Vmac VR70 Manual

1

SalesRepServiceInformationSheet

VMACrotaryscrewcompressorsystemsaredesignedandmachinedtoexactingtolerances.Theyare

uniqueinthattheycontainnoreed‐valvesorothereasilyfouled,fatigue‐pronecomponents.However,

propermaintenanceisneededtoensureperformanceandlongevityofthecompressorsandcanreduce

theneedforprematurerepairorcomponentreplacement.

Systemfiltersalsoenhanceperformanceandextendcomponentlifebyreducingdamagefromdustand

otherdebris.Foreignparticlesenteringthesystemwilldrasticallydamageorshortenthelifeexpectancy

ofthecompressorandwillresultindamagetobearings,gears,rotorsandtheinsideofthehousing.

Thefollowingmaintenancescheduleshouldbeobservedtoassuregoodperformanceandlongservice

life.ThehoursindicatedarethosedisplayedontheCompressorControlPanel.Serviceintervalshould

bewhicheveroccurssooner(e.g.,200hoursofoperationor6months)

UNDERHOODMaintenanceSchedule

50hours:Checkthedrivebelt

200hoursor6months:Replacetheairfilter,oilfilterandchangeoil.Useservicekit#A700019(VR70)

#A700059(VR140)

400hoursor1year:Replacetheairfilter,oilfilter,coalescingelementandchangeoil.Useservicekit

#A700020(VR70)#A700060(VR140)

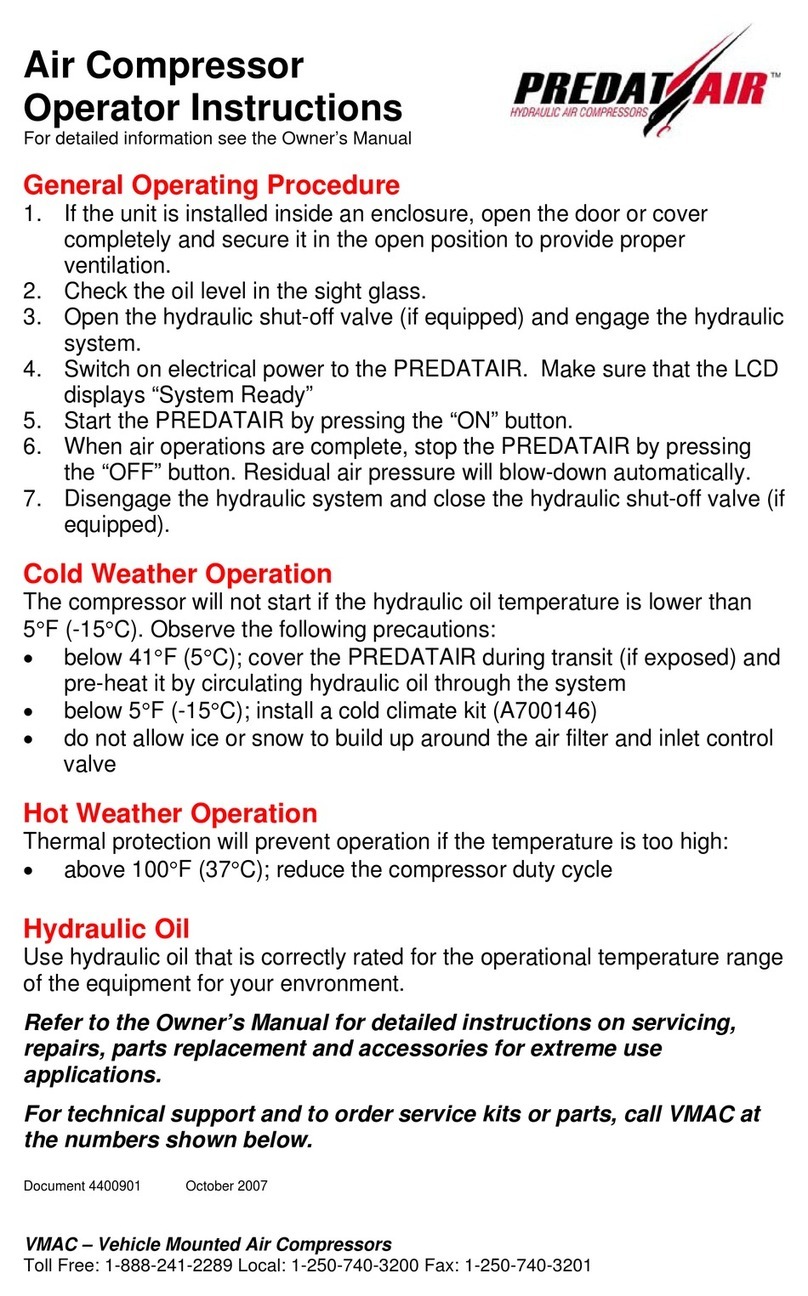

PREDATAIRMaintenanceSchedule

PREDATAIR(H600001)

200hoursor6months:Replacetheairfilter,oilfilterandchangeoil

PREDATAIR(H600002andH400001)

500hoursorevery6months

Inadditiontoregularservicing,besuretocheckthecompressor’sairfilterfrequentlytoensurethatitis

notrestrictedordamaged.Properfiltermaintenanceisalsokeytolongcompressorlife.Regular,

scheduledmaintenanceincludes:

•inspectingtheaircleanerandmaintainingtheoillevel

•morefrequentserviceinsevereoperatingconditions

ServiceTips

•Neverrunthecompressor,drivethevehicleorevenallowthevehicletositparkedwithoutthe

recommendedairfilterandfiltercoverinstalled.

•AlwaysuseaVMACoilfilterwhichisdesignedtowithstandthehighpressures,notan

automotivefilter.

•Operatethesystematleastevery30daysfor15minutesatnoloadtoensurebearing

lubricationandrotation.Impactdamageandprematurebearingfailuremayoccurinthe

compressorbearingsifthesystemisnotoperatedonaregularbasisduetovibrationcausedby

truckoperation.

•Neverattempttocleanthefilterelementwithcompressedair.Replacethefilterelement.

•Donotattempttochangetheoilfilteruntiltheoilhascooled.Hotoilcancausesevereburns.

•Neverover‐tightenthefilter,asthismaydamagethesealorthefilter.

•Useonlythesuppliedcompressoroilinthissystem.Failuretousethisspecialoilwillresultin

damagetothecompressorandwillvoidyourwarranty.

•Donotoverfillthesystem.Overfillingthesystemwithoilcanfloodthesightglasswindowand

makethesystemappearempty.

•Ifyouusesolventsforcleaning,thoroughlyrinsethepartswithhotwatertoremoveallsolvent

residues.

•Checktheinsideofthetankforanyevidenceofmetalfilingsorcontamination;iffound,flush

thetank,hosesandcooler.Metalfilingswilldamagethecompressor.

4

Maintaining

VR70andVR140

UNDERHOOD

AirCompressors

5

MaintainingtheVRSystem

Organizedmaintenancepracticeswillincreasethelifeexpectancyofthecompressorsystemand

maintainoperationwithinthemanufacturedparameters.VMAChasrecommendedserviceintervalsfor

theirsystemthatisbasedonactualtestingandperformance.TheVRsystemrequiresregular

maintenancethatincludes:

•inspectingandreplacingthedrivebelt

•changingsystemoil

•changingfilters

•cleaningfilterscreens

DuringthewarrantyperiodyoumustfollowthemaintenancescheduleandonlyuseoriginalVMAC

replacementpartstomaintainthesystemandthewarranty.Periodicmaintenanceservicekitsare

availablefromVMAC.

Themostcriticalaspectofcompressoroperationisproperairfiltration.Contaminationenteringthe

intakecancausesevere,rapiddamagetorollerbearings,gearsandrotorsinthecompressor.

Neveroperatethetruck,thecompressororevenallowthetrucktoremainparkedwithoutthe

recommendedairfilterandcoverinstalledonthecompressor.

Performingapre‐serviceinspection

Inspectthesystemcarefullyandcheckthefollowing:

•lookforleaksatthecompressor,cooler,tank,filterandlinefittings

•checkthecompressorandbrackettomakesurethattheyaretightandsecure

•checkthecoolertomakesurethatitistightandsecure

•checkthetankbracketsandtankmountingtomakesurethattheyarenotloose

•checkallfastenersforevidenceofmotionorvibrationloosening

•examineallthelinesforevidenceofrubbing,chafingorotherenvironmentaldamage

•usingtheappropriatetools,checkallthelinefittingstomakesurethattheyaretight

•checkelectricalconnectionsforsecurity

•checkallwiringforsecurityanddamage

•checkthecontrolunitstomakesurethattheyaresecure

Ifyoudiscoveranyproblems,performthenecessaryrepairstopreventfurtherdamage.Protectall

wiring,lines,connectionsandfittingsasrequired.Tightenanyloosefastenersandreplaceanydamaged

fastenersorcomponents.

6

PeriodicMaintenance

Themaintenancescheduleforthesystemisshowninthefollowingtable.Thehoursshownonthetable

arethosedisplayedonthecontrolpanelread‐out.Serviceshouldbeperformedatthelesserofthetwo

intervals,whicheveroccursfirst.Followingthisprocedurewillensureoptimumperformanceandlong

lifefromtheVRsystem.

Theseserviceintervalsarebasedonnormaloperation.Commonsenseandgoodmaintenancepractices

willindicatewhethertheseproceduresshouldoccurmorefrequently.Forexample,ifthetruckis

continuouslyoperatinginanextremelydustyenvironment,theairfilterandbeltshouldbeinspected

morefrequently.Sincethecompressordrawsinlargequantitiesofairduringoperation,thefiltermay

becomepluggedandwillaffectoperation.

InspectingtheDriveBelt

Periodicinspectionofthedrivebeltisnecessarytoidentifypotentialproblemsbeforetheycausefailure

ordamage.WhileVMACrecommendsa50hourinterval,iftheoperatingenvironmentissevere,you

shouldinspectthebeltmorefrequently.

Checkthebeltcarefullyforsignsofglazing,missingportionsoftheribsordamagetotheedgesor

surface.Ifthereisdamage,itmayindicateaproblemwithpulleyalignmentorimproperusebythe

operator.Installinganewbeltwillnotcorrecttheproblem,itwilljustresultindamagetothenewbelt.

Abeltthatisheat‐damagedindicatesthatthebeltisslippingonthecompressororcrankshaftpulleys.

Thismaybecausedbyadefectivetensionerorbytheoperatorengagingthecompressorwhilethereis

pressureinthesystem.Thiscancausethecompressorclutchtostallandthebeltwillslip.Ifthe

tensionerisapplyingsufficientpressureandismaintainingbelttensioncorrectly,talktotheoperator

andfindouthowtheyareusingthesystem.Inspecttheidlers,pulleysandtensionerfordamage.Any

componentthatshowschips,cracksorotherphysicaldamageshouldbereplaced.

Ifthebeltisdamagedorwornalongtheedges,itcouldindicateanalignmentproblem.Ifthisoccurs,

checkthealignmentofallpulleys,idlersandtensionerswithastraightedge.Ifthereisanalignment

problem,checkallsystemfastenerstomakesurethattheyaretight.Alsocheckforcrackingordamage

onthemountingbracketandatthecompressor.

7

InspectingandReplacingtheAirFilter

Properairflowintothecompressorisvitallyimportantforgoodperformance.Ifthefilterbecomes

plugged,thecompressorwillnotbeabletomeetthedemandsandwillprobablyoverheat.While

VMACrecommendsthatyoureplacethefilterevery200operatinghoursortwiceayear,youshould

replacethefiltermorefrequentlyinsevereoperatingconditions,whereitcouldbecomecontaminated

morequickly.

Tocheckthefilter,followthisprocedure:

1.Makesurethatallairpressurehasbeenventedfromthesystem.

2.Cleantheareaaroundthecompressorandfiltercover.

3.Removethefiltercoverretainingnut,thecoverandthefilterelement.

4.Immediatelycovertheopeningofthecompressorwithaclean,dryclothorwithmaskingtoprevent

contaminationfromenteringthecompressor.Donotoperatethetruckorthecompressoruntilthefilter

andcoverhavebeeninstalled.

5.Cleantheinsideofthefiltercoverwithaclean,drycloth.Ifnecessary,youcanusesolventtoclean

theinsideofthecover.Ifyouusesolvent,makesurethatyourinsethecoverwithwateranddryit

thoroughlybeforeinstallingitonthecompressor.Solventfumesenteringthecompressorcouldignite

duringthecompressionprocess,causinganexplosion.

6.Examinethefiltercarefullyforcontamination.Placeatrouble‐lightontheinsideofthefilterand

rotateitoverthelightwhileexaminingtheelement.Theamountoflightthatshinesthroughthe

elementisagoodindicatorofhowmuchaircanpassthroughtheelement.Ifthelightisdimorblocked,

airwillnotbeabletogetthrough.

7.Ifthefilterisdirty,removetheclothormaskingandinstallanewfilter.Donotattempttowashor

blowthefilterelementclean.Thesearenotserviceablefilters,theymustbereplaced.Using

compressedairtocleanafilterelementwilldamagethematerialandallowcontaminationtoenterthe

system.

8.Replacethecoverandthecovernut.Becarefulnottoovertightenthenut.

8

CompleteMaintenanceoftheVRSystem

Completesystemmaintenanceshouldbeperformedonceeachyearorevery400systemoperating

hours,whicheveroccursfirst.Again,aswithpreviousserviceitems,youmayhavetoservicemore

frequentlyinsevereoperatingconditions.

Completemaintenancenotonlyincludesreplacingoilandfilters,italsoincludesacompleteinspection

ofthesystem.Thiswillensurethatthesystemcontinuestoprovideoptimumperformanceandwill

extendthelifeexpectancyofthecomponents.

Forbestresults,followthesestepsforservicing:

1.Performacompletepre‐serviceinspectionofthesystem.

2.Replacetheairfilter

3.Draintheoilfromthesystem

4.Replacetheoilfilter

5.Replacethecoalescingseparatorandcleanorreplacethescavengefilter

6.Fillthesystemwithoilandcheckoperation

ReplacingtheAirFilter

Followtheproceduresoutlinedpreviouslyforairfilterreplacement.

DrainingOilfromtheSystem

Theoilshouldbedrainedfromthesystembeforechangingfiltersorcleaningthescavengefilter.Make

surethatyouhaveasuitablecontainerthatwillholdapproximately2gallons(US)beforeyoubegin.

Whendrainingtheoil,followthisprocedure:

1.Makesurethatallairpressureisventedfromthesystem.Ifthereisanypressureinthesystem,you

couldbeinjuredwhenyouremovethedrainplug.

2.Placethedraincontainerunderthetankbelowthedrainplug.

3.Usingthecorrecttool,removethedrainplugfromthetank.Becarefulwhendrainingthetank.Ifthe

systemwasoperatedrecently,theoilmaybeveryhotandcancauseburns.

4.Cleanthedrainplugthreadsandinspectthemfordamage.

5.Cleanandinspectthethreadsinthetank.

6.Installandtightenthedrainplugsecurely.

9

ReplacingtheOilFilter

Cleanlubricatingoilisvitalforefficientoperationandforpreventingdamagetocomponents.Replacing

theoilfilteratregularintervalswillhelpkeepcontaminantsoutofthecompressorandtherestofthe

system.Whenreplacingtheoilfilter,rememberto:

•makesurethatthereisnopressureinthesystem

•useaproperfilterwrench

•neverover‐tightenthefilter

•checktheoillevelafteroperatingthesystem

•checkforoilleaksafterservice

Toreplacetheoilfilter,followthisprocedure:

1.Cleantheareaaroundthefiltertopreventcontamination.

2.Removethefilterbyturningitcounter‐clockwise.Makesurethatyoudraintheoilfromthefilterinto

asuitablecontaineranddisposeofthefilterandoilaccordingtolocalregulations.Beforeyoudisposeof

thefilter,checktomakesurethatthethreadednippledidnotunscrewwiththefilter.Ifthenippleisin

thefilterratherthaninthecompressor,tankorremotemount,removeitcarefullytopreventthread

damageandreplaceitinitsoriginallocation.

3.Checkthesealingsurfaceonthecompressor,tankorremotemounttomakesurethatitiscleanand

smooth.

4.Applyalightcoatingofcompressoroiltothegasketonthenewfilter.

5.Spinthefilteronthethreadednippleuntilthegasketcontactstheseat.

6.Tightenthefilteranadditional¾to1fullturntoprovideagoodseal.

ReplacingtheCoalescingSeparatorandScavengeFilter

Toperformthispartoftheservice,youmustremovethebackcoveronthetank.Beforeattemptingto

replacethecoalescingseparatorandscavengefilter,alwaysmakesureofthefollowing:

•thereisnopressureinthesystem

•theoilhasbeendrainedfromthetank

•thebackofthetankhasbeencleanedtopreventcontamination

•becarefulofhotoil

Whentheseconditionshavebeenmet,followthisprocedure:

1.Cleanthebackofthetanktopreventcontamination.

2.Disconnecttheairoutletline,1/4inchand5/16inchlinesfromthebackofthetank.

3.Removetheboltsholdingthedischargecapfromthebackofthetankandremovethecapandsmall

spring,ifequipped.

Topreventdamagetothetank,removealloftheboltscompletelywhileholdingthe

dischargecapfirmlyinplaceasthecoalescingseparatorelementisspringloadedagainst

thedischargecap.

10

4.Removethecoalescingseparatorelement,largespring(andontheVR140,thespringplate)from

insidethetank.Discardthecoalescingseparatorelement.

5.RemoveanddiscardtheO‐ringsealandtherearcapseal.

6.Wipeouttheinsideofthetank

11

7.Ifthetankhasasmallspringandthimblescreen,thescreencanberemovedbycarefullypushingit

outoftheoilscavengeholefromtheinsideofthetank.

8.Ifthesystemdoesnothaveasmallspring,thescavengescreenwillbelocatedinsidethetank

coalescingchamberandisretainedbyasmallscrew.

9.Checkthethimblescreenorscavengescreenforcontaminationordamage.Ifcontaminated,cleanas

necessaryandblowoutwithcompressedair.Ifdamaged,replacethethimblescreenorscavenge

screen.

10.InstallnewO‐rings(includingthesmallO‐ringfortankswiththeinternalscavengescreen)andrear

capseal.

11.ThoroughlycleanthelargespringandthespringplateonVR140systems.Removeanyrustor

contaminants.

12.Installthelargespring(withspringplateon140systems–taperedendawayfromthefilter)anda

newcoalescingseparatorelement.Makesurethatthespringisinplace,asitholdsthecoalescing

separatorelementtightagainsttherearcapseal.

Thelargespringalsoprevents

electrostaticbuildupbygrounding

thecoalescingseparatorelement.

Ifthespringisnotinstalled,an

electricarcmayoccur,whichcould

resultinanexplosion,potential

tankruptureorfire.

Thecoalescingseparatorelement

servicekitmayincludeawave‐type

spring(Figure6.1).Replacethelarge

coilspringwiththewavespringand

discardthecoilspring.

13.Installthedischargecapandtorquetheboltstospecifications.

14.Installthelinesonthebackofthetank.

15.Removethefillerplugfromtheairinletcontrolvalve.

Ifyouusesolventsforcleaning,

thoroughlyrinsethepartswith

hotwatertoremoveallsolvent

residues.

12

16.Pourcompressoroilintotheoilfillerholeontheinletcontrolvalveusingafunnel.

17.Turnthecompressorclutchclockwisetospeedthefillprocess.

18.Allowfiveminutesfortheoiltodrainintothetank,thencheckthelevelatthesightglassatthe

frontofthetank.Continueaddingoiluntiltheleveliscorrect.

19.Installthefillplugintheinletcontrolvalveandtightenitsecurely.

FillingtheSystemwithOil

1.Removethefillplugfromtheinletvalveonthecompressor.

2.Usingafunnel,pouroilintothecompressorwhileturningthecompressorinaclockwisedirection

usingthehexheadcapscrewatthecenterofthecompressorclutchassembly.

3.Atregularintervals,checktheoillevelatthesight‐glassuntilitreachesthespecifiedlevel.

4.Replacethefillplugortheinletcontrolvalve.

5.Performaquickinspectionofthesystemtomakesurethatalllinesareonandtightandthatthefilter

istight.

CompletingtheService

1.Placethemanualtransmissioninneutralortheautomatictransmissioninparkandfullyapplythe

parkbrake.

2.Starttheengineandallowittoreachoperatingtemperature.

3.Turnthecompressorswitchonthecontrolunittothe“ON”position,allowthesystemtopressurize

andreturntopresetbaseidlespeed.

4.Turnthecompressorswitchonthecontrolunittothe“OFF”position.

5.Allowthesystemtosettleforfiveminutes,andthenchecktheoillevelthroughthesightglass.The

levelmustbebetweentheminimumandmaximumlevelindicators.

6.Checkforoilleaks.

Other manuals for VR70

24

This manual suits for next models

1

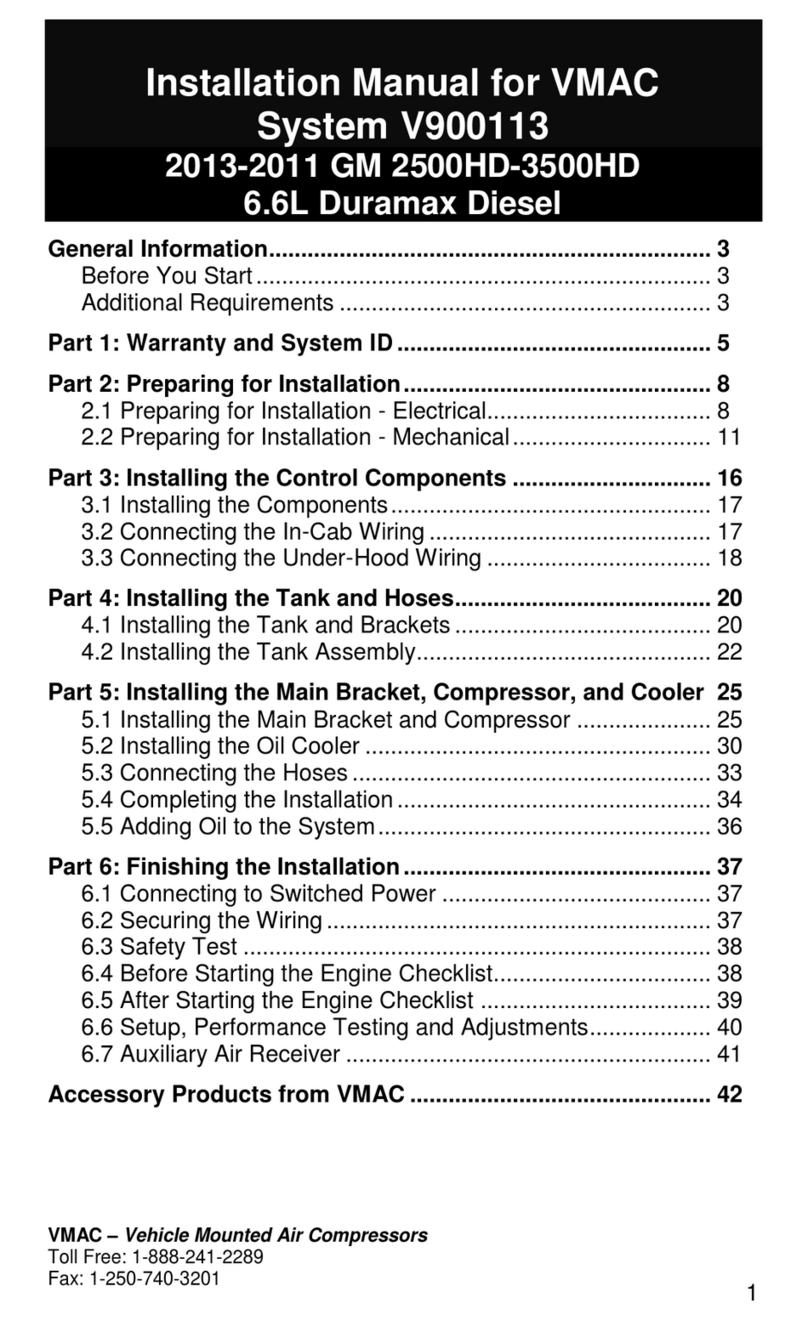

Table of contents

Other Vmac Air Compressor manuals

Vmac

Vmac V400010 User manual

Vmac

Vmac UNDERHOOD 40 Series User manual

Vmac

Vmac DM00021 User manual

Vmac

Vmac UNDERHOOD 40 Series User manual

Vmac

Vmac RAPTAIR-MF Use and care manual

Vmac

Vmac UNDERHOOD 40 Series User manual

Vmac

Vmac V400001 User manual

Vmac

Vmac V900104 User manual

Vmac

Vmac VR70 User manual

Vmac

Vmac VR70 User manual