Northern Fridge TF86DC User manual

TF86DC User Manual

Updated 23 April 2020 Page 1

By

DESIGNED & MANUFACTURED IN ITALY

TF86DC User Manual

Updated 23 April 2020 Page 2

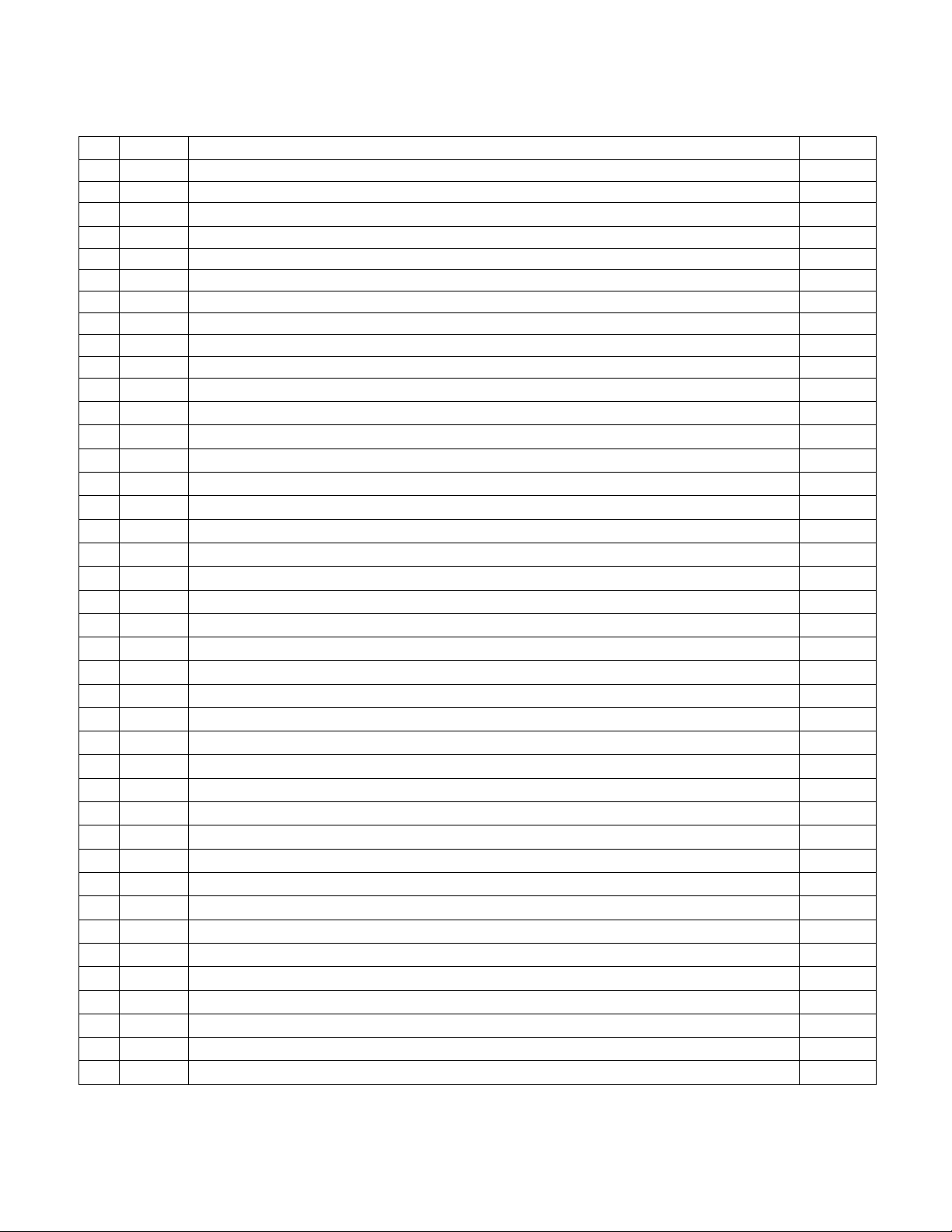

TABLE OF CONTENTS

1.0

GENERAL INFORMATION

3

1.1

Introduction

3

1.2

Notice

3-4

2.0

COMPONENTS

4

2.1

Refrigeration System

4

2.1.1

Compressor

4

2.1.2

Electronic Control Unit (ECU)

4

2.1.2.1

Replacing the ECU

5

2.1.3

Condenser

6

2.1.4

Evaporator

6

2.1.5

Thermostat

6

3.0

INSTALLATION

6

3.1

Installing the TF86DC with TF86FK Installation Kit

7

3.2

Installing the TF86DC without TF86FK Installation Kit

7

3.3

Installing the TF86DC in the Freightliner “New” P4 Cascadia

8

3.3.1

Installing the CPlug Extension Adapter Wire Harness in the “New” P4 Cascadia

8

3.4

Ventillation

8

3.5

Wiring System: Function and Features

8

3.5.1

Wiring Connections

8-9

3.6

TF86DC Door Assembly

9

3.6.1

Replacing the Door Panel

9

3.6.2

Reversing the Door Opening

10

4.0

FEATURES

11

4.1

Setting the Inside Temperature

11

4.2

Filling

11

4.3

Defrosting

11

5.0

MAINTENANCE

11

5.1

Useful Advice

12

6.0

TROUBLESHOOTING

12

6.1

Troubleshooting Guide

12

6.2

Self-Diagnostics Procedure

13

6.3

Thermostat Test Procedure

14

7.0

SPECIFICATIONS

14

8.0

ILLUSTRATIONS

15

8.1

Figure 8.1: TF86DC Parts Diagram

15

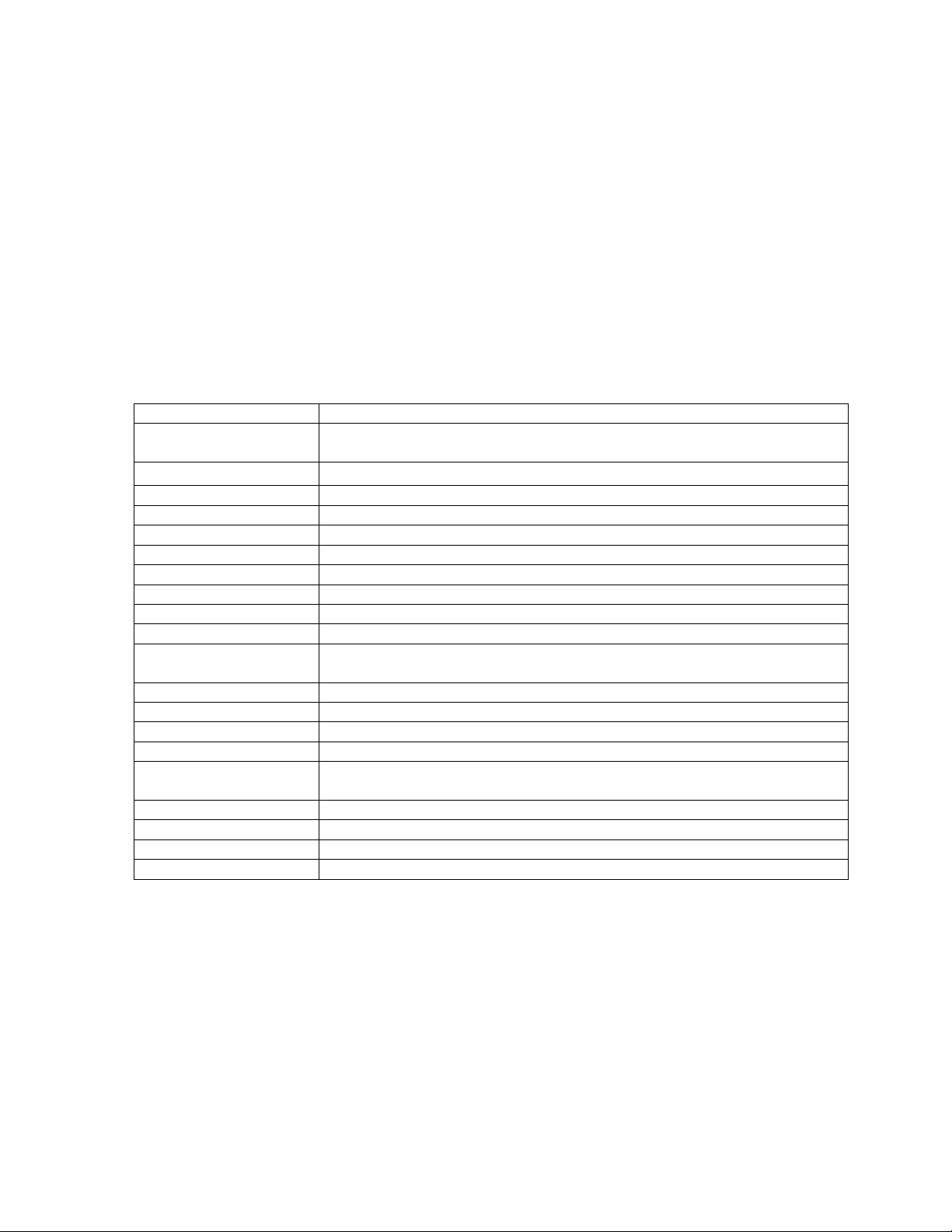

8.1.1

Figure 8.1.1: TF86DC Parts List/Description

16

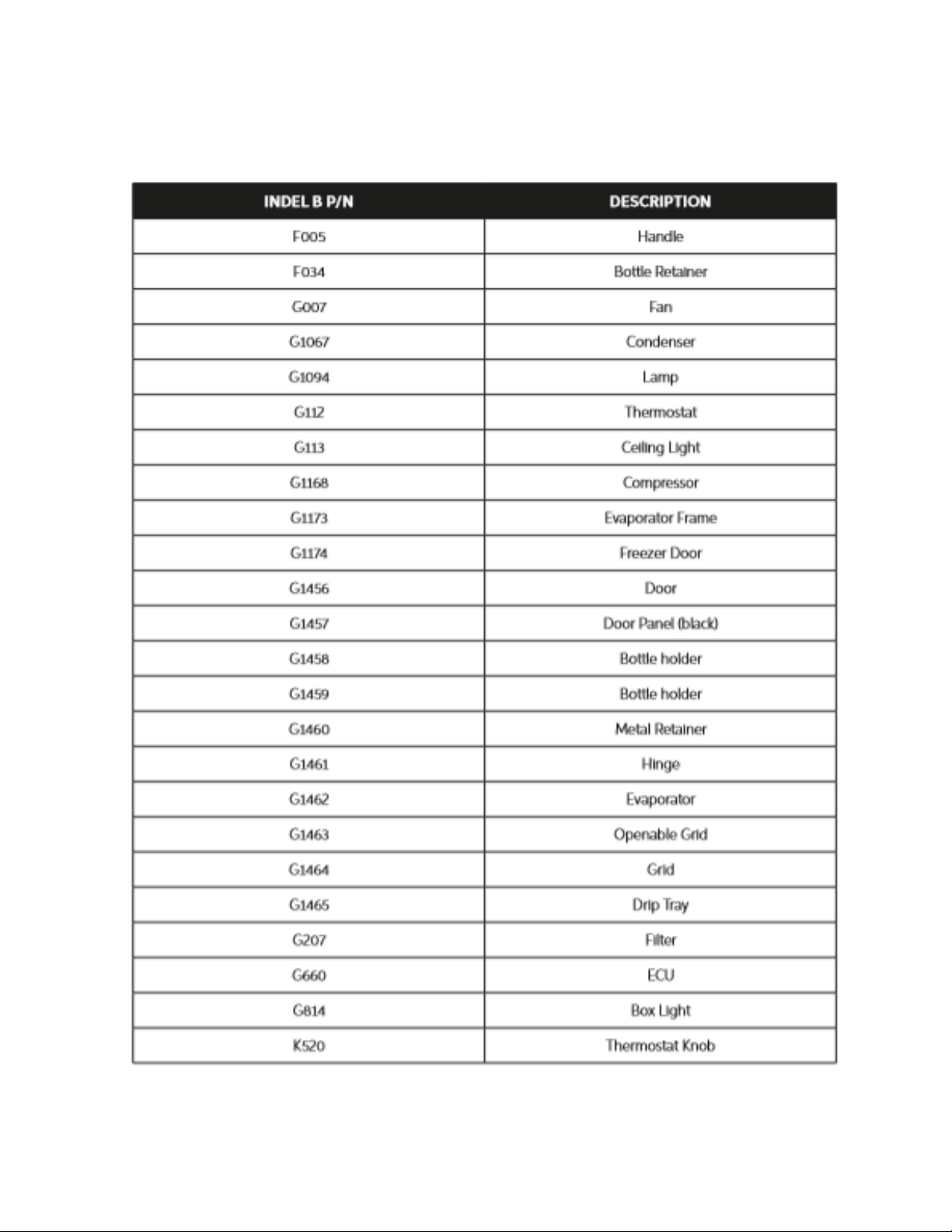

8.2

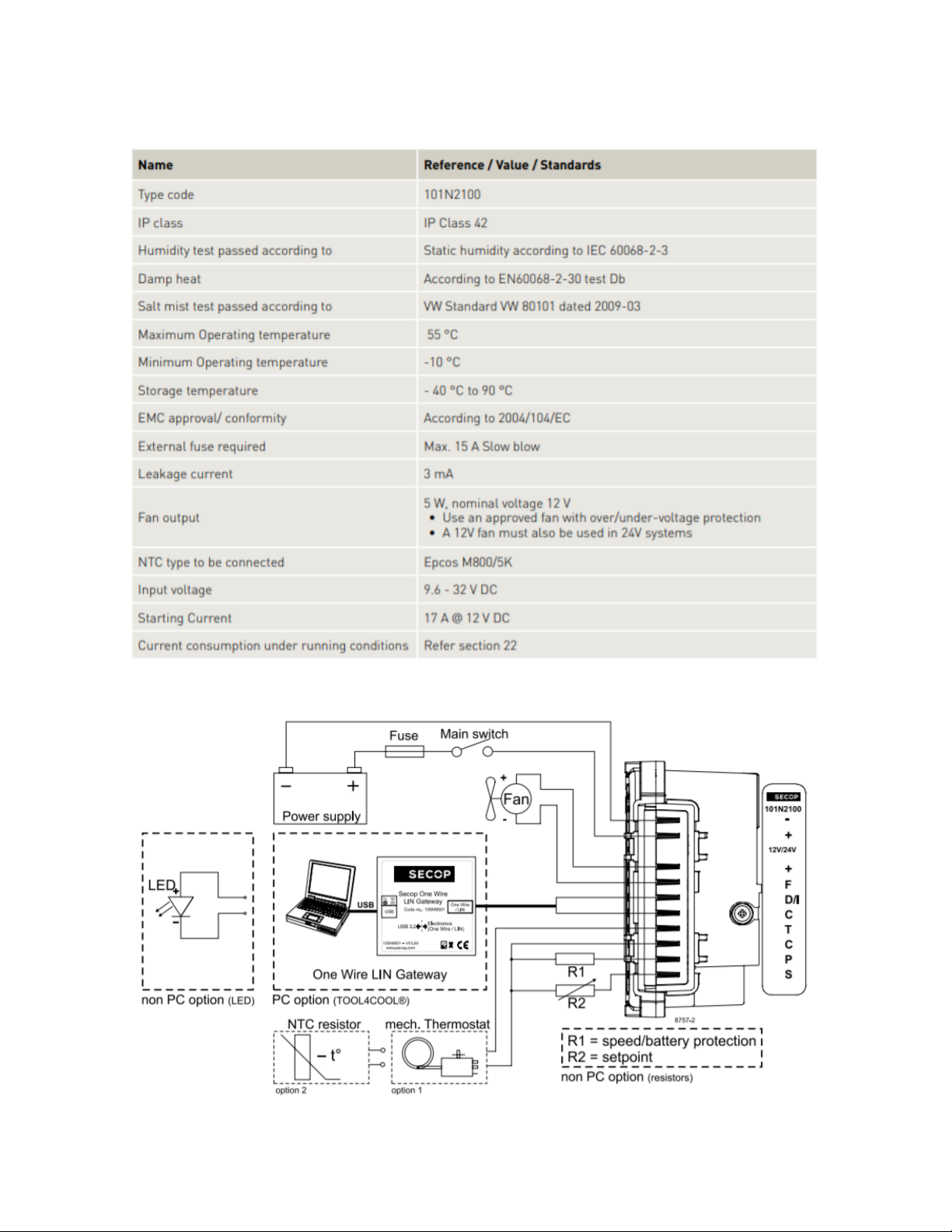

Figure 8.2: Danfoss/Secop BD1.4F-VSD-HD Specifications

17-18

8.3

Figure 8.3: 101N2100 ECU Specifications

19

8.3.1

Figure 8.3.1: 101N2100 ECU Wiring Diagram

19

8.4

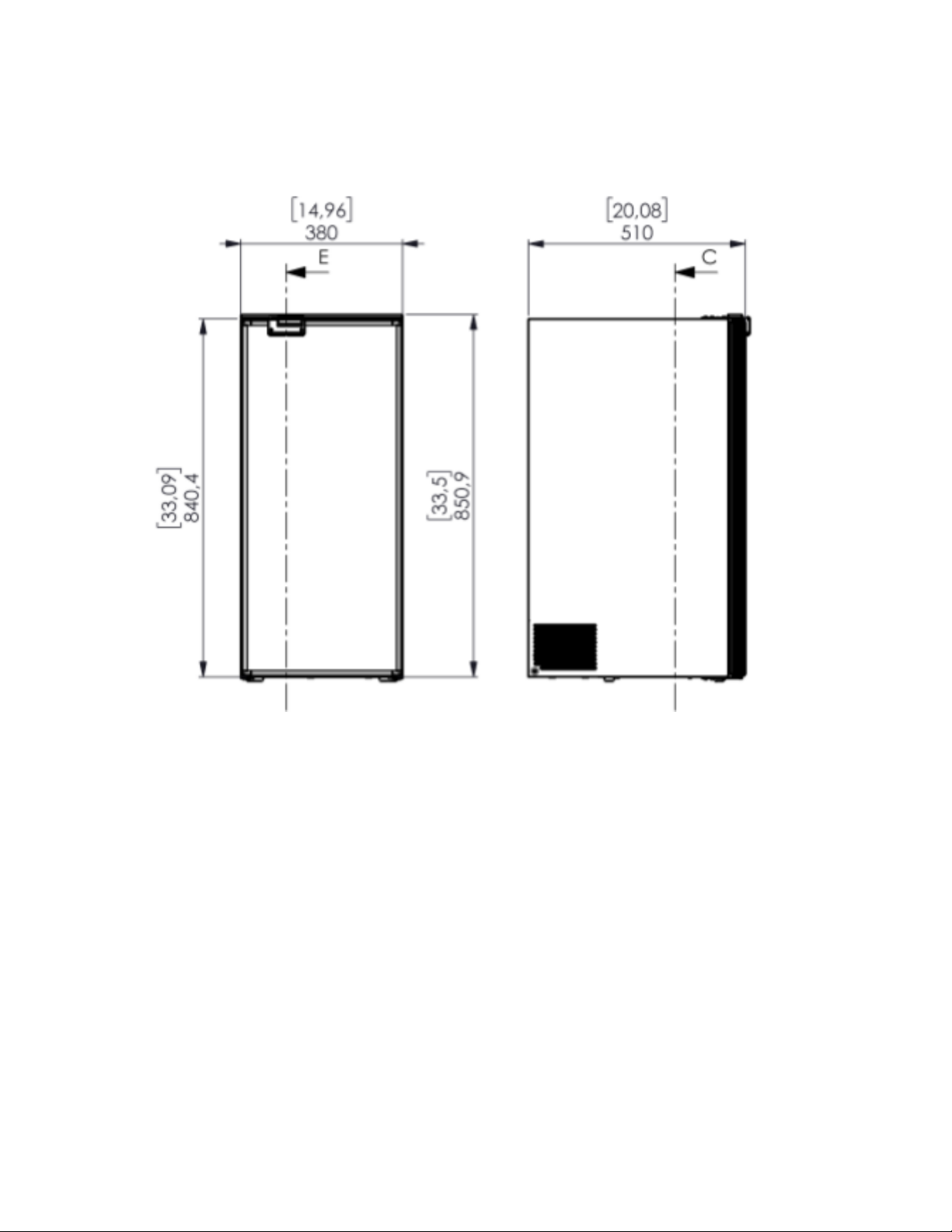

Figure 8.4: TF86DC Dimensional Diagram

20

8.5

Figure 8.5: TF86DC Ventilation Diagram

21

TF86DC User Manual

Updated 23 April 2020 Page 3

1.0 GENERAL INFORMATION

1.1 Introduction

The TF86DC refrigerator has been designed and tested to give many years of performance and reliability. The 12/24 V power

supply makes them especially versatile. The power source can either be a battery, a transformer or a photo-voltaic (Solar)

panel. Provided with a totally watertight compressor, they offer a minimal power consumption and noise level. All the models

are extremely easy to install. They can work even if they are assembled at a slant of up to 30°. In order to make sure that your

TF86DC refrigerator works as efficiently as possible, please pay attention to the following general instructions:

•Never connect a battery charger directly to the refrigerator. A battery and in-line 15 amp fuse must be used to

protect the compressor and Electronic Control Unit (ECU).

•Reduce opening the door of the refrigerator to reduce the waste of energy

•Proper ventilation of the compressor and of the condenser unit reduces the energy consumption and increases

overall efficiency and performance.

•Ensure the wiring system of the vehicle is in proper condition. Routinely check the batteries and the charge level.

Follow the instructions about the cable cross sections and the fuse connections strictly. See Section 3.5: Wiring

System: Function and Features for details.

•Keep the inside of the refrigerator clean and dry. Remove any condensate water which might gather in the tray

under the freezer compartment

•Keep the door of the refrigerator slightly open in order to air it out if you do not use it for a long time, for example in

winter. (See 3.6 TF86DC Door Assembly for further details).

1.2 Notice

WARNING! Do not install the refrigerator near heat sources.

WARNING! Keep ventilation openings in the appliance enclosure or in the built-in structure, clear of obstruction.

WARNING! Do not use mechanical devices or other means to accelerate the defrosting process as this

could damage the evaporator and result in leaks which are not covered under warranty.

WARNING! Do not damage the refrigerant circuit.

WARNING! Do not use electrical appliances inside the food storage compartments of the appliance, unless they are

of the type recommended by the manufacturer.

WARNING! Do not store explosive substances such as aerosol cans with a flammable propellant in this appliance.

WARNING! Risk of fire and electrical shock or fire.

WARNING! Do not let hot items to touch the plastic parts of the appliance.

WARNING! Do not store flammable gas and liquid in the appliance.

WARNING! Do not put flammable products or items that are wet with flammable products in, near or on the

appliance.

WARNING! Do not touch the compressor or the condenser. They may be hot.

TF86DC User Manual

Updated 23 April 2020 Page 4

WARNING!

• The refrigerator is suitable for the preservation and/or storage of food items and maintaining already

frozen food.

• Use the fridge exclusively for cooling and storing closed beverages and snacks.

• Food may only be stored in its original packaging or in suitable containers.

• The fridge is not intended to be brought into contact with food.

• The fridge is not intended for the proper storage of medicines.

2.0 COMPONENTS

2.1 Refrigeration System

Refer to 8.0 ILLUSTRATIONS: Figure 8.1 “TF86DC Parts Diagram”.

2.1.1 Compressor

The TF86DC uses the new generation direct current Danfoss/Secop BD1.4F-VSD-HD Micro Variable Speed

compressor that is specially designed for extraordinary performance at minimum power consumption, superbly

silent-running, reliable operation even when tilted up to 30 degrees. The BD Micro series from Secop is 60% smaller

than previous models and weighs in at only 2.3 kilograms.

The variable speed compressor minimizes compressor speed as input voltage varies to reduce power consumption.

The BD1.4F-VSD-HD Heavy Duty can handle extreme vibrations.

(See 8.0 ILLUSTRATIONS: Figure 8.2: Danfoss/Secop BD1.4F-VSD-HD Specifications for complete details).

(See WARNING in 2.1.4: Evaporator).

2.1.2 Electronic Control Unit (ECU)

The Electronic control unit (ECU) of the compressor is a piece of electronic equipment which carries out all the

controls and electrical protection of the compressor system. Its main features include;

a) Protection of the battery with automatic turning off of the compressor when the feeding voltage reaches the

minimum threshold (cut out) typically 10 volts. The compressor will start up automatically again when the voltage

goes back to normal values (cut in). Typically 11 volts.

b.) Thermal overload protection cut out. The compressor will shut down when temperatures exceed 125 deg F

ambient to protect the compressor from overheating. It will cut in automatically when temperatures drop below this

temperature.

c.) Cooling fan operation will begin automatically when compressor starts and stop when compressor shuts off in

normal operation.

The main functions of the 101N2100 ECU is to provide all controls for the BD1.4F-VSD-HD compressor systems

including:

• Motor / Compressor speed control

• Condenser fan control including speed setting

• Battery protection functions

TF86DC User Manual

Updated 23 April 2020 Page 5

2.1.2.1 Replacing the ECU

The ECU can be simply removed and/or installed by removing a screw to release module for the side of the

compressor to reveal the 3-pin plug that attaches the ECU to the compressor. Follow these simple steps;

Note. ECU and compressor shown in diagrams appear different than actual TF86DC ECU and compressor (For display

purposes only) however the procedures is similar.

1. Disconnect all terminals (22) from the control ECU and, while doing so, mark them adequately, so as not to

connect them wrongly during reassembly. See Figure 2.1.2.1.1

2. Unscrew the screw (23). See Figure 2.1.2.1.2.

3. Disconnect the connector (24) from the ECU, from the compressor (25). See Figure 2.1.2.1.3

4. Replace the damaged ECU by first assembling the left hand side and afterwards press the right hand side on the

screw head on the bracket. ln this way the ECU gets locked on the bracket and is securely fastened to the

compressor.

2.1.3 Condenser

The condenser may be of static or ventilated type. Since its function is to dissipate heat, it must be placed in a zone

allowing for the maximum heat exchange with the environment and must not be clogged with dust or other

substances preventing the exchange of heat. (See 3.4: Ventilation).

Figure 2.1.2.1.1

Figure 2.1.2.1.2

Figure 2.1.2.1.3

TF86DC User Manual

Updated 23 April 2020 Page 6

2.1.4 Evaporator

The evaporator is the element where the gas is expanded causing heat absorption thereby cooling the ambient air

around it. The capillary pipe is an integral part of the evaporator that creates a narrow path for the gas causing a

pressure difference between the circuit delivery and suction. If the capillary pipe gets obstructed, the entire

evaporator must be replaced.

2.1.5 Thermostat

The TF86DC is provided with a manual thermostat located inside the

refrigerator on the right side just below the freezer. Turn the knob

clockwise to lower the temperature and turn it counter clockwise to

raise the temperature and activate the ON-OFF switch in its end (0)

position. In case of anomalies or fault, the thermostat cannot be

repaired and must be replaced. See Figure 2.1.5.1: TF86DC

Thermostat.

3.0 INSTALLATION

The refrigerators from TruckFridge are assembled to be installed in a standard factory cabinet. In some cases, if the

truck was not equipped with a fridge from the truck factory, the cabinet may be slightly different and require a slight

modification to install a fridge. Note any additional instructions included with the packing list when purchasing the

fridge new. The fridge weight must always be sitting on its feet to support the weight. In some cases, a block may be

needed under the bottom of the fridge to lift it off the floor of some cabinets to fill in gaps at the top. This allows air

to enter the cabinet from the bottom. In other cases, a filler strip may be needed to make up gaps in the side of

some truck cabinets that were not originally designed for fridge. (See 8.4 ILLUSTRATION: TF86DC Dimensional

Diagram for details).

Most models from TruckFridge can be installed by attaching the fridge installation trim frame to the trucks cabinet

using the appropriate screws required for the material of the truck cabinet.

It is very important for the refrigerating unit, consisting of the compressor and the condenser, to be well ventilated,

with the cool air coming in from the bottom and going out from the top. You must ensure proper ventilation of the

refrigerating unit. The air inlets and outlets must have a free cross section of at least 10 square inches total. (See 8.0

ILLUSTRATIONS: Figure 8.5: TF86DC Ventilation Diagram for details).

Figure 2.1.5.1: TF86DC Thermostat.

WARNING !!

DO NOT POWER ON THE FRIDGE FOR A MINIMUM OF 4 HOURS AFTER INSTALLATION.

The compressor must normally stand in a vertical position. During shipping, the fridge may be turned on its

side or upside down. This may cause the compressor oil to drain from the compressor into the capillary pipe

thereby obstructing operation of the evaporator. You must allow time for the oil to drain back into the

compressor for proper lubrication. FAILURE TO DO THIS MAY DAMAGE THE COMPRESSOR AND/OR

EVAPORATOR AND VOID YOUR WARRANTY.

TF86DC User Manual

Updated 23 April 2020 Page 7

Take great care when handling the fridge and avoid handling the refrigeration tubes in order to prevent breakages.

The compressor must normally stand in a vertical position

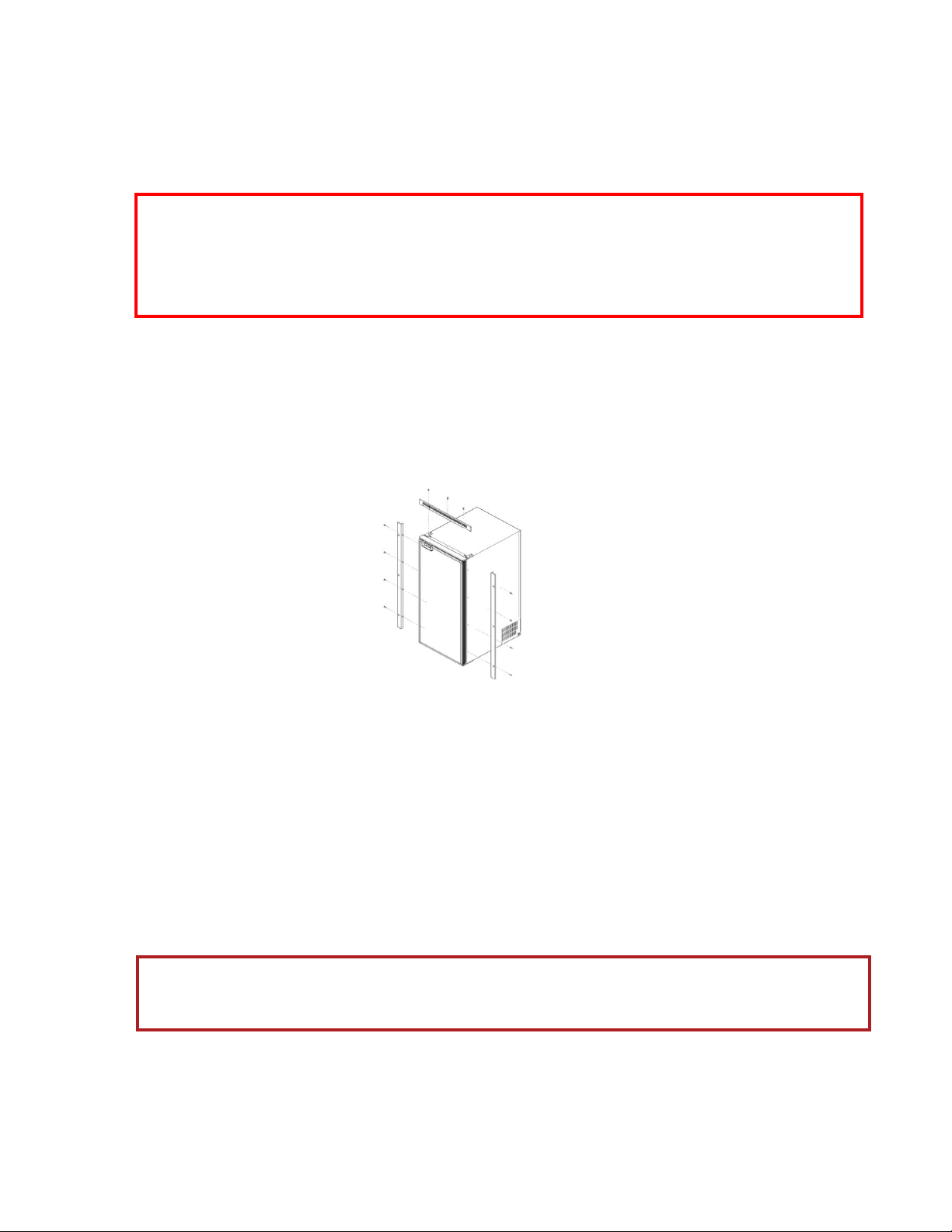

3.1 Installing the refrigerator with TF86FK Installation Kit.

The TF86DC is designed for built-in installation and can be fixed in place using the optional TF86FK Installation Kit.

The TF86FK includes three flanges (two at the sides and one on top) and fixing screws. The side flanges are fixed to

the refrigerator with 4 screws each, while the top flange is fixed with 3 screws. (See Figure 3.1.1 “TF86DC Installation

Diagram”below).

Figure 3.1.1: TF86FK Installation Diagram

3.2 Installing the refrigerator without TF86FK Installation Kit

Alternatively, the TF86DC may be installed without the use of the TF86FK Installation Kit following these instructions,

1. Build the cabinet as per the TF86DC Line Diagram (8.0 ILLUSTRATIONS: Figure 8.4 TF86DC “Dimensional

Diagram”) with at least ¼” space on both the sides and top of the fridge.

2. Cut hole vents at the bottom/rear of both sides of the cabinet for ventilation.

3. Allow 1-2” at rear of cabinet for ventilation. Note. The better the ventilation the better the performance.

4. Use screws through the side walls of the cabinet and into the sides of the fridge to secure it in place.

WARNING !!.

Screw cannot penetrate more than ½” into the sides of the fridge to avoid damage and void warranty.

WARNING !

If the fridge has been leaned over prior to installation, it must sit upright for at least 4 hours prior to

connecting power and turning on. FAILURE TO ALLOW FRIDGE TO STAND UPRIGHT MAY DESTROY

COMPRESSOR AND WILL VOID THE WARRANTY!

TF86DC User Manual

Updated 23 April 2020 Page 8

3.3 Installing the TF86DC refrigerator in the Freightliner “New” P4 Cascadia

The TF86DC can be installed in the Freightliner 2018+ P4 Cascadia using the OEM supplied base plate and two straps.

Connect the 12VDC power using the CPlug Extension Adapter Wire Harness (Sold separately).

The CPlug is a 3' power adapter cable specifically designed for "New" P4 Cascadia installations where the TF86DC is

being installed onto the OEM provided base plate behind the passenger seat. The CPlug extends the factory supplied

"New" P4 Cascadia power connection under the bunk bed on the passenger end to the mounting plate behind the

passenger seat. The CPlug is approximately 36 inches in length and consists of two (2) 12 gauge wires; Red (positive)

and Black (negative). One end terminates in a female double spade Delph connector that connects to

the TF86DC and the other end terminates in a male Delphi connector that connects to the "New" P4 Cascadia

existing OEM connector under the bunk bed.

3.3.1 Installing the CPlug Extension Adapter Wire Harness for “new” Cascadia P4

Lift the bed, unplug the connector from the back of the outlet and connect to the Delphi connector end of the CPlug

and run it along the under bunk wall and out at the rear of the platform to the TF86DC located behind the passenger

seat.

3.4 Ventilation

It is very important for the refrigerating unit, consisting of the compressor and the condenser to be well ventilated

with adequate air flow into and out of the cabinet housing the refrigerator. (See 8.0 Illustrations: Figure 8.5 “TF86DC

Ventilation Diagram” for details). Do not install the refrigerator near heat sources

3.5 Wiring System: Function and Features

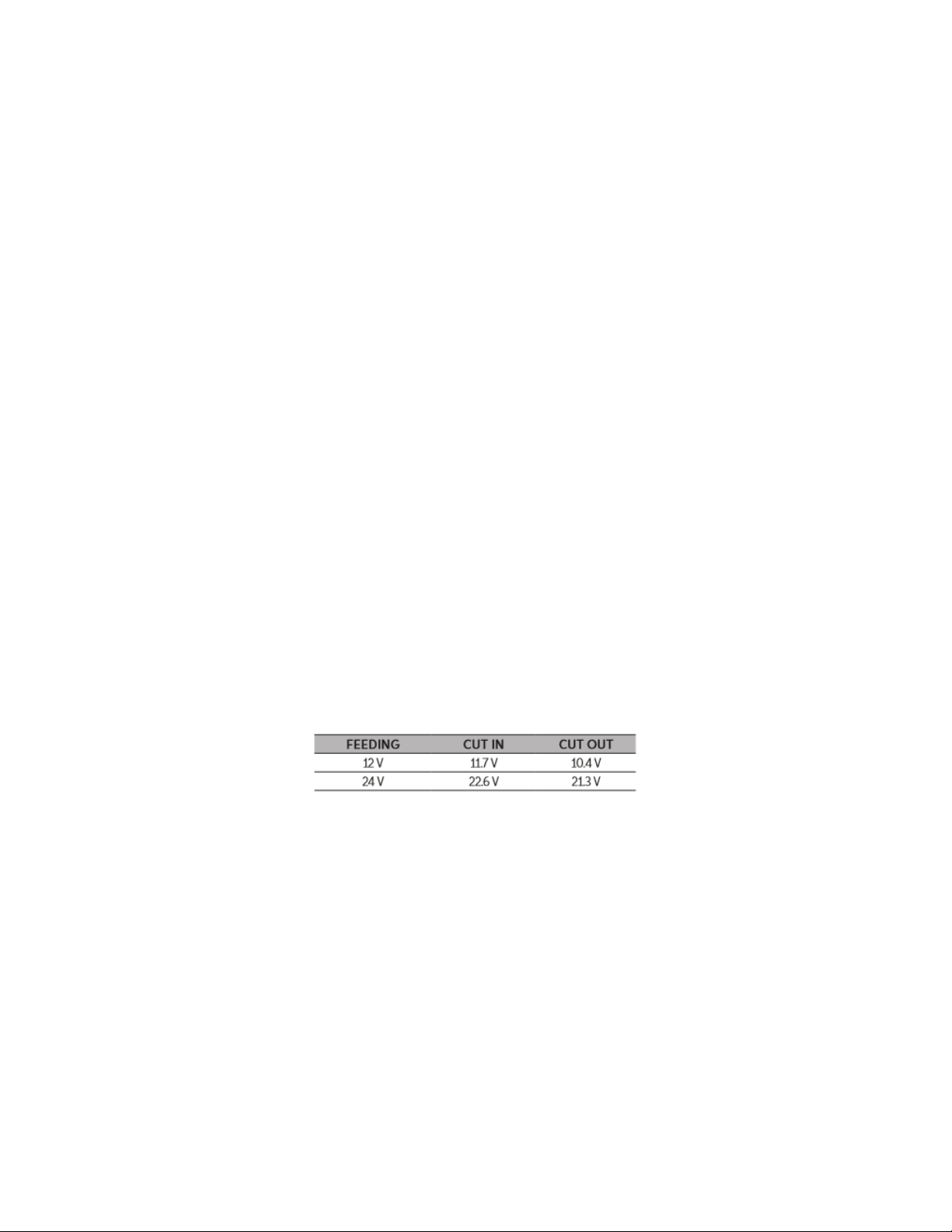

The Electronic Control Unit (ECU) is a piece of electronic equipment which controls the motor of the compressor and

carries out all the controls and electrical protection of the system. The ECU provides protection of the battery with

automatic turning off of the compressor when the feeding voltage reaches the minimum threshold level (cut out).

The compressor will start up automatically again when the voltage goes back to normal values (cut in). (See Table

3.5.1 “ECM Cut-Out / Cut-In Voltages”).

Table 3.5.1: ECU Cut-Out / Cut-In Voltages

3.5.1 Wiring Connections

Typically, your TruckFridge will have the correct gauge wire and connector installed on the fridge to connect to the

standard truck factory wiring. If the truck was not equipped with a fridge from the factory, the manufacturer would

often connect the fridge wire to a 12v cigarette type receptacle. In these cases, unplug the connector from the rear

of this receptacle and plug this into the connector on the fridge wires. NOTE: There are proper wire connectors

available from TruckFridge for most truck wiring installations.

When you connect the refrigerator, you must remember the following:

1) Use cables having the proper cross section to make the feeding lines. If possible, such cables should be without any

joints on the leads which could lead to voltage falls. (see “Table 3.5.1.1 “12VDC Wire Gauge Chart”)

TF86DC User Manual

Updated 23 April 2020 Page 9

Cross-

section

(mm2)

AWG

Section

Max 12V Cable Length

m/ft

Max 12V Cable Length

m/ft

BD1.4F / BD35F / BD50F

2.5

13

2.5 / 8

5 / 16

4

11

4 / 13

8 / 26

6

9

6 / 19

12 / 39

10

7

10 / 33

20 / 66

2) If the wiring system of the vehicle is insufficient or not properly sized for the refrigerator, we suggest you connect it

directly to the battery. Note. The use of cables having an insufficient cross section may lead to the compressor

stopping even when the battery is charged.

3) Any switches must have a breaking load not less than 20 A (10 A if powered at 24 Volt).

4) Make sure the polarity is right: connect the RED cable to the positive terminal (+) and the BLACK cable to the

negative terminal (-).

5) For system protection, the fuse must be installed in the RED positive wires (+) as close as possible to the battery. We

recommend using 15 A fuses for 12 V and 7.5 A fuses for 24 V. If using a main switch, it must be able to withstand a

minimum current of 20 A. Avoid extra junctions in wiring to prevent voltage drops that can influence battery

protection settings.

3.6 TF86DC Door Assembly

The TF86DC “Click Lock” door has 3 shelves, replaceable front panel

and reversible hinges.

The “Click Lock” door latch allows the door to be held open during

defrosting and/or storage. Using a bunt instrument or coin, gently

bend the “click lock” upwards slightly to protrude above door latch.

(See Figure 3.6.1 “TF86DC Click Lock Door Latch”).

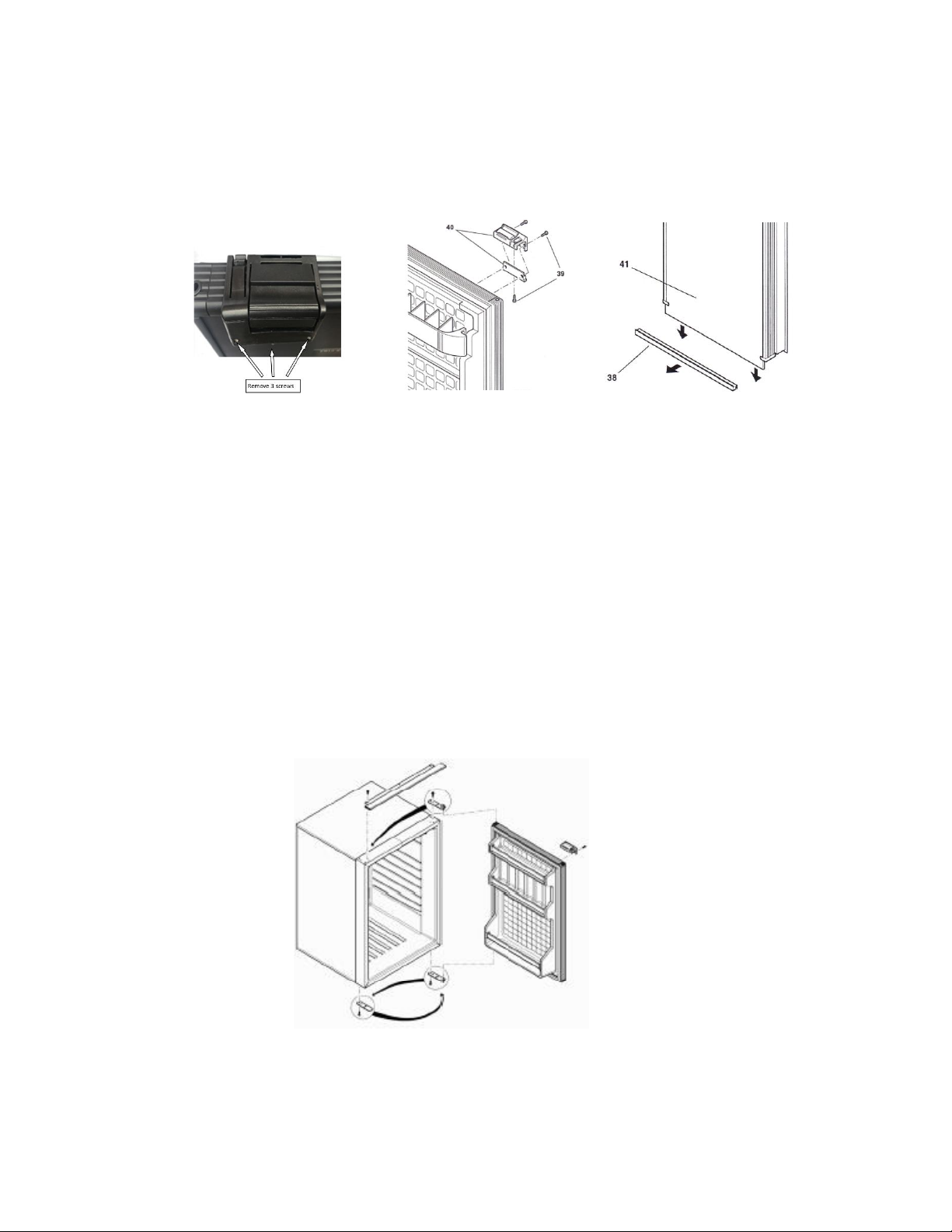

3.6.1 Replacing the Door Panel

You can replace the door panel without having to dismantle the door of the refrigerator, by proceeding as follows:

1. Take out the three screws (39) which hold the handle in place.

Table 3.5.1.1: 12VDC Wire Gauge Chart

Selection

Gauge Sizes

WARNING!

Never connect bare electric wire(s) and use only connectors of a size suitable to the cross section of the cable

being used.

Never connect the refrigerator power to a cigarette lighter plug. Always connect directly to the battery.

Figure 3.6.1: TF86DC Click Lock Door Latch

TF86DC User Manual

Updated 23 April 2020 Page 10

2. Remove the profile strip which anchors the panel located at the bottom of the door using a screwdriver as a

lever. Remove the profile strip.

3. Pre-drill holes in the new panel to reattach the door latch on the opposite side.

4. Fit in the new panel, letting it slide, and put back the profile strip and door latch.

3.6.2 Reversing the Door Opening

The TF86DC door normally opens towards the right. To change the side, move the hinges and door latch as shown in

Figure 3.6.2.1 “Reversing Door Opening”. Image of refrigerator shown is generic and not the TF86DC however the

procedure is similar.

1Remove screws and top flange.

2Remove screws holding top and bottom door brackets.

3Replace bottom door bracket to opposite side.

4Reposition door pin to opposite side of door.

5Replace door in bracket (bottom first then attached top bracket)

6Take off the door latch and put it back in the opposite side of door.

Figure 3.6.1.1: Replacing Door Panel

Figure 3.6.2.1: Reversing Door Opening

TF86DC User Manual

Updated 23 April 2020 Page 11

4.0 FEATURES

4.1 Setting the Inside Temperature

The TF86DC is provided with a manual thermostat. Turn it clockwise to lower the temperature and turn it counter-

clockwise to raise the temperature and activate the ON-OFF switch in its end position. The knob of the thermostat is

located inside the refrigerator. See Figure 2.1.5.1 “TF86DC Thermostat”.

4.2 Filling

Do not put hot food into the refrigerator. Place the products in a position where they do not hit each other or break

while the vehicle is moving. Make sure the door is always well closed and reduce opening time to a minimum to

reduce power consumption.

4.3 Defrosting

Defrosting is done manually and must be carried out when the ice layer is thicker than 3-4 mm (1/8”). Set the

thermostat at the OFF (0) position. While defrosting, keep food and beverages in a cool place. Do not use any sharp

metal object to remove the ice or frost. Do not start the refrigerator up again until it is completely defrosted and dry.

Also empty the tray under the freezer compartment.

5.0 MAINTENANCE

The TF86DC is equipped with closed cooling system, which does not require maintenance or refrigerant refills. The

compressor is of a domestic type, is highly efficient and has an extraordinarily long life. General maintenance

consists simply of;

•Routinely cleaning the condenser from dust, at least once a year. Use a soft brush and no hard object.

•Regularly clean the inside and outside of the refrigerator using only warm water and a neutral detergent.

Subsequent to washing, rinse with clean water and dry thoroughly using a soft cloth.

•Do not use the following: special glass and mirror cleaning products, liquid, powder, or spray detergents,

alcohol, ammonia or abrasive products.

•If you are not using the refrigerator, we suggest cleaning it well inside and leaving the door ajar to ventilate the

interior. To do, release the lock of the door using a coin or a small screwdriver. (See Figure 3.6.1: TF86DC Click

Lock Door Latch)

5.1 Useful Advise

1. If the TF86DC does not work properly, check the following before calling customer support;

a. Make sure power is not missing.

b. The voltage which reaches the ECU is equal to the one shown on the plate (minimum 11 volts, maximum 14

volts) .

c. The connections have the proper polarity and are secure.

d. The condenser fan is not jammed or obstructed.

e. The refrigerating unit is not near a source of heat.

f. The in-line fuse mounted on the feeding line is not blown.

2. Heavy frost buildup can be caused by several factors:

1Warm foods introduced into the freezer or fridge section.

TF86DC User Manual

Updated 23 April 2020 Page 12

2Fridge door frequently opened and closed (especially in a high humidity environment).

3Fridge door not properly aligned with fridge body as to affect the rubber seals ability to seal as designed.

4Failure of the putty seal between the back wall of the fridge and the evaporator tube. Would need to be

examined and resealed with existing putty.

5Certain foods, mainly leafy vegetables, have a tendency to cause ice to form faster due to their high moisture

content.

Note: If the ice builds up more than 1/8 inch on either side, it can interfere with the freezer door opening and

shutting properly and can cause the freezer door to pop loose and reduces the ability of the fridge to cool properly

and the fridge will need to be defrosted. It goes without saying, the fridge needs to defrost naturally by turning off

power and opening the door.

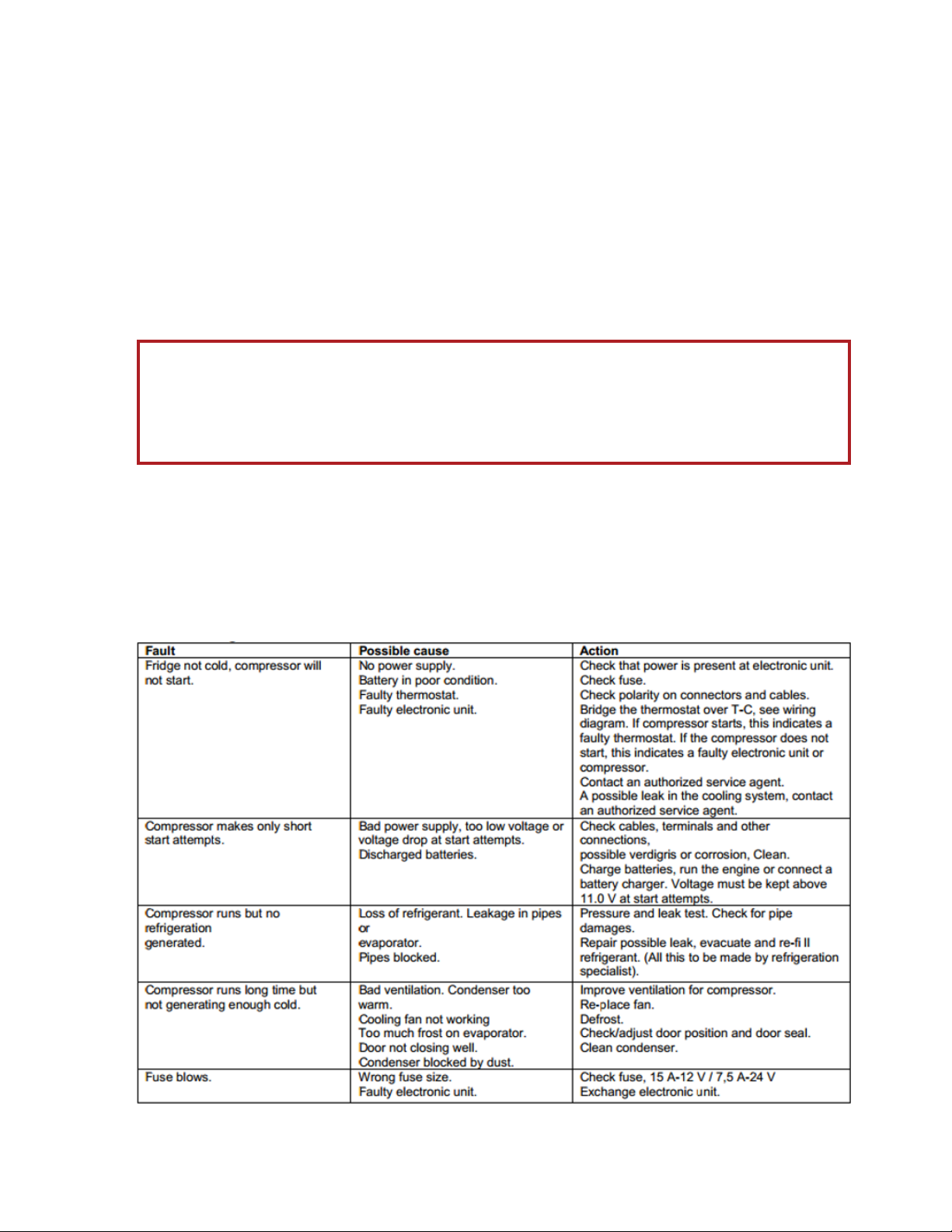

6.0 TROUBLESHOOTING

6.1 Troubleshooting Guide

Use the troubleshooting guide below to determine the nature of the problem before calling Northern Fridge

support.

WARNING !

The user needs to be reminded to not use ANY object to pry ice loose or to use any heat source to speed up

the defrost process as damage will occur. Make sure the fridge is thoroughly dry inside before restarting and

remove excess moisture from any food and/or food packaging.

TF86DC User Manual

Updated 23 April 2020 Page 13

Figure 6.1.1: Troubleshooting Guide

6.2 Self-Diagnostics Procedure

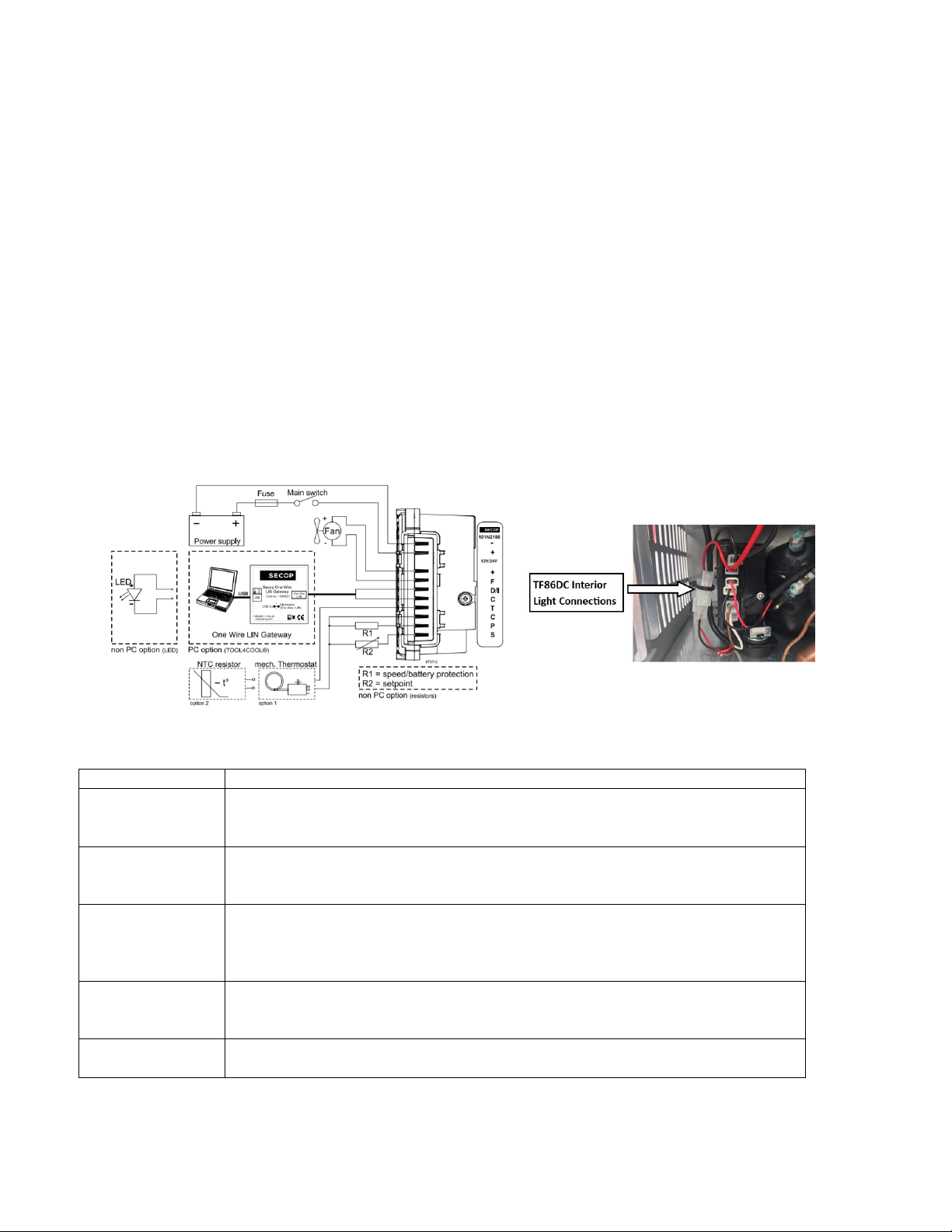

LED (optional) Figure 6.2: Electrical Schematic

A 10mA light emitting diode (LED) (6) can be connected between the terminals + and D. In case the electronic unit records an

operational error, the diode will flash a number of times. The number of flashes depends on what kind of operational error

was recorded. Each flash will last ¼ second. After the actual number of flashes there will be a delay with no flashes, so that

the sequence for each error recording is repeated every 4 seconds.

Diagnostic Procedure

1. Locate interior light connections (white connectors). See Figure 6.2.2: TF86DC Interior Light Connection below.

2. Disconnect the negative (-) black wire connector

3. Reconnect to terminal marked (D/I).

4. Observe the number of flashes of the interior LED light bulb.

5. See Table 6.2.3: Error Code Chart for error code description.

6. Disconnect from terminal “D/I” and reconnect black wire light connection (white connector).

No. of flashes

Error Type

5

Thermal cut-out of electronic unit

(If the refrigeration system has been too heavily loaded, or if the ambient temperature is

high, the electronic unit will run too hot).

4

Minimum motor speed error

(If the refrigeration system is too heavily loaded, the motor cannot maintain minimum

speed 1,850 rpm).

3

Motor start error

(The rotor is blocked or the differential pressure in the refrigeration system is too high

(>5 bar)).

2

Fan over-current cut-out

(The fan loads the electronic unit with more than 1A peak).

1

Battery protection cut-out

(The voltage is outside the cut-out setting)

Table 6.2.3: Error Code Chart

Figure 6.2.1: TF86 Electrical Schematic

Figure 6.2.2: TF86 Interior Light Connection

TF86DC User Manual

Updated 23 April 2020 Page 14

6.3 Thermostat Test Procedure

If the thermostat is defective the refrigerator fan and compressor may not operate. To test the thermostat, jumper

pins “T” and “C” using a jumper wire. (See 8.0 ILLUSTRATIONS: Figure 8.3.1 “101N2100 ECU Wiring Diagram” for

details).

1. If the fan and compressor turn on, the thermostat is defective and must be replaced

2. If the fan and compressor do not turn on, contact Northern Fridge support for service.

7.0 SPECIFICATIONS

Description

TF86DC

Outside

Dimensions (inches)

15"W x 34"H x 22"D

Inside Dimensions (inches)

Fridge (Main)

12.5"W x 14.25"H x 17"D / 1.75 Cu.Ft.

Fridge (Lower/Step)

12.5"W x 5.25"H x 10.75"D / .43 Cu.Ft.

Freezer

9.5"W x 8.75"H x 17"D / .83 Cu.Ft.

Total Capacity

86 litre / 3.01 cu. ft.

Fridge (Upper/Lower)

63 Liter / 2.2

Freezer

23 Liter / .81

Nominal voltage

12-24Vdc

Nominal input power

60 watt/hour (5 amp/hour)

Average power

consumption

45 Amps/24h. (1.9 amp/hour)

In-line fuse

15A (12VDC), 7.5A (24VDC)

Refrigerant

R134a

Temperature Range

+2oC to -7oC (35oF to 18oF)

Air cooling

Forced with fan

Standard Features

Interior light, adjustable thermostat, (2) wire shelves, (3) door shelves and low

voltage cut-out.

Colour

Cabinet (Dark Grey); Door Panel (Dark Grey matt finish)

EMC conformity

Yes

Net weight (lbs)

55 lbs

Warranty

Two (2) year parts and labour

Note. If in doubt about the model for your truck, always confirm by measuring the height, width and depth of the cabinet

opening before ordering.

Please note that models, prices, and availability is subject to change without obligation or notice.

TF86DC User Manual

Updated 23 April 2020 Page 15

8.0 ILLUSTRATIONS

Figure 8.1: TF86DC Parts Diagram

TF86DC User Manual

Updated 23 April 2020 Page 16

Figure 8.1.1: TF86DC Parts List/Description

TF86DC User Manual

Updated 23 April 2020 Page 17

Figure 8.2: Danfoss/Secop BD1.4F-VSD-HD Specifications

TF86DC User Manual

Updated 23 April 2020 Page 18

TF86DC User Manual

Updated 23 April 2020 Page 19

Figure 8.3: 101N2100 ECU Specifications for BD1.4-VSD-HD

Figure 8.3.1: 101N2100 ECU Wiring Diagram

TF86DC User Manual

Updated 23 April 2020 Page 20

Figure 8.4: TF86DC Dimensional Diagram

TF86DC Front View

TF86DC Side View

Table of contents

Other Northern Fridge Refrigerator manuals

Popular Refrigerator manuals by other brands

Accucold

Accucold CT66 Series user manual

PROFILO

PROFILO BD2074W2AN Operating and installation instructions

Grundig

Grundig GFTU 13130 N user manual

Indesit

Indesit C 239 NF UK Instructions for installation and use

Dometic

Dometic REFRIGERATION 10-Series installation manual

Sub-Zero

Sub-Zero 600 Series BI-48SD quick start