the saw which can result in injury

and/or damage to yourself or the

saw. Stop the saw and drive a

plastic or wood wedge into the cut

until the saw can be removed.

Restart the saw and re-enter the

cut. Using a metal wedge can

cause kickback and chain damage.

Do not attempt to restart your saw

when it is pinched in a log.

6

Overcutting is when the bottom of

the saw is against the top of the log.

Use a light, downward pressure

when overcutting.

Undercutting is when the log is cut

from the underside with the top of the

saw against the log. Use a light

upward pressure. Hold the saw firmly

and maintain control of the saw

because it will tend to push

backwards.

DO NOT turn the saw upside down

to undercut. Control of the saw

cannot be maintained in this position.

Always make your first cut on the

compression side of the log (where

the pressure of the log’s weight is

concentrated).

Bucking Without A Support

Using an overcut, cut through 1/3 the

diameter of the log.

Roll the log over and finish with a

second overcut.

Watch out for logs with a

compression side to prevent the saw

from being pinched.

Bucking Using A Log or Support

Stand

Make your first cut on the

compression side of the log and

extend it 1/3 into the diameter of the

log. Finish with a second cut.

Limbing and Pruning

WARNING: Be on alert for kickback.

Keep the moving chain away from

any other branches or objects when

limbing or pruning. Never climb into a

tree to limb or prune. Do not stand

on ladders, platforms, other logs or in

a position with unsteady footing.

Important Safety Reminders

Work slowly with both hands

gripping the saw. Maintain balance

and a secure footing.

Use caution when cutting smaller

limbs. Small limbs may catch in the

chain and be flung towards you or

throw you off balance.

Watch out for branches that are

under pressure or bent. When the

wood is cut, the tension may cause

the wood to be flung.

Keep your work area clear. Clear

away branches from the work area

in order to avoid tripping over them.

Limbing

Limbing should only be done when a

tree is already cut down.

Leave any large limbs under the tree

for support as you work.

Start at the base of the tree and

work towards the top. Small limbs

can be removed in one cut.

Keep the tree between you and the

chain. Cut opposite from the branch

being cut.

Remove any larger, supportive

branches with the technique

described in Bucking Without A

Support.

Always use an overcut to cut small

and free hanging limbs. Do not use

an undercut because it may cause

limbs to fall and pinch the saw.

Pruning

WARNING: Do not prune limbs that

are above shoulder height. If the

branches are higher than your

shoulder, have a professional

perform the job.

Make your first cut 1/3 of the way

through the limb.

Make the second cut all the way

through the limb. The cut a third

overcut through the branch, leaving

a 1 –2 inch collar from the trunk of

the tree.

MAINTENANCE

Maintenance Schedule

Check before each use:

Fuel mixture level

Bar lubrication

Chain tension

Chain sharpness

For damaged parts

For loose caps, fasteners and parts

Inspect and Clean

Bar: Before each use

Saw: After each use

Air filter: Every 5 hours of use

Chain brake: Every 5 hours of use

Spark arresting screen and

muffler: Every 25 hours of use

Replace spark plug: Yearly

Replace fuel filter: Yearly

Maintenance Safety Instructions

1) Be sure to have your chainsaw

regularly serviced by a qualified

dealer.

2) Never modify the chainsaw in any

way.

3) Keep the handles clean and dry,

and free from oil or fuel.

4) Make sure the fuel and oil caps,

fasteners and screws are tightened

and secure after performing

maintenance.

5) Always wear protective gloves

when performing maintenance.

6) Do not perform maintenance

while the engine is hot.

7

Air Filter Cleaning

DO NOT clean the air filter in

gasoline or other flammable

solutions. Doing so can create a fire

hazard or harmful emissions.

DO NOT operate the saw without an

air filter. Dust and dirt will be drawn

directly into the engine and damage

it. Keep the air filter clean.

1) Remove the top cover by

unscrewing the fastening screw.

2) Lift out the air filter.

3) Clean the air filter in warm, soapy

water and rinse in clean water.

4) Allow the filter to air dry

completely.

5) Insert the air filter back into the

chainsaw. Replace the cover on the

chainsaw. Make sure the cover is

fitted securely and properly before

tightening the screw.

Fuel Filter Cleaning

NEVER use the saw without a fuel

filter. After 100 hours of use, the filter

should be cleaned or replaced, if

damaged.

Make sure the fuel tank is empty

before changing the filter.

1) Remove the fuel tank cap.

2) Bend a piece of soft wire.

3) Reach into the tank opening and

hook the fuel line. Carefully pull the

line towards the opening until you

can reach it with your fingers.

DO NOT pull the hose completely

out of the tank.

4) Lift the filter out of the tank.

5) Pull off the filter. If it is damaged,

discard and replace with a new one.

6) Insert a new filter. Place the filter

into the opening and push it into the

tank. Make sure it is situated in the

lower corner of the tank. If need be,

use a long screwdriver to

move the filter into the correct

position. Be careful not to damage the

filter.

7) Fill the tank with new fuel mixture.

Spark Plug

The spark plug must be cleaned or

replaced after every 20 hours of

service.

1) Make sure the ON/OFF switch is

turned off.

2) Remove the top cover by

unscrewing the fastener.

3) Remove the air filter.

4) Disconnect the ignition cable from

the spark plug by pulling and twisting

simultaneously.

5) Remove the spark plug by using a

spark plug wrench.

6) Clean the spark plug with a copper

wire brush. The electrode gap should

be 0.6mm.

7) Reconnect the ignition cable.

8) Replace the air filter.

9) Replace the top cover, make sure

the cover is securely fitted, and then

screw down the fastener.

Carburetor

The carburetor has already been

properly adjusted at the factory. If it

requires additional adjustment, take

the saw to an authorized service

dealer.

Chain Bar Maintenance

The chain bar needs to be regularly

lubricated and maintained in order for

it to work.

Tools for lubrication

A lube gun is recommended, but not

required, for applying grease to the

guide bar sprocket tip. The gun is

equipped with a needle nose tip,

which allows the grease to be

efficiently applied.

Lubricating the sprocket tip

The sprocket tip on your new saw

has been pre-lubricated in the

factory. It needs to be lubricated

properly otherwise it will perform

poorly, and possibly seize.

Lubrication is recommended once a

week or after 10 hours of use. Clean

the bar tip before lubrication.

The chain does not have to be

removed to lubricate the bar tip.

Lubrication is possible while

working, however the engine must

be turned off.

Warning: Wear work gloves when

handling the chain and bar.

1) Make sure the engine is off, with

the ON/OFF switch in the Off

position.

2) Clean the guide bar tip.

3) Using the lubrication gun, insert

the nose into the lubrication hole

and fill it with grease until it appears

at the edges of the tip.

4) Rotate the saw by hand. Add

additional lubrication until the entire

tip has been greased.

Many guide bar problems can be

avoided by properly maintaining the

bar and chain saw. Insufficient

lubrication or using a saw with a

chain that is too tight will cause the

bar to wear rapidly.

Maintaining the chain bar

The bar should be reversed after 8

hours of work to keep uniform wear.

Check the bar frequently for wear,

and if need be, remove burs and

square up the rails by using the flat

file.

1) Be sure the ON/OFF switch is Off.

2) Loosen the bar knob and remove

the cover.

3) Remove the chain and bar from

the saw.

8

4) Clean the oil holes and bar

groove.

5) If the bar is burred, remove the

burs with a flat file.

6) If the rail top is uneven, use a flat

file to make the sides and edges

square again.

Replace the guide bar when the

groove is worn, the bar is bent or

cracked, or when excessive heating

or burring occurs. If the bar needs

replacing, only use the guide bar

specified in the parts list or on the

chain saw.

Oil passages

The oil passages should be cleaned

to allow proper lubrication of the bar

and chain.

The condition of the passages can

be checked. If they are clear, the

chain will automatically send off a

spray of oil within seconds of starting

the saw because it is equipped with

an automatic oiler system.

Automatic chain lubrication

The chain is equipped with an

automatic oil system with a toothed

wheel drive. It will automatically

supply the bar and chain with the

right amount of oil. When the engine

is accelerated, the oil will flow

through the bar more quickly.

The lubrication system has been set

at the factory. The screw for

adjusting the lubrication is located on

the underside of the chainsaw. By

turning the screw counterclockwise,

it will increase the lubrication and

turning it clockwise will decrease the

lubrication.

To check the lubrication, hold the

chain saw over a piece of paper and

run it at full speed for a few seconds.

The amount of oil on the paper will

determine if the lubrication needs to

be increased or not.

Chain Maintenance

Sharpening

Chain sharpening requires special

tools to ensure that the cutters are

sharpened to the proper angle and

depth. We recommend you allow a

professional chain sharpener to

sharpen your chain.

Breaking in a new chain

A new chain and bar will need

adjusting after as few as 5 cuts. This

is normal during the break-in period

and the interval between future

adjustments will begin to lengthen.

Chain lubrication

Make sure the oil tank is filled with

the appropriate oil to lubricate the

chain. Running the saw with low or

no oil will cause damage to the

chain and the saw, causing

overheating and excessive wear.

STORAGE

If a chainsaw is going to be in

storage for longer than 30 days,

follow these instructions.

Storing a chainsaw

1) Remove the fuel tank slowly in

order to release any pressure in the

tank. Carefully drain the fuel from

the tank.

2) To remove all of the fuel from the

carburetor, start the engine and let it

run until the saw stops.

3) Allow the engine to cool

completely.

4) Remove the spark plug.

5) Pour 1 teaspoon of 2-cycle oil into

the combustion chamber. Slowly pull

the starter rope a few times in order

to coat the internal parts. Replace

spark plug.

Note: Store the unit away from

water, sources of flame and sparks

and in a cool, dry location.

Preparation to use saw again

1) Remove the spark plug.

2) Pull the starter rope briefly to

clear excess oil from the

combustion chamber.

3) Clean the spark plug and check

the electrode gap.

4) Replace the spark plug.

5) Fill the fuel tank with the proper

fuel mixture.

6) Check oil levels.

9

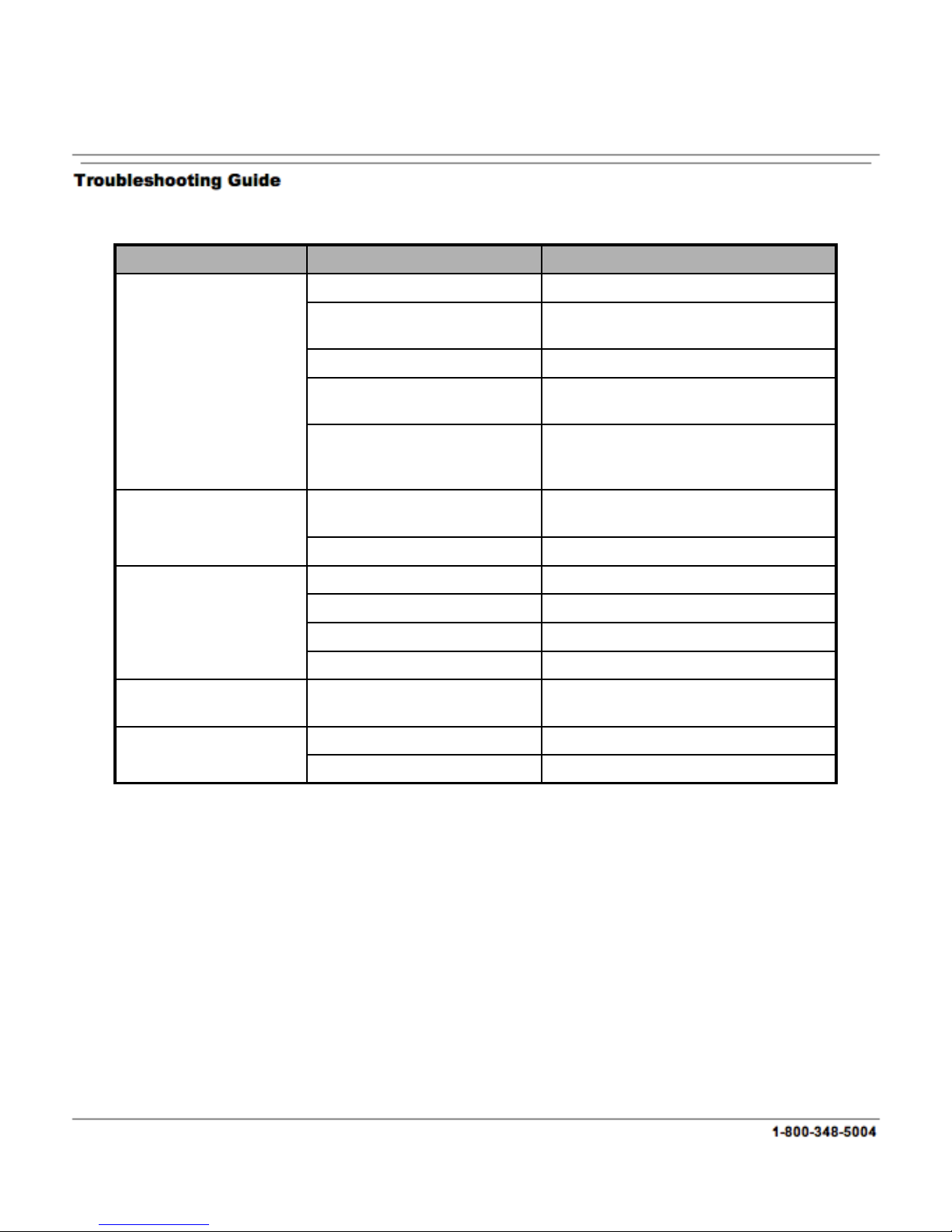

feedback@natitools.com

Contact an authorized service dealerClutch requires repair

Contact an authorized service dealerIdle speed requires adjustment

Chain moves while

idling

Empty fuel tank and refill with proper

fuel mixture

Too much oil mixed with

gasoline

Engine smokes

excessively

Contact an authorized service dealerCarburetor needs adjustment

Disengage chain brakeChain brake is engaged

Clean or replace plug or correct gapSpark Plug is faulty

Clean or replace filterAir filter is dirty

Engine will not

accelerate, lacks power

or dies under a load

Contact an authorized service dealerCrankshaft seal is worn

Contact an authorized service dealer

Carburetor requires

adjustment

Engine will not idle

properly

Check for dirty fuel filter (replace if

necessary). Check for faulty fuel line

(repair or replace if necessary).

Fuel is not reaching carburetor

Install new spark plug

Spark plug is not working

properly

Fill tank with proper fuel mixtureFuel tank is empty

Reference digital starting section of this

manual

Engine is flooded

Turn ignition switch ONIgnition switch is not ON

Engine will not start or

will not stay running

Corrective ActionPossible Cause(s)Symptom

10

feedback@natitools.com

North American Tool Industries (NATI) makes every effort to ensure that this product meets high

quality and durability standards. NATI warrants to the original retail consumer a 1-year limited

warranty from the date the product was purchased at retail and each product is free from defects in

materials. Warranty does not apply to defects due directly or indirectly to misuse, abuse, negligence,

or accidents, repairs or alterations, or a lack of maintenance. NATI shall in no event be liable for

death, injuries to persons or property, or for incidental, special, or consequential damages arising from

the use of our products. To receive service under warranty, the original manufacturer part must be

returned for examination by an authorized service center. Shipping and handling charges may apply. If

a defect is found, NATI will either repair or replace the product at its discretion.

DO NOT RETURN TO STORE

For Customer Service:

Email: [email protected] or Call 1-800-348-5004

8808902 06/13

14/20 INCH CHAINSAW

Model: 8902, 50969

For Customer Service, please call 1-800-348-5004 or

email feedback@natitools.com

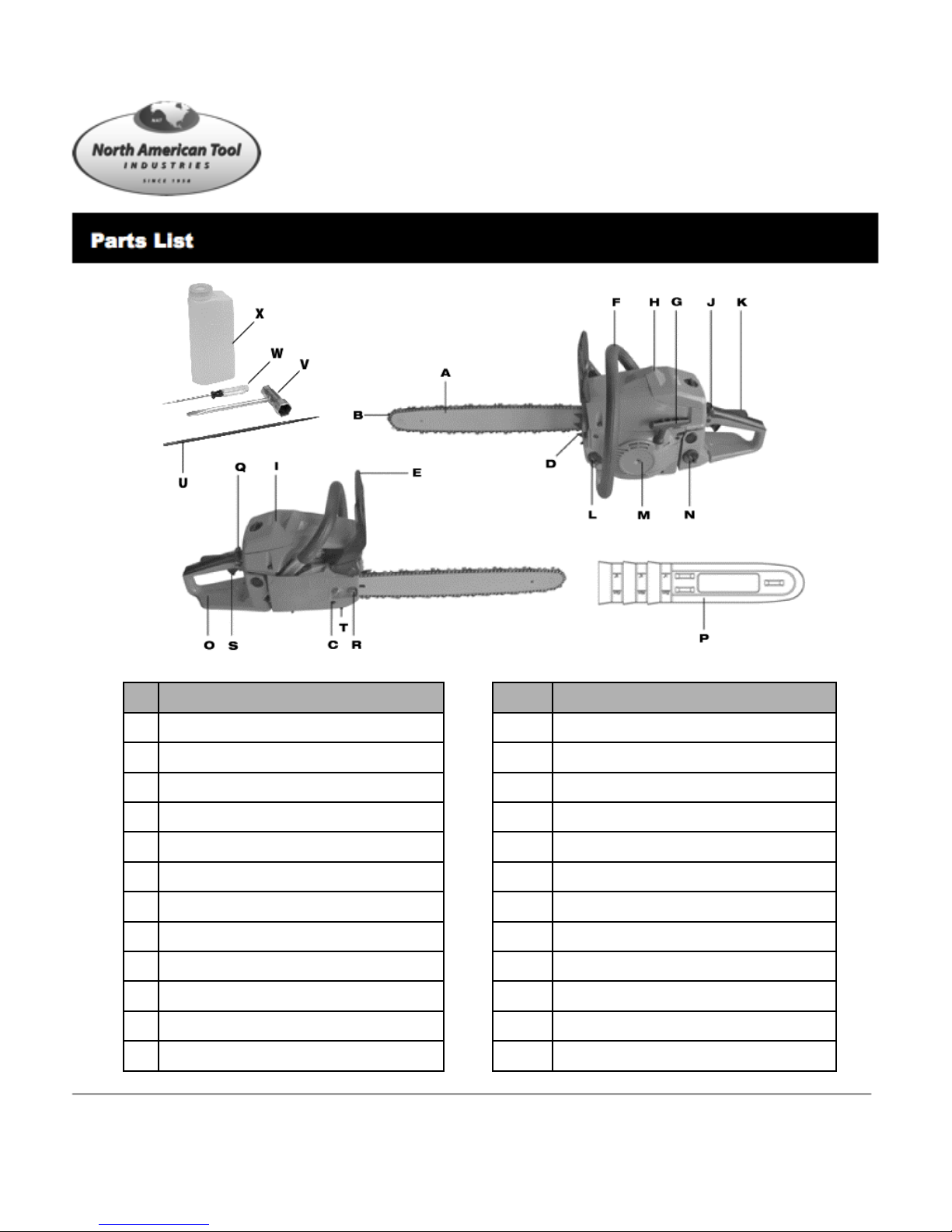

Safety LockK

Oil Tank CapL

Stop SwitchJ

#Part Description

AChain Bar qty 2 (size varies by model)

BSaw Chain qty 2 (size varies by model)

CChain Tensioning Screw

DStop Claw

EChain Brake Lever/Front Hand Guard

FFront Handle

GStarter Handle

HSpark Plug (under air filter cover)

IAir Filter Cover

Screw DriverW

Chain FileU

Plug WrenchV

Chain CatchT

#Part Description

MFan Housing

NFuel Tank Cap

ORear Handle/Bootstrap

PBar Cover

QChoke/Carburetor Setting

RBar Fastening Nut

SThrottle Lever

XMixing Bottle

11

8808902 06/13

12

For customer service, call 1-800-348-5004 or

e-mail feedback@natitools.com

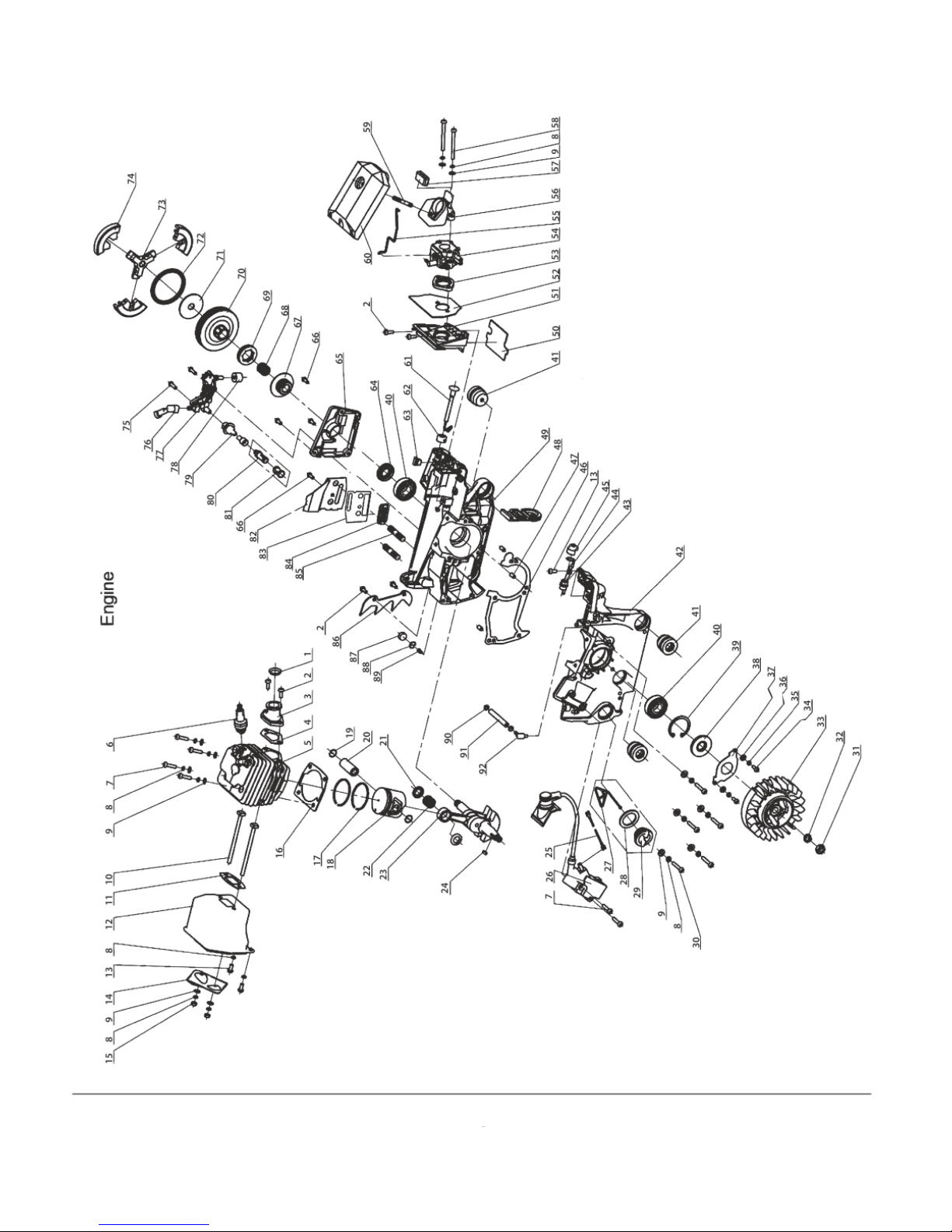

Parts List

8808902 06/13

13

For Customer Service, please call 1-800-348-5004 or

email feedback@natitools.com

Parts List

14

feedback@natitools.com

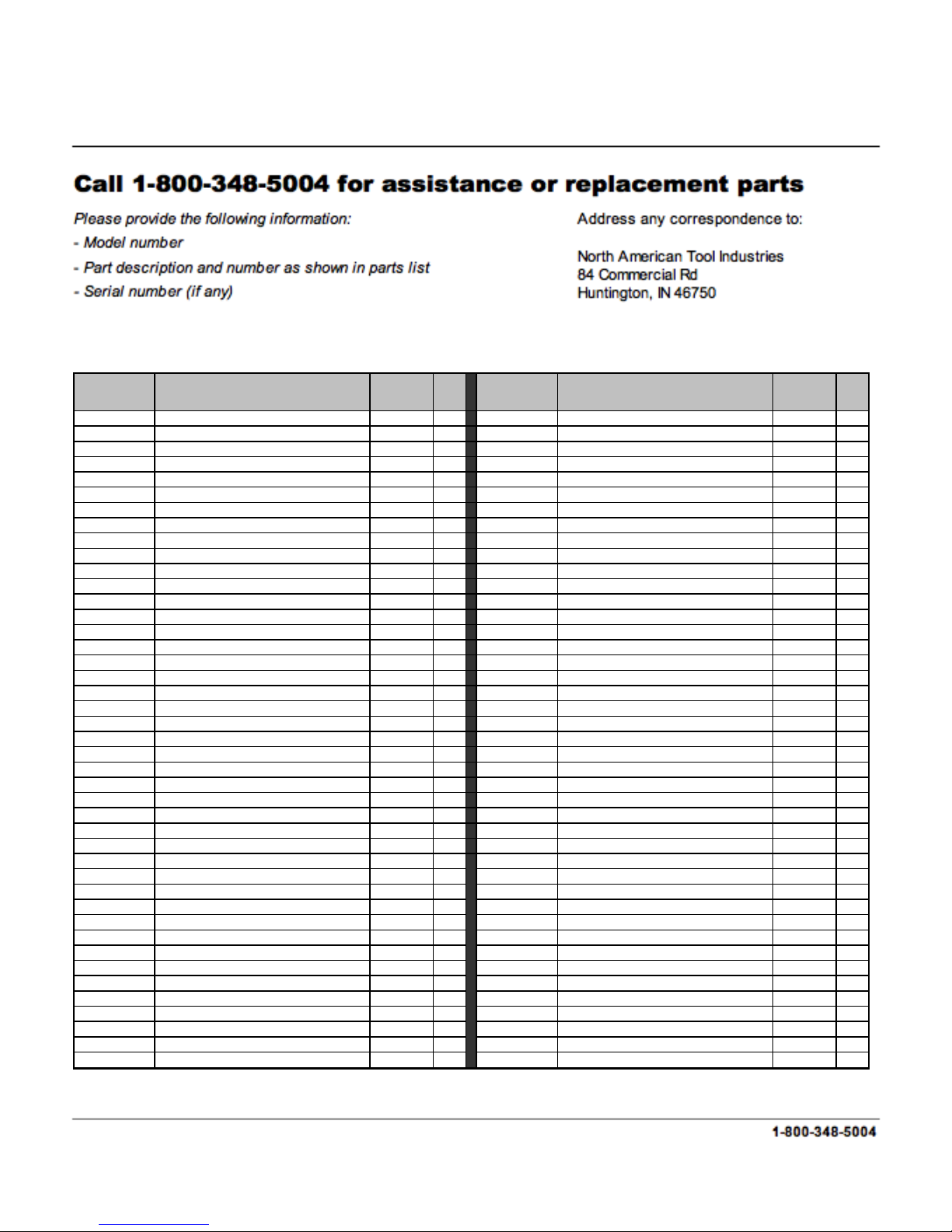

Parts List

Part

Reference#

Parts Description

NATI

SKU#

Qty

Part

Reference#

Parts Description

NATI

SKU#

Qty

1 Retainer Ring

38544 144 Ground Strip 38904 1

2 Screw M5X12

39348 645 Flameout Switch Retainer 38905 1

3 Air Intake Tube

38545 146 Crankshaft Case Gasket 38906 1

4 Air Intake Tube Gasket

38546 147 Pin 38907 3

5 Cylinder

38547 148 Dust Plate 38908 1

6 Spark Plug

38548 149 Right Crankshaft Case 38909 1

7 Screw M5X20

38549 650 Backing Board 38910 1

8 Spring Washer 5

38550 13 51 Air Intake Tube Support 38911 1

9 Washer 5

38551 15 52 Air Intake Tube Support Gasket 38912 1

10 Silencer Bolt

38552 253 Air Intake Flange 38913 1

11 Silencer Gasket

38553 154 Carburetor 38914 1

12 Silencer

38554 155 Accelerator Rod 38915 1

13 Screw M5x10

40946 456 Air Intake 38919 1

14 Silencer Cap

38555 157 Air Intake Cushion 38925 1

15 Nut M5

38556 358 Screw M5-52mm 38929 1

16 Cylinder Gasket

38557 159 Screw 38955 1

17 Piston Ring

38558 260 Air Filter 38956 1

18 Piston

38559 161 Choke Knob 38959 1

19 Piston Pin Circlip

38560 262 Choke Knob Retainer 38969 1

20 Piston Pin

38561 263 Anti-Shock Block 38970 1

21 Needle Bearing Ring

38562 264 Oil Seal 38974 1

22 Needle Bearing

38563 165 Oil Pump Cover Plate 38975 1

23 Crankshaft Components

38669 166 Screw 38976 4

24 Semicircular Key

38748 167 Worm Gear 38994 1

25 Flameout Wire

38812 168 Needle Bearing 39001 1

26 Igniter

38881 169 Sprocket Wheel 39068 1

27 Oil Cap Retainer

38885 170 Clutch Shell w/ Sprocket 39079 1

28 Oil Cap Packing

38888 171 Clutch Washer 39080 1

29 Oil Cap

38889 172 Clutch Extension Spring 39081 1

30 Screw

38890 573 Retainer 39082 1

31 Nut

38891 174 Shoe Block 39083 3

32 Spring Washer 8

38892 172-73-74 Clutch Assembly 43853 1

33 Flywheel

38893 175 Screw 39084 2

34 Screw

38894 276 Oil Nozzle 39085 1

35 Spring Washer 4

38895 277 Oil Pump 39086 1

36 Washer 4

38896 278 Oil Sponge Ring 39087 1

37 Oil Seal Protector Plate

38897 179 Oil Tube 39094 1

38 Oil Seal 15x35x4.5

38898 180 Oil Filter Body 39095 1

39 Snap Ring 35

38899 181 Oil Filter Screen 39096 1

40 Bearing 6202 Grade D

38900 282 Protecting Shield 39151 1

41 Anti-Vibration Cushion D

38901 383 Protecting Shield Cover 39215 1

42 Left Crankshaft Case

38902 184 Chain Guide 39237 1

43 Flameout Switch

38903 185 Screw (Bar Stud M8X28-8.8) 39238 2

15

feedback@natitools.com

Parts List

Part

Reference#

Parts Description

NATI

SKU#

Qty

Part

Reference#

Parts Description

NATI

SKU#

Qty

86 Spiked Bumper 39244 1128 Screw 40900 1

87 Sponge Block 39245 1129 Trigger Controller 44426 1

88 Aeration Nozzle Circlip 39246 1130 Handle Cover 44098 1

89 Aeration Nozzle 39251 1131 Trigger 39369 1

90 Suction Tube Circlip 39252 2132 Trigger Torsion Rod Spring 39369 1

91 Suction Tube 39268 1133 Pin 39369 1

92 Suction Nozzle 39284 1134 Balancer Cover 39369 1

93 Air Filter Lock Nut 39285 1135 Filter 39369 1

94 Lock Nut Washer 39286 1136 Balancer Rubber 39369 1

95 Air Filter Cover 40896 1137 Balancer Body 39369 1

96 Shock Rubber Cushion 39306 1138 Fuel Tube 44029 1

97 Upper Cover Plate 40897 1139 Fuel Tube Base 44030 1

98 Screw 44100 10 140 Fuel Filter Components 44031 1

99 Chain Catcher 39310 1171 Chain Brake Assembly 39368 1

100 Screw 39319 4141 Chain Adjusting Tightener 39341 1

101 Conical Spring Base 39333 1142 Tightening Screw 39342 1

102 Conical Spreader Spring 39334 1143 Tightening Gear 39343 1

103 Idle Adjusting Guide 39335 1144 Brake Spring Cover 39368 1

104 Screw ST4.8X16 39336 4145 Screw 44096 5

105 Front Handle Assembly 39337 1146 Shock Rubber Washer 39368 1

170 Recoil Assembly 39367 1147 Shield Ring 39368 1

106 Kick Spring Base 39367 1148 Washer 39368 1

107 Kick Spring 39367 2149 Brake Torsion Rod Spring 39368 1

108 Starter Cover 39367 1150 Front Guard Tube 39368 1

109 Start Rope 39367 1151 Tightener Cover 39344 1

110 L H Sheathing 39367 1152 Dust Shield 39368 1

111 Coil Spring 39367 1153 Brake Belt 39368 1

112 Starting Handle 39367 1154 Chain Guide 39368 1

113 Coil Spring Shell 39367 1155 Nut 40947 2

114 Starter Wheel 39367 1156 Right Cover 39368 1

115 Big Washer 39367 2157 Shock Rubber Cushion 39368 1

116 Cooling-Air Mask 40899 1158 Cam plate 39368 1

172 Main Frame/Gas Tank Assembly 39369 1159 Shield Ring 39368 1

117 Dust Cover 44092 5160 Front Guard Pin 39368 1

118 Screw M5X16 39319 2161 Shield Ring 39368 1

119 Double-Ended Pin 39369 1162 Front Guard 39368 1

120 Anti-Vibration Cushion C 44097 2163 Positioning Pin 39368 1

121 Fuel Cap 39338 1164 Secondary Brake Spring 39368 1

122 Fuel Cap Washer 39339 1165 Brake Spring 39368 1

123 Fuel Cap Retainer 39340 1166 Brake Control Rod 39368 1

124 Button 44093 1167 Pin 40902 2

125 Button Spring 44094 1168 Secondary Pull-Rod 39368 1

126 Button Shaft 44095 1169 Main Pull-Rod 39368 1

127 Base 39369 1

16

feedback@natitools.com

I. EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The United States Environmental Protection Agency (EPA), together with North American Tool Industries are

pleased to explain the Emission Control System Warranty on your new small off-road engine. New small off-road

engines must be designed, built, and equipped to meet stringent anti-smog standards for the state of the federal

government. NATI will warrant the emission control system on your engine for the periods of time listed below

provided there has been no abuse, neglect, unapproved modification, or improper maintenance to your engine.

Your emission control system may include parts such as the carburetor, ignition, intake, and exhaust systems. NATI

will repair your engine at no cost to you for diagnosis, replacement parts, and labor, should a warrantable

condition occur.

MANUFACTURER’S EMISSION CONTROL SYSTEM WARRANTY COVERAGE:

Emission control systems on 2012 and later model year engines are warranted for two years as hereinafter noted. If,

during such warranty period, any emission-related component or system on your engine is found to be defective in

materials or workmanship, a NATI Authorized Warranty Service Facility will perform repairs or replacement.

PURCHASER’S/OWNER’S WARRANTY RESPONSIBILITIES:

As the small off-road engine purchaser/owner, you are responsible for the completion of all required maintenance

as listed in your factory supplied OWNER’S MANUAL. For warranty purposes, NATI recommends that you retain

all receipts covering maintenance on your engine. However, NATI cannot deny warranty solely because of the lack

of receipts or for your failure to ensure the completion of scheduled maintenance.

As the small off-road engine purchaser/owner, you should, however, be aware that NATI may deny any and/or all

warranty coverage, or responsibility if your engine, or a part/component thereof, has failed due to abuse, neglect,

improper maintenance, unapproved modifications, or the use of counterfeit and/or “gray market

”

parts not made,

supplied, or approved by NATI.

You are responsible for presenting your engine to a NATI Authorized Warranty Service Facility as soon as a

problem occurs. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

Warranty service can be arranged by contacting either your selling dealer or a NATI Authorized Warranty Service

Facility. To locate the NATI Authorized Service Facility nearest you, call our toll-free number:

1-800-348-5004

IMPORTANT NOTE: This warranty statement explains your rights and obligations under the Emission Control

System Warranty (ECS Warranty), which is provided to you by NATI pursuant to California and federal law. The

ECS Warranty applies only to the emission control system of your new engine. If there is any conflict in terms

between the ECS Warranty and the NATI Warranty, the ECS Warranty shall apply except in circumstances where

the NATI Warranty may provide a longer warranty period. Both the ECS Warranty and the NATI Warranty describe

important rights and obligations with respect to your new engine.

17

feedback@natitools.com

Only a NATI Authorized Warranty Service Facility can perform warranty service. When requesting warranty

service, evidence must be presented showing the date of the sale to the original purchaser/owner. The

purchaser/owner shall be responsible for any expenses or other charges incurred for service calls and/or

transportation of the product to/from the inspection or repair facilities. The purchaser/owner shall also be

responsible for any and/or all damages or losses incurred while the engine is being transported/shipped for

inspection or warranty repairs.

IF YOU HAVE ANY QUESTIONS REGARDING YOUR WARRANTY RIGHTS AND

RESPONSIBILITIES, YOU SHOULD CONTACT NATI AT THE FOLLOWING ADDRESS:

84 COMMERCIAL RD. HUNTINGTON, IN 46750, USA

feedback@natitools.com

II. EMISSION CONTROL SYSTEM WARRANTY

Emission Control System Warranty (ECS Warranty) for 2012 and later model engines:

(a) Applicability: This warranty shall apply to 2012 and later model year engines. The ECS Warranty

Period shall begin on the date the new engine or equipment is purchased by/delivered to its original,

end-use purchaser/owner and shall continue for 24 consecutive months thereafter.

(b) General Emissions Warranty Coverage: NATI warrants to the original, end-use purchaser/owner of the

new engine or equipment and to each subsequent purchaser/owner that each of its engines is

…

a. Designed, built, and equipped so as to conform with all applicable regulations adopted by the

EPA pursuant to their respective authority, and

b. Free from defects in materials and workmanship which, at any time during the ECS Warranty

Period, may cause a warranted emissions-related part to fail to be identical in all material

respects to the part as described in the engine manufacturer’s application for certification.

The ECS Warranty only pertains to emission-related parts on your engine, as follows:

1. Any warranted, emissions-related parts that are not scheduled for replacement as required maintenance

in the Owner’s Manual shall be warranted for the ECS Warranty Period. If any such part fails during

the ECS Warranty Period, it shall be repaired or replaced by NATI according to subsection 4 below.

Any such part repaired or replaced under the ECS Warranty shall be warranted for the remainder of

the ECS Warranty Period.

2. Any warranted, emissions-related part that is scheduled only for regular inspection as specified in the

Owner’s Manual should be warranted for the ECS Warranty Period. A statement in such written

instructions to the effect of “repair or replace as necessary”shall not reduce the ECS Warranty Period.

Any such part repaired or replaced under the ECS Warranty shall be warranted for the remainder of

the ECS Warranty Period.

18

feedback@natitools.com

3. Any warranted, emissions-related part that is scheduled for replacement as required maintenance

in the Owner’s Manual shall be warranted for the period of time prior to the first scheduled

replacement point for that part. If the part fails prior to the first scheduled replacement, the part

shall be repaired or replaced by NATI according to subsection 4 below. Any such emissions-related

part repaired or replaced under the ECS Warranty shall be warranted for the remainder of the ECS

Warranty Period prior to the first scheduled replacement point for such emissions-related part.

4. Repair or replacement of any warranted, emissions-related part under this ECS Warranty shall be

performed at no charge to the owner at a NATI Authorized Warranty Service Facility.

5. When the engine is inspected by a NATI Authorized Warranty Service Facility, the owner shall not

be held responsible for diagnostic costs if the repair is deemed warrantable.

6. NATI shall be liable for damages to other original engine components or approved modifications

proximately caused by a failure under warranty of any emission-related part covered by the ECS

warranty.

7. Throughout the ECS Warranty Period, NATI shall maintain a supply of warranted emission-related

parts sufficient to meet the expected demand for such emissions-related parts.

8. Any NATI authorized and approved emissions-related replacement parts may be used in the

performance of any ECS Warranty maintenance or repairs and will be provided without charge to

the purchaser/owner. Such use shall not reduce NATI’s ECS Warranty obligations.

9. Unapproved, add-on, modified, counterfeit, and/or “gray market

”

parts may not be used to modify

or repair a NATI engine. Such use voids this ECS Warranty and shall be sufficient grounds for

disallowing an ECS Warranty claim. NATI shall not be held liable hereunder for failures of any

warranted parts of a NATI engine caused by the use of such an unapproved, add-on, modified,

counterfeit, and/or “gray market

”

part.

19

feedback@natitools.com

EMISSIONS-RELATED PARTS INCLUDE THE FOLLOWING:

For engine families CZHWS.0454SN

1. Fuel Metering System:

a. Gasoline carburetor assembly and its internal components (if so equipped).

b. Fuel Filter (if so equipped).

c. Carburetor Gaskets

d. Fuel Pump (if so equipped).

e. Fuel Hose

f. Clamps

2. Air Induction System including:

a. Intake Pipe/Manifold

b. Air Cleaner

3. Ignition System including:

a. Spark Plug

b. Ignition Module/Coil

4. Catalytic Muffler Assembly (if so equipped)

a. Muffler Gasket

b. Exhaust Manifold

5. Crankcase Breather Assembly including:

a. Breather Connection Tube

6. Fuel tank evaporative emissions control system include:

a. Fuel Tank

b. Fuel Cap

c. Fuel Hose

d. Clamps

7. Miscellaneous items used in above systems including:

a. Switches

b. Hoses, Belts, Connectors, and Assemblies

This manual suits for next models

3

Table of contents

Other North American Tool Chainsaw manuals