For technicalquestions and replacementparts, pleasecall 1-800-222-5381.

Thankyouvery much for choosinga NORTHERNTOOL+ EQUIPMENT CO., Product!

For future reference, pleasecomplete theowner'srecordbelow:

Model: _______________ Purchase Date:_______________

Savethe receipt,warranty andthese instructions. It isimportant that you read the

entireinstruction sheet to become familiarwith this productbeforeyoubegin using it.

This productis designedforcertain applications only.Northern Tool+ Equipment

stronglyrecommends that thisproduct isnot modifiedand/orusedforany

application other than thatforwhich it was designed. If you have any questionsrelative

to aparticular application, DONOTuse the product until you havefirst contacted

Northern Tool+ Equipmentto determine ifit canor should be performedon theproduct.

Beforeusingthis product,please read the followinginstructions carefully.

TechnicalSpecifications

SAVETHISMANUAL

Youwill need this manual for thesafetywarnings andprecautions, assembly, operating,

inspection, maintenance and cleaning procedures, parts listand assemblydiagram.

Keepthis manualand invoicein asafeand dry placeforfuturereference.

WARNINGSANDSAFETYRULES

1.Wear proper clothing.Alwaysuse ANSI-approvedsafetyimpactgoggles when

assembling orusing this tool. Wear long sleevedshirts, long pants and hard-toedshoes.

Take offanyloosefitting jewelryand keep long hair coveredto preventbeing caught in

movingparts.

2.Wear proper breathingprotection.Remember that a"dust mask" is not abreathing

respirator.Use arespirator that usescharcoal filters for thebestprotection.

3.Keep work area clean and well lighted.A dimand/or cluttered work area invites

personalinjury.

4.Keep children and pets awayfromworkareas.Childrencan be adistraction and

shouldbe supervised by an adult when near theworkarea. Neverallowchildrento

playwiththis productevenif itis turned off.

5.Store idletoolsproperly. Keep this tool outof thereachof children.

6.Donot use theToolif under theinfluence ofalcoholor prescriptiondrugs.Doing so

maycausedamageto the tool, orpersonalinjury.Do not usethis or anytoolif you are

tired.Use commonsenseat alltimes.

7.Check fordamagedparts. Beforeusingthis tool, carefullycheck foranyparts that

maybe missingor damagedand any other conditionsthat may affect the operation

of thistool.Replaceor repair damaged and worn parts immediatelyusingonly

qualifiedrepair facility.

8.Alwaysuse the proper tools.This tool was designedfora specific task. Donot alter

this tool, or useit for apurposeforwhich it was notintended.

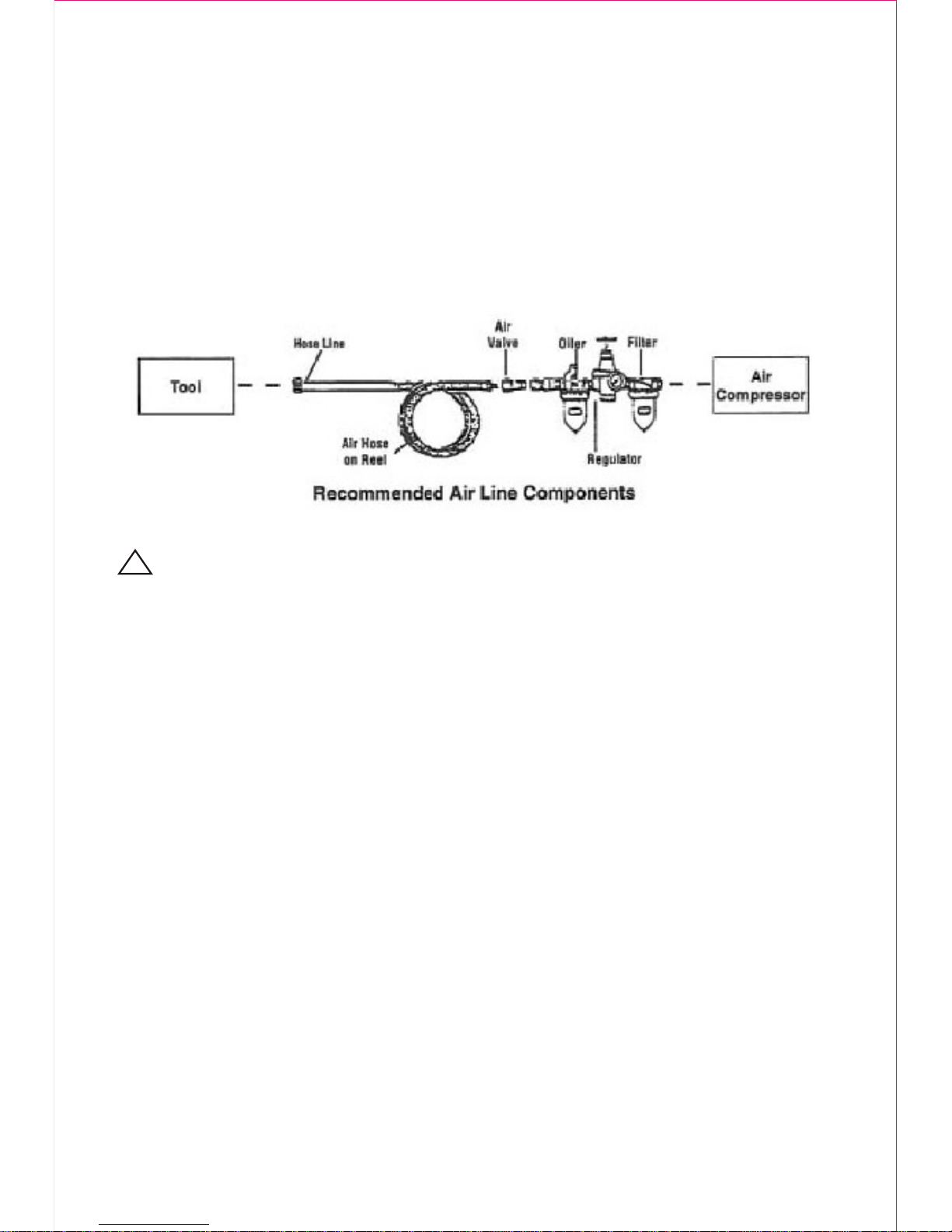

9.Becareful when connecting/disconnectingair supply.It isrecommendedto use quick

disconnects (not included)ratherthan screw-onair connections.

1 of 4

Item Description Description

Item

Drive Size

Free Speed

Max. Torque

Air Consumption

Air Inlet Diameter

Max. Air Pressure

1/2"

7000 RPM

300 ft-lbs

5.6 CFM

1/4"- 18NPT

90 PSI