Northern Industrial Tools 123010 User manual

Thank you verymuch for choosinga NORTHERNTOOL+ EQUIPMENTCO., INC., Product!

For future reference,please complete theowner's record below:

Model: _______________ PurchaseDate: _______________

Save the receipt,warranty and theseinstructions. It isimportant that youread the entire

manual to becomefamiliar with thisproduct before youbegin using it.

This machine isdesigned for certainapplications only. NorthernTool+ Equipment strongly

recommends this machineis not modifiedand/or used forany application otherthan that for

which it wasdesigned. If youhave any questionsrelative to aparticular application, DO

NOT usethe machine untilyou have firstcontacted NorthernTool+ Equipment todetermine

if it canor should beperformed on theproduct.

For technical questionsand replacement parts,please call 1-800-222-5381.

DESCRIPTION & INTENDEDUSE

The Northern IndustrialAirbrush Compressor#123010 Features andFunctions:

· Portable & lightweight

· Low noise

· Thermally protected

· Powerful and highair flow

· Auto stop

· Pressure-adjustable

· Double switch

Switch 1:Auto stop @58 PSI

Switch 2: Maxpressure @ 87PSI

TECHNICAL SPECIFICATIONS

GENERAL SAFETYRULES

WARNING: Readand understand allinstructions. Failure to followall instructions

listed below mayresult in electricshock, fire and/orserious injury.

WARNING: Thewarnings, cautions, andinstructions discussed inthis

instruction manual cannotcover all possibleconditions or situationsthat could

occur. Itmust be understoodby the operatorthat common senseand caution are

factors which cannotbe built intothis product, butmust be suppliedby the operator.

WARNING: HIGHPRESSURE AIR.Bypassing, modifying orremoving safety/relief

valves can causeserious injury ordeath. Do notbypass, modify oreremove safety/relief

valves. Do notdirect air streamat body. Rusted tankscan cause explosionand sever injury

or death. Draintank daily orafter each use.Drain valve locatedat bottom oftank.

1 OF 5

Type:

Power:

Voltage:

Maximum pressure:

Air output

Double switch:

Includes:

Connections:

Weight:

Dimensions:

Power Cord:

TwinCylinder Piston Compressor

1/3 HP

120V/60HZ

87 PSI

11.2CFM

Switch1: Auto start @41 PSI

Auto stop @58 PSI

Switch 2: Max pressure @87 PSI

Manometer; pressure regulator;air filter

1/4" NPT

12 Lbs.

12" x 5-5/16"x 8" (320x135x205mm)

6 Feet

CAUTION: RISK OFBURSTING. Use only suitableair handling partsacceptable for

pressure of notless than themaximum allowable workingpressure of themachine.

DANGER: RISK TO BREATHING. The compressedair from yourcompressor is not

safe for breathing.The airstream may containcarbon monoxide, toxicvapors or other

contaminants. Never inhaleair from thecompressor either directlyor from abreathing

device connected tothe compressor.

SAVETHESE INSTRUCTIONS

WORK AREA

· Keep work areaclean, free of clutterand well lit.Cluttered and darkwork areas can

cause accidents.

· Do not useyour compressor wherethere is arisk of causinga fire oran explosion;

e.g. in thepresence of flammableliquids, gasses, ordust.

· Keep children andbystanders away while operatinga compressor.Distractions can

cause you tolose control, sovisitors should remainat a safedistance from thework area.

· Be aware ofall power lines,electrical circuits,water pipes andother mechanical

hazards in yourwork area, particularlythose hazards belowthe work surfacehidden from

the operator's viewthat may beunintentionally contacted andmay cause personalharm or

property damage.

· Be alert ofyour surroundings.Using compressors inconfined work areasmay put you

dangerously close tocutting tools androtating parts.

ELECTRICAL SAFETY

WARNING:Unqualified use andimprove maintenance ofthis mini aircompressor

could result inserious personal injury. Thefollowing safety instructionsshould be operated

to avoid anyrisk! Please readall of theseinstructions carefully andfollow them.

WARNING!Always check toensure the powersupply corresponds tothe voltage onthe

rating plate.

· Do not abusethe cord.Never carry acompressor by itspower cord, oryank cord or

extension cord fromthe receptacle. Keeppower and extensioncords away fromheat, oil,

sharp edges ormoving parts. Replacedamaged cords immediately. Damaged cordsmay

cause a fireand increase therisk of electricshock.

· Grounded toolsmust be pluggedinto an outletproperly installed andgrounded in

accordance with allcodes and ordinances.Never remove thegrounding prong ormodify the

plug in anyway.Do not useany adapter plugs.Check with aqualified electrician ifyou are in

doubt as towhether the outletis properly grounded.

· Double insulated toolsare equipped witha polarized plug(one blade iswider than the

other). Thisplug will fitin a polarizedoutlet only oneway.If the plugdoes not fitfully in the

outlet, reverse theplug. If itstill doesn't fit,contact a qualifiedelectrician to installa

polarized outlet. Donot change theplug in anyway.

· Avoid bodycontact with grounded surfacessuch as pipes,radiators, ranges, and

refrigerators. Thereis an increaserisk of electricshock if yourbody is grounded.

· When operating apower tool outside,use an outdoorextension cord marked" W-A" or

" W." These cordsare rated foroutdoor use andreduce the riskof electric shock.

· Extension Cord Use.

A. Use only'Listed' extension cords.If used outdoors,they must bemarked " ForOutdoor

Use." Thosecords having 3-pronggrounding type plugsand mating receptaclesare to be

used with groundedtools.

B. Replace damagedor worn cordsimmediately.

C. Check thename plate ratingof your tool.Use of impropersize or gaugeof extension cord

may cause unsafeor inefficientoperation of yourtool. Be sureyour extension cordis rated

to allow sufficient current flowto the motor. For theproper wire gaugefor your tool,see

chart.

2 OF 5

CHART FOR MINIMUMWIRE SIZE OFEXTENSION CORD:

If in doubt,use larger cord.

Be sure tocheck voltage requirementsof the toolto your incomingpower source.

· Do not exposecompressor to rainor wet conditions.Water enteringa motor willincrease

the risk ofelectric shock.

· Do not letyour fingerstouch the terminalsof plug wheninstalling to orremoving from the

outlet.

· Ground fault circuitinterrupters. If work areais not equippedwith a permanently

installed Ground FaultCircuit Interrupter outlet(GFCI), use aplug-in GFCI between

compressor or extensioncord and powerreceptacle.

PERSONAL SAFETY

· Stay alert,watch what youare doing anduse common sensewhen operating a

compressor. Donot use acompressor while youare tired orunder the influenceof drugs,

alcohol or medication.Amoment of inattentionwhile operating acompressor may resultin

serious personal injury.

· Dress properly. Do not wearloose clothing, danglingobjects, or jewelry. Keep yourhair,

clothing and glovesaway from movingparts. Loose clothes,jewelry or longhair can be

caught in movingparts. Airvents often covermoving parts andshould be avoided.

· Use safety appareland equipment.Use ANSI-approvedsafety goggles orsafety glasses

with side shieldswhich comply withcurrent national standards,or when needed,a face

shield. Use asdust mask industy work conditions.This appliesto all personsin the work

area. Alsouse non-skid safetyshoes, hardhat, gloves,dust collection systems,and hearing

protection when appropriate.

· Avoid accidentalstarting. Ensure the switchis in theoff positionbefore plugging tool

into power outlet.In the eventof a powerfailure, while acompressor is beingused, turn the

switch offto prevent surprisestarting when poweris restored.

· Do not overreach.Keep proper footingand balance atall times.

· Remove adjusting keysor wrenchesbefore connecting tothe power supplyor turning

on the tool.Awrench or keythat is leftattached to arotating part ofthe tool mayresult in

personal injury.

TOOL USEAND CARE

· Never use acompressor with a malfunctioningswitch. Any compressor thatcannot be

controlled with theswitch is dangerousand must berepaired by anauthorized service

representative before using.

· Disconnect powerfrom compressor andplace the switchin the lockedor offposition

before servicing, adjusting,installing accessories orattachments, or storing.Such

preventive safety measuresreduce the riskof starting thecompressor accidentally.

· Secure workwith clamps ora vise insteadof your handto hold workwhen practical.This

safety precaution allowsfor proper tooloperation using bothhands.

· Store idle compressor. When a compressoris not inuse, store themin a dry, secure

place out ofthe reach ofchildren. Inspect thecompressor for goodworking condition prior

to storage andbefore re-use.

· Use only accessoriesthat are recommendedby the manufacturerfor your model.

Accessories that maybe suitable forone compressor maycreate a riskof injury whenused

on another compressor.

· Never leave compressorrunning unattended.

3 OF 5

Nameplate AMPS

0-6

6-10

10-12

12-16

25'

18 AWG

18 AWG

16 AWG

14 AWG

50'

16 AWG

16 AWG

16 AWG

12 AWG

100'

16 AWG

14 AWG

14 AWG

150'

14 AWG

12 AWG

12 AWG

(NOT RECOMMENDED)

CORD LENGTH

· The compressor willcut off onoverload and/or excess temperaturerise. Turnoff the

switch and startit again whenthe compressor reachesright temperature.

· Choose the suitablepressure switch accordingto the differentusage. When the

setup pressure islower than thestandard pressure, themachine will shutdown

automatically,and it willreduce the lifeof the machine.

OPERATION

· This compressor isfitted with a1/4" NPTscrew thread connectionfor high-pressure air

hose as astandard feature.

· Connect the appropriatepressure hose.

· Connect the righttools.

· Plug into themain power supply.

· The manometer showsthe working pressure.Youcan use thepressure adjustment toset a

suitable working pressure.

· Ensure that theworking area iswell ventilated.

THE DIFFERENCE BETWEENMAXIMUM ANDWORKING PRESSURE

A compressor'smaximum pressure isthe highest pressureit can buildup. When a

connected tool (suchas airbrush, spraygun) is opened,it is preciselywith this pressurethat

compressed air initiallyshoots out throughthe tool nozzle.In contrast, theworking pressure

is the constantpressure the compressorcan maintain duringairbrushing. Thelevel of this

working pressure depends,on one hand,on the compressor'spower (combination ofCFM

and maximum pressure)and, on theother hand, thenozzle diameter ofthe tool towhich it is

connected; the largerthe nozzle diameter, the greaterthe amount ofair which canescape

and the lowerthe compressor's workingpressure.

HOSE CONNECTIONS

The connections betweencompressor and hoseconnector are notalways airtight. 100%air

tightness is, however, only absolutelyessential in thecase of automaticmodels. It ishighly

recommended to useTeflon tape toprevent leakage.

4 OF 5

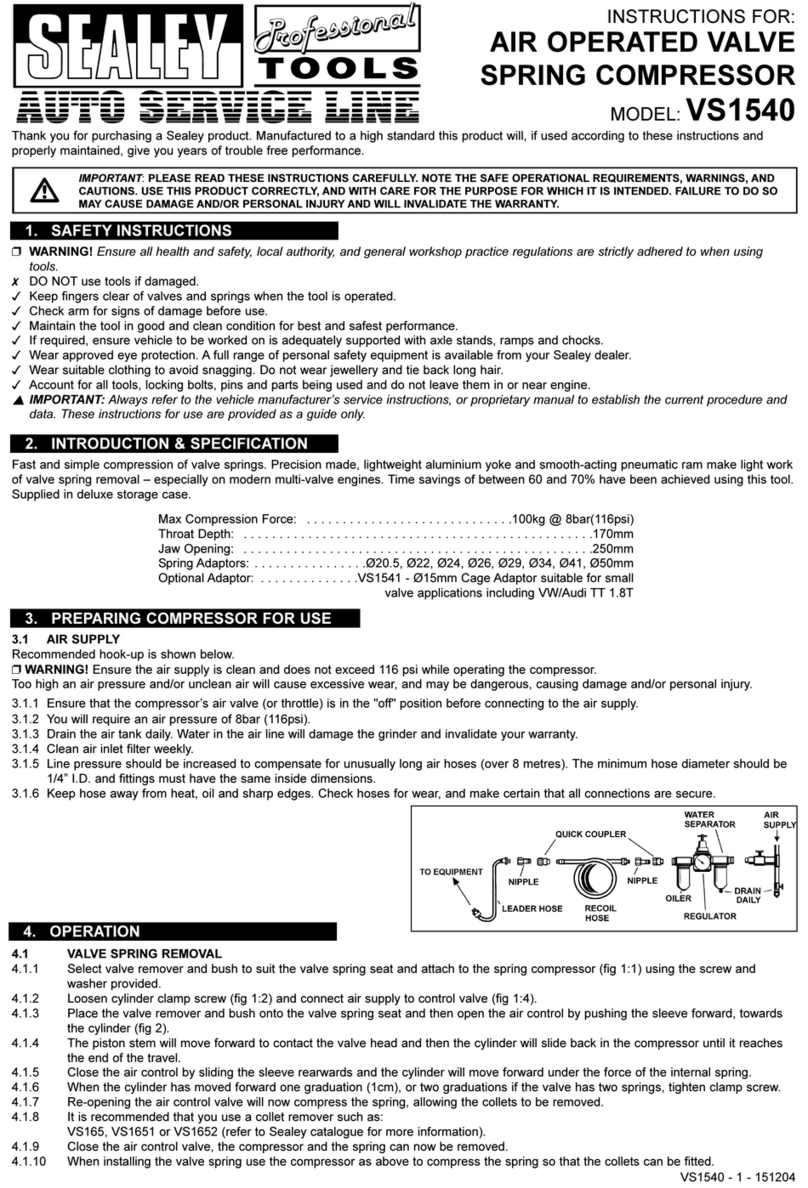

AIR COMPRESSOR STRUCTURE

a.Pressure regulator

b.Pressure gauge

c.Connection

d.Air filter

5 OF 5

a

b

d

c

WARNING

Some dust createdby power sanding,sawing, grinding, drilling,and other construction

activities contains chemicalsknown to theState of Californiato cause cancer, birth defects

or other reproductiveharm. Some examplesof these chemicalsare:

Lead from lead-basedpaints

Crystalline silica frombricks and cementand other masonryproducts, and arsenicand

chromium from chemically-treatedlumber.

Yourrisk from theseexposures varies, dependingon how oftenyou do thistype of work.To

reduce your exposureto these chemicals:work in awell ventilated area,and work with

approved safety equipment,such as thosedust masks thatare specially designedto filter

out microscopic particles.

·

·

Table of contents

Other Northern Industrial Tools Air Compressor manuals